seat adjustment FORD MONDEO 1993 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 7 of 279

0•7

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standard as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

before submitting the vehicle for the test.

Where a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discretion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements here,

based on the regulations in force at the time of printing. Test standards

are becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Haynes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeMTest the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorrect brake or cable adjustment.

MCheck that the handbrake cannot be

released by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

MDepress the brake pedal and check that it

does not creep down to the floor, indicating a

master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

resistance is felt, brake adjustment or repair is

necessary. If the pedal feels spongy, there is

air in the hydraulic system which must be

removed by bleeding.MCheck that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

MCheck the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

MExamine the steering wheel for fractures or

looseness of the hub, spokes or rim.

MMove the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

MCheck that the steering wheel is not loose

on the column, and that there is no abnormalmovement of the steering wheel, indicating

wear in the column support bearings or

couplings.

Windscreen and mirrors

MThe windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secure, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

MOT Test Checks

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

procarmanuals.com

Page 15 of 279

Chapter 1 Routine maintenance and servicing

Air conditioning system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . 7

Automatic transmission linkage lubrication . . . . . . . . . . . . . . . . . . . 18

Auxiliary drivebelt check and renewal . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery check, maintenance and charging . . . . . . . . . . . . . . . . . . . . 9

Brake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Clutch pedal adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2, 28

Door and bonnet check and lubrication . . . . . . . . . . . . . . . . . . . . . . 24

Driveshaft rubber gaiter and CV joint check . . . . . . . . . . . . . . . . . . . 20

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine compartment wiring check . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Engine oil and filter change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Idle speed and mixture check and adjustment . . . . . . See Chapter 4Ignition timing check . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual transmission oil level check . . . . . . . . . . . . . . . . . . . . . . . . . 16

Positive Crankcase Ventilation (PCV) system check

and filter cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power steering fluid level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Roadwheel nut tightness check . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . See end of Chapter

Steering, suspension and roadwheel check . . . . . . . . . . . . . . . . . . . 19

Timing belt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Tyre and tyre pressure checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Underbody and fuel/brake line check . . . . . . . . . . . . . . . . . . . . . . . . 22

Underbonnet check for fluid leaks and hose condition . . . . . . . . . . 12

Ventilation system pollen filter renewal . . . . . . . . . . . . . . . . . . . . . . . 27

Windscreen/tailgate washer system and wiper blade check . . . . . . 6

1•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,suitable

for competent DIY

mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty Contents

1

procarmanuals.com

Page 17 of 279

Ford Mondeo maintenance schedule

1•3

1

Maintenance schedule

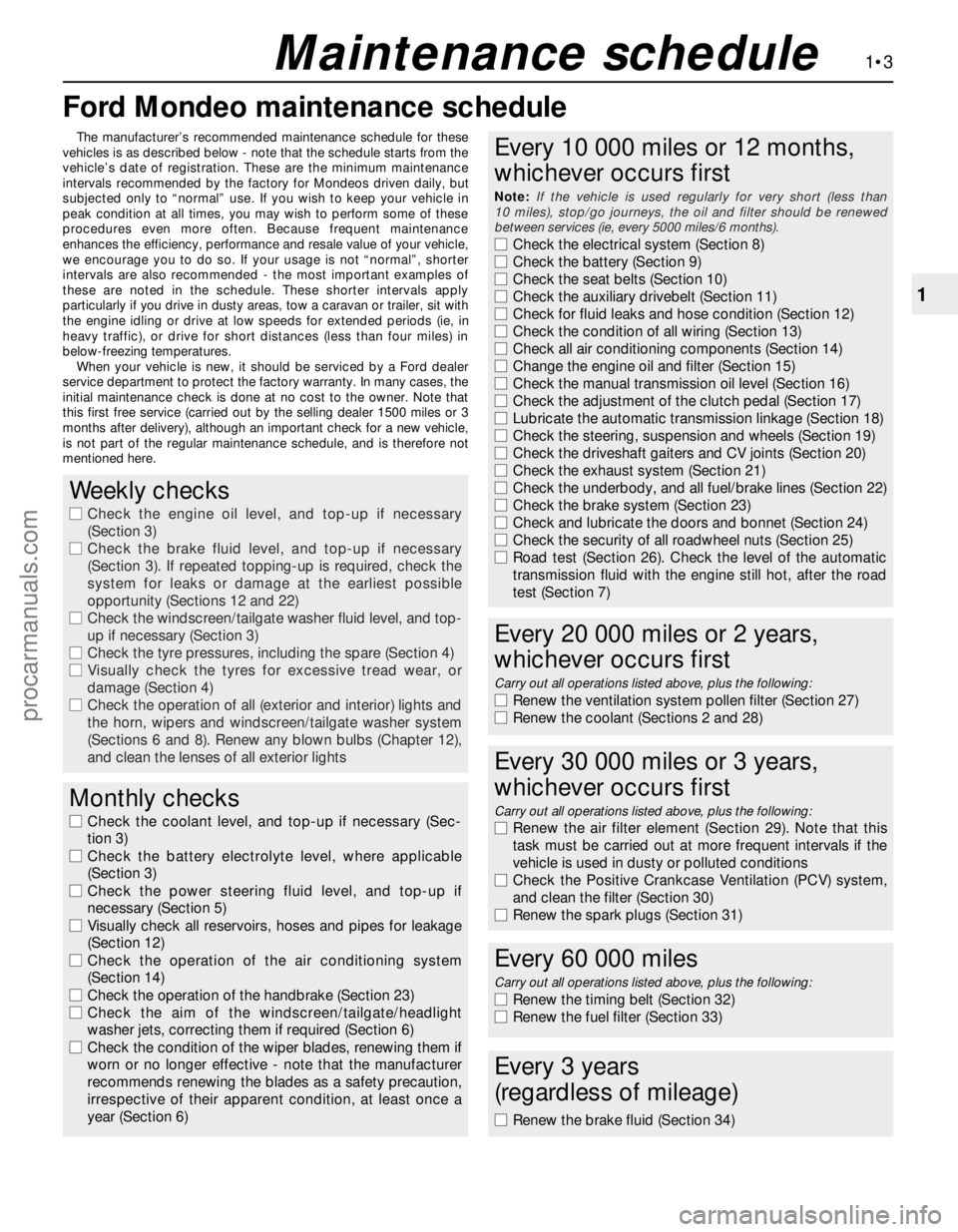

The manufacturer’s recommended maintenance schedule for these

vehicles is as described below - note that the schedule starts from the

vehicle’s date of registration. These are the minimum maintenance

intervals recommended by the factory for Mondeos driven daily, but

subjected only to “normal” use. If you wish to keep your vehicle in

peak condition at all times, you may wish to perform some of these

procedures even more often. Because frequent maintenance

enhances the efficiency, performance and resale value of your vehicle,

we encourage you to do so. If your usage is not “normal”, shorter

intervals are also recommended - the most important examples of

these are noted in the schedule. These shorter intervals apply

particularly if you drive in dusty areas, tow a caravan or trailer, sit with

the engine idling or drive at low speeds for extended periods (ie, in

heavy traffic), or drive for short distances (less than four miles) in

below-freezing temperatures.

When your vehicle is new, it should be serviced by a Ford dealer

service department to protect the factory warranty. In many cases, the

initial maintenance check is done at no cost to the owner. Note that

this first free service (carried out by the selling dealer 1500 miles or 3

months after delivery), although an important check for a new vehicle,

is not part of the regular maintenance schedule, and is therefore not

mentioned here.

