clock FORD RANGER 2002 2.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2002, Model line: RANGER, Model: FORD RANGER 2002 2.GPages: 288, PDF Size: 3.03 MB

Page 78 of 288

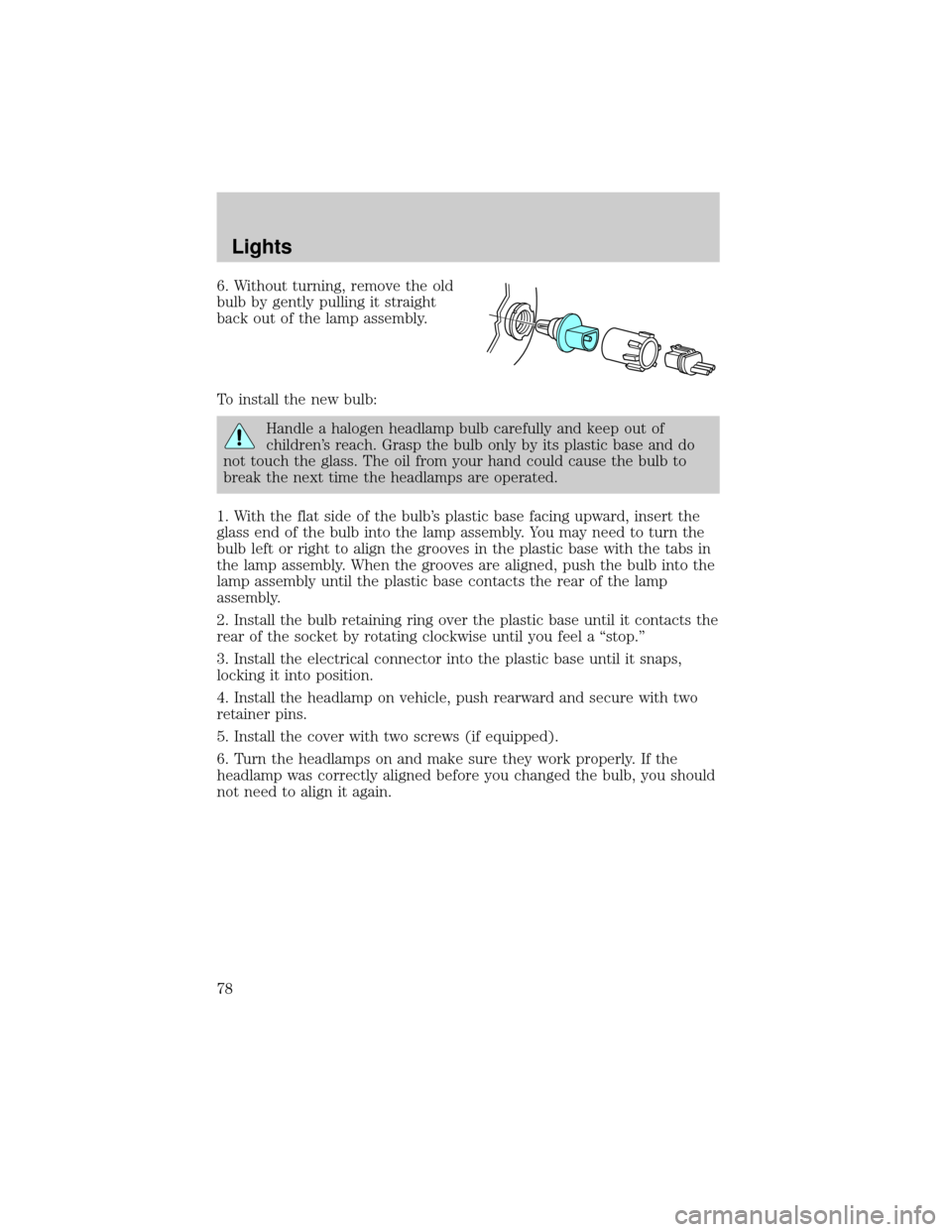

6. Without turning, remove the old

bulb by gently pulling it straight

back out of the lamp assembly.

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. With the flat side of the bulb's plastic base facing upward, insert the

glass end of the bulb into the lamp assembly. You may need to turn the

bulb left or right to align the grooves in the plastic base with the tabs in

the lamp assembly. When the grooves are aligned, push the bulb into the

lamp assembly until the plastic base contacts the rear of the lamp

assembly.

2. Install the bulb retaining ring over the plastic base until it contacts the

rear of the socket by rotating clockwise until you feel a ªstop.º

3. Install the electrical connector into the plastic base until it snaps,

locking it into position.

4. Install the headlamp on vehicle, push rearward and secure with two

retainer pins.

