mirror FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 6 of 279

0•6General Dimensions & Weights

Dimensions

Overall length:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4481 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4631 mm

Overall width - including mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1925 mm

Overall height - at kerb weight:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1403 to 1435 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1416 to 1501 mm

Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2704 mm

Front track - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1503 mm

Rear track:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1486 to 1487 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1504 mm

Turning circle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9 m

Weights

Kerb weight:

1.6 Saloon, Hatchback models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1215 to 1250 kg

1.6 Estate models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1265 to 1275 kg

1.8 Saloon, Hatchback models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1225 to 1260 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1260 to 1280 kg

1.8 Estate models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1275 to 1285 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1305 kg

2.0 Saloon, Hatchback models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1250 to 1310 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1285 to 1340 kg

2.0 Estate models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1295 to 1335 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1330 to 1415 kg

Maximum gross vehicle weight:

Saloon, Hatchback:

1.6 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1725 kg

1.8 Saloon models, automatic transmission . . . . . . . . . . . . . . . . . 1750 kg

2.0 models, automatic transmission . . . . . . . . . . . . . . . . . . . . . . . 1800 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1775 kg

Estate:

1.6 models, 2.0 models with manual transmission . . . . . . . . . . . . 1900 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1925 kg

Maximum roof rack load:

Estate models with integral roof rack . . . . . . . . . . . . . . . . . . . . . . . . 100 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg

Maximum towing weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 kg

Trailer nose weight limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg

procarmanuals.com

Page 7 of 279

0•7

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

MOT Test Checks

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

procarmanuals.com

Page 178 of 279

Chapter 11 Bodywork and fittings

Body side-trim mouldings and adhesive emblems - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 8

Bonnet lock - removal, refitting and adjustment . . . . . . . . . . . . . . . . 10

Bonnet release cable and lever - removal and refitting . . . . . . . . . . . 9

Boot lid - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Boot lid lock components - removal and refitting . . . . . . . . . . . . . . . 19

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Central locking system components - testing, removal and refitting . 23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 30

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Door handle and lock components - removal and refitting . . . . . . . . 14

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . 11

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 12

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 13

Exterior mirror and glass - removal and refitting . . . . . . . . . . . . . . . . 16

Facia - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Glovebox - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 17

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . 29

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . 2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . 3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . . 31

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sunroof - general information and adjustment . . . . . . . . . . . . . . . . . 26

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tailgate lock components - removal and refitting . . . . . . . . . . . . . . . 22

Tailgate support strut - removal and refitting . . . . . . . . . . . . . . . . . . 21

Wheel arch liner - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 34

Windscreen and fixed windows - removal and refitting . . . . . . . . . . 24

Torque wrench settingsNm lbf ft

Bonnet and tailgate hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 18

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Front seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Seat belt mounting nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Bumper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

11

The bodyshell and underframe on all

models is of all-steel welded construction,

incorporating progressive crumple zones at

the front and rear, and a rigid centre safety

cell. The bulkhead behind the engine

compartment incorporates crash grooves

which determine its energy-absorption

characteristics, and special beams to prevent

the intrusion of the front wheels into the

passenger compartment during a serious

accident. All passenger doors incorporate

side impact bars.

All sheet metal surfaces which are prone tocorrosion are galvanized. The painting

process includes a base colour which closely

matches the final topcoat, so that any stone

damage is not noticeable.

Hatchback, Saloon and Estate versions are

available. The front section of the vehicle up to

the “B” pillar is identical on all models.