Weekly checks

m mCheck the engine oil level, and top-up if necessary

(Section 3)

m mCheck the brake fluid level, and top-up if necessary

(Section 3). If repeated topping-up is required, check the

system for leaks or damage at the earliest possible

opportunity (Sections 12 and 22)

m mCheck the windscreen/tailgate washer fluid level, and top-

up if necessary (Section 3)

m mCheck the tyre pressures, including the spare (Section 4)

m mVisually check the tyres for excessive tread wear, or

damage (Section 4)

m mCheck the operation of all (exterior and interior) lights and

the horn, wipers and windscreen/tailgate washer system

(Sections 6 and 8). Renew any blown bulbs (Chapter 12),

and clean the lenses of all exterior lights

Monthly checks

m mCheck the coolant level, and top-up if necessary (Sec-

tion 3)

m mCheck the battery electrolyte level, where applicable

(Section 3)

m mCheck the power steering fluid level, and top-up if

necessary (Section 5)

m mVisually check all reservoirs, hoses and pipes for leakage

(Section 12)

m mCheck the operation of the air conditioning system

(Section 14)

m mCheck the operation of the handbrake (Section 23)

m mCheck the aim of the windscreen/tailgate/headlight

washer jets, correcting them if required (Section 6)

m mCheck the condition of the wiper blades, renewing them if

worn or no longer effective - note that the manufacturer

recommends renewing the blades as a safety precaution,

irrespective of their apparent condition, at least once a

year (Section 6)

Every 10 000 miles or 12 months,

whichever occurs first

Note:If the vehicle is used regularly for very short (less than

10 miles), stop/go journeys, the oil and filter should be renewed

between services (ie, every 5000 miles/6 months).

m mCheck the electrical system (Section 8)

m mCheck the battery (Section 9)

m mCheck the seat belts (Section 10)

m mCheck the auxiliary drivebelt (Section 11)

m mCheck for fluid leaks and hose condition (Section 12)

m mCheck the condition of all wiring (Section 13)

m mCheck all air conditioning components (Section 14)

m mChange the engine oil and filter (Section 15)

m mCheck the manual transmission oil level (Section 16)

m mCheck the adjustment of the clutch pedal (Section 17)

m mLubricate the automatic transmission linkage (Section 18)

m mCheck the steering, suspension and wheels (Section 19)

m mCheck the driveshaft gaiters and CV joints (Section 20)

m mCheck the exhaust system (Section 21)

m mCheck the underbody, and all fuel/brake lines (Section 22)

m mCheck the brake system (Section 23)

m mCheck and lubricate the doors and bonnet (Section 24)

m mCheck the security of all roadwheel nuts (Section 25)

m mRoad test (Section 26). Check the level of the automatic

transmission fluid with the engine still hot, after the road

test (Section 7)

Every 20 000 miles or 2 years,

whichever occurs first

Carry out all operations listed above, plus the following:

m mRenew the ventilation system pollen filter (Section 27)

m mRenew the coolant (Sections 2 and 28)

Every 30 000 miles or 3 years,

whichever occurs first

Carry out all operations listed above, plus the following:

m mRenew the air filter element (Section 29). Note that this

task must be carried out at more frequent intervals if the

vehicle is used in dusty or polluted conditions

m mCheck the Positive Crankcase Ventilation (PCV) system,

and clean the filter (Section 30)

m mRenew the spark plugs (Section 31)

Every 60 000 miles

Carry out all operations listed above, plus the following:

m

mRenew the timing belt (Section 32)

m mRenew the fuel filter (Section 33)

Every 3 years

(regardless of mileage)

m mRenew the brake fluid (Section 34)

procarmanuals.com

Page 27 of 279

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery (ie no more than 5 amps, typically).

Rapid boost charges that claim to restore the

power of the battery in one to two hours are

hardest on the battery, and can damage

batteries not in good condition. This type of

charging should only be used in emergency

situations.

14The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to

16 hours.

1Check the seat belts for satisfactory

operation and condition. Inspect the webbing

for fraying and cuts. Check that they retract

smoothly and without binding into their reels.

2Check that the seat belt mounting bolts are

tight, and if necessary tighten them to the

specified torque wrench setting.

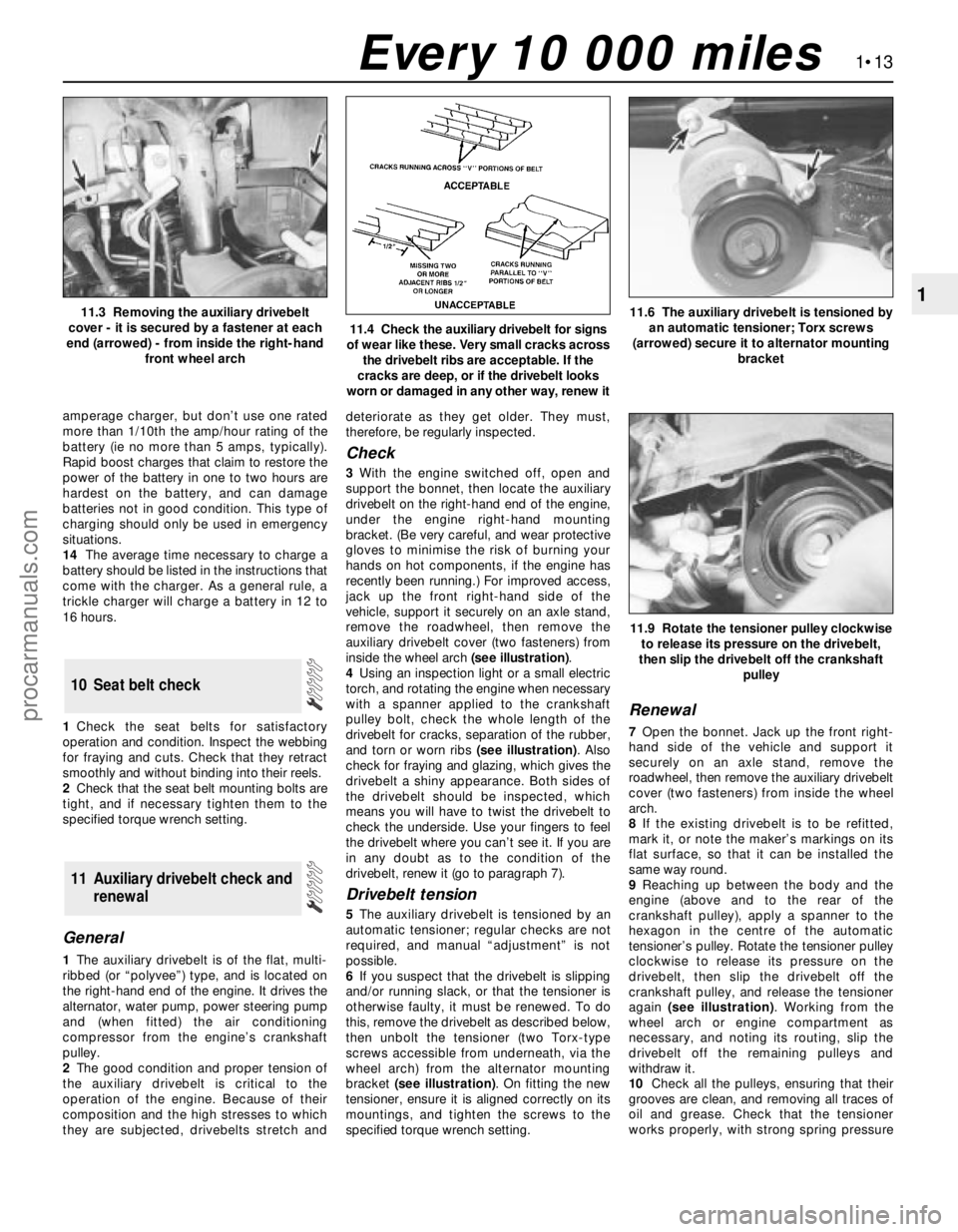

General

1The auxiliary drivebelt is of the flat, multi-

ribbed (or “polyvee”) type, and is located on

the right-hand end of the engine. It drives the

alternator, water pump, power steering pump

and (when fitted) the air conditioning

compressor from the engine’s crankshaft

pulley.

2The good condition and proper tension of

the auxiliary drivebelt is critical to the

operation of the engine. Because of their

composition and the high stresses to which

they are subjected, drivebelts stretch anddeteriorate as they get older. They must,

therefore, be regularly inspected.

Check

3With the engine switched off, open and

support the bonnet, then locate the auxiliary

drivebelt on the right-hand end of the engine,

under the engine right-hand mounting

bracket. (Be very careful, and wear protective

gloves to minimise the risk of burning your

hands on hot components, if the engine has

recently been running.) For improved access,

jack up the front right-hand side of the

vehicle, support it securely on an axle stand,

remove the roadwheel, then remove the

auxiliary drivebelt cover (two fasteners) from

inside the wheel arch (see illustration).

4Using an inspection light or a small electric

torch, and rotating the engine when necessary

with a spanner applied to the crankshaft

pulley bolt, check the whole length of the

drivebelt for cracks, separation of the rubber,

and torn or worn ribs (see illustration). Also

check for fraying and glazing, which gives the

drivebelt a shiny appearance. Both sides of

the drivebelt should be inspected, which

means you will have to twist the drivebelt to

check the underside. Use your fingers to feel

the drivebelt where you can’t see it. If you are

in any doubt as to the condition of the

drivebelt, renew it (go to paragraph 7).

Drivebelt tension

5The auxiliary drivebelt is tensioned by an

automatic tensioner; regular checks are not

required, and manual “adjustment” is not

possible.