5. Install the cover with two screws (if equipped).

6. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Lights

78

Page 80 of 288

6. Rotate bulb socket

counterclockwise and remove from

lamp assembly.

7. Carefully pull bulb straight out of

socket and push in the new bulb.

8. Install the bulb socket in lamp

assembly by turning clockwise.

9. Align the lamp on the vehicle and

push to snap in place.

10. Install screw(s) on lamp assembly.

11. Install the headlamp on vehicle, push rearward and secure with two

retainer pins.

12. Install the cover with two screws (if equipped).

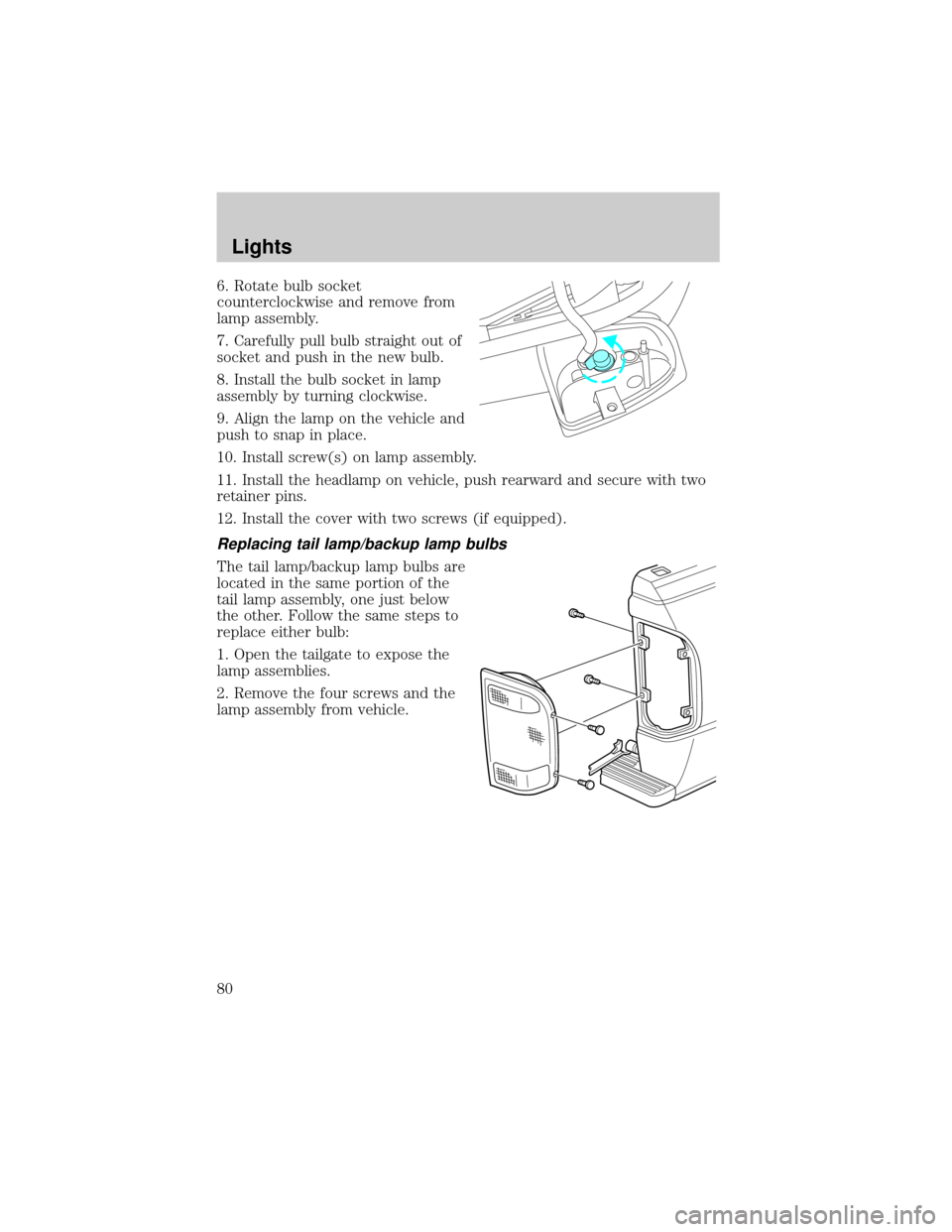

Replacing tail lamp/backup lamp bulbs

The tail lamp/backup lamp bulbs are

located in the same portion of the

tail lamp assembly, one just below

the other. Follow the same steps to

replace either bulb:

1. Open the tailgate to expose the

lamp assemblies.

