roof FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 6 of 279

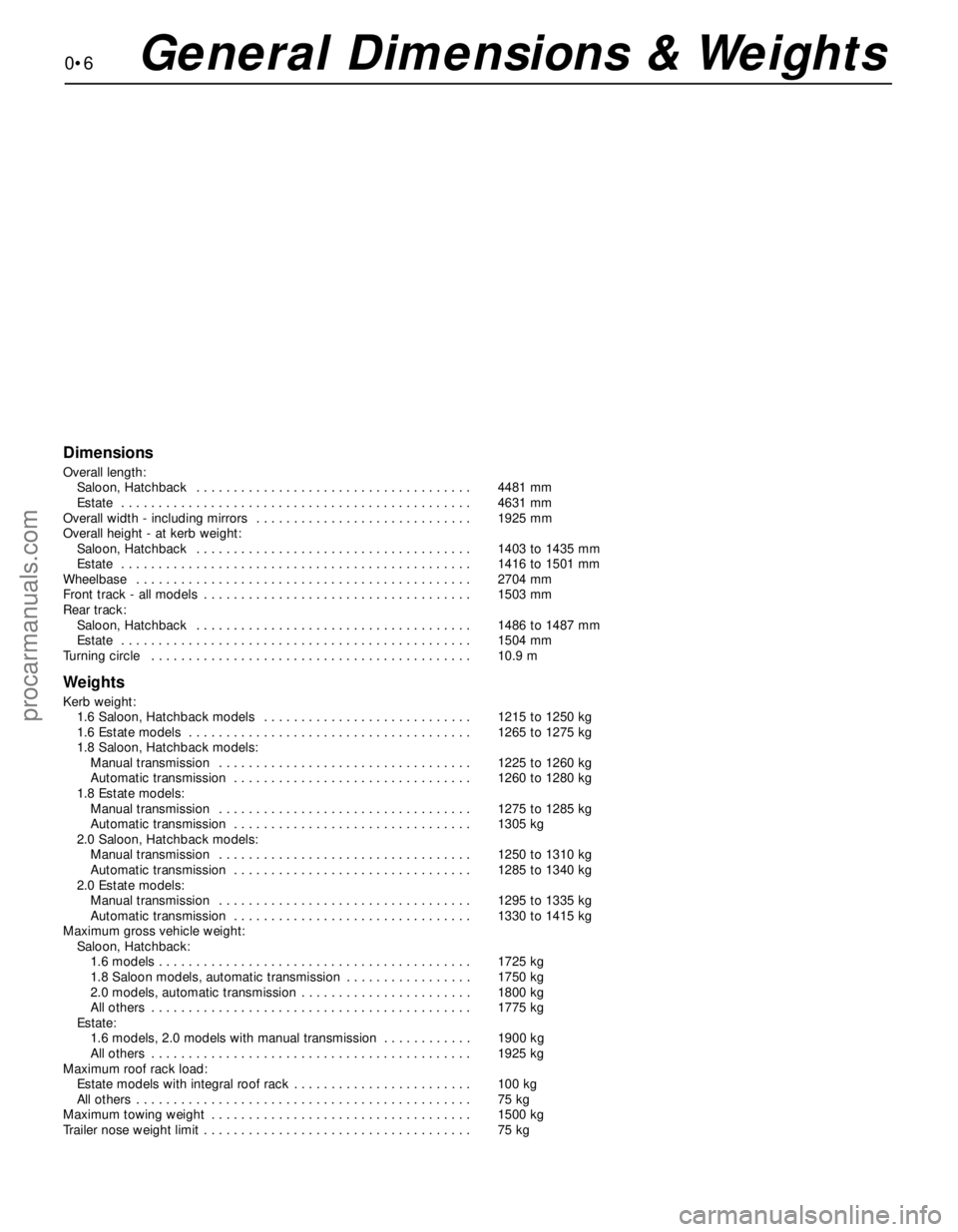

0•6General Dimensions & Weights

Dimensions

Overall length:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4481 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4631 mm

Overall width - including mirrors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1925 mm

Overall height - at kerb weight:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1403 to 1435 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1416 to 1501 mm

Wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2704 mm

Front track - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1503 mm

Rear track:

Saloon, Hatchback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1486 to 1487 mm

Estate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1504 mm

Turning circle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.9 m

Weights

Kerb weight:

1.6 Saloon, Hatchback models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1215 to 1250 kg

1.6 Estate models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1265 to 1275 kg

1.8 Saloon, Hatchback models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1225 to 1260 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1260 to 1280 kg

1.8 Estate models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1275 to 1285 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1305 kg

2.0 Saloon, Hatchback models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1250 to 1310 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1285 to 1340 kg

2.0 Estate models:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1295 to 1335 kg

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1330 to 1415 kg

Maximum gross vehicle weight:

Saloon, Hatchback:

1.6 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1725 kg

1.8 Saloon models, automatic transmission . . . . . . . . . . . . . . . . . 1750 kg

2.0 models, automatic transmission . . . . . . . . . . . . . . . . . . . . . . . 1800 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1775 kg

Estate:

1.6 models, 2.0 models with manual transmission . . . . . . . . . . . . 1900 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1925 kg

Maximum roof rack load:

Estate models with integral roof rack . . . . . . . . . . . . . . . . . . . . . . . . 100 kg

All others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg

Maximum towing weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1500 kg

Trailer nose weight limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg

procarmanuals.com

Page 49 of 279

9Remove the nuts and detach the manifold

and gasket (see illustration). Take care not

to damage vulnerable components such as

the EGR pipe as the manifold assembly is

manoeuvred out of the engine compartment.

When removing the manifold with the engine

in the vehicle, additional clearance can be

obtained by unscrewing the studs from the

cylinder head; a female Torx-type socket will

be required (see illustration).

10Always fit a new gasket on reassembly, to

carefully-cleaned components (see below).

Do notattempt to re-use the original gasket.

Inspection

11Use a scraper to remove all traces of old

gasket material and carbon deposits from the

manifold and cylinder head mating surfaces. If

the gasket was leaking, have the manifold

checked for warpage at an automotive

machine shop, and have it resurfaced if

necessary.

Caution: When scraping, be very

careful not to gouge or scratch

the delicate aluminium alloy

cylinder head.

12Provided both mating surfaces are clean

and flat, a new gasket will be sufficient to

ensure the joint is gas-tight. Do notuse any

kind of exhaust sealant upstream of the

catalytic converter.

13Note that the downpipe is secured to the

manifold by two bolts, with a coil spring,

spring seat and self-locking nut on each. On

refitting, tighten the nuts until they stop on thebolt shoulders; the pressure of the springs will

then suffice to make a leakproof joint (see

illustrations).

14Do not overtighten the nuts to cure a leak

- the bolts will shear; renew the gasket and

the springs if a leak is found. The bolts

themselves are secured by spring clips to the

manifold, and can be renewed easily if

damaged (see illustration).