6If you suspect that the drivebelt is slipping

and/or running slack, or that the tensioner is

otherwise faulty, it must be renewed. To do

this, remove the drivebelt as described below,

then unbolt the tensioner (two Torx-type

screws accessible from underneath, via the

wheel arch) from the alternator mounting

bracket (see illustration). On fitting the new

tensioner, ensure it is aligned correctly on its

mountings, and tighten the screws to the

specified torque wrench setting.

Renewal

7Open the bonnet. Jack up the front right-

hand side of the vehicle and support it

securely on an axle stand, remove the

roadwheel, then remove the auxiliary drivebelt

cover (two fasteners) from inside the wheel

arch.

8If the existing drivebelt is to be refitted,

mark it, or note the maker’s markings on its

flat surface, so that it can be installed the

same way round.

9Reaching up between the body and the

engine (above and to the rear of the

crankshaft pulley), apply a spanner to the

hexagon in the centre of the automatic

tensioner’s pulley. Rotate the tensioner pulley

clockwise to release its pressure on the

drivebelt, then slip the drivebelt off the

crankshaft pulley, and release the tensioner

again (see illustration). Working from the

wheel arch or engine compartment as

necessary, and noting its routing, slip the

drivebelt off the remaining pulleys and

withdraw it.

10Check all the pulleys, ensuring that their

grooves are clean, and removing all traces of

oil and grease. Check that the tensioner

works properly, with strong spring pressure

11 Auxiliary drivebelt check and

renewal

10 Seat belt check

1•13

1

11.9 Rotate the tensioner pulley clockwise

to release its pressure on the drivebelt,

then slip the drivebelt off the crankshaft

pulley

11.3 Removing the auxiliary drivebelt

cover - it is secured by a fastener at each

end (arrowed) - from inside the right-hand

front wheel arch

11.4 Check the auxiliary drivebelt for signs

of wear like these. Very small cracks across

the drivebelt ribs are acceptable. If the

cracks are deep, or if the drivebelt looks

worn or damaged in any other way, renew it

11.6 The auxiliary drivebelt is tensioned by

an automatic tensioner; Torx screws

(arrowed) secure it to alternator mounting

bracket

Every 10 000 miles

procarmanuals.com

Page 31 of 279

Warning: To avoid personal

injury, never get beneath the

vehicle when it is supported by

only by a jack. The jack provided

with your vehicle is designed solely for

raising the vehicle to remove and refit the

roadwheels. Always use axle stands to

support the vehicle when it becomes

necessary to place your body underneath

the vehicle.

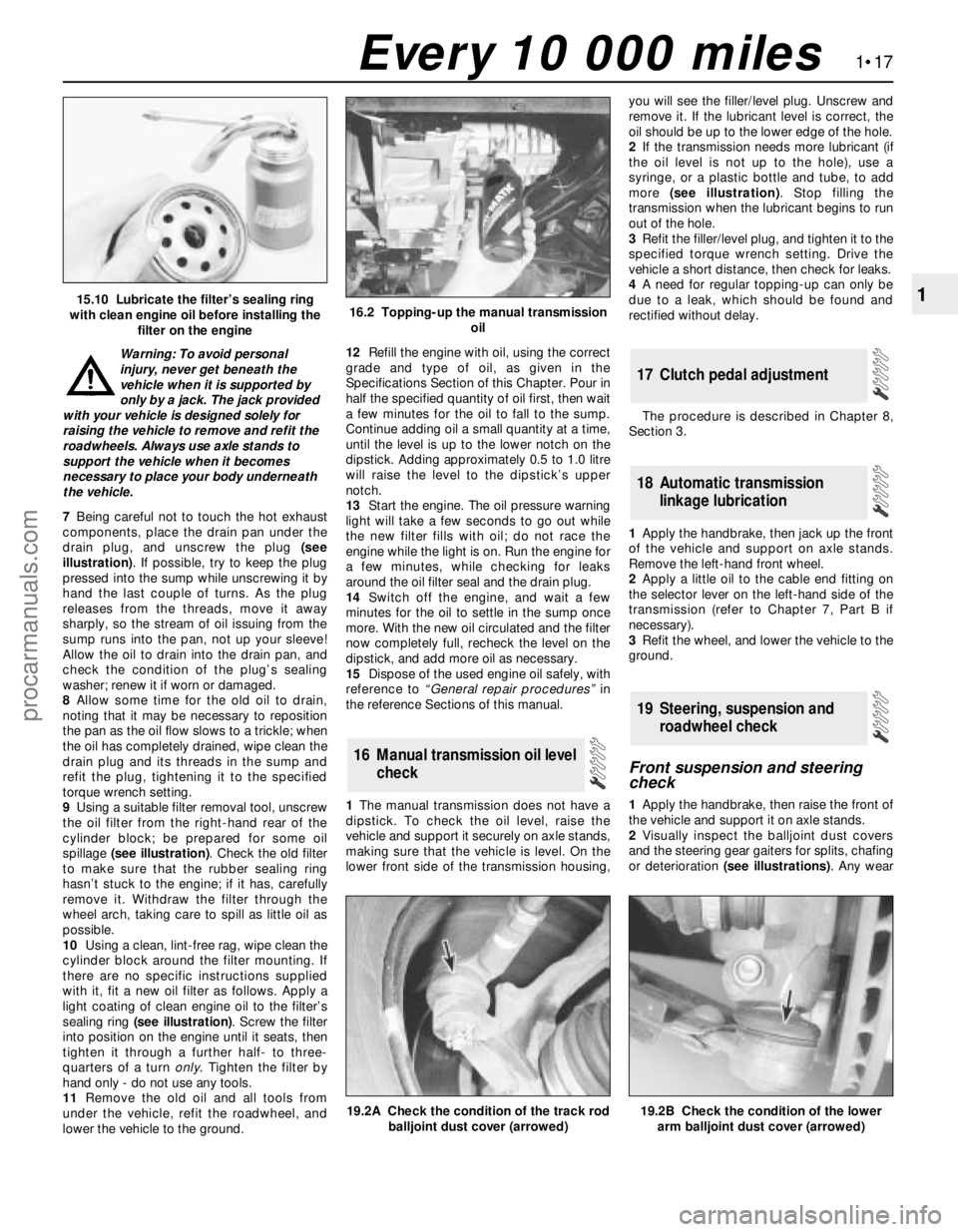

7Being careful not to touch the hot exhaust

components, place the drain pan under the

drain plug, and unscrew the plug (see

illustration). If possible, try to keep the plug

pressed into the sump while unscrewing it by

hand the last couple of turns. As the plug

releases from the threads, move it away

sharply, so the stream of oil issuing from the

sump runs into the pan, not up your sleeve!

Allow the oil to drain into the drain pan, and

check the condition of the plug’s sealing

washer; renew it if worn or damaged.

8Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the pan as the oil flow slows to a trickle; when

the oil has completely drained, wipe clean the

drain plug and its threads in the sump and

refit the plug, tightening it to the specified

torque wrench setting.

9Using a suitable filter removal tool, unscrew

the oil filter from the right-hand rear of the

cylinder block; be prepared for some oil

spillage (see illustration). Check the old filter

to make sure that the rubber sealing ring

hasn’t stuck to the engine; if it has, carefully

remove it. Withdraw the filter through the

wheel arch, taking care to spill as little oil as

possible.

10Using a clean, lint-free rag, wipe clean the

cylinder block around the filter mounting. If

there are no specific instructions supplied

with it, fit a new oil filter as follows. Apply a

light coating of clean engine oil to the filter’s

sealing ring (see illustration). Screw the filter

into position on the engine until it seats, then

tighten it through a further half- to three-

quarters of a turn only. Tighten the filter by

hand only - do not use any tools.

11Remove the old oil and all tools from

under the vehicle, refit the roadwheel, and

lower the vehicle to the ground.12Refill the engine with oil, using the correct

grade and type of oil, as given in the

Specifications Section of this Chapter. Pour in

half the specified quantity of oil first, then wait

a few minutes for the oil to fall to the sump.

Continue adding oil a small quantity at a time,

until the level is up to the lower notch on the

dipstick. Adding approximately 0.5 to 1.0 litre

will raise the level to the dipstick’s upper

notch.

13Start the engine. The oil pressure warning

light will take a few seconds to go out while

the new filter fills with oil; do not race the

engine while the light is on. Run the engine for

a few minutes, while checking for leaks

around the oil filter seal and the drain plug.

14Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

now completely full, recheck the level on the

dipstick, and add more oil as necessary.

15Dispose of the used engine oil safely, with

reference to “General repair procedures”in

the reference Sections of this manual.

1The manual transmission does not have a

dipstick. To check the oil level, raise the

vehicle and support it securely on axle stands,

making sure that the vehicle is level. On the

lower front side of the transmission housing,you will see the filler/level plug. Unscrew and

remove it. If the lubricant level is correct, the

oil should be up to the lower edge of the hole.