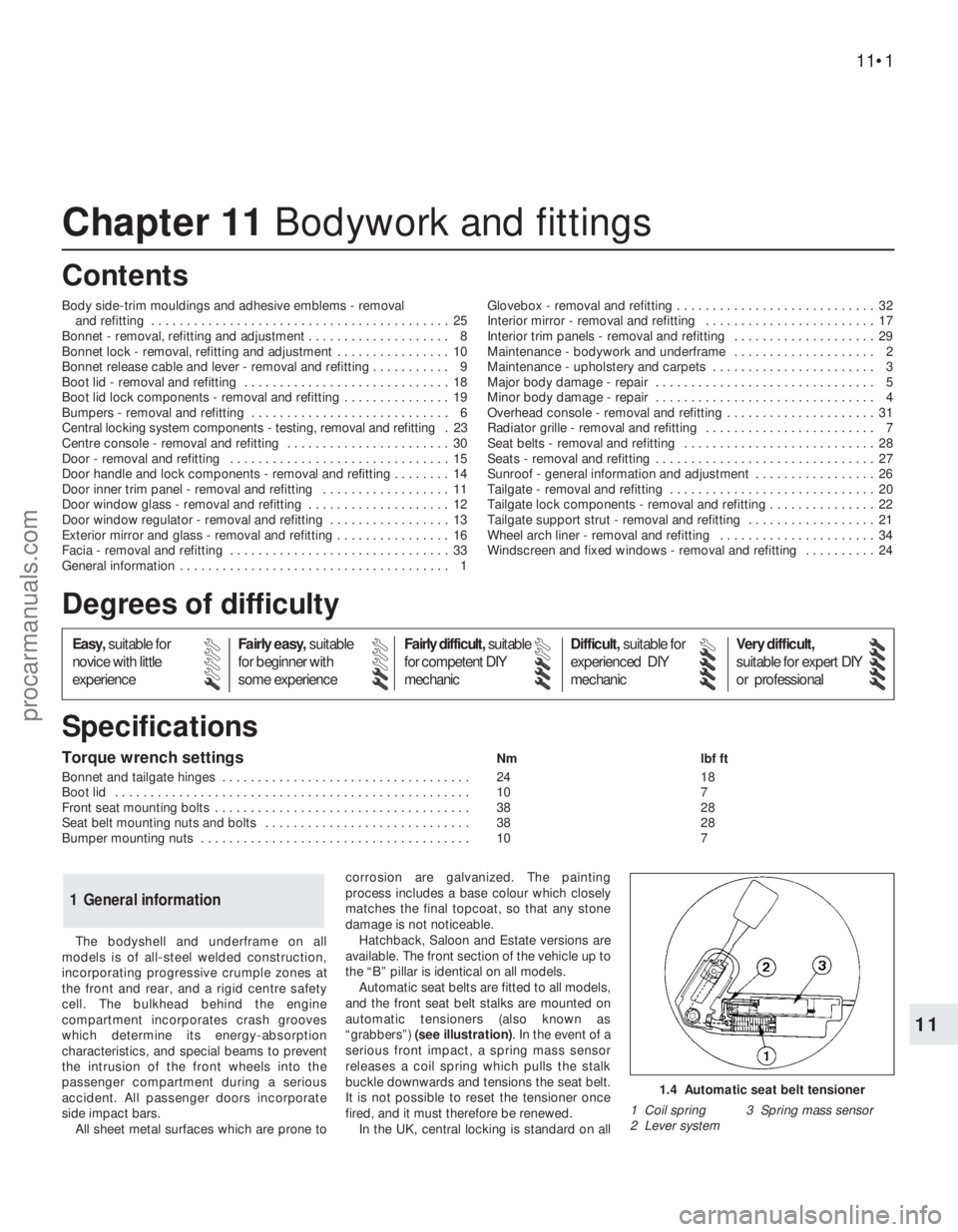

Automatic seat belts are fitted to all models,

and the front seat belt stalks are mounted on

automatic tensioners (also known as

“grabbers”) (see illustration). In the event of a

serious front impact, a spring mass sensor

releases a coil spring which pulls the stalk

buckle downwards and tensions the seat belt.

It is not possible to reset the tensioner once

fired, and it must therefore be renewed.