Refitting

15Refitting is the reverse of the removal

procedure, noting the following points:

(a) Position a new gasket over the cylinder

head studs, and fit a new plastic guide

sleeve to the stud nearest to the

thermostat housing, so that the manifold

will be correctly located (see illustration).

Do notrefit the manifold without this

sleeve.

(b) Refit the manifold, and finger-tighten the

mounting nuts.

(c) Working from the centre out, and in three

or four equal steps, tighten the nuts to the

torque wrench setting given in the

Specifications Section of this Chapter.

(d) Refit the remaining parts in the reverse

order of removal. Tighten all fasteners to

the specified torque wrench settings.

(e) Refill the cooling system (see Chapter 1).

(f) Run the engine, and check for exhaust

leaks. Check the coolant level when fully

warmed-up to normal operating

temperature.1Remove the auxiliary drivebelt - either

remove the drivebelt completely, or just

secure it clear of the crankshaft pulley,

depending on the work to be carried out (see

Chapter 1).

2If necessary, rotate the crankshaft until the

timing marks align (see Section 4).

3The crankshaft must now be locked to

prevent its rotation while the pulley bolt is

unscrewed. Proceed as follows:

(a) If the engine/transmission is still installed

in the vehicle:

(1) If the vehicle is fitted with manual

transmission, select top gear, and have an

assistant apply the brakes hard.

(2) If the vehicle is fitted with automatic

transmission, unbolt the small metal cover

plate from the sump, and use a large

screwdriver or similar to lock the

driveplate ring gear teeth while an

assistant slackens the pulley bolt; take

care not to damage the teeth or the

surrounding castings when using this

method.

(b) If the engine/transmission has been

removed but not yet separated:

(1) If the vehicle is fitted with manual

transmission, remove the starter motor

(see Chapter 5) and lock the flywheel

8 Crankshaft pulley -

removal and refitting

In-car engine repair procedures 2A•9

2A

7.13B Renew exhaust system downpipe-

to-manifold gasket to prevent leaks7.14 Release spring clip to extract

securing bolt from manifold, when required7.15 Fit plastic guide sleeve to stud

arrowed when refitting exhaust manifold

7.9A Unscrew nuts (arrowed) to remove

exhaust manifold . . .

7.9B . . . studs can be unscrewed also, if

required, to provide additional working

space7.13A Showing exhaust downpipe-to-

manifold securing bolts - note coil spring,

and shoulder on bolt

procarmanuals.com

Page 110 of 279

Idle-increase solenoid valve

Check

43If this valve is thought to be faulty, unplug

its electrical connector and disconnect its

vacuum hoses, then connect a battery directly

across the valve’s terminals. Check that air

can flow through the valve’s passages when

the solenoid is energised, and that nothing

can pass when the solenoid is not energised.

Alternatively, connect an ohmmeter to

measure the resistance between the valve’s

terminals, and compare this reading to that

listed in the Specifications Section at the

beginning of this Chapter. Renew the valve if

it is faulty (see illustration).

44The solenoid’s diode is fitted to control

any voltage “spikes” which might occur as the

solenoid is switched off. A faulty diode would

not, therefore, necessarily interfere with the

operation of the valve. If the diode is thought

to be faulty, however, it can be checked by

unplugging it and connecting an ohmmeter

across its terminals, to check that continuity

exists in one direction only. If continuity is

found in both directions, or in neither, the

diode is faulty, and must be renewed.

Renewal

45If better access is required, remove the

plenum chamber (see Section 4).

46Disconnect the battery negative (earth)

lead - see Section 1 of Chapter 5.

46Unplug the valve’s electrical connector.

Unclip the valve from the bulkhead, then

disconnect its vacuum hoses and withdraw it.

47Refitting is the reverse of the removal

procedure.

Warning: Inspection and repair of

exhaust system components

should be done only after enough

time has elapsed after driving the vehicle

to allow the system components to cool

completely. This applies particularly to the

catalytic converter, which runs at very

high temperatures. Also, when working

under the vehicle, make sure it is securely

supported on axle stands.

1The exhaust system is composed of an

exhaust manifold, the front downpipe and

catalytic converter, and a rear section

incorporating two silencers (three on some

versions) and the tailpipe assembly. The

service replacement exhaust system consists

of three or four sections: the front

downpipe/catalytic converter, the

intermediate pipe and front silencer, and the

tailpipe and rear silencer. On some versions,

the tailpipe is in two pieces, with two rear

silencers. The system is suspended

throughout its entire length by rubber

mountings.

2If any of these parts are damaged ordeteriorated, excessive noise and vibration

will occur.

3Conduct regular inspections of the exhaust

system, to keep it safe and quiet. Look for any

damaged or bent parts, open seams, holes,

loose connections, excessive corrosion, or

other defects which could allow exhaust

fumes to enter the vehicle. Deteriorated

exhaust system components should not be

repaired - they should be replaced with new

parts.