2If the transmission needs more lubricant (if

the oil level is not up to the hole), use a

syringe, or a plastic bottle and tube, to add

more (see illustration). Stop filling the

transmission when the lubricant begins to run

out of the hole.

3Refit the filler/level plug, and tighten it to the

specified torque wrench setting. Drive the

vehicle a short distance, then check for leaks.

4A need for regular topping-up can only be

due to a leak, which should be found and

rectified without delay.

The procedure is described in Chapter 8,

Section 3.

1Apply the handbrake, then jack up the front

of the vehicle and support on axle stands.

Remove the left-hand front wheel.

2Apply a little oil to the cable end fitting on

the selector lever on the left-hand side of the

transmission (refer to Chapter 7, Part B if

necessary).

3Refit the wheel, and lower the vehicle to the

ground.

Front suspension and steering

check

1Apply the handbrake, then raise the front of

the vehicle and support it on axle stands.

2Visually inspect the balljoint dust covers

and the steering gear gaiters for splits, chafing

or deterioration (see illustrations). Any wear

19 Steering, suspension and

roadwheel check

18 Automatic transmission

linkage lubrication

17 Clutch pedal adjustment

16 Manual transmission oil level

check

1•17

1

19.2B Check the condition of the lower

arm balljoint dust cover (arrowed)

15.10 Lubricate the filter’s sealing ring

with clean engine oil before installing the

filter on the engine16.2 Topping-up the manual transmission

oil

19.2A Check the condition of the track rod

balljoint dust cover (arrowed)

Every 10 000 miles

procarmanuals.com

Page 39 of 279

check the cylinder head threads and tapered

sealing surfaces for signs of wear, excessive

corrosion or damage; if any of these

conditions is found, seek the advice of a Ford

dealer as to the best method of repair.

7As each plug is removed, examine it as

follows - this will give a good indication of the

condition of the engine. If the insulator nose of

the spark plug is clean and white, with no

deposits, this is indicative of a weak mixture.

8If the tip and insulator nose are covered

with hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

9If the insulator nose is covered with light tan

to greyish-brown deposits, then the mixture is

correct, and it is likely that the engine is in

good condition.

10If you are renewing the spark plugs,

purchase the new plugs, then check each of

them first for faults such as cracked insulators

or damaged threads. Note also that,

whenever the spark plugs are renewed as a

routine service operation, the spark plug (HT)

leads should be checked as described below.

11The spark plug electrode gap is of

considerable importance as, if it is too large or

too small, the size of the spark and its

efficiency will be seriously impaired. The gap

should be set to the value given in the

Specifications Section of this Chapter. New

plugs will not necessarily be set to the correct

gap, so they should always be checked

before fitting.

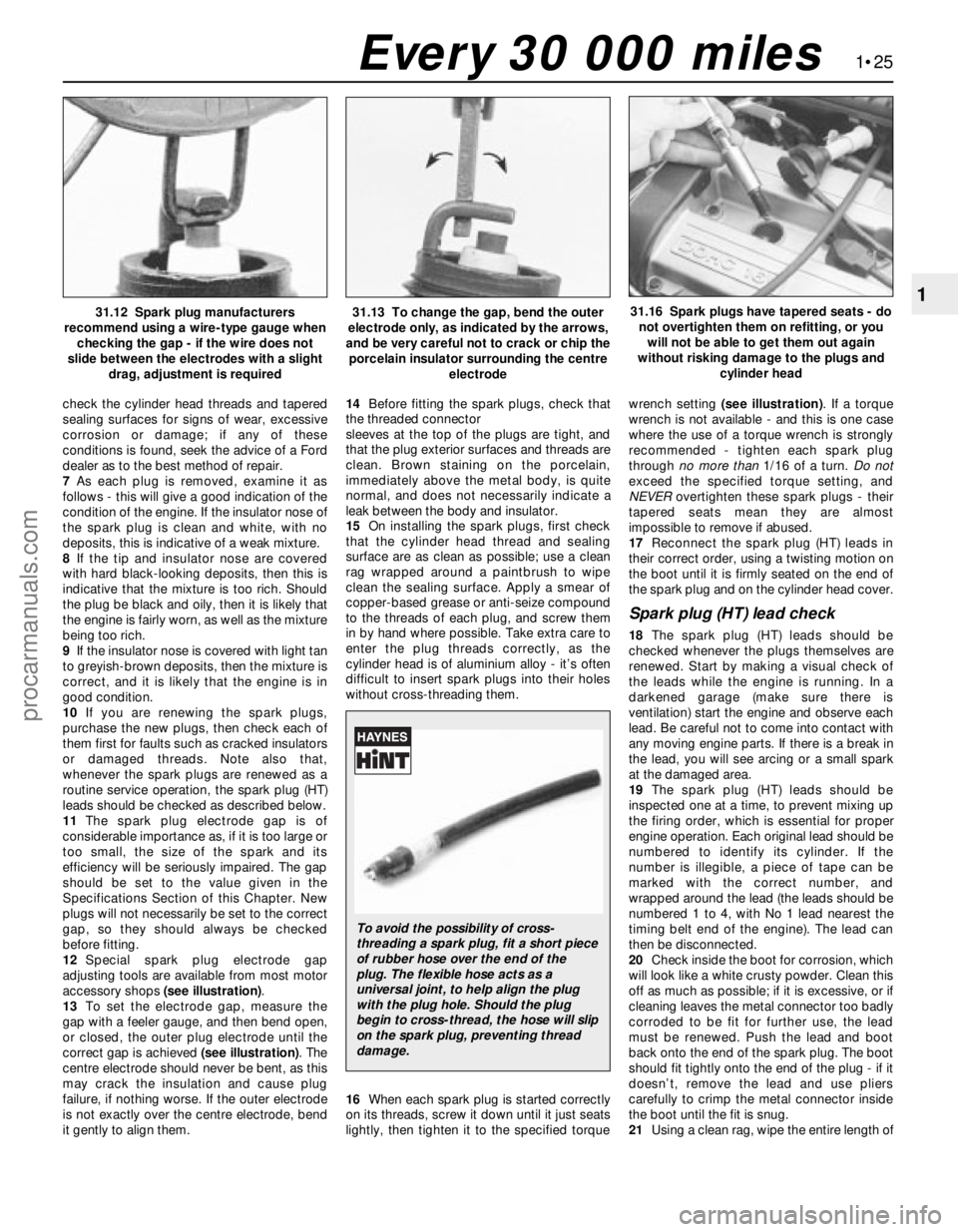

12Special spark plug electrode gap

adjusting tools are available from most motor

accessory shops (see illustration).

13To set the electrode gap, measure the

gap with a feeler gauge, and then bend open,

or closed, the outer plug electrode until the

correct gap is achieved (see illustration). The

centre electrode should never be bent, as this

may crack the insulation and cause plug

failure, if nothing worse. If the outer electrode

is not exactly over the centre electrode, bend

it gently to align them.14Before fitting the spark plugs, check that

the threaded connector

sleeves at the top of the plugs are tight, and

that the plug exterior surfaces and threads are

clean. Brown staining on the porcelain,

immediately above the metal body, is quite

normal, and does not necessarily indicate a

leak between the body and insulator.

15On installing the spark plugs, first check

that the cylinder head thread and sealing

surface are as clean as possible; use a clean

rag wrapped around a paintbrush to wipe

clean the sealing surface. Apply a smear of

copper-based grease or anti-seize compound

to the threads of each plug, and screw them

in by hand where possible. Take extra care to

enter the plug threads correctly, as the

cylinder head is of aluminium alloy - it’s often

difficult to insert spark plugs into their holes

without cross-threading them.