In the UK, central locking is standard on all

1 General information

1.4 Automatic seat belt tensioner

1 Coil spring 3 Spring mass sensor

2 Lever system

procarmanuals.com

Page 185 of 279

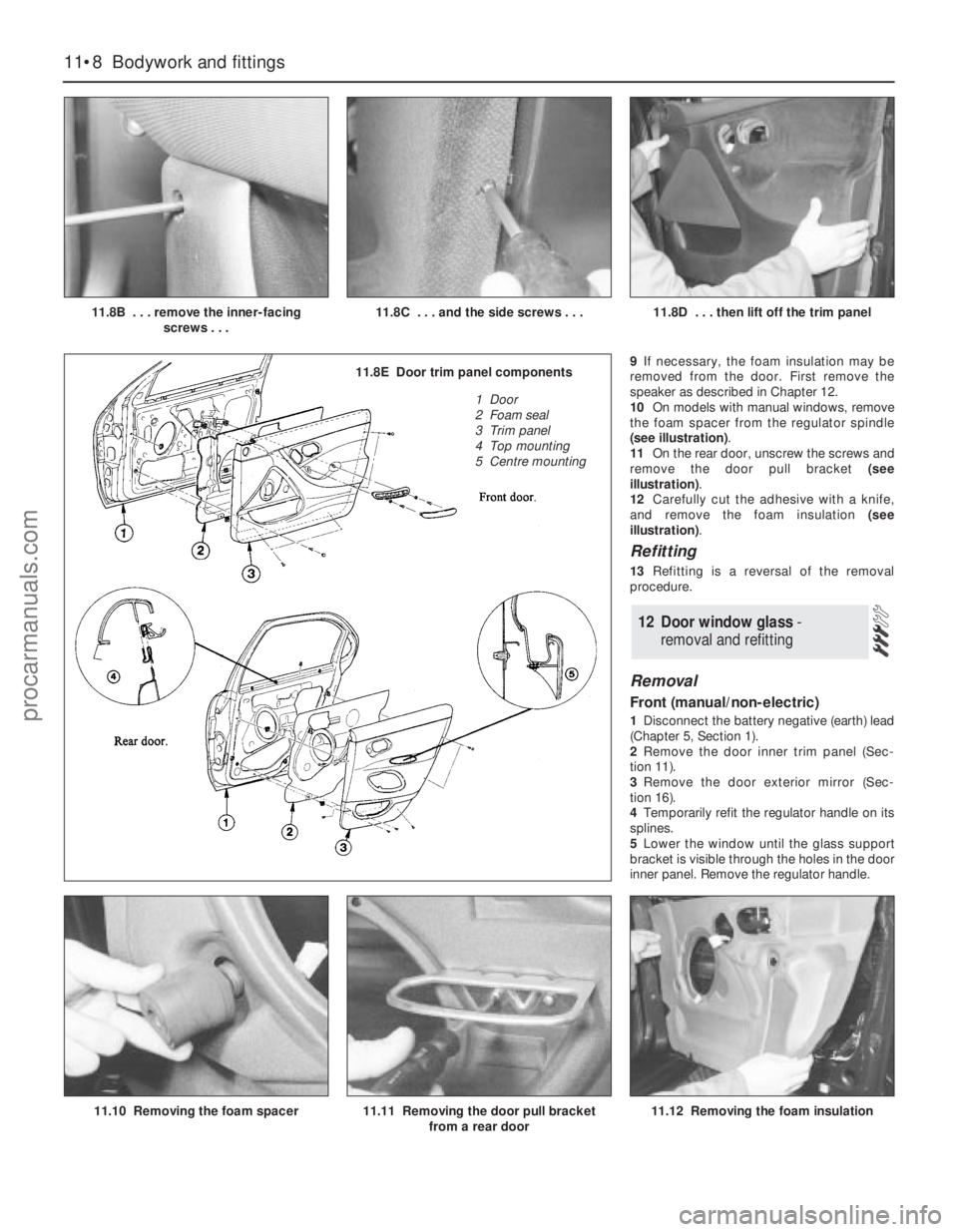

9If necessary, the foam insulation may be

removed from the door. First remove the

speaker as described in Chapter 12.

10On models with manual windows, remove

the foam spacer from the regulator spindle

(see illustration).

11On the rear door, unscrew the screws and

remove the door pull bracket (see

illustration).

12Carefully cut the adhesive with a knife,

and remove the foam insulation (see

illustration).

Refitting

13Refitting is a reversal of the removal

procedure.

Removal

Front (manual/non-electric)

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2Remove the door inner trim panel (Sec-

tion 11).

3Remove the door exterior mirror (Sec-

tion 16).

4Temporarily refit the regulator handle on its

splines.

5Lower the window until the glass support

bracket is visible through the holes in the door

inner panel. Remove the regulator handle.

12 Door window glass -

removal and refitting

11•8 Bodywork and fittings

11.8B . . . remove the inner-facing

screws . . .11.8C . . . and the side screws . . .11.8D . . . then lift off the trim panel