4If the exhaust system components are

extremely corroded or rusted together, they

will probably have to be cut from the exhaust

system. The most convenient way of

accomplishing this is to have a quick-fit

exhaust repair specialist remove the corroded

sections. If, however, you want to save money

by doing it yourself (and you don’t have an

oxy/acetylene welding outfit with a cutting

torch), simply cut off the old components with

a hacksaw. If you have compressed air,

special pneumatic cutting chisels can also be

used. If you do decide to tackle the job at

home, be sure to wear eye protection, to

protect your eyes from metal chips, and work

gloves, to protect your hands. If the

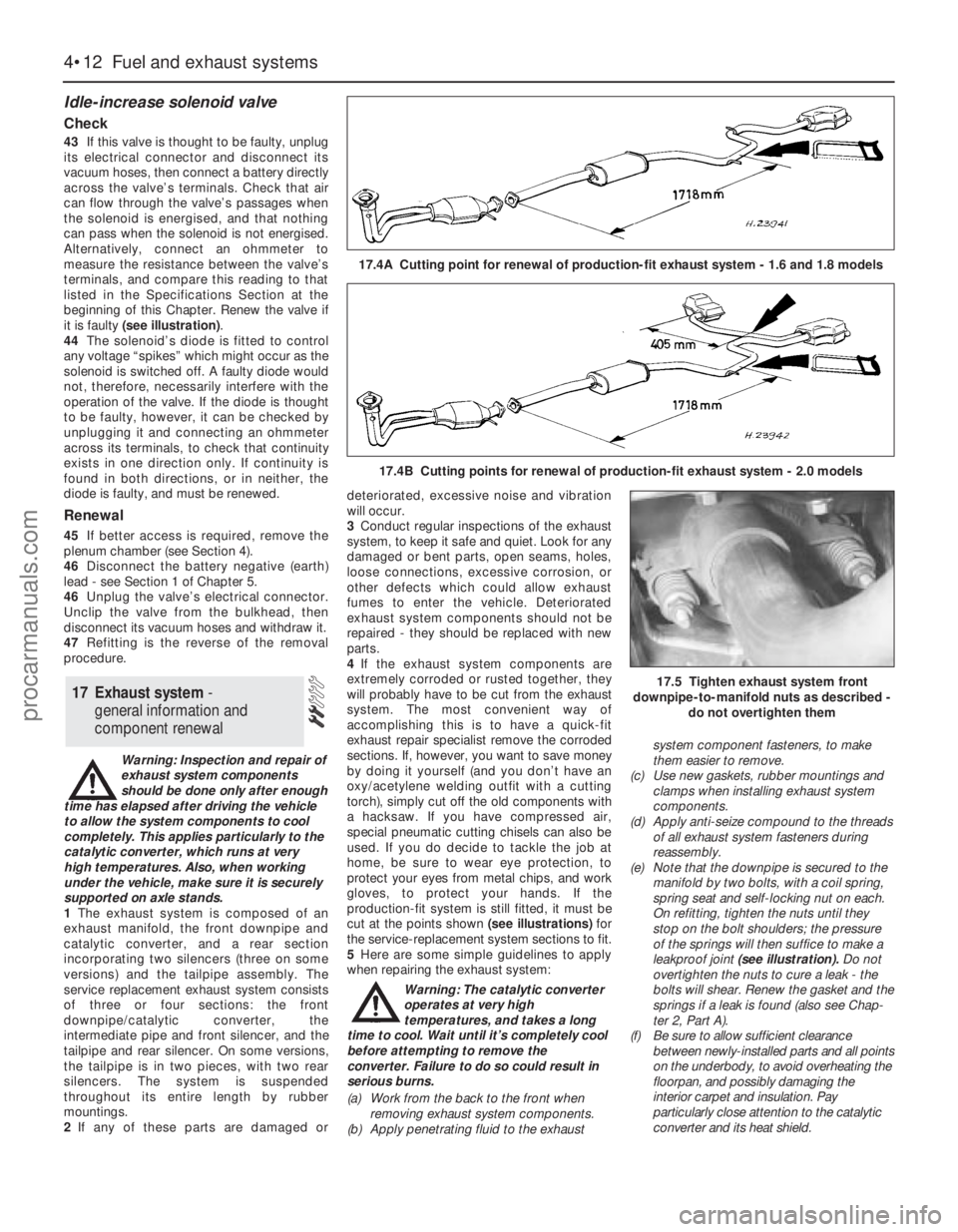

production-fit system is still fitted, it must be

cut at the points shown (see illustrations) for

the service-replacement system sections to fit.

5Here are some simple guidelines to apply

when repairing the exhaust system:

Warning: The catalytic converter

operates at very high

temperatures, and takes a long

time to cool. Wait until it’s completely cool

before attempting to remove the

converter. Failure to do so could result in

serious burns.

(a) Work from the back to the front when

removing exhaust system components.

(b) Apply penetrating fluid to the exhaustsystem component fasteners, to make

them easier to remove.

(c) Use new gaskets, rubber mountings and

clamps when installing exhaust system

components.

(d) Apply anti-seize compound to the threads

of all exhaust system fasteners during

reassembly.

(e) Note that the downpipe is secured to the

manifold by two bolts, with a coil spring,

spring seat and self-locking nut on each.

On refitting, tighten the nuts until they

stop on the bolt shoulders; the pressure

of the springs will then suffice to make a

leakproof joint (see illustration). Do not

overtighten the nuts to cure a leak - the

bolts will shear. Renew the gasket and the

springs if a leak is found (also see Chap-

ter 2, Part A).

(f) Be sure to allow sufficient clearance

between newly-installed parts and all points

on the underbody, to avoid overheating the

floorpan, and possibly damaging the

interior carpet and insulation. Pay

particularly close attention to the catalytic

converter and its heat shield.

17 Exhaust system -

general information and

component renewal

4•12 Fuel and exhaust systems

17.4A Cutting point for renewal of production-fit exhaust system - 1.6 and 1.8 models

17.4B Cutting points for renewal of production-fit exhaust system - 2.0 models

17.5 Tighten exhaust system front

downpipe-to-manifold nuts as described -

do not overtighten them

procarmanuals.com

Page 112 of 279

General information

The engine electrical systems include all

ignition, charging and starting components.

Because of their engine-related functions,

these components are discussed separately

from body electrical devices such as the

lights, the instruments, etc (which are

included in Chapter 12).

Precautions

Always observe the following precautions

when working on the electrical system:

(a) Be extremely careful when servicing

engine electrical components. They are

easily damaged if checked, connected or

handled improperly.

(b) Never leave the ignition switched on for

long periods of time when the engine is

not running.

(c) Don’t disconnect the battery leads while

the engine is running.

(d) Maintain correct polarity when connecting

a battery lead from another vehicle during

jump starting - see the “Booster battery

(jump) starting” section at the front of this

manual.

(e) Always disconnect the negative lead first,

and reconnect it last, or the battery may

be shorted by the tool being used to

loosen the lead clamps (see illustration).

It’s also a good idea to review the safety-

related information regarding the engine

electrical systems located in the “Safety first!”

section at the front of this manual, before

beginning any operation included in this Chapter.

Battery disconnection

Several systems fitted to the vehicle require

battery power to be available at all times, either

to ensure their continued operation (such as

the clock) or to maintain control unit memories

(such as that in the engine management

system’s ECU) which would be wiped if the

battery were to be disconnected. Whenever thebattery is to be disconnected therefore, first

note the following, to ensure that there are no

unforeseen consequences of this action:

(a) First, on any vehicle with central locking, it

is a wise precaution to remove the key

from the ignition, and to keep it with you,

so that it does not get locked in if the

central locking should engage accidentally

when the battery is reconnected!

(b) The engine management system’s ECU will

lose the information stored in its memory -

referred to by Ford as the “KAM” (Keep-

Alive Memory) - when the battery is

disconnected. This includes idling and

operating values, and any fault codes

detected - in the case of the fault codes, if it

is thought likely that the system has

developed a fault for which the

corresponding code has been logged, the

vehicle must be taken to a Ford dealer for

the codes to be read, using the special

diagnostic equipment necessary for this (see

Chapter 6). Whenever the battery is

disconnected, the information relating to idle

speed control and other operating values will

have to be re-programmed into the unit’s

memory. The ECU does this by itself, but

until then, there may be surging, hesitation,

erratic idle and a generally inferior level of

performance. To allow the ECU to relearn

these values, start the engine and run it as

close to idle speed as possible until it

reaches its normal operating temperature,

then run it for approximately two minutes at

1200 rpm. Next, drive the vehicle as far as

necessary - approximately 5 miles of varied

driving conditions is usually sufficient - to

complete the relearning process.

(c) If the battery is disconnected while the

alarm system is armed or activated, the

alarm will remain in the same state when

the battery is reconnected. The same

applies to the engine immobiliser system

(where fitted).