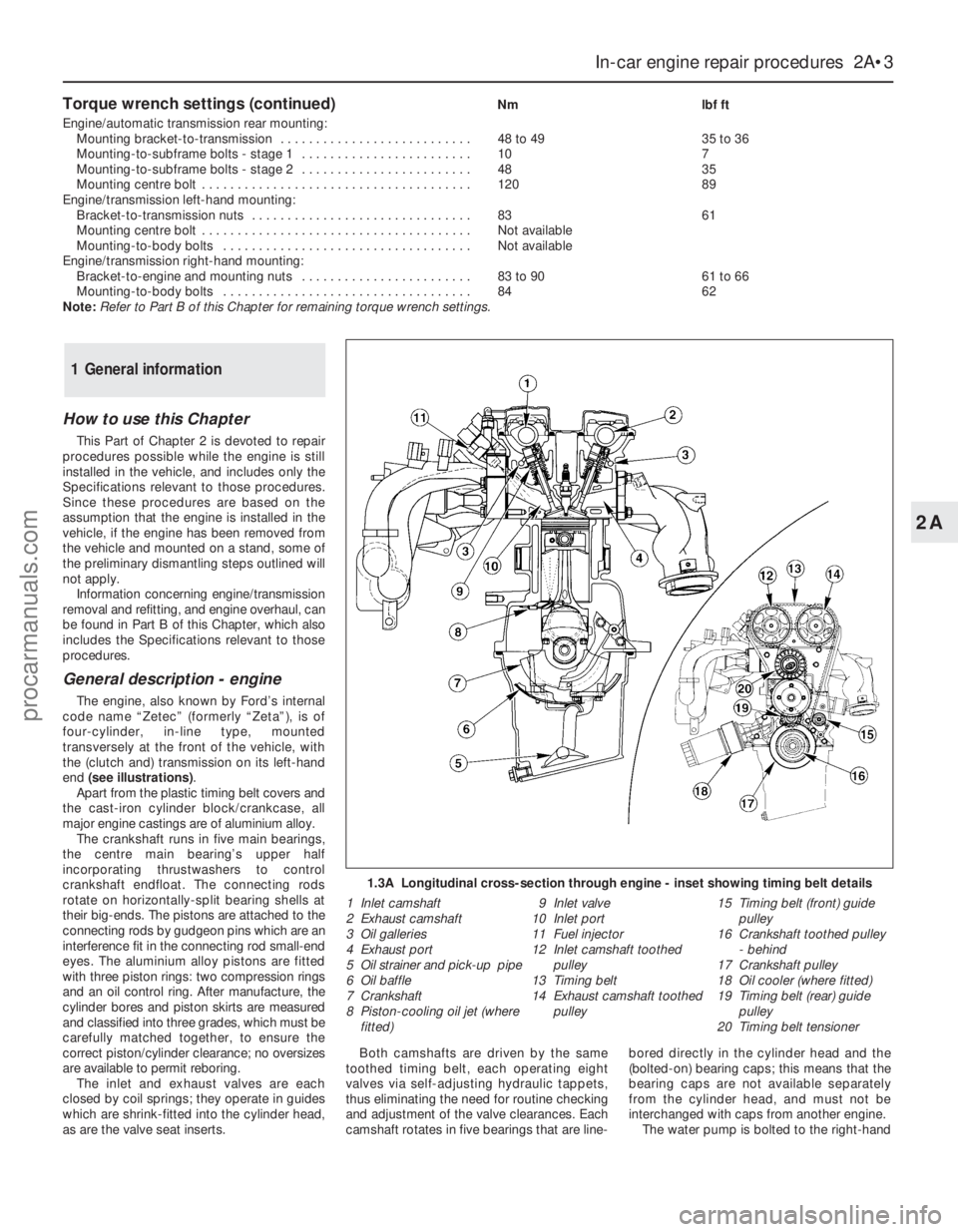

16When each spark plug is started correctly

on its threads, screw it down until it just seats

lightly, then tighten it to the specified torquewrench setting (see illustration). If a torque

wrench is not available - and this is one case

where the use of a torque wrench is strongly

recommended - tighten each spark plug

through no more than1/16 of a turn. Do not

exceed the specified torque setting, and

NEVERovertighten these spark plugs - their

tapered seats mean they are almost

impossible to remove if abused.

17Reconnect the spark plug (HT) leads in

their correct order, using a twisting motion on

the boot until it is firmly seated on the end of

the spark plug and on the cylinder head cover.

Spark plug (HT) lead check

18The spark plug (HT) leads should be

checked whenever the plugs themselves are

renewed. Start by making a visual check of

the leads while the engine is running. In a

darkened garage (make sure there is

ventilation) start the engine and observe each

lead. Be careful not to come into contact with

any moving engine parts. If there is a break in

the lead, you will see arcing or a small spark

at the damaged area.

19The spark plug (HT) leads should be

inspected one at a time, to prevent mixing up

the firing order, which is essential for proper

engine operation. Each original lead should be

numbered to identify its cylinder. If the

number is illegible, a piece of tape can be

marked with the correct number, and

wrapped around the lead (the leads should be

numbered 1 to 4, with No 1 lead nearest the

timing belt end of the engine). The lead can

then be disconnected.

20Check inside the boot for corrosion, which

will look like a white crusty powder. Clean this

off as much as possible; if it is excessive, or if

cleaning leaves the metal connector too badly

corroded to be fit for further use, the lead

must be renewed. Push the lead and boot

back onto the end of the spark plug. The boot

should fit tightly onto the end of the plug - if it

doesn’t, remove the lead and use pliers

carefully to crimp the metal connector inside

the boot until the fit is snug.

21Using a clean rag, wipe the entire length of

1•25

1

Every 30 000 miles

31.12 Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire does not

slide between the electrodes with a slight

drag, adjustment is required31.13 To change the gap, bend the outer

electrode only, as indicated by the arrows,

and be very careful not to crack or chip the

porcelain insulator surrounding the centre

electrode31.16 Spark plugs have tapered seats - do

not overtighten them on refitting, or you

will not be able to get them out again

without risking damage to the plugs and

cylinder head

To avoid the possibility of cross-

threading a spark plug, fit a short piece

of rubber hose over the end of the

plug. The flexible hose acts as a

universal joint, to help align the plug

with the plug hole. Should the plug

begin to cross-thread, the hose will slip

on the spark plug, preventing thread

damage.

procarmanuals.com

Page 43 of 279

Torque wrench settings (continued)Nm lbf ft

Engine/automatic transmission rear mounting:

Mounting bracket-to-transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 to 49 35 to 36

Mounting-to-subframe bolts - stage 1 . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Mounting-to-subframe bolts - stage 2 . . . . . . . . . . . . . . . . . . . . . . . . 48 35

Mounting centre bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 89

Engine/transmission left-hand mounting:

Bracket-to-transmission nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 61

Mounting centre bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not available

Mounting-to-body bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not available

Engine/transmission right-hand mounting:

Bracket-to-engine and mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . 83 to 90 61 to 66

Mounting-to-body bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 62

Note:Refer to Part B of this Chapter for remaining torque wrench settings.

In-car engine repair procedures 2A•3

2A

How to use this Chapter

This Part of Chapter 2 is devoted to repair

procedures possible while the engine is still

installed in the vehicle, and includes only the

Specifications relevant to those procedures.

Since these procedures are based on the

assumption that the engine is installed in the

vehicle, if the engine has been removed from

the vehicle and mounted on a stand, some of

the preliminary dismantling steps outlined will

not apply.

Information concerning engine/transmission

removal and refitting, and engine overhaul, can

be found in Part B of this Chapter, which also

includes the Specifications relevant to those

procedures.

