check engine FORD POSTAL EXPLORER 2001 2.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2001, Model line: POSTAL EXPLORER, Model: FORD POSTAL EXPLORER 2001 2.GPages: 88, PDF Size: 0.7 MB

Page 5 of 88

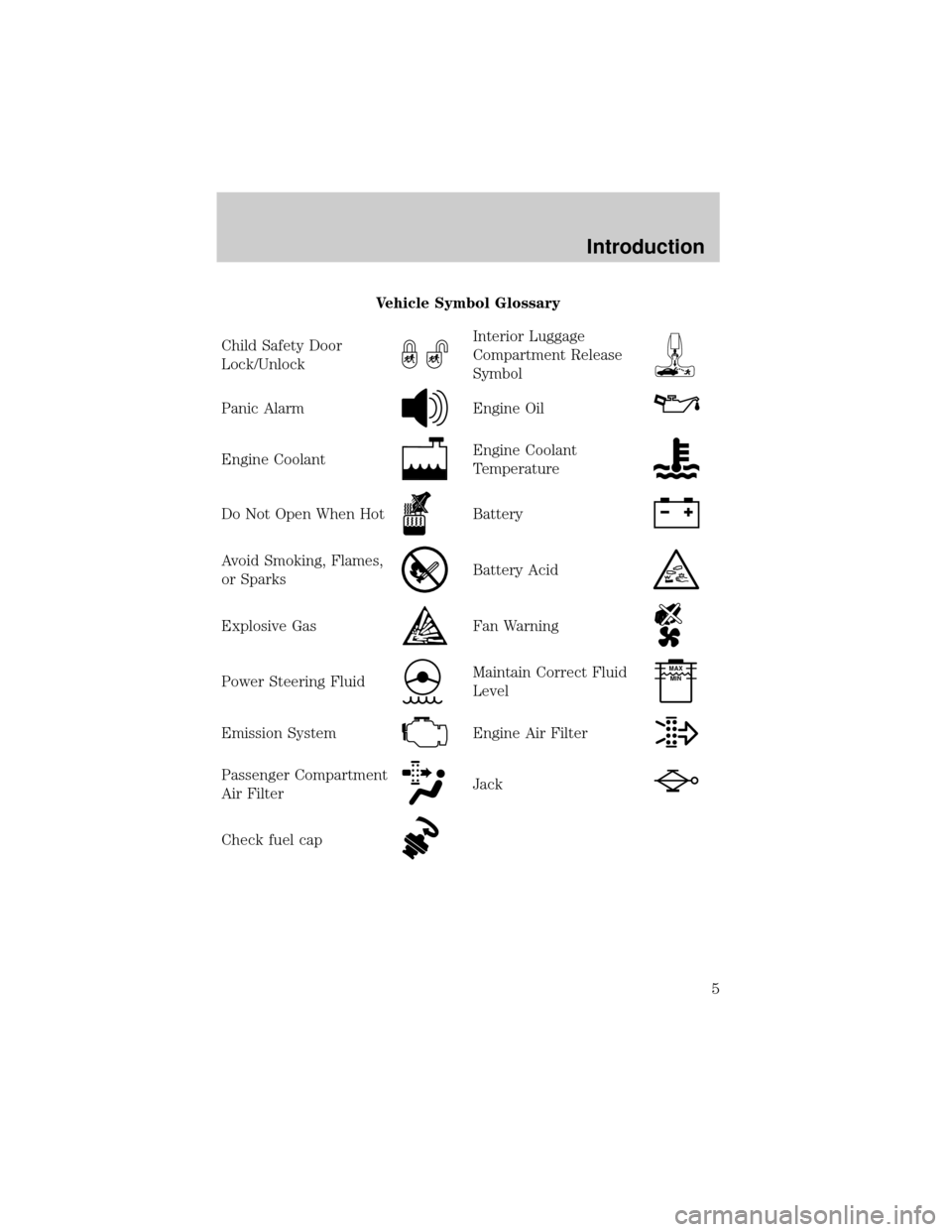

Vehicle Symbol Glossary

Child Safety Door

Lock/Unlock

Interior Luggage

Compartment Release

Symbol

Panic AlarmEngine Oil

Engine CoolantEngine Coolant

Temperature

Do Not Open When HotBattery

Avoid Smoking, Flames,

or SparksBattery Acid

Explosive GasFan Warning

Power Steering FluidMaintain Correct Fluid

LevelMAX

MIN

Emission SystemEngine Air Filter

Passenger Compartment

Air FilterJack

Check fuel cap

Introduction

5

Page 6 of 88

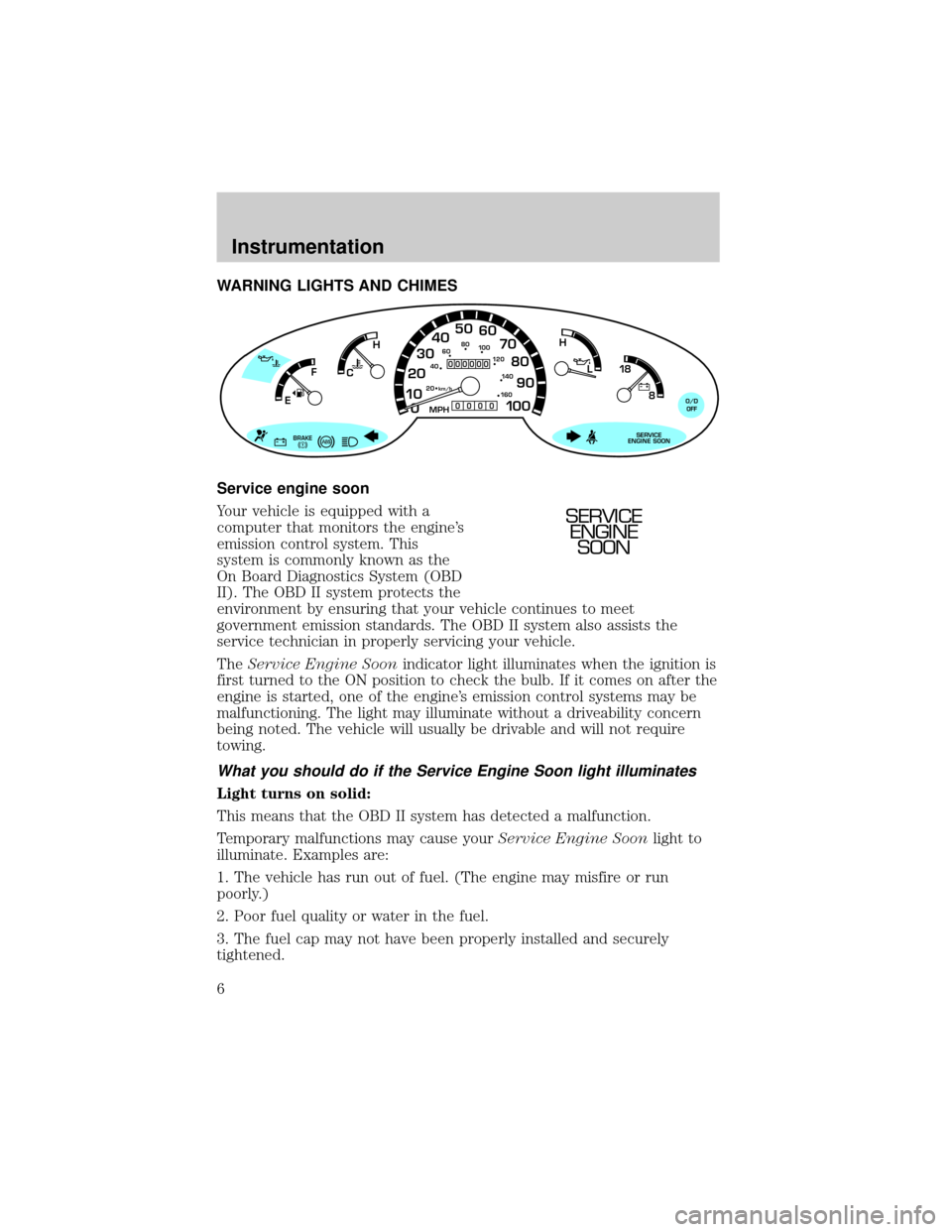

WARNING LIGHTS AND CHIMES

Service engine soon

Your vehicle is equipped with a

computer that monitors the engine's

emission control system. This

system is commonly known as the

On Board Diagnostics System (OBD

II). The OBD II system protects the

environment by ensuring that your vehicle continues to meet

government emission standards. The OBD II system also assists the

service technician in properly servicing your vehicle.

TheService Engine Soonindicator light illuminates when the ignition is

first turned to the ON position to check the bulb. If it comes on after the

engine is started, one of the engine's emission control systems may be

malfunctioning. The light may illuminate without a driveability concern

being noted. The vehicle will usually be drivable and will not require

towing.

What you should do if the Service Engine Soon light illuminates

Light turns on solid:

This means that the OBD II system has detected a malfunction.

Temporary malfunctions may cause yourService Engine Soonlight to

illuminate. Examples are:

1. The vehicle has run out of fuel. (The engine may misfire or run

poorly.)

2. Poor fuel quality or water in the fuel.

3. The fuel cap may not have been properly installed and securely

tightened.