2. Remove the four screws and the

lamp assembly from vehicle.

Lights

80

Page 81 of 288

3. Rotate bulb socket

counterclockwise turn and remove

from lamp assembly.

4. Carefully pull the bulb straight

out of the socket and push in the

new bulb.

5. Install the bulb socket in lamp

assembly by turning clockwise.

6. Install the lamp assembly and

secure with four screws.

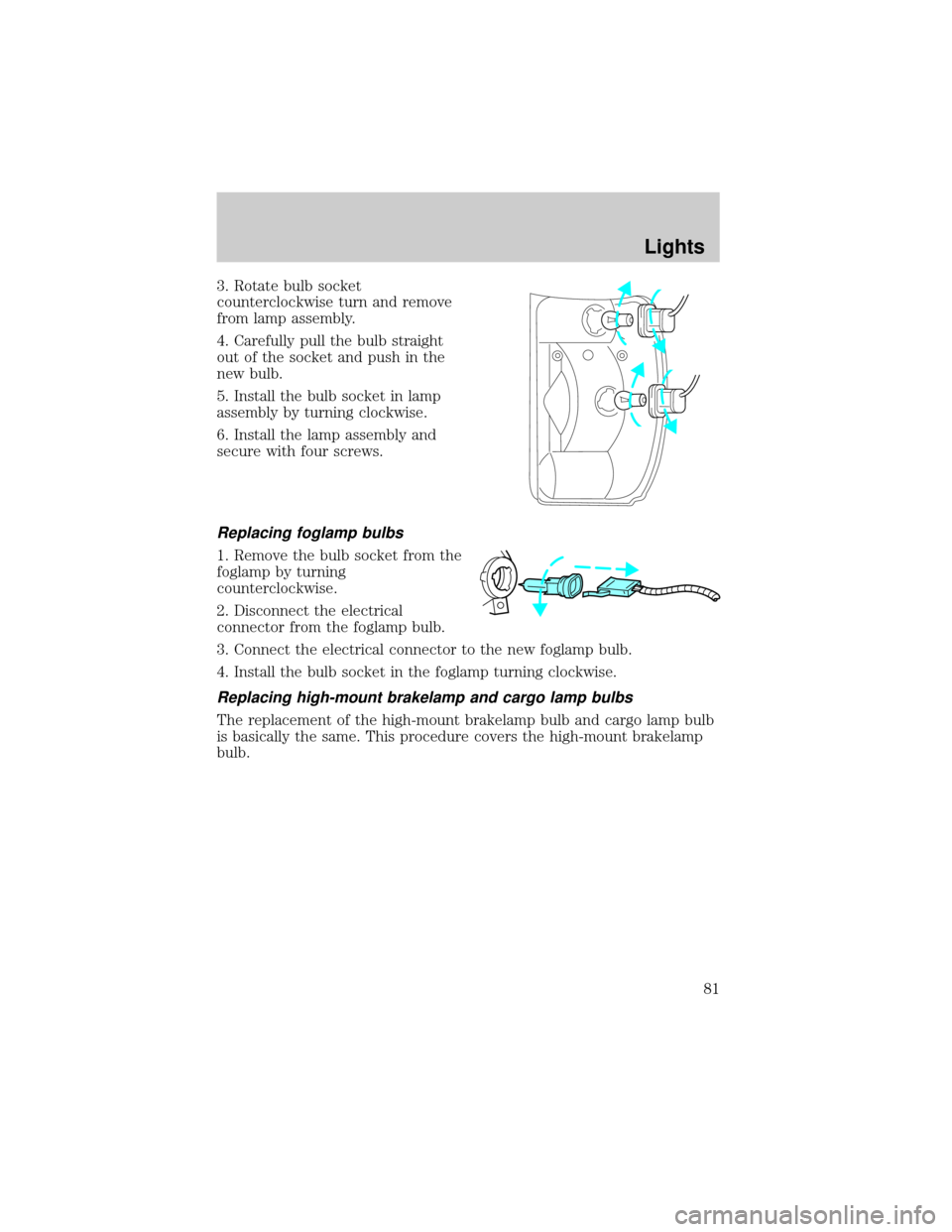

Replacing foglamp bulbs

1. Remove the bulb socket from the

foglamp by turning

counterclockwise.

2. Disconnect the electrical

connector from the foglamp bulb.

3. Connect the electrical connector to the new foglamp bulb.

4. Install the bulb socket in the foglamp turning clockwise.

Replacing high-mount brakelamp and cargo lamp bulbs

The replacement of the high-mount brakelamp bulb and cargo lamp bulb

is basically the same. This procedure covers the high-mount brakelamp

bulb.