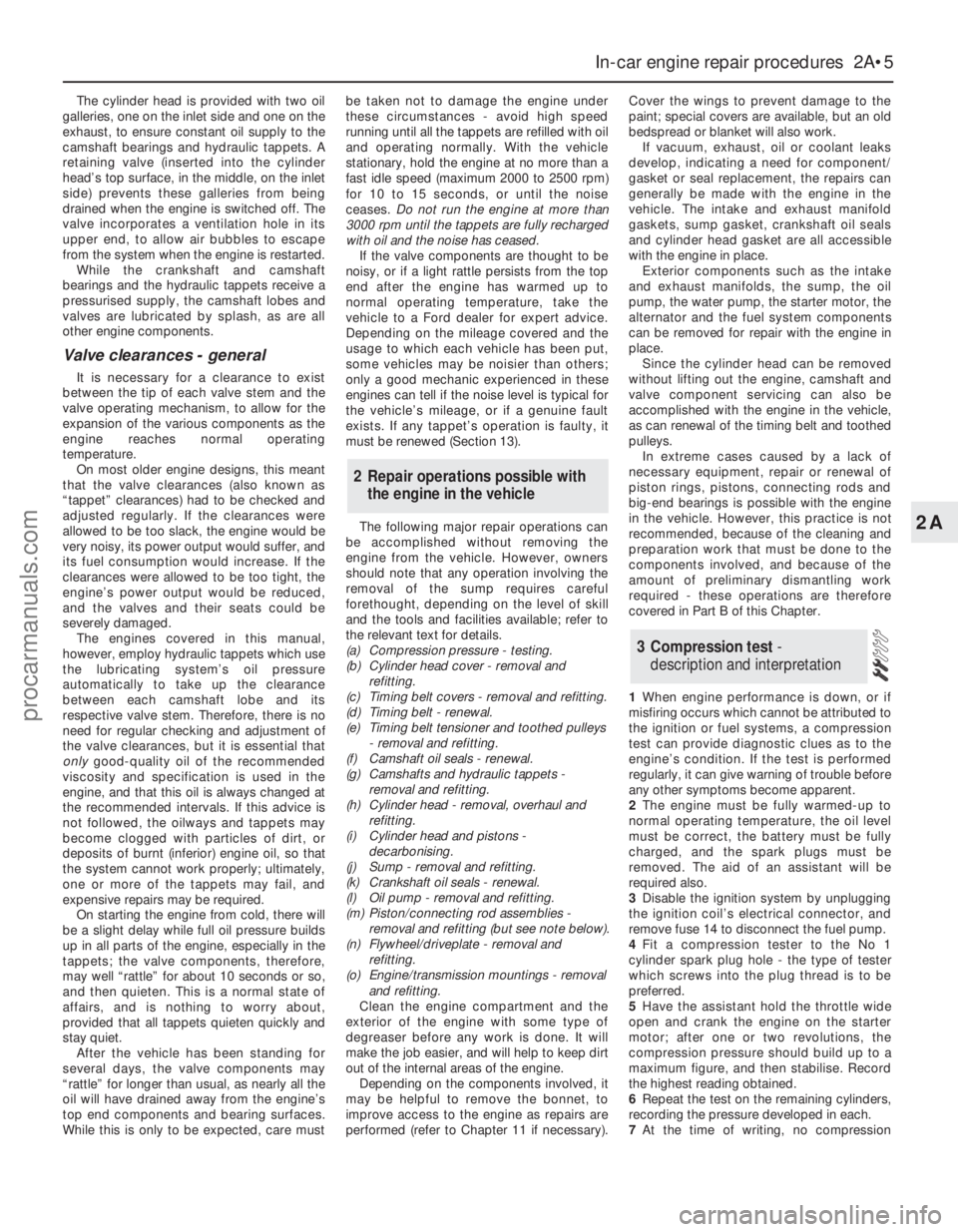

General description - engine

The engine, also known by Ford’s internal

code name “Zetec” (formerly “Zeta”), is of

four-cylinder, in-line type, mounted

transversely at the front of the vehicle, with

the (clutch and) transmission on its left-hand

end (see illustrations).

Apart from the plastic timing belt covers and

the cast-iron cylinder block/crankcase, all

major engine castings are of aluminium alloy.

The crankshaft runs in five main bearings,

the centre main bearing’s upper half

incorporating thrustwashers to control

crankshaft endfloat. The connecting rods

rotate on horizontally-split bearing shells at

their big-ends. The pistons are attached to the

connecting rods by gudgeon pins which are an

interference fit in the connecting rod small-end

eyes. The aluminium alloy pistons are fitted

with three piston rings: two compression rings

and an oil control ring. After manufacture, the

cylinder bores and piston skirts are measured

and classified into three grades, which must be

carefully matched together, to ensure the

correct piston/cylinder clearance; no oversizes

are available to permit reboring.

The inlet and exhaust valves are each

closed by coil springs; they operate in guides

which are shrink-fitted into the cylinder head,

as are the valve seat inserts.Both camshafts are driven by the same

toothed timing belt, each operating eight

valves via self-adjusting hydraulic tappets,

thus eliminating the need for routine checking

and adjustment of the valve clearances. Each

camshaft rotates in five bearings that are line-bored directly in the cylinder head and the

(bolted-on) bearing caps; this means that the

bearing caps are not available separately

from the cylinder head, and must not be

interchanged with caps from another engine.

The water pump is bolted to the right-hand

1 General information

1.3A Longitudinal cross-section through engine - inset showing timing belt details

1 Inlet camshaft

2 Exhaust camshaft

3 Oil galleries

4 Exhaust port

5 Oil strainer and pick-up pipe

6 Oil baffle

7 Crankshaft

8 Piston-cooling oil jet (where

fitted)9 Inlet valve

10 Inlet port

11 Fuel injector

12 Inlet camshaft toothed

pulley

13 Timing belt

14 Exhaust camshaft toothed

pulley15 Timing belt (front) guide

pulley

16 Crankshaft toothed pulley

- behind

17 Crankshaft pulley

18 Oil cooler (where fitted)

19 Timing belt (rear) guide

pulley

20 Timing belt tensioner

procarmanuals.com

Page 45 of 279

The cylinder head is provided with two oil

galleries, one on the inlet side and one on the

exhaust, to ensure constant oil supply to the

camshaft bearings and hydraulic tappets. A

retaining valve (inserted into the cylinder

head’s top surface, in the middle, on the inlet

side) prevents these galleries from being

drained when the engine is switched off. The

valve incorporates a ventilation hole in its

upper end, to allow air bubbles to escape

from the system when the engine is restarted.

While the crankshaft and camshaft

bearings and the hydraulic tappets receive a

pressurised supply, the camshaft lobes and

valves are lubricated by splash, as are all

other engine components.

Valve clearances - general

It is necessary for a clearance to exist

between the tip of each valve stem and the

valve operating mechanism, to allow for the

expansion of the various components as the

engine reaches normal operating

temperature.

On most older engine designs, this meant

that the valve clearances (also known as

“tappet” clearances) had to be checked and

adjusted regularly. If the clearances were

allowed to be too slack, the engine would be

very noisy, its power output would suffer, and

its fuel consumption would increase. If the

clearances were allowed to be too tight, the

engine’s power output would be reduced,

and the valves and their seats could be

severely damaged.

The engines covered in this manual,

however, employ hydraulic tappets which use

the lubricating system’s oil pressure

automatically to take up the clearance

between each camshaft lobe and its

respective valve stem. Therefore, there is no

need for regular checking and adjustment of

the valve clearances, but it is essential that

onlygood-quality oil of the recommended

viscosity and specification is used in the

engine, and that this oil is always changed at

the recommended intervals. If this advice is

not followed, the oilways and tappets may

become clogged with particles of dirt, or

deposits of burnt (inferior) engine oil, so that

the system cannot work properly; ultimately,

one or more of the tappets may fail, and

expensive repairs may be required.

On starting the engine from cold, there will

be a slight delay while full oil pressure builds

up in all parts of the engine, especially in the

tappets; the valve components, therefore,

may well “rattle” for about 10 seconds or so,

and then quieten. This is a normal state of

affairs, and is nothing to worry about,

provided that all tappets quieten quickly and

stay quiet.

After the vehicle has been standing for

several days, the valve components may

“rattle” for longer than usual, as nearly all the

oil will have drained away from the engine’s

top end components and bearing surfaces.

While this is only to be expected, care mustbe taken not to damage the engine under

these circumstances - avoid high speed

running until all the tappets are refilled with oil

and operating normally. With the vehicle

stationary, hold the engine at no more than a

fast idle speed (maximum 2000 to 2500 rpm)

for 10 to 15 seconds, or until the noise

ceases. Do not run the engine at more than

3000 rpm until the tappets are fully recharged

with oil and the noise has ceased.

If the valve components are thought to be

noisy, or if a light rattle persists from the top

end after the engine has warmed up to

normal operating temperature, take the

vehicle to a Ford dealer for expert advice.

Depending on the mileage covered and the

usage to which each vehicle has been put,

some vehicles may be noisier than others;

only a good mechanic experienced in these

engines can tell if the noise level is typical for

the vehicle’s mileage, or if a genuine fault

exists. If any tappet’s operation is faulty, it

must be renewed (Section 13).

The following major repair operations can

be accomplished without removing the

engine from the vehicle. However, owners

should note that any operation involving the

removal of the sump requires careful

forethought, depending on the level of skill

and the tools and facilities available; refer to

the relevant text for details.

(a) Compression pressure - testing.

(b) Cylinder head cover - removal and

refitting.

(c) Timing belt covers - removal and refitting.

(d) Timing belt - renewal.

(e) Timing belt tensioner and toothed pulleys

- removal and refitting.

(f) Camshaft oil seals - renewal.

(g) Camshafts and hydraulic tappets -

removal and refitting.

(h) Cylinder head - removal, overhaul and

refitting.

(i) Cylinder head and pistons -

decarbonising.

(j) Sump - removal and refitting.

(k) Crankshaft oil seals - renewal.

(l) Oil pump - removal and refitting.

(m) Piston/connecting rod assemblies -

removal and refitting (but see note below).

(n) Flywheel/driveplate - removal and

refitting.

(o) Engine/transmission mountings - removal

and refitting.

Clean the engine compartment and the

exterior of the engine with some type of

degreaser before any work is done. It will

make the job easier, and will help to keep dirt

out of the internal areas of the engine.

Depending on the components involved, it

may be helpful to remove the bonnet, to

improve access to the engine as repairs are

performed (refer to Chapter 11 if necessary).Cover the wings to prevent damage to the

paint; special covers are available, but an old

bedspread or blanket will also work.