0 1020304050

60

70

80

90

10 0

20 km/h

406080

10 0

12 0

14 0

H

L

16 0

MPH

000000

0000

BRAKE

18

8

SERVICE

ENGINE SOON

FH

C

E

O/D

OFF

SERVICE

ENGINE

SOON

Instrumentation

6

Page 10 of 88

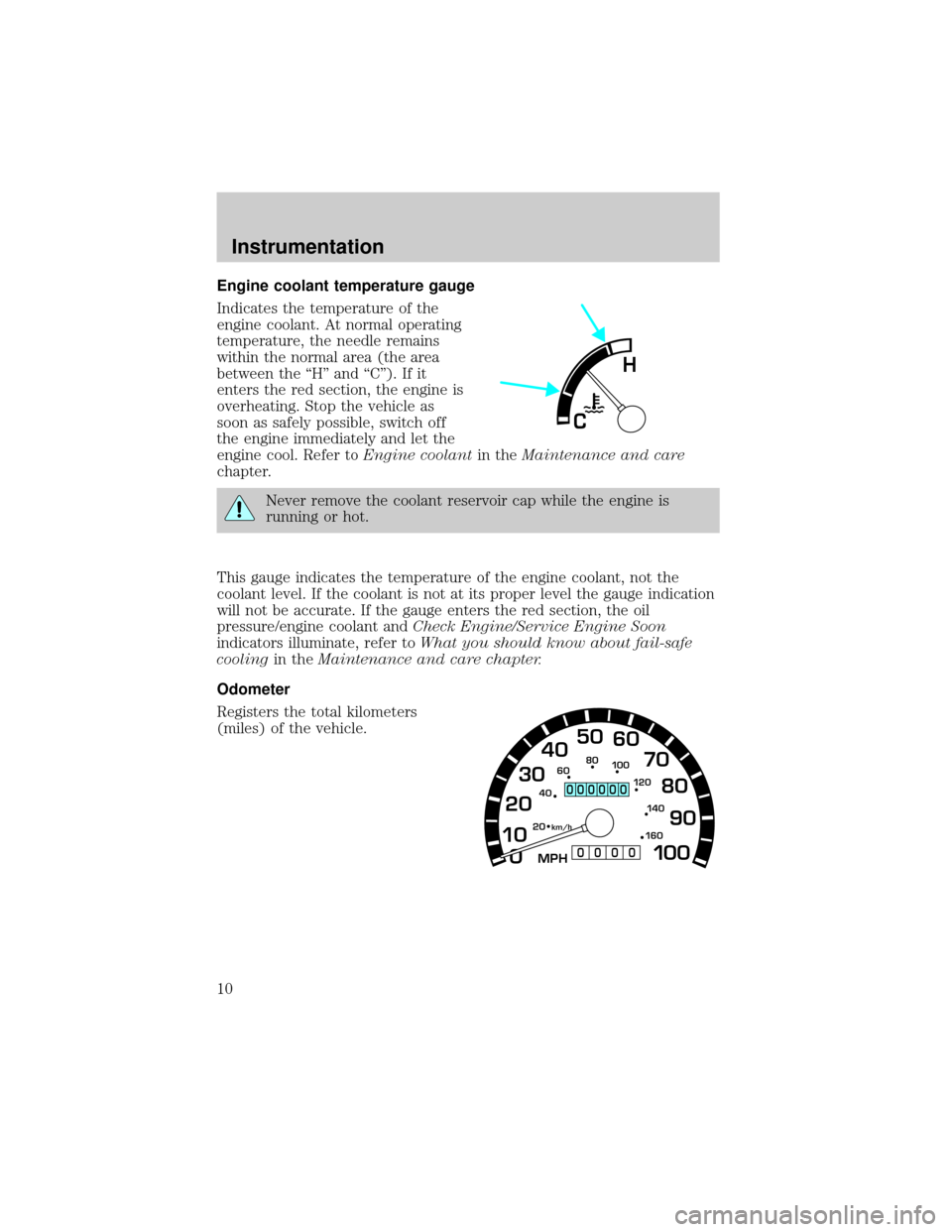

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the ªHº and ªCº). If it

enters the red section, the engine is

overheating. Stop the vehicle as

soon as safely possible, switch off

the engine immediately and let the

engine cool. Refer toEngine coolantin theMaintenance and care

chapter.

Never remove the coolant reservoir cap while the engine is

running or hot.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate. If the gauge enters the red section, the oil

pressure/engine coolant andCheck Engine/Service Engine Soon

indicators illuminate, refer toWhat you should know about fail-safe

coolingin theMaintenance and care chapter.

Odometer

Registers the total kilometers

(miles) of the vehicle.