11.10 Removing the foam spacer11.11 Removing the door pull bracket

from a rear door11.12 Removing the foam insulation

11.8E Door trim panel components

1 Door

2 Foam seal

3 Trim panel

4 Top mounting

5 Centre mounting

procarmanuals.com

Page 186 of 279

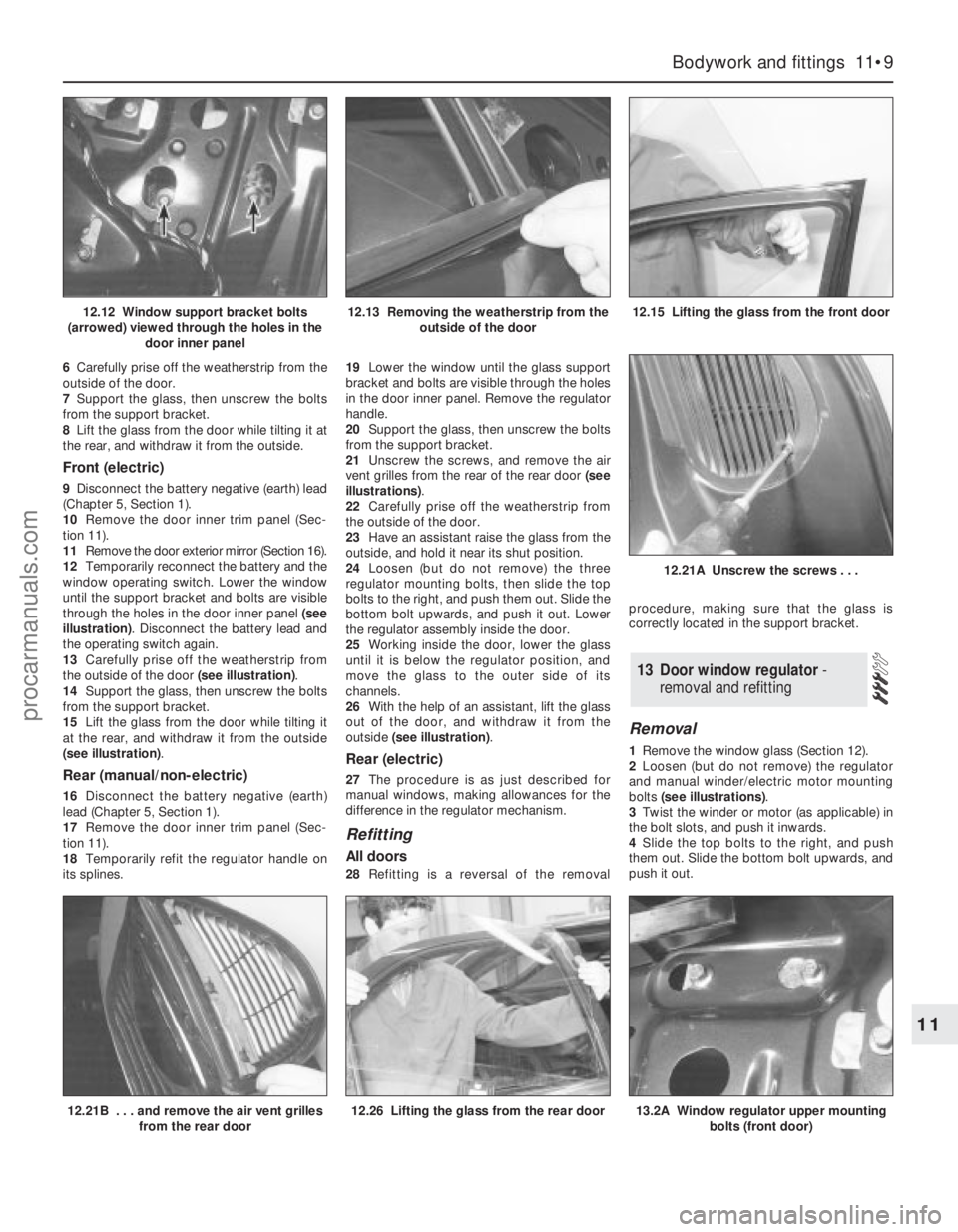

6Carefully prise off the weatherstrip from the

outside of the door.

7Support the glass, then unscrew the bolts

from the support bracket.

8Lift the glass from the door while tilting it at

the rear, and withdraw it from the outside.

Front (electric)

9Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

10Remove the door inner trim panel (Sec-

tion 11).

11Remove the door exterior mirror (Section 16).

12Temporarily reconnect the battery and the

window operating switch. Lower the window

until the support bracket and bolts are visible

through the holes in the door inner panel (see

illustration). Disconnect the battery lead and

the operating switch again.

13Carefully prise off the weatherstrip from

the outside of the door (see illustration).

14Support the glass, then unscrew the bolts

from the support bracket.

15Lift the glass from the door while tilting it

at the rear, and withdraw it from the outside

(see illustration).

Rear (manual/non-electric)

16Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

17Remove the door inner trim panel (Sec-

tion 11).

18Temporarily refit the regulator handle on

its splines.19Lower the window until the glass support

bracket and bolts are visible through the holes

in the door inner panel. Remove the regulator

handle.

20Support the glass, then unscrew the bolts

from the support bracket.

21Unscrew the screws, and remove the air

vent grilles from the rear of the rear door (see

illustrations).

22Carefully prise off the weatherstrip from

the outside of the door.

23Have an assistant raise the glass from the

outside, and hold it near its shut position.

24Loosen (but do not remove) the three

regulator mounting bolts, then slide the top

bolts to the right, and push them out. Slide the

bottom bolt upwards, and push it out. Lower

the regulator assembly inside the door.

25Working inside the door, lower the glass

until it is below the regulator position, and

move the glass to the outer side of its

channels.

26With the help of an assistant, lift the glass

out of the door, and withdraw it from the

outside (see illustration).

Rear (electric)

27The procedure is as just described for

manual windows, making allowances for the

difference in the regulator mechanism.

Refitting

All doors

28Refitting is a reversal of the removalprocedure, making sure that the glass is

correctly located in the support bracket.

Removal

1Remove the window glass (Section 12).

2Loosen (but do not remove) the regulator

and manual winder/electric motor mounting

bolts (see illustrations).

3Twist the winder or motor (as applicable) in

the bolt slots, and push it inwards.

4Slide the top bolts to the right, and push

them out. Slide the bottom bolt upwards, and

push it out.

13 Door window regulator-

removal and refitting

Bodywork and fittings 11•9

11

12.21B . . . and remove the air vent grilles

from the rear door12.26 Lifting the glass from the rear door13.2A Window regulator upper mounting

bolts (front door)

12.12 Window support bracket bolts

(arrowed) viewed through the holes in the

door inner panel12.13 Removing the weatherstrip from the

outside of the door12.15 Lifting the glass from the front door

12.21A Unscrew the screws . . .

procarmanuals.com

Page 191 of 279

door, then drive the hinge pins down through

the hinges using a small drift (see

illustrations).