If vacuum, exhaust, oil or coolant leaks

develop, indicating a need for component/

gasket or seal replacement, the repairs can

generally be made with the engine in the

vehicle. The intake and exhaust manifold

gaskets, sump gasket, crankshaft oil seals

and cylinder head gasket are all accessible

with the engine in place.

Exterior components such as the intake

and exhaust manifolds, the sump, the oil

pump, the water pump, the starter motor, the

alternator and the fuel system components

can be removed for repair with the engine in

place.

Since the cylinder head can be removed

without lifting out the engine, camshaft and

valve component servicing can also be

accomplished with the engine in the vehicle,

as can renewal of the timing belt and toothed

pulleys.

In extreme cases caused by a lack of

necessary equipment, repair or renewal of

piston rings, pistons, connecting rods and

big-end bearings is possible with the engine

in the vehicle. However, this practice is not

recommended, because of the cleaning and

preparation work that must be done to the

components involved, and because of the

amount of preliminary dismantling work

required - these operations are therefore

covered in Part B of this Chapter.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly, it can give warning of trouble before

any other symptoms become apparent.

2The engine must be fully warmed-up to

normal operating temperature, the oil level

must be correct, the battery must be fully

charged, and the spark plugs must be

removed. The aid of an assistant will be

required also.

3Disable the ignition system by unplugging

the ignition coil’s electrical connector, and

remove fuse 14 to disconnect the fuel pump.

4Fit a compression tester to the No 1

cylinder spark plug hole - the type of tester

which screws into the plug thread is to be

preferred.

5Have the assistant hold the throttle wide

open and crank the engine on the starter

motor; after one or two revolutions, the

compression pressure should build up to a

maximum figure, and then stabilise. Record

the highest reading obtained.

6Repeat the test on the remaining cylinders,

recording the pressure developed in each.

7At the time of writing, no compression

3 Compression test -

description and interpretation

2 Repair operations possible with

the engine in the vehicle

In-car engine repair procedures 2A•5

2A

procarmanuals.com

Page 75 of 279

gear linkage heat shield. Reconnect the

gearchange linkage and transmission support

rods to the transmission, adjusting the linkage

using the marks made on removal (see

Chapter 7, Part A, for details).

56Re-install the remaining components and

fasteners in the reverse order of removal.

57Add coolant, engine oil and transmission

fluids as needed (see Chapter 1).

58Run the engine, and check for proper

operation and the absence of leaks. Shut off

the engine, and recheck the fluid levels.

59Remember that, since the front suspension

subframe and steering gear have been

disturbed, the wheel alignment and steering

angles must be checked fully and carefully as

soon as possible, with any necessary

adjustments being made. This operation is best

carried out by an experienced mechanic, using

proper checking equipment; the vehicle should

therefore be taken to a Ford dealer or similarly-

qualified person for attention.

1It is much easier to dismantle and work on

the engine if it is mounted on a portable engine

stand. These stands can often be hired from a

tool hire shop. Before the engine is mounted

on a stand, the flywheel/driveplate should be

removed (Part A of this Chapter, Section 21)

so that the stand bolts can be tightened into

the end of the cylinder block/crankcase.

2If a stand is not available, it is possible to

dismantle the engine with it mounted on

blocks, on a sturdy workbench or on the floor.

Be extra-careful not to tip or drop the engine

when working without a stand.

3If you are going to obtain a reconditioned

engine, all external components must be

removed first, to be transferred to the

replacement engine (just as they will if you are

doing a complete engine overhaul yourself).

Note:When removing the external

components from the engine, pay close

attention to details that may be helpful or

important during refitting. Note the fitted

position of gaskets, seals, spacers, pins,

washers, bolts and other small items.These

external components include the following:

(a) Alternator and brackets (Chapter 5).

(b) HT leads and spark plugs (Chapter 1).

(c) Thermostat and housing (Chapter 3).

(d) Dipstick tube.

(e) Fuel injection system components

(Chapter 4).

(f) All electrical switches and sensors - refer

to the appropriate Chapter.

(g) Inlet and exhaust manifolds (Part A of this

Chapter).

(h) Oil filter (Chapter 1).

(i) Engine/transmission mounting brackets

(Part A of this Chapter, Section 22).

(j) Flywheel/driveplate (Part A of this

Chapter, Section 21).

4If you are obtaining a “short” engine (whichconsists of the engine cylinder

block/crankcase, crankshaft, pistons and

connecting rods all assembled), then the

cylinder head, sump, oil pump, and timing belt

will have to be removed also.

5If you are planning a complete overhaul, the

engine can be dismantled and the internal

components removed in the following order.

(a) Inlet and exhaust manifolds (Part A of this

Chapter).

(b) Timing belt, toothed pulleys and

tensioner, and timing belt inner cover

(Part A of this Chapter).

(c) Cylinder head (Part A of this Chapter,

Section 14).

(d) Flywheel/driveplate (Part A of this

Chapter, Section 21).

(e) Sump (Part A of this Chapter, Section 15).

(f) Oil pump (Part A of this Chapter, Sec-

tion 16).

(g) Piston/connecting rod assemblies

(Section 9).

(h) Crankshaft (Section 10).

6Before beginning the dismantling andoverhaul procedures, make sure that you have

all of the correct tools necessary. Refer to the

introductory pages at the beginning of this

manual for further information.

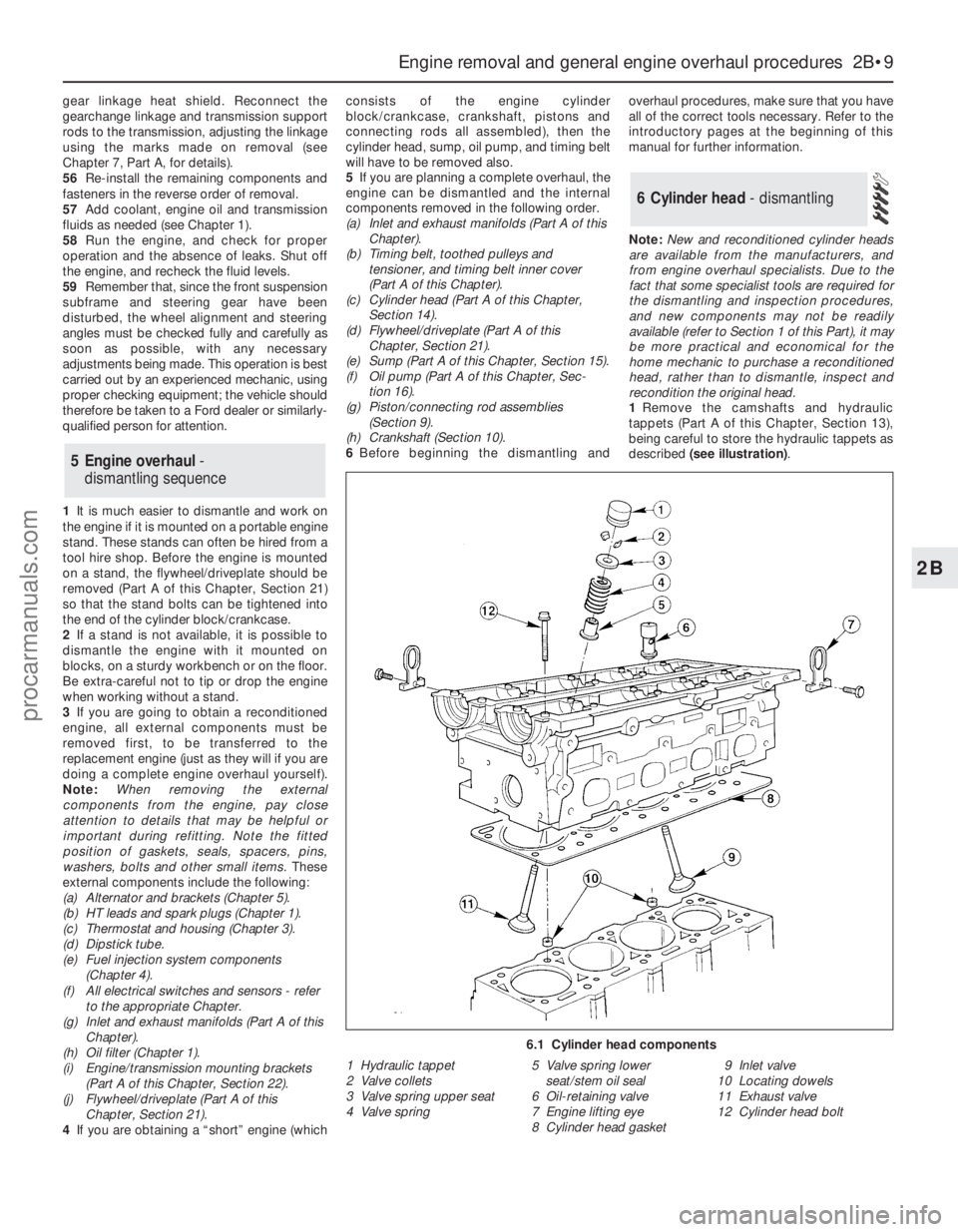

Note:New and reconditioned cylinder heads

are available from the manufacturers, and

from engine overhaul specialists. Due to the

fact that some specialist tools are required for

the dismantling and inspection procedures,

and new components may not be readily

available (refer to Section 1 of this Part), it may

be more practical and economical for the

home mechanic to purchase a reconditioned

head, rather than to dismantle, inspect and

recondition the original head.