H

C

0 1020304050

60

70

80

90

10 0

20 km/h

406080

10 0

12 0

14 0

16 0

MPH

000000

0000

Instrumentation

10

Page 11 of 88

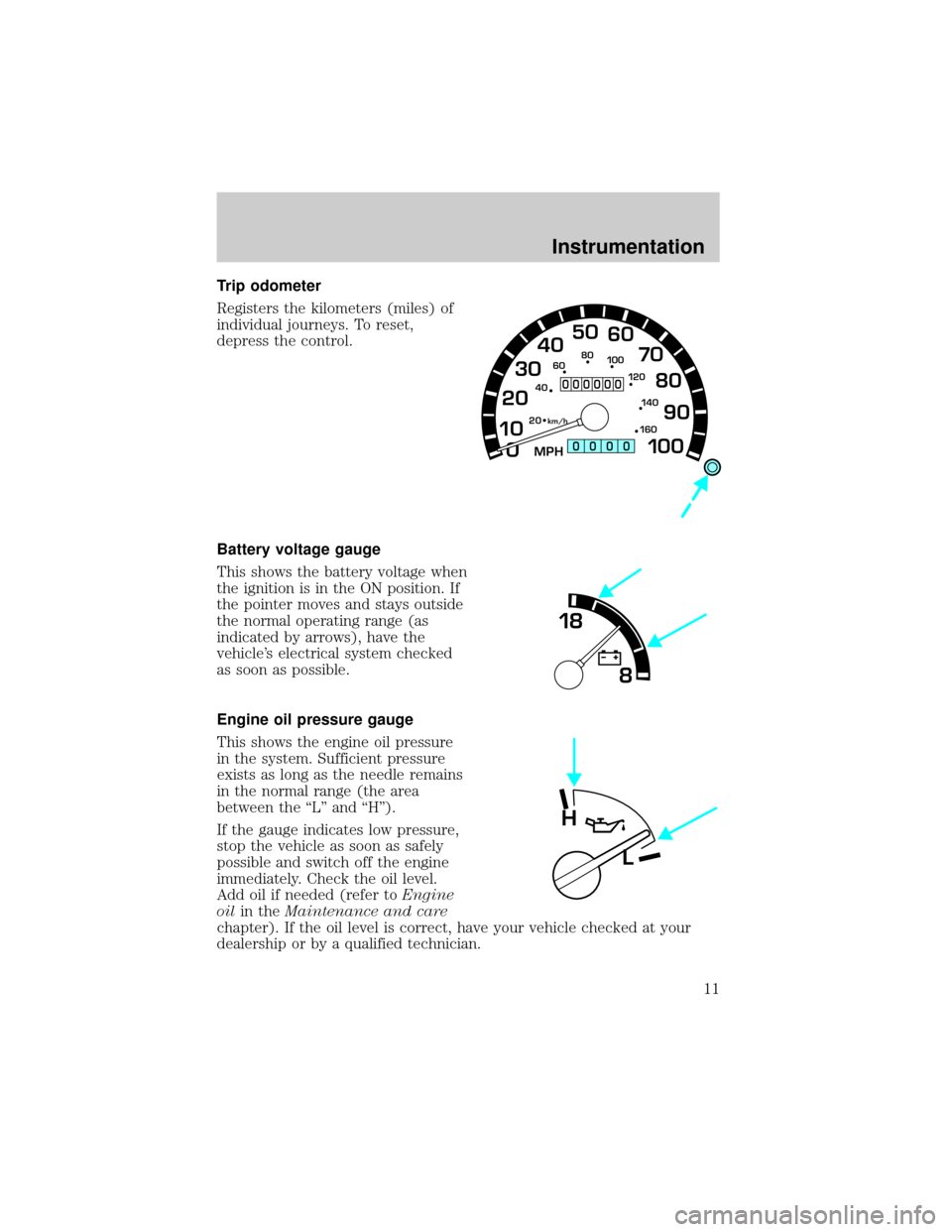

Trip odometer

Registers the kilometers (miles) of

individual journeys. To reset,

depress the control.

Battery voltage gauge

This shows the battery voltage when

the ignition is in the ON position. If

the pointer moves and stays outside

the normal operating range (as

indicated by arrows), have the

vehicle's electrical system checked

as soon as possible.

Engine oil pressure gauge

This shows the engine oil pressure

in the system. Sufficient pressure

exists as long as the needle remains

in the normal range (the area

between the ªLº and ªHº).

If the gauge indicates low pressure,

stop the vehicle as soon as safely

possible and switch off the engine

immediately. Check the oil level.

Add oil if needed (refer toEngine

oilin theMaintenance and care

chapter). If the oil level is correct, have your vehicle checked at your

dealership or by a qualified technician.

0 1020304050

60

70

80

90

10 0

20 km/h

406080

10 0

12 0

14 0

16 0

MPH

000000

0000

18

8

H

L

Instrumentation

11

Page 19 of 88

Important safety precautions

A computer system controls the engine's idle revolutions per minute

(RPM). When the engine starts, the idle RPM runs faster to warm the

engine. If the engine idle speed does not slow down automatically, have

the vehicle checked.

Before starting the vehicle:

1. Make sure all vehicle occupants have buckled their safety belts. For

more information on safety belts and their proper usage, refer to the

Seating and safety restraintschapter.