6Carefully withdraw the door from the

hinges.

Refitting

7Refitting is a reversal of the removal

procedure, but check that the door lock

passes over the striker centrally. If necessary,

re-position the striker.

Removal

1Where electric mirrors are fitted, disconnect

the battery negative (earth) lead (Chapter 5,

Section 1).

2Prise off the cap, unscrew the screw, and

remove the quarter bezel from the front of the

window opening.

3On manual mirrors, detach the adjustment

lever.

4On electric mirrors, disconnect the wiring

multi-plug (see illustration).

5On both types of mirror, use a Torx key to

unscrew the mirror mounting screws, then

withdraw the mirror from the outside of the

door (see illustrations). Recover the gasket.

Refitting

6Refitting is a reversal of the removal

procedure.

Removal

1Using a length of strong thin cord or fishing

line, break the adhesive bond between the

base of the mirror and the glass. Have an

assistant support and remove the mirror as it

is released.

2If the original mirror is to be refitted,

thoroughly clean its base with methylated

spirit and a lint-free cloth. Allow a period of

one minute for the spirit to evaporate. Clean

the windscreen black patch in a similar

manner.

Refitting

3During the installation of the mirror, it is

important that the mirror base, windscreen

black patch and the adhesive patch are not

touched or contaminated in any way,

otherwise poor adhesion will result.

4Prior to fitting the mirror, the vehicle should

have been at an ambient temperature of at

least 20ºC.

5With the contact surfaces thoroughly

cleaned, remove the protective tape from one

side of the adhesive patch, and press it firmly

into contact with the mirror base.

6If fitting the mirror to a new windscreen, the

protective tape must also be removed from

the windscreen black patch.

7Using a hairdryer or a hot air gun, warm themirror base and the adhesive patch for about

30 seconds to a temperature of 50 to 70ºC.

Peel back the protective tape from the other

side of the adhesive patch on the mirror base.

Align the mirror base and the windscreen

patch, and press the mirror firmly into

position. Hold the base of the mirror firmly

against the windscreen for a minimum period

of two minutes, to ensure full adhesion.

8Wait at least thirty minutes before adjusting

the mirror position.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1), and open the boot lid.

2Where applicable, pull off the trim covering,

and release the wiring on the hinge arm.

3Where fitted, remove the trim from inside

the boot lid.

4Disconnect the wiring at the connectors

visible through the boot lid inner skin aperture.

5Attach a length of strong cord to the end of

the wires in the aperture, to act as an aid to

guiding the wiring through the lid when it is

refitted.

6Release the cable guide rubber grommet,

and withdraw the wiring loom through it. Untie

the cord, and leave it in the boot lid.

7Mark the position of the hinge arms with a

pencil.

8Place rags beneath each corner of the boot

lid, to prevent damage to the paintwork.

9With the help of an assistant, unscrew the

mounting bolts and lift the boot lid from the

car.

Refitting

10Refitting is a reversal of the removal

procedure. Check that the boot lid is correctly

aligned with the surrounding bodywork, with

an equal clearance around its edge.

Adjustment is made by loosening the hinge

bolts, and moving the boot lid within the

elongated mounting holes. Check that the

lock enters the striker centrally when the boot

lid is closed.

18 Boot lid - removal and refitting

17 Interior mirror -

removal and refitting

16 Exterior mirror and glass-

removal and refitting

11•14 Bodywork and fittings

15.5A . . . then drive out the hinge pins . . .15.5B . . . and remove them16.4 Disconnecting the wiring multi-plug

from an electric exterior mirror

16.5A Unscrew the screws . . .16.5B . . . and withdraw the mirror

procarmanuals.com

Page 197 of 279

8Unscrew the mounting bolt securing the

seat belt stalk, and withdraw the stalk. Also

unscrew the mounting bolt from the lower

anchorage, where applicable (see

illustration).

Rear centre seat belt

9Unscrew the mounting bolts securing the

seat belt and stalks to the floor. Note that the

stalks are handed, and are marked Left or

Right.

Refitting

10Refitting is a reversal of the removal

procedure. Tighten the mounting nuts and

bolts to the specified torque.

Removal

Sun visor

1Disconnect the wiring for the vanity mirror

light, where fitted.

2Unscrew the mounting screws and remove

the visor.

3Prise up the cover, unscrew the inner

bracket mounting screws, and remove the

bracket.

Passenger grab handle

4Prise up the covers, then unscrew the

mounting screws and remove the grab

handle.

“A” pillar trim

5Pull away the door weatherstrip in the area

of the trim.

6Release the alarm and aerial wiring from the

upper and middle clips.

7Carefully press the trim away from the

upper and middle clips, and pull the trim

upwards. Recover the lower sealing strip.