(d) If a trip computer is in use, any

information stored in memory will be lost.

(e) If a Ford “Keycode” audio unit is fitted,

and the unit and/or the battery is

disconnected, the unit will not function

again on reconnection until the correct

security code is entered. Details of thisprocedure, which varies according to the

unit and model year, are given in the

“Ford Audio Systems Operating Guide”

supplied with the vehicle when new, with

the code itself being given in a “Radio

Passport” and/or a “Keycode Label” at

the same time. Ensure you have the

correct code before you disconnect the

battery. For obvious security reasons, the

procedure is not given in this manual. If

you do not have the code or details of the

correct procedure, but can supply proof

of ownership and a legitimate reason for

wanting this information, the vehicle’s

selling dealer may be able to help.

Devices known as “memory-savers” (or

“code-savers”) can be used to avoid some of

the above problems. Precise details vary

according to the device used. Typically, it is

plugged into the cigarette lighter, and is

connected by its own wires to a spare battery;

the vehicle’s own battery is then disconnected

from the electrical system, leaving the

“memory-saver” to pass sufficient current to

maintain audio unit security codes and ECU

memory values, and also to run permanently-

live circuits such as the clock, all the while

isolating the battery in the event of a short-

circuit occurring while work is carried out.

Warning: Some of these devices

allow a considerable amount of

current to pass, which can mean

that many of the vehicle’s systems are still

operational when the main battery is

disconnected. If a “memory-saver” is used,

ensure that the circuit concerned is

actually “dead” before carrying out any

work on it!

Note:See also the relevant Sections of

Chapter 1.

1Disconnect the battery leads, negative

(earth) lead first - see Section 1.

2Remove the battery hold-down clamp (see

illustrations).

3Lift out the battery. Be careful - it’s heavy.

4While the battery is out, inspect the tray for

corrosion (see Chapter 1).

2 Battery- removal and refitting

1 General information,

precautions and battery

disconnection

5•2 Engine electrical systems

1.2 Always disconnect battery - negative

(earth) lead first - to prevent the possibility

of short-circuits2.2A Unscrew hold-down nuts (one of two

arrowed) . . .2.2B . . . and withdraw hold-down clamp

to release battery

procarmanuals.com

Page 144 of 279

Ignition timing and base idle

speed check

Note:The following procedure is a check only,

essentially of the ECU. Both the ignition timing

and the base idle speed are controlled by the

ECU. The ignition timing is not adjustable at

all; the base idle speed is set in production,

and should not be altered.

38If the fault code read-out (with any checks

resulting from it) has not eliminated the fault,

the next step is to check the ECU’s control of

the ignition timing and the base idle speed.

This task requires the use of a Ford STAR

tester (a proprietary fault code reader can be

used only if it is capable of inducing the ECU

to enter its “Service Adjustment Programme”),

coupled with an accurate tachometer and a

good-quality timing light. Without this

equipment, the task is not possible; the

vehicle must be taken to a Ford dealer for

attention.

39To make the check, apply the handbrake,

switch off the air conditioning (where fitted)

and any other electrical loads (lights, heated

rear window, etc), then select neutral (manual

transmission) or the “P” position (automatic

transmission). Start the engine, and warm it

up to normal operating temperature. The

radiator electric cooling fan must be running

continuously while the check is made; this

should be activated by the ECU, when

prompted by the tester. Switch off the engine,

and connect the test equipment as directed

by the manufacturer - refer to paragraph 26

above for details of STAR tester connection.

40Raise and support the front of the vehicle

securely, and remove the auxiliary drivebelt

cover (see Chapter 1). Emphasise the two

pairs of notches in the inner and outer rims of

the crankshaft pulley, using white paint. Note

that an ignition timing reference mark is not

provided on the pulley - in the normal

direction of crankshaft rotation (clockwise,

seen from the right-hand side of the vehicle)

the first pair of notches are irrelevant to the

vehicles covered in this manual, while the

second pair indicate Top Dead Centre (TDC)

when aligned with the rear edge of the raised

mark on the sump; when checking the ignition

timing, therefore, the (rear edge of the) sumpmark should appear just before the TDC

notches (see Part A of Chapter 2, Section 4,

for further information if required).

41Start the engine and allow it to idle. Work

through the engine-running test procedure

until the ECU enters its “Service Adjustment

Programme” - see paragraph 35 above.

42Use the timing light to check that the

timing marks appear approximately as

outlined above at idle speed. Do not spend

too much time on this check; if the timing

appears to be incorrect, the system may have

a fault, and a full system test must be carried

out (see below) to establish its cause.

43Using the tachometer, check that the

base idle speed is as given in the

Specifications Section of Chapter 4.

44If the recorded speed differs significantly

from the specified value, check for air leaks,

as described in the preliminary checks

(paragraphs 15 to 18 above), or any other

faults which might cause the discrepancy.

45The base idle speed is set in production

by means of an air bypass screw (located in

the front right-hand corner of the throttle

housing) which controls the amount of air that

is allowed to pass through a bypass passage,

past the throttle valve when it is fully closed in

the idle position; the screw is then sealed with

a white tamperproof plug (see illustration). In

service, the idle speed is controlled by the

ECU, which has the ability to compensate for

engine wear, build-up of dirt in the throttle

housing, and other factors which might

require changes in idle speed. The air bypass

screw setting should not, therefore, be

altered. If any alterations are made, a blue

tamperproof plug must be fitted, and the

engine should be allowed to idle for at least

five minutes on completion, so that the ECU

can re-learn its idle values.

46When both checks have been made and

the “Service Adjustment Programme” is

completed, follow the tester instructions to

return to the fault code read-out, and

establish whether the fault has been cured or

not.

Basic check of ignition system

47If the checks so far have not eliminated

the fault, the next step is to carry out a basic

check of the ignition system components,

using an engine analyser with an oscilloscope

- without such equipment, the only tests

possible are to remove and check each spark

plug in turn, to check the spark plug (HT) lead

connections and resistances, and to check

the connections and resistances of the

ignition coil. Refer to the relevant Sections of

Chapters 1 and 5.

Basic check of fuel system

48If the checks so far have not eliminated

the fault, the next step is to carry out a basic

check of the fuel system components.

49Assuming that the preliminary checks

have established that the fuel pump is

operating correctly, that the fuel filter isunlikely to be blocked, and also that there are

no leaks in the system, the next step is to

check the fuel pressure (see Chapter 4). If this

is correct, check the injectors (see Chapter 4)

and the Positive Crankcase Ventilation system

(see Chapter 1).

System test

50The final element of the Ford testing

procedure is to carry out a system test, using

a break-out box - this is a device that is

connected between the ECU and its electrical

connector, so that the individual circuits

indicated by the fault code read-out can be

tested while connected to the system, if

necessary with the engine running. In the case

of many of the system’s components, this

enables their output voltages to be measured

- a more accurate means of testing.