2. Make sure the vehicle accessories are off.

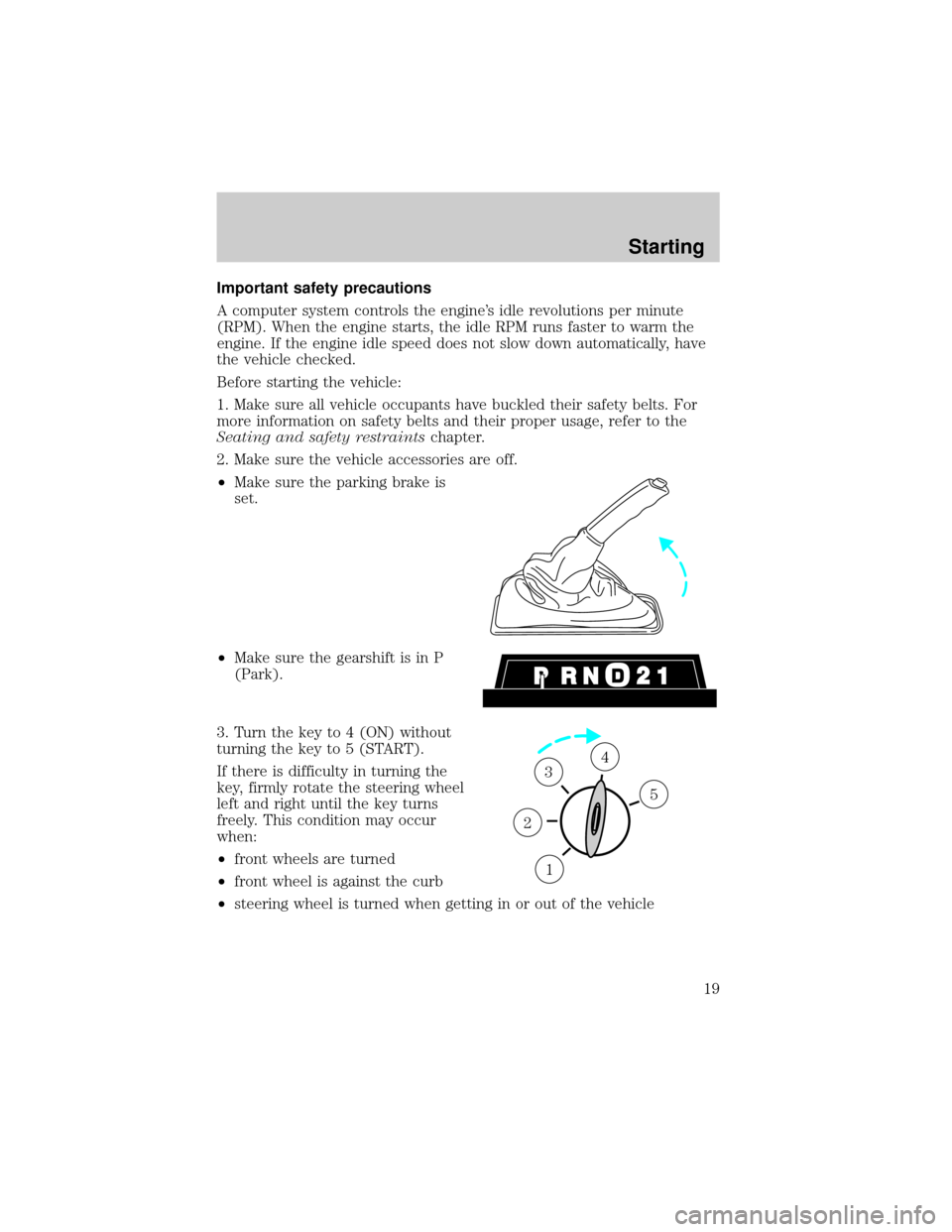

²Make sure the parking brake is

set.

²Make sure the gearshift is in P

(Park).

3. Turn the key to 4 (ON) without

turning the key to 5 (START).

If there is difficulty in turning the

key, firmly rotate the steering wheel

left and right until the key turns

freely. This condition may occur

when:

²front wheels are turned

²front wheel is against the curb

²steering wheel is turned when getting in or out of the vehicle

1

2

34

5

Starting

19

Page 22 of 88

Have the exhaust and body ventilation systems checked whenever:

²the vehicle is raised for service.

²the sound of the exhaust system changes.

²the vehicle has been damaged in a collision.

WARNING:Engine exhaust, some of its constituents, and

certain vehicle components contain or emit chemicals known to

the State of California to cause cancer and birth defects or other

reproductive harm. In addition, certain fluids contained in vehicles and

certain products of component wear contain or emit chemicals known

to the State of California to cause cancer and birth defects or other

reproductive harm.

Important ventilating information

If the engine is idling while the vehicle is stopped in an open area for

long periods of time, open the windows at least 2.5 cm (one inch).