8Remove the upper and middle clips from

the pillar.

“B” pillar and cowl side trim

9Pull away the door weatherstrip in the area

of the trim.

10Undo the screws, release the fasteners

and remove the lower trim (see illustrations).

11Carefully separate the lower trim from the

upper trim, using a screwdriver if necessary

(see illustration).

12Unscrew the seat belt mounting bolt from

under the front seat, remove the remaining

trim from the “B” pillar, and feed the belt

through the trim.

“C” pillar trim (Saloon and Hatchback)

13Pull away the door weatherstrip in the

area of the trim.

14Fold the rear seat cushion forwards.

15Pull up the rear seat bolster, and release

29 Interior trim panels-

removal and refitting

11•20 Bodywork and fittings

28.6B Removing the plastic cover from the

rear seat lock28.7A Rear seat belt shackle mounting

bolt28.7B Rear seat belt reel mounting bolt

29.10B Releasing the fasteners from the

cowl side trim29.11 Separating the “B” pillar lower and

upper trim

28.8 Rear seat belt lower anchorage29.10A Removing a middle screw from the

lower trim

29.15A Pull up the rear seat bolster . . .

procarmanuals.com

Page 203 of 279

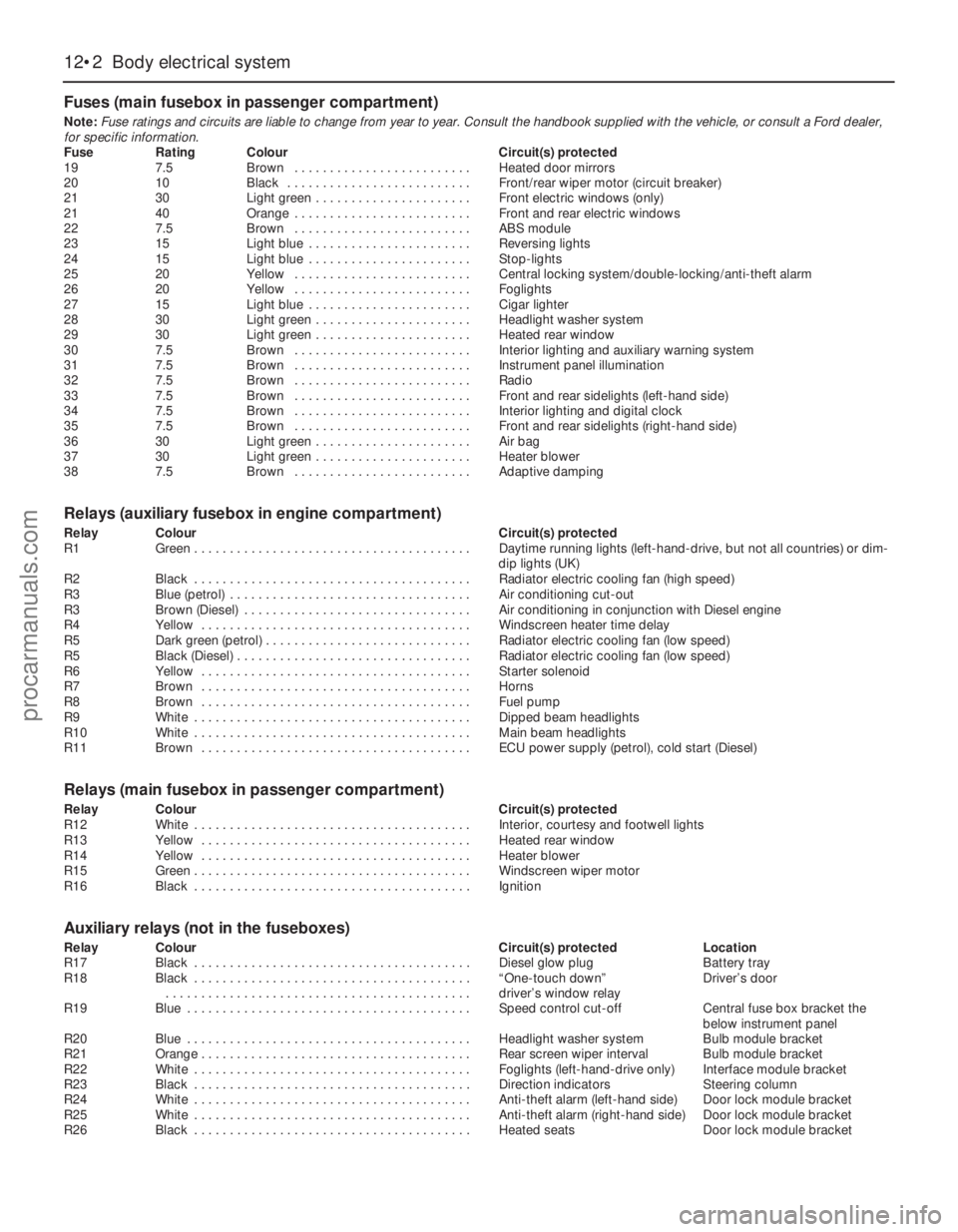

Fuses (main fusebox in passenger compartment)

Note:Fuse ratings and circuits are liable to change from year to year. Consult the handbook supplied with the vehicle, or consult a Ford dealer,

for specific information.