51In addition to the break-out box and the

adaptors required to connect it, several items

of specialist equipment are needed to

complete these tests. This puts them quite

beyond the scope of many smaller dealers, let

alone the DIY owner; the vehicle should be

taken to a Ford dealer for attention.

Note:This Section is concerned principally

with the sensors which give the ECU the

information it needs to control the various

engine management sub-systems - for further

details of those systems and their other

components, refer to the relevant Chapter of

this manual.

General

ECU (Electronic Control Unit)

1This component is the heart of the entire

engine management system, controlling the

fuel injection, ignition and emissions control

systems. It also controls sub-systems such as

the radiator cooling fan, air conditioning and

automatic transmission, where appropriate.

Refer to Section 2 of this Chapter for an

illustration of how it works.

Air mass meter

2This uses a “hot-wire” system, sending the

ECU a constantly-varying (analogue) voltage

signal corresponding to the mass of air

passing into the engine. Since air mass varies

with temperature (cold air being denser than

warm), measuring air mass provides the ECU

with a very accurate means of determining the

correct amount of fuel required to achieve the

ideal air/fuel mixture ratio.

Crankshaft speed/position sensor

3This is an inductive pulse generator bolted

(in a separate bracket) to the cylinder

block/crankcase, to scan the ridges between

36 holes machined in the inboard (right-hand)

face of the flywheel/driveplate. As each ridge

4 Information sensors -

general information, testing,

removal and refitting

6•10 Emissions control systems

3.45 Throttle housing air bypass screw is

sealed on production with a white

tamperproof plug (arrowed)

procarmanuals.com

Page 178 of 279

Chapter 11 Bodywork and fittings

Body side-trim mouldings and adhesive emblems - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonnet - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . . 8

Bonnet lock - removal, refitting and adjustment . . . . . . . . . . . . . . . . 10

Bonnet release cable and lever - removal and refitting . . . . . . . . . . . 9

Boot lid - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Boot lid lock components - removal and refitting . . . . . . . . . . . . . . . 19

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Central locking system components - testing, removal and refitting . 23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . 30

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Door handle and lock components - removal and refitting . . . . . . . . 14

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . 11

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . . 12

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . 13

Exterior mirror and glass - removal and refitting . . . . . . . . . . . . . . . . 16

Facia - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1Glovebox - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 17

Interior trim panels - removal and refitting . . . . . . . . . . . . . . . . . . . . 29

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . 2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . 3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . . 31

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 7

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Sunroof - general information and adjustment . . . . . . . . . . . . . . . . . 26

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tailgate lock components - removal and refitting . . . . . . . . . . . . . . . 22

Tailgate support strut - removal and refitting . . . . . . . . . . . . . . . . . . 21

Wheel arch liner - removal and refitting . . . . . . . . . . . . . . . . . . . . . . 34

Windscreen and fixed windows - removal and refitting . . . . . . . . . . 24

Torque wrench settingsNm lbf ft

Bonnet and tailgate hinges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 18

Boot lid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Front seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Seat belt mounting nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Bumper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

Specifications Contents

11

The bodyshell and underframe on all

models is of all-steel welded construction,

incorporating progressive crumple zones at

the front and rear, and a rigid centre safety

cell. The bulkhead behind the engine

compartment incorporates crash grooves

which determine its energy-absorption

characteristics, and special beams to prevent

the intrusion of the front wheels into the

passenger compartment during a serious

accident. All passenger doors incorporate

side impact bars.

All sheet metal surfaces which are prone tocorrosion are galvanized. The painting

process includes a base colour which closely

matches the final topcoat, so that any stone

damage is not noticeable.

Hatchback, Saloon and Estate versions are

available. The front section of the vehicle up to

the “B” pillar is identical on all models.

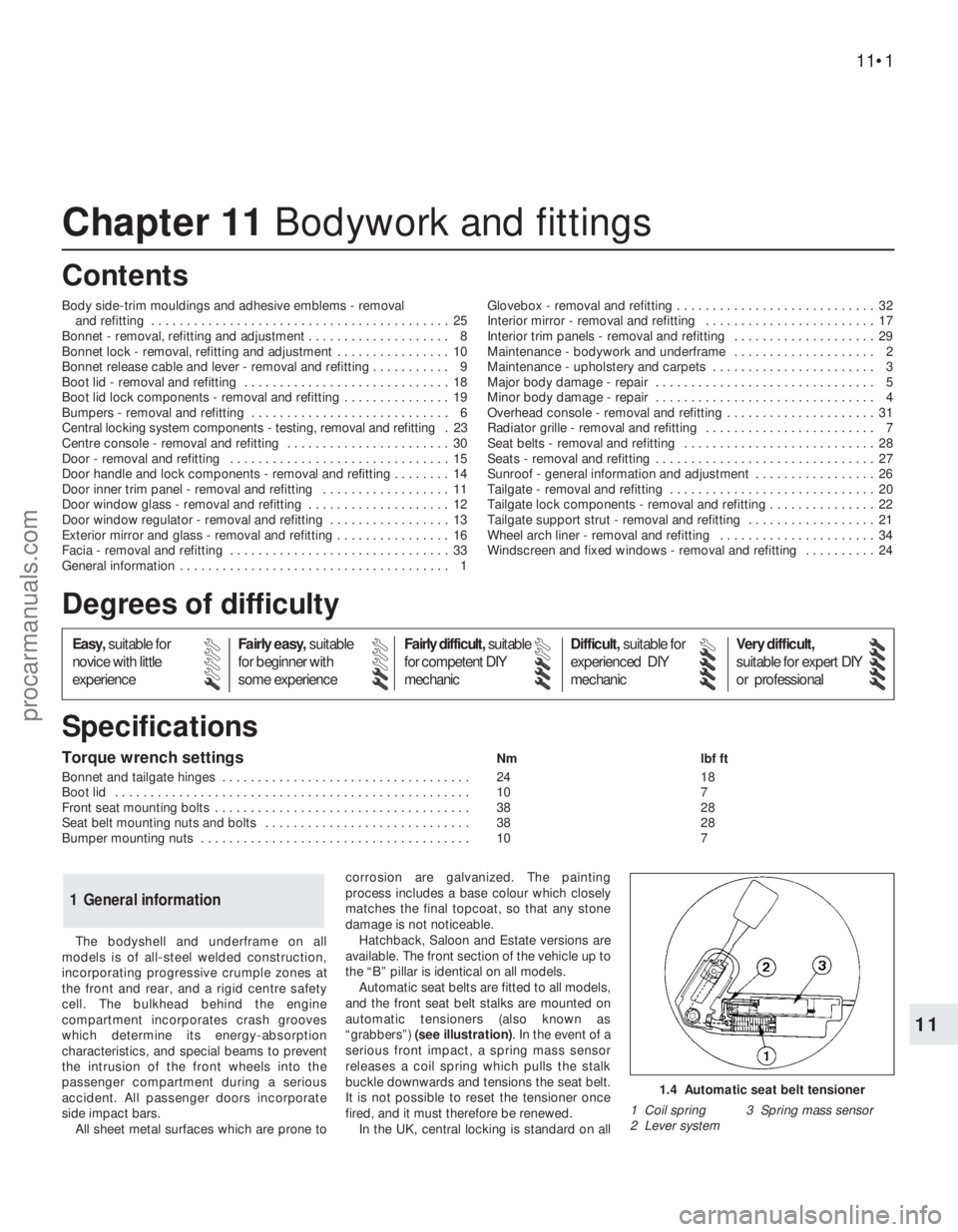

Automatic seat belts are fitted to all models,

and the front seat belt stalks are mounted on

automatic tensioners (also known as

“grabbers”) (see illustration). In the event of a

serious front impact, a spring mass sensor

releases a coil spring which pulls the stalk

buckle downwards and tensions the seat belt.