Adjust the heating or air conditioning (if equipped) to bring in fresh air.

Improve vehicle ventilation by keeping all air inlet vents clear of snow,

leaves and other debris.

Starting

22

Page 23 of 88

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Four-wheel anti-lock brake system (ABS)

This vehicle is equipped with an anti-lock braking system (ABS). A noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

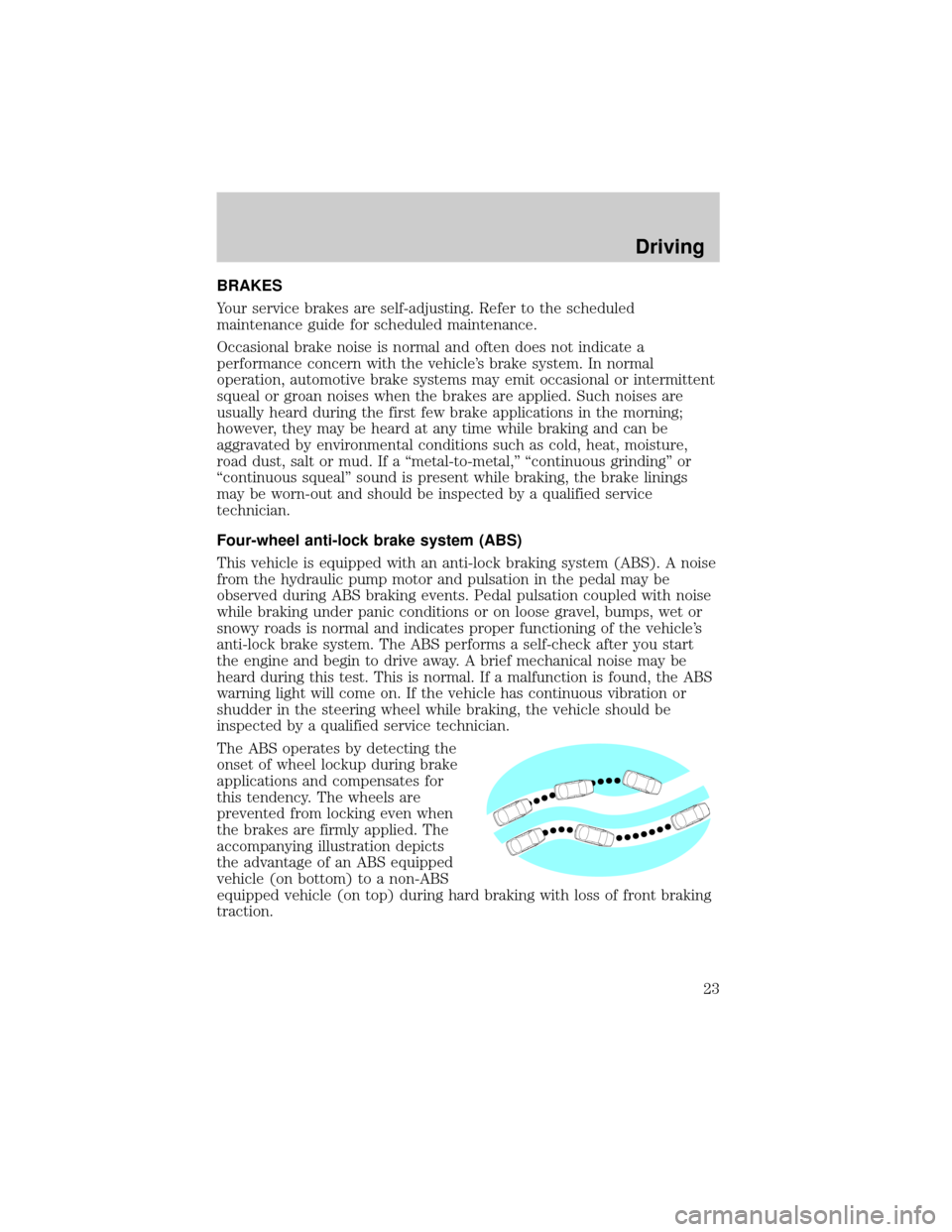

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

23

Page 32 of 88

Sand

When driving over sand, try to keep all four wheels on the most solid

area of the trail. Do not reduce the tire pressures but shift to a lower

gear and drive steadily through the terrain. Apply the accelerator slowly

and avoid spinning the wheels.

Mud and water

If you must drive through high water, drive slowly. Traction or brake

capability may be limited.

When driving through water, determine the depth; avoid water higher

than the bottom of the hubs (if possible) and proceed slowly. If the

ignition system gets wet, the vehicle may stall.

Once through water, always try the brakes. Wet brakes do not stop the

vehicle as effectively as dry brakes. Drying can be improved by moving

your vehicle slowly while applying light pressure on the brake pedal.