1Remove the camshafts and hydraulic

tappets (Part A of this Chapter, Section 13),

being careful to store the hydraulic tappets as

described (see illustration).

6 Cylinder head - dismantling

5 Engine overhaul-

dismantling sequence

Engine removal and general engine overhaul procedures 2B•9

2B

6.1 Cylinder head components

1 Hydraulic tappet

2 Valve collets

3 Valve spring upper seat

4 Valve spring5 Valve spring lower

seat/stem oil seal

6 Oil-retaining valve

7 Engine lifting eye

8 Cylinder head gasket9 Inlet valve

10 Locating dowels

11 Exhaust valve

12 Cylinder head bolt

procarmanuals.com

Page 102 of 279

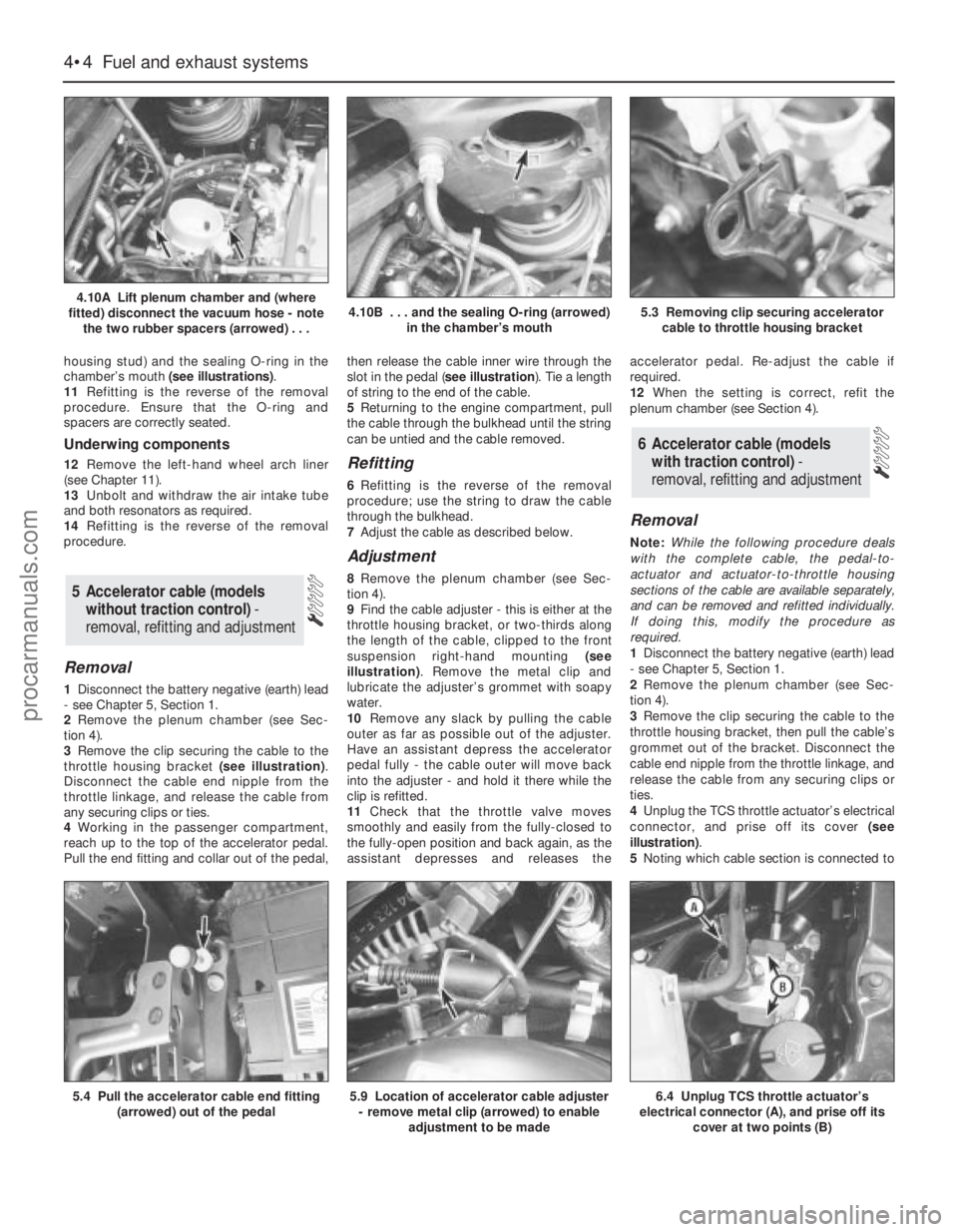

housing stud) and the sealing O-ring in the

chamber’s mouth (see illustrations).

11Refitting is the reverse of the removal

procedure. Ensure that the O-ring and

spacers are correctly seated.

Underwing components

12Remove the left-hand wheel arch liner

(see Chapter 11).

13Unbolt and withdraw the air intake tube

and both resonators as required.

14Refitting is the reverse of the removal

procedure.

Removal

1Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

2Remove the plenum chamber (see Sec-

tion 4).

3Remove the clip securing the cable to the

throttle housing bracket (see illustration).

Disconnect the cable end nipple from the

throttle linkage, and release the cable from

any securing clips or ties.

4Working in the passenger compartment,

reach up to the top of the accelerator pedal.

Pull the end fitting and collar out of the pedal,then release the cable inner wire through the

slot in the pedal (see illustration). Tie a length

of string to the end of the cable.

5Returning to the engine compartment, pull

the cable through the bulkhead until the string

can be untied and the cable removed.

Refitting

6Refitting is the reverse of the removal

procedure; use the string to draw the cable

through the bulkhead.

7Adjust the cable as described below.

Adjustment

8Remove the plenum chamber (see Sec-

tion 4).

9Find the cable adjuster - this is either at the

throttle housing bracket, or two-thirds along

the length of the cable, clipped to the front

suspension right-hand mounting (see

illustration). Remove the metal clip and

lubricate the adjuster’s grommet with soapy

water.

10Remove any slack by pulling the cable

outer as far as possible out of the adjuster.

Have an assistant depress the accelerator

pedal fully - the cable outer will move back

into the adjuster - and hold it there while the

clip is refitted.

11Check that the throttle valve moves

smoothly and easily from the fully-closed to

the fully-open position and back again, as the

assistant depresses and releases theaccelerator pedal. Re-adjust the cable if

required.

12When the setting is correct, refit the

plenum chamber (see Section 4).

Removal

Note:While the following procedure deals

with the complete cable, the pedal-to-

actuator and actuator-to-throttle housing

sections of the cable are available separately,

and can be removed and refitted individually.

If doing this, modify the procedure as

required.

1Disconnect the battery negative (earth) lead

- see Chapter 5, Section 1.

2Remove the plenum chamber (see Sec-

tion 4).

3Remove the clip securing the cable to the

throttle housing bracket, then pull the cable’s

grommet out of the bracket. Disconnect the

cable end nipple from the throttle linkage, and

release the cable from any securing clips or

ties.

4Unplug the TCS throttle actuator’s electrical

connector, and prise off its cover (see

illustration).

5Noting which cable section is connected to

6 Accelerator cable (models

with traction control)-

removal, refitting and adjustment

5 Accelerator cable (models

without traction control) -

removal, refitting and adjustment

4•4 Fuel and exhaust systems

4.10A Lift plenum chamber and (where

fitted) disconnect the vacuum hose - note

the two rubber spacers (arrowed) . . .4.10B . . . and the sealing O-ring (arrowed)

in the chamber’s mouth5.3 Removing clip securing accelerator

cable to throttle housing bracket

5.4 Pull the accelerator cable end fitting

(arrowed) out of the pedal5.9 Location of accelerator cable adjuster

- remove metal clip (arrowed) to enable

adjustment to be made6.4 Unplug TCS throttle actuator’s

electrical connector (A), and prise off its

cover at two points (B)

procarmanuals.com