It is not possible to reset the tensioner once

fired, and it must therefore be renewed.

In the UK, central locking is standard on all

1 General information

1.4 Automatic seat belt tensioner

1 Coil spring 3 Spring mass sensor

2 Lever system

procarmanuals.com

Page 192 of 279

Removal

Lock barrel

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the boot lid open, remove the luggage

space trim from the right-hand rear corner.

3Remove the screws, and prise out the rear

light trim cover from the guides.

4Release the door-ajar sensor from the clip

near the lock.

5Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it.

6Pull out the lock locating spring clip.

7Detach the cable mounting bracket from

the barrel, and remove the barrel.

Lock

8Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

9With the boot lid open, prise out the clips

and remove the trim from inside the boot lid.

10Release the door-ajar sensor from the clip

near the lock.

11Using a Torx key, unscrew the lock

mounting screws, and withdraw the lock for

access to the cables.

12Disconnect both the inner and outer

cables from the lock bracket.13Prise open the plastic lip, and remove the

central locking control rod.

14Withdraw the lock assembly.

Refitting

Lock barrel and lock

15Refitting is a reversal of the removal

procedure.

Removal

Hatchback

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1). Open the tailgate.

2The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the roof panel

by unscrewing the mounting nuts. In the latter

case, carefully pull down the rear edge of the

headlining for access to the nuts. Take care

not to damage the headlining.

3Remove the parcel shelf left-hand support

bracket as follows. Fold the rear seat

forwards, and disconnect the left-hand seat

pull cable from the bracket and clips.

Unscrew the screws and remove the bracket.

4Pull up the rear seat side bolster, then

carefully remove the side trim from the left-

hand side of the luggage area. On low-series

models, the bolster is retained with a screw.5Separate the tailgate wiring loom multi-

plugs, located on the left-hand side of the

luggage compartment, on top of the wheel

arch.

6Unclip and remove the upper trim panel

from the inside of the tailgate. Also remove

the rear shelf cord plastic post (see

illustrations).

7Prise out the rubber grommet from the top

of the tailgate aperture, and pull the wiring

loom out through the hole in the body (see

illustration).

8Disconnect the rear window washer tube

from the jet.

9Prise out the rubber grommet from the

right-hand side of the tailgate aperture, and

pull out the washer tube.

10Have an assistant support the tailgate in

its open position.

11Using a small screwdriver, prise off the

clips securing the struts to the tailgate. Pull

the sockets from the ball-studs, and move the

struts downwards.

12If the headlining has been pulled back,

unscrew and remove the hinge nuts from the

roof panel. Otherwise, unscrew the bolts

securing the tailgate to the hinges (see

illustration).

13Withdraw the tailgate from the body

aperture, taking care not to damage the

paintwork.

Estate

14Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

15The tailgate may be unbolted from the

hinges and the hinges left in position, or the

hinges may be detached from the rear roof

panel by unscrewing the mounting nuts. In the

latter case, carefully pull down the rear edge

of the headlining for access to the nuts. Take

care not to damage the headlining.

16Unscrew the retaining screws, then unclip

the “D” pillar trim panels from both sides (see

illustration).

17Unclip and remove the upper trim panel

from inside the tailgate.

18Carefully remove the side trim from the

left-hand side of the luggage area, and

separate the tailgate wiring loom multi-plugs

in the rear light cluster housing.

20 Tailgate -

removal and refitting

19 Boot lid lock components-

removal and refitting

Bodywork and fittings 11•15

11

20.12 Unscrewing the bolts securing the

tailgate to the hinges20.16 “D” pillar trim panel retaining

screws (arrowed) - Estate models

20.6A Unclipping the upper trim panel

from the tailgate20.6B Shelf cord post removal20.7 Removing the wiring loom rubber

grommet

procarmanuals.com

Page 193 of 279

19Attach a strong fine cord to the end of the

wiring loom, to act as an aid to guiding the

wiring through the tailgate when it is refitted.

20Prise the rubber grommet from the top

left-hand side of the tailgate aperture, and pull

out the wiring loom. Untie the cord, leaving it

in position in the “D” pillar.

21Disconnect the rear window washer tube

from the jet. Pull out the rubber grommet, and

remove the tube.

22Have an assistant support the tailgate in

its open position.

23Using a small screwdriver, prise off the

clip securing the struts to the tailgate. Pull the

sockets from the ball-studs, and move the

struts downwards.

24Unscrew and remove the hinge nuts from

the roof panel, or the hinge bolts from thehinge, as desired (see illustration). Withdraw

the tailgate from the body aperture, taking

care not to damage the paintwork.

Refitting

Hatchback and Estate

25Refitting is a reversal of the removal

procedure, but check that the tailgate is

located centrally in the body aperture, and

that the striker enters the lock centrally. If

necessary, loosen the mounting nuts and re-

position the tailgate as required.