After driving through mud, clean off residue stuck to rotating driveshafts

and tires. Excess mud stuck on tires and rotating driveshafts causes an

imbalance that could damage drive components.

If the transmission, transfer case or front axle are submerged in water,

their fluids should be checked and changed, if necessary.

Water intrusion into the transmission may damage the

transmission.

If the rear axle is submerged in water, the rear axle lubricant should be

checked and changed, if necessary. The rear axle is filled with a

synthetic lubricant and does not normally require a lubricant change for

the life of the vehicle. Rear axle lubricant quantities should not need to

be checked unless a leak is suspected.

Driving on hilly or sloping terrain

When climbing a steep hill, start in a lower gear rather than downshifting

to a lower gear from a higher gear once the ascent has started. This

reduces the strain on the engine.

When descending a steep hill, avoid sudden braking. Shift to a lower gear

when added engine braking is desired.

Automatic transmissions may shift frequently while driving up steep

grades. Eliminate frequent shifting by shifting out of

(Overdrive) into

D (Drive).

Driving

32

Page 34 of 88

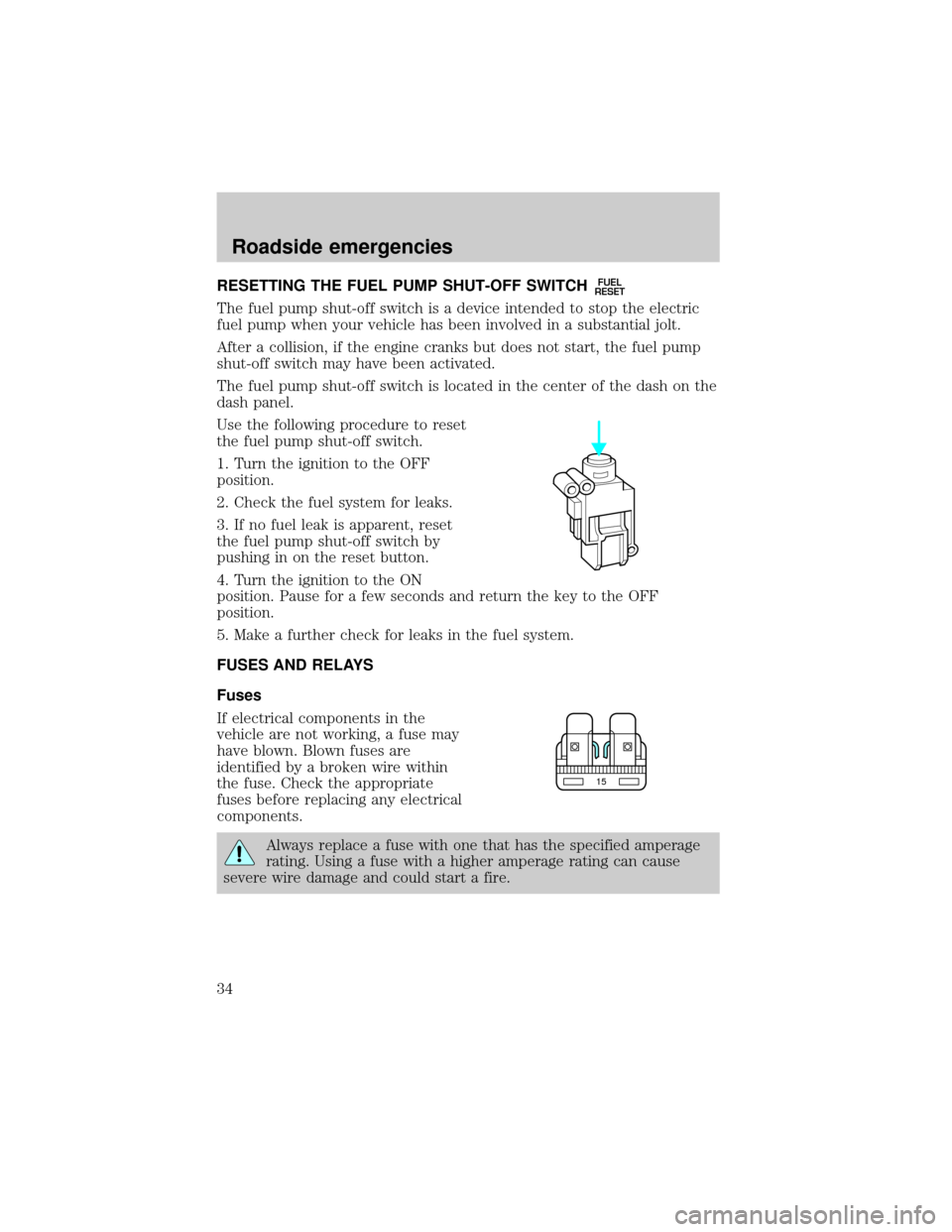

RESETTING THE FUEL PUMP SHUT-OFF SWITCHFUEL

RESET

The fuel pump shut-off switch is a device intended to stop the electric

fuel pump when your vehicle has been involved in a substantial jolt.