Fuse Rating Colour Circuit(s) protected

19 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Heated door mirrors

20 10 Black . . . . . . . . . . . . . . . . . . . . . . . . . . Front/rear wiper motor (circuit breaker)

21 30 Light green . . . . . . . . . . . . . . . . . . . . . . Front electric windows (only)

21 40 Orange . . . . . . . . . . . . . . . . . . . . . . . . . Front and rear electric windows

22 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . ABS module

23 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Reversing lights

24 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Stop-lights

25 20 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Central locking system/double-locking/anti-theft alarm

26 20 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . Foglights

27 15 Light blue . . . . . . . . . . . . . . . . . . . . . . . Cigar lighter

28 30 Light green . . . . . . . . . . . . . . . . . . . . . . Headlight washer system

29 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heated rear window

30 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Interior lighting and auxiliary warning system

31 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Instrument panel illumination

32 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Radio

33 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Front and rear sidelights (left-hand side)

34 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Interior lighting and digital clock

35 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Front and rear sidelights (right-hand side)

36 30 Light green . . . . . . . . . . . . . . . . . . . . . . Air bag

37 30 Light green . . . . . . . . . . . . . . . . . . . . . . Heater blower

38 7.5 Brown . . . . . . . . . . . . . . . . . . . . . . . . . Adaptive damping

Relays (auxiliary fusebox in engine compartment)

Relay Colour Circuit(s) protected

R1 Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Daytime running lights (left-hand-drive, but not all countries) or dim-

dip lights (UK)

R2 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fan (high speed)

R3 Blue (petrol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air conditioning cut-out

R3 Brown (Diesel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Air conditioning in conjunction with Diesel engine

R4 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Windscreen heater time delay

R5 Dark green (petrol) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fan (low speed)

R5 Black (Diesel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Radiator electric cooling fan (low speed)

R6 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Starter solenoid

R7 Brown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Horns

R8 Brown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel pump

R9 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dipped beam headlights

R10 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Main beam headlights

R11 Brown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ECU power supply (petrol), cold start (Diesel)

Relays (main fusebox in passenger compartment)

Relay Colour Circuit(s) protected

R12 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Interior, courtesy and footwell lights

R13 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heated rear window

R14 Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heater blower

R15 Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Windscreen wiper motor

R16 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ignition

Auxiliary relays (not in the fuseboxes)

Relay Colour Circuit(s) protected Location

R17 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diesel glow plug Battery tray

R18 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . “One-touch down” Driver’s door

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . driver’s window relay

R19 Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Speed control cut-off Central fuse box bracket the

below instrument panel

R20 Blue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Headlight washer system Bulb module bracket

R21 Orange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rear screen wiper interval Bulb module bracket

R22 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Foglights (left-hand-drive only) Interface module bracket

R23 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direction indicators Steering column

R24 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Anti-theft alarm (left-hand side) Door lock module bracket

R25 White . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Anti-theft alarm (right-hand side) Door lock module bracket

R26 Black . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Heated seats Door lock module bracket

12•2 Body electrical system

procarmanuals.com

Page 208 of 279

Main light, auxiliary foglight and rear

foglight combination switch

Note:From July 1994 a rvised main light

switch was introduced; this was fitted as

standard in production. If the revised switch is

to be fitted to a pre-July 1994 model, an

adapter lead will also be required to prevent

electrical damage ocurring. Refer to your Ford

dealer for further information

9Disconnect the battery negative (earth) lead

(refer to Chapter 5, Section 1).

10Carefully prise the switch panel from the

facia, using a screwdriver against a cloth pad

to prevent damage to the facia (see

illustration).

11Disconnect the multi-plugs and withdraw

the switch panel (see illustration).

12Unscrew the four mounting screws, and

remove the switch from the panel.

13Pull off the switch control knob, and

remove the blanking plug and retainer.

14Depress the plastic tabs, and remove the

front cover and switch.

Instrument light rheostat

15Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

16Carefully prise the light switch panel from

the facia, using a screwdriver against a cloth

pad to prevent damage to the facia.

17Disconnect the multi-plugs from the rear

of the switch, then remove the screws and

withdraw the instrument light rheostat from

the panel.

Door mirror control switch

18Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

19Carefully prise the switch from the facia,

using a screwdriver against a cloth pad to

prevent damage to the facia.

20Disconnect the multi-plug and withdraw

the switch.

Direction indicator, dipped beam and

hazard flasher multi-function switch

21Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

22Remove the rubber gaiters and locking

rings, then remove the screws and take off the

steering column upper shroud.23Depress the retaining lug and withdraw

the switch assembly, then disconnect the

multi-plug (see illustration).