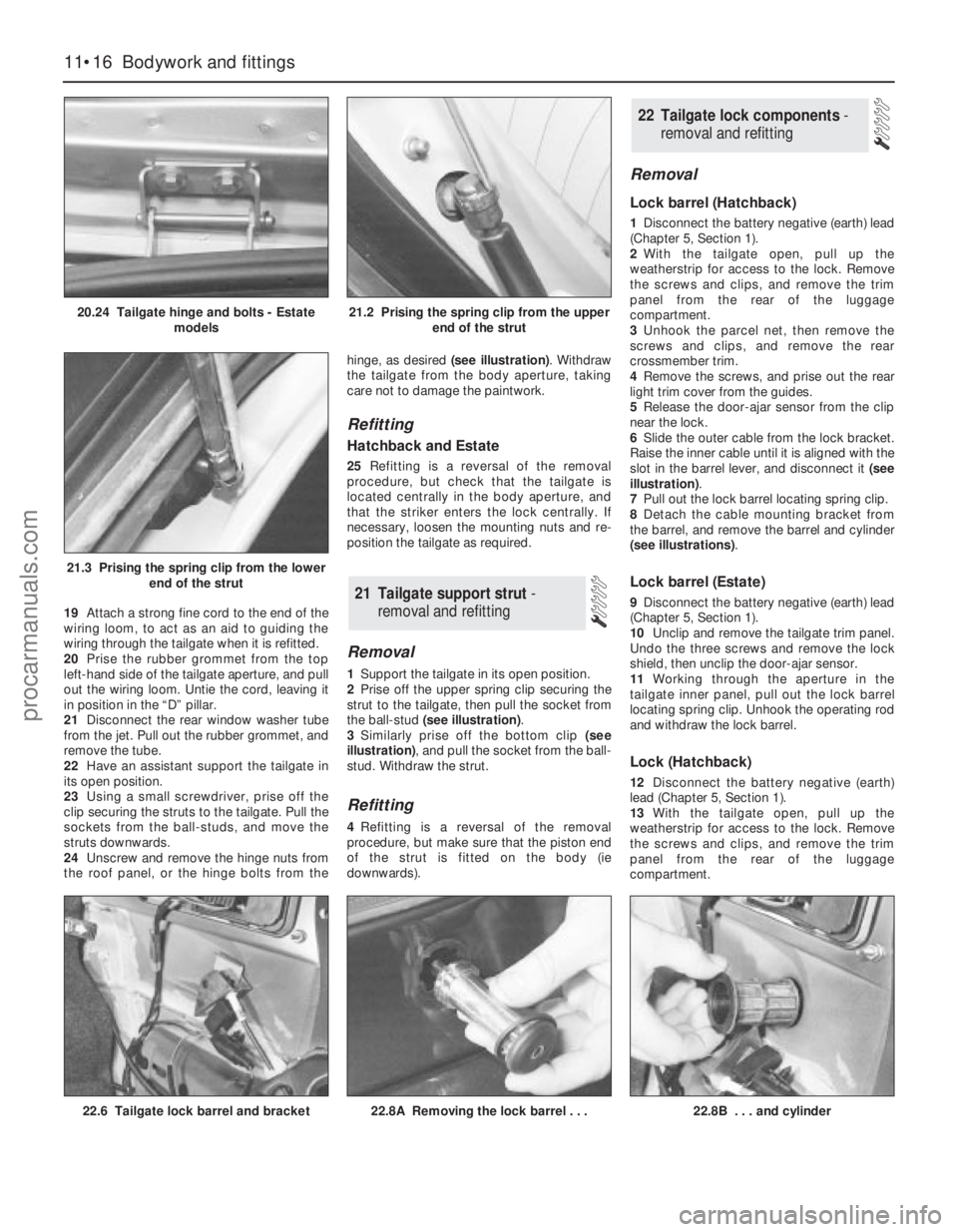

Removal

1Support the tailgate in its open position.

2Prise off the upper spring clip securing the

strut to the tailgate, then pull the socket from

the ball-stud (see illustration).

3Similarly prise off the bottom clip (see

illustration), and pull the socket from the ball-

stud. Withdraw the strut.

Refitting

4Refitting is a reversal of the removal

procedure, but make sure that the piston end

of the strut is fitted on the body (ie

downwards).

Removal

Lock barrel (Hatchback)

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

3Unhook the parcel net, then remove the

screws and clips, and remove the rear

crossmember trim.

4Remove the screws, and prise out the rear

light trim cover from the guides.

5Release the door-ajar sensor from the clip

near the lock.

6Slide the outer cable from the lock bracket.

Raise the inner cable until it is aligned with the

slot in the barrel lever, and disconnect it (see

illustration).

7Pull out the lock barrel locating spring clip.

8Detach the cable mounting bracket from

the barrel, and remove the barrel and cylinder

(see illustrations).

Lock barrel (Estate)

9Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

10Unclip and remove the tailgate trim panel.

Undo the three screws and remove the lock

shield, then unclip the door-ajar sensor.

11Working through the aperture in the

tailgate inner panel, pull out the lock barrel

locating spring clip. Unhook the operating rod

and withdraw the lock barrel.

Lock (Hatchback)

12Disconnect the battery negative (earth)

lead (Chapter 5, Section 1).

13With the tailgate open, pull up the

weatherstrip for access to the lock. Remove

the screws and clips, and remove the trim

panel from the rear of the luggage

compartment.

22 Tailgate lock components -

removal and refitting

21 Tailgate support strut-

removal and refitting

11•16 Bodywork and fittings

20.24 Tailgate hinge and bolts - Estate

models21.2 Prising the spring clip from the upper

end of the strut

21.3 Prising the spring clip from the lower

end of the strut

22.6 Tailgate lock barrel and bracket22.8A Removing the lock barrel . . .22.8B . . . and cylinder

procarmanuals.com

Page 195 of 279

adhesive bond between the moulding or

emblem and the panel (see illustration).

2Thoroughly clean all traces of adhesive

from the panel using

methylated spirit, and allow the location to

dry.

Refitting

3Peel back the protective paper from the

rear face of the new moulding or emblem.

Carefully fit it into position on the panel

concerned, but take care not to touch the

adhesive. When in position, apply hand

pressure to the moulding/emblem for a short

period, to ensure maximum adhesion to the

panel.1The sunroof should operate freely, without

sticking or binding, as it is opened and

closed. When in the closed position, check

that the panel is flush with the surrounding

roof panel.

2If adjustment is required, open the sun

blind, but leave the glass panel shut. Unscrew

and remove the three lower frame-to-glass

panel retaining screws. Slide the lower frame

back into the roof.

3Loosen the central and front securing

screws. Adjust the glass roof panel so that it is

flush at its front edge with the roof panel, then

retighten the securing screws.

4Pull the lower frame forwards, and insert

and tighten its retaining screws to complete.