After a collision, if the engine cranks but does not start, the fuel pump

shut-off switch may have been activated.

The fuel pump shut-off switch is located in the center of the dash on the

dash panel.

Use the following procedure to reset

the fuel pump shut-off switch.

1. Turn the ignition to the OFF

position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset

the fuel pump shut-off switch by

pushing in on the reset button.

4. Turn the ignition to the ON

position. Pause for a few seconds and return the key to the OFF

position.

5. Make a further check for leaks in the fuel system.

FUSES AND RELAYS

Fuses

If electrical components in the

vehicle are not working, a fuse may

have blown. Blown fuses are

identified by a broken wire within

the fuse. Check the appropriate

fuses before replacing any electrical

components.

Always replace a fuse with one that has the specified amperage

rating. Using a fuse with a higher amperage rating can cause

severe wire damage and could start a fire.

15

Roadside emergencies

34

Page 44 of 88

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

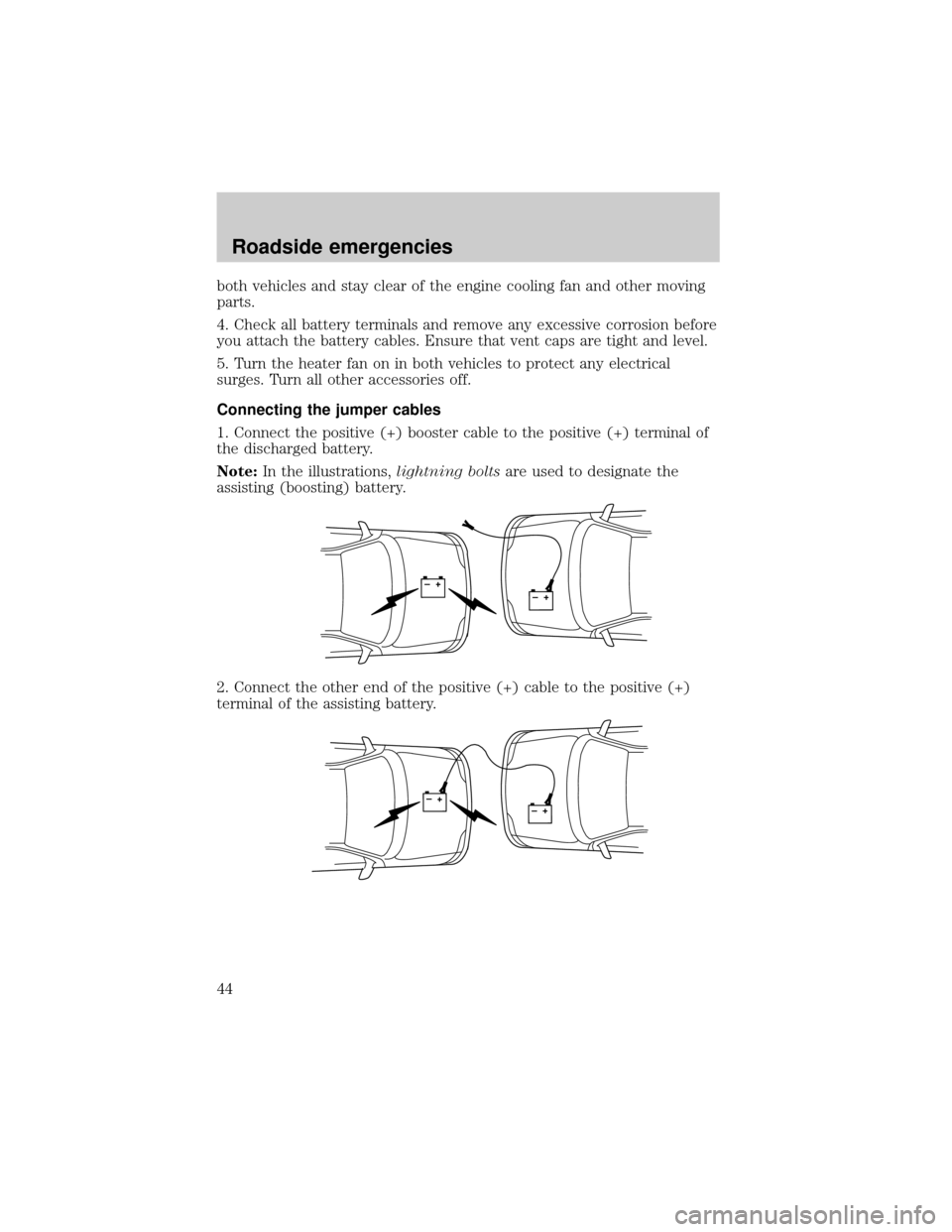

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

+–+–

+–+–

Roadside emergencies

44