24With the switch assembly removed, pull

out the direction indicator relay if required.

Horn switch (steering wheel without

air bag)

Note:When an air bag is fitted, the horn

switch is removed with the air bag unit. Refer

to Section 28.

25Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

26Carefully pull off the padded centre of the

steering wheel which incorporates the horn

switch.

27Disconnect the wiring and remove the

switch assembly.

Luggage compartment switch

28Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

29With the tailgate/bootlid open, pull the

weatherstrip from the centre of the rear cross

panel.

30Carefully prise out the trim fasteners from

the bottom corners of the rear trim, then

unscrew the retaining screws and remove the

trim panel.

31Disconnect the wiring multi-plug, and pull

out the switch.

Electrically-operated window switch

(single)

32Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

33Carefully prise out the switch from the

door inner trim panel, using a cloth pad to

prevent damage to the trim.

34Disconnect the multi-plug and remove the

switch.

Electrically-operated window switch

(multiple) and isolator

35Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

36Prise the blanking cap from inside the

inner door handle cavity, and remove the

screw.

37Hold the inner door handle in its open

position, then remove the bezel and withdraw

it over the handle.38Depress the retaining lug and remove the

switch assembly, then disconnect the multi-

plug.

Electrically-operated sunroof switch

and traction control switch

39Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

40Carefully prise out the switch with a

screwdriver, using a cloth pad to prevent

damage to the trim.

41Disconnect the multi-plug and remove the

switch.

Handbrake-on warning switch

42Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

43Remove the centre console as described

in Chapter 11.

44Disconnect the multi-plug, then remove

the screw and withdraw the switch from the

handbrake lever mounting bracket (see

illustration).

“Economy/Sport” mode switch

(automatic transmission models)

45Disconnect the battery negative (earth)

lead (refer to Chapter 5, Section 1).

46Select Neutral, then prise out the selector

indicator panel, using a cloth pad to prevent

damage to the surrounding trim.

47Push the switch out of the panel, and

disconnect the multi-plug.

Body electrical system 12•7

12

4.44 Disconnecting the multi-plug from

the handbrake lever

4.10 Prising out the light switch4.11 Disconnecting the multi-plugs from

the light switch and rheostat4.23 Removing the direction indicator,

dipped beam and hazard flasher multi-

function switch. Direction indicator relay

(flasher unit) is attached

procarmanuals.com

Page 243 of 279

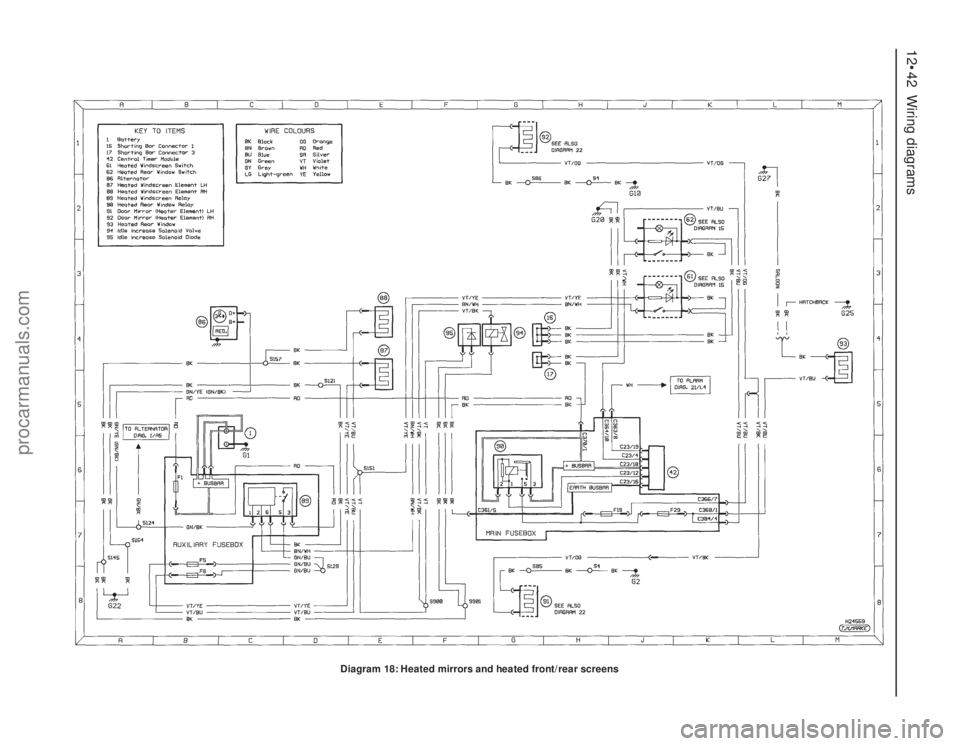

12•42 Wiring diagrams

Diagram 18: Heated mirrors and heated front/rear screens

procarmanuals.com