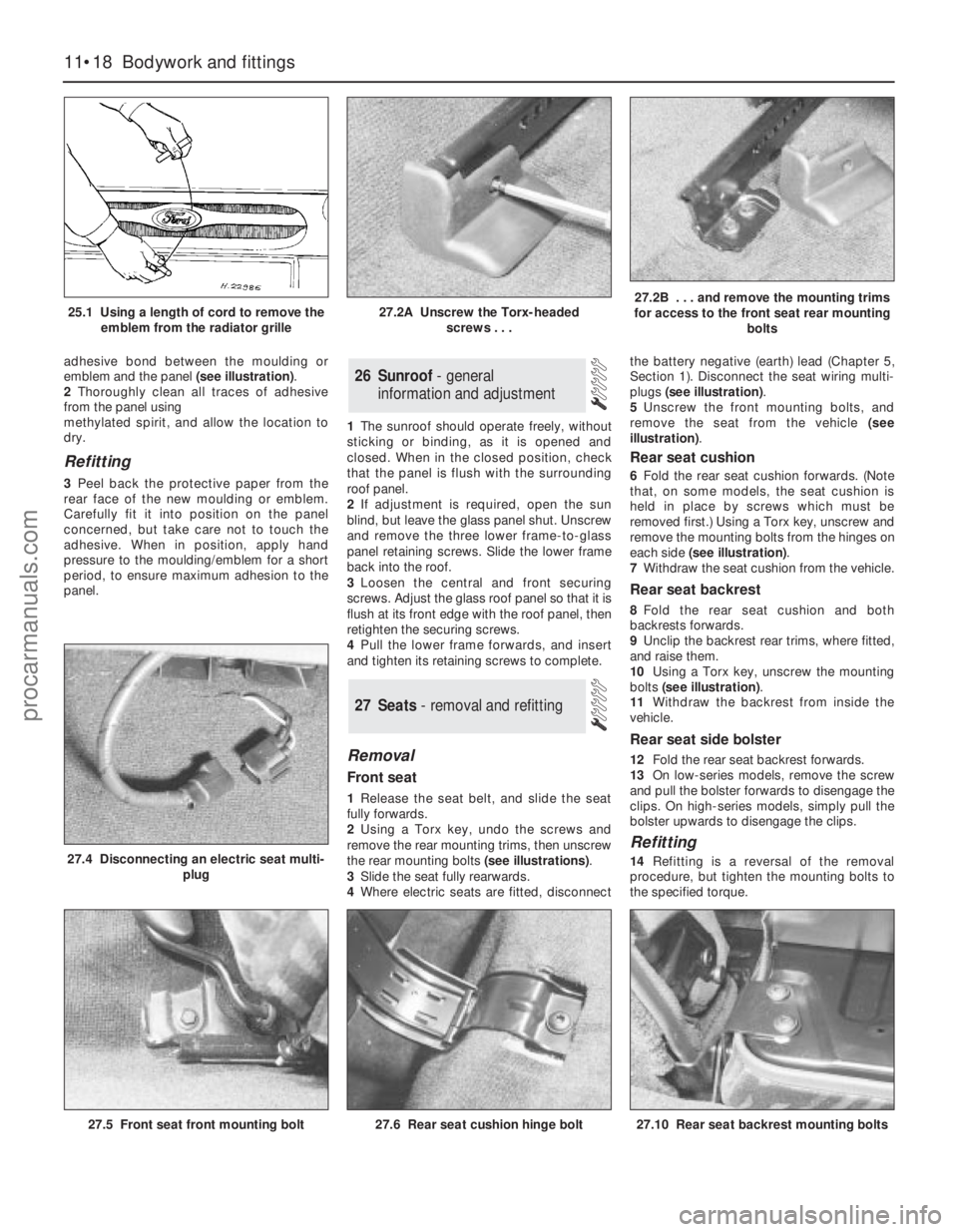

Removal

Front seat

1Release the seat belt, and slide the seat

fully forwards.

2Using a Torx key, undo the screws and

remove the rear mounting trims, then unscrew

the rear mounting bolts (see illustrations).

3Slide the seat fully rearwards.

4Where electric seats are fitted, disconnectthe battery negative (earth) lead (Chapter 5,

Section 1). Disconnect the seat wiring multi-

plugs (see illustration).

5Unscrew the front mounting bolts, and

remove the seat from the vehicle (see

illustration).

Rear seat cushion

6Fold the rear seat cushion forwards. (Note

that, on some models, the seat cushion is

held in place by screws which must be

removed first.) Using a Torx key, unscrew and

remove the mounting bolts from the hinges on

each side (see illustration).

7Withdraw the seat cushion from the vehicle.

Rear seat backrest

8Fold the rear seat cushion and both

backrests forwards.

9Unclip the backrest rear trims, where fitted,

and raise them.

10Using a Torx key, unscrew the mounting

bolts (see illustration).

11Withdraw the backrest from inside the

vehicle.

Rear seat side bolster

12Fold the rear seat backrest forwards.

13On low-series models, remove the screw

and pull the bolster forwards to disengage the

clips. On high-series models, simply pull the

bolster upwards to disengage the clips.

Refitting

14Refitting is a reversal of the removal

procedure, but tighten the mounting bolts to

the specified torque.

27 Seats - removal and refitting

26 Sunroof - general

information and adjustment

11•18 Bodywork and fittings

25.1 Using a length of cord to remove the

emblem from the radiator grille27.2A Unscrew the Torx-headed

screws . . .27.2B . . . and remove the mounting trims

for access to the front seat rear mounting

bolts

27.5 Front seat front mounting bolt

27.4 Disconnecting an electric seat multi-

plug

27.6 Rear seat cushion hinge bolt27.10 Rear seat backrest mounting bolts

procarmanuals.com

Page 199 of 279

6Prise off the plastic caps, then unscrew the

centre console mounting screws. These are

located on each side, on the front top, and

inside the cassette storage box. The screws

with the washers go on the side of the

console; the front screws are smaller than the

others, and black in colour (see illustrations).

7Fully apply the handbrake lever. Withdraw

the centre console, at the same time passing

the gaiter over the handbrake lever (see

illustrations).

8Disconnect the cigar lighter wiring (see

illustration).

Refitting

9Refitting is a reversal of the removal

procedure.

Removal

1Disconnect the battery negative (earth) lead

(Chapter 5, Section 1).

2When applicable, remove the sunroof

switch (Chapter 12).

3When applicable, remove the sunroof

handle, after undoing the securing screw (see

illustration).

3Push the console towards the windscreen,

to disengage it from the clips.

Refitting

4Refitting is a reversal of the removal

procedure.

Removal

1Open the glovebox. Using a screwdriver,

carefully press in one side of the glovebox

near the hinge, to release it from the plastic

clip (see illustration).

2Withdraw the glovebox and, where

necessary, disconnect the wiring multi-plug

for the light.

3If necessary, the lock may be removed by

unscrewing the mounting screws and removing

the lock plate and spring (see illustration).

4To remove the lock barrel, depress the

spring tabs.

Refitting

5Locate the barrel in the lock plate, making

sure that the clips are fully engaged.

6Hold the latch pins together, and engage

the right-hand pin of the lock plate.

7Refit the spring, and engage the left-hand

pin of the lock plate.

8Refit the lock plate, and tighten the screws.

9Reconnect the wiring multi-plug and refit

the glovebox, making sure that it is fully

inserted in the plastic clips.

32 Glovebox -

removal and refitting

31 Overhead console -

removal and refitting

11•22 Bodywork and fittings

30.6C . . . at the sides . . .30.6D . . . and inside the cassette storage

box30.7A Withdrawing the front of the

console from the facia

31.3 Removing the sunroof handle

securing screw32.1 Glovebox removal

30.8 Disconnecting the cigar lighter wiring

30.7B Passing the gaiter over the

handbrake lever

32.3 Glovebox lock mounting screws

(arrowed)

procarmanuals.com