Lights

81

Page 82 of 288

To remove the brakelamp assembly:

1. Remove the two screws and lamp

assembly from vehicle.

2. Remove the bulb socket from

lamp assembly by rotating it

counterclockwise.

3. Carefully pull bulb straight out of

socket and push in the new bulb.

To install the brakelamp assembly:

1. Install the bulb socket into the

lamp assembly by rotating

clockwise.

2. Install the lamp assembly on the vehicle and secure with two screws.

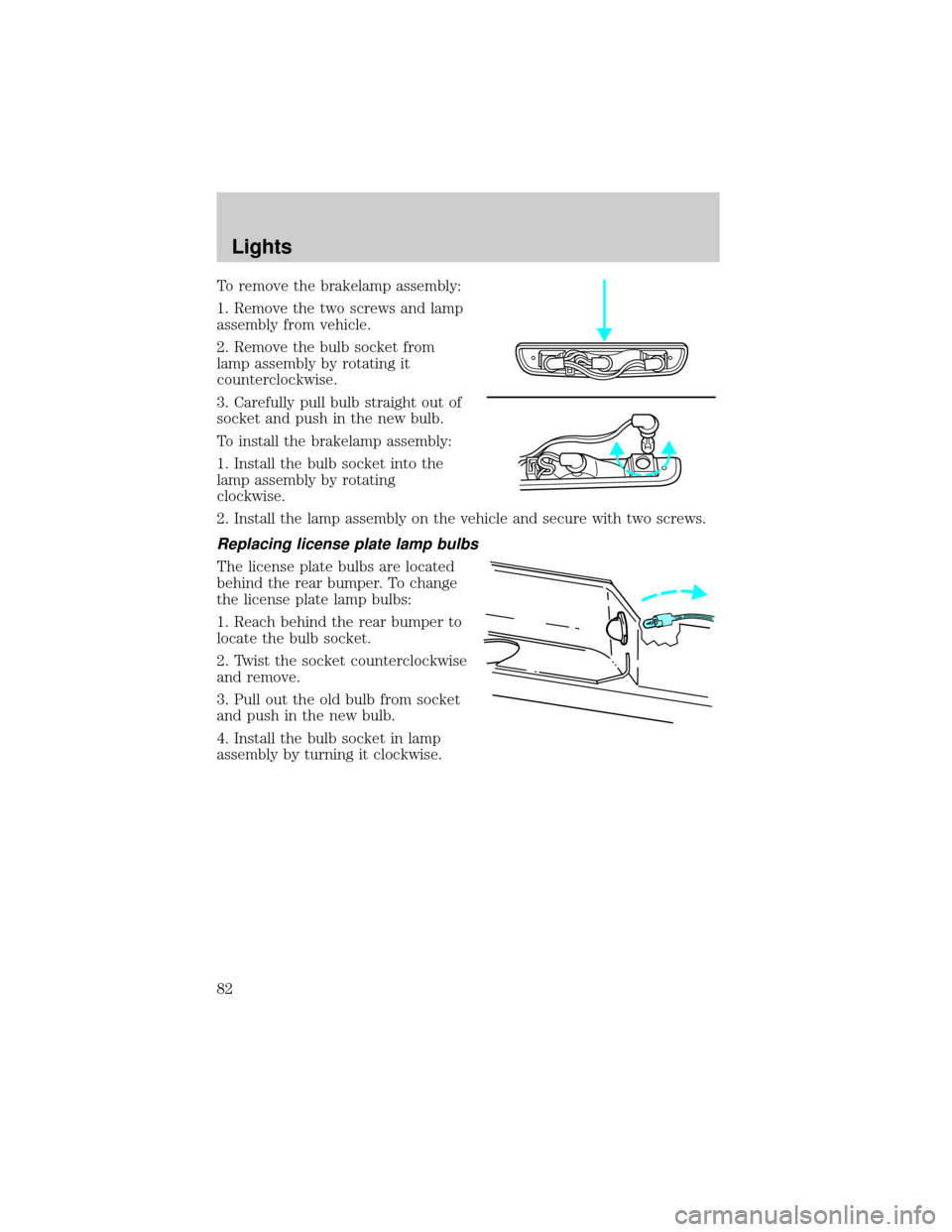

Replacing license plate lamp bulbs

The license plate bulbs are located

behind the rear bumper. To change

the license plate lamp bulbs:

1. Reach behind the rear bumper to

locate the bulb socket.

2. Twist the socket counterclockwise

and remove.

3. Pull out the old bulb from socket

and push in the new bulb.

4. Install the bulb socket in lamp

assembly by turning it clockwise.

Lights

82

Page 94 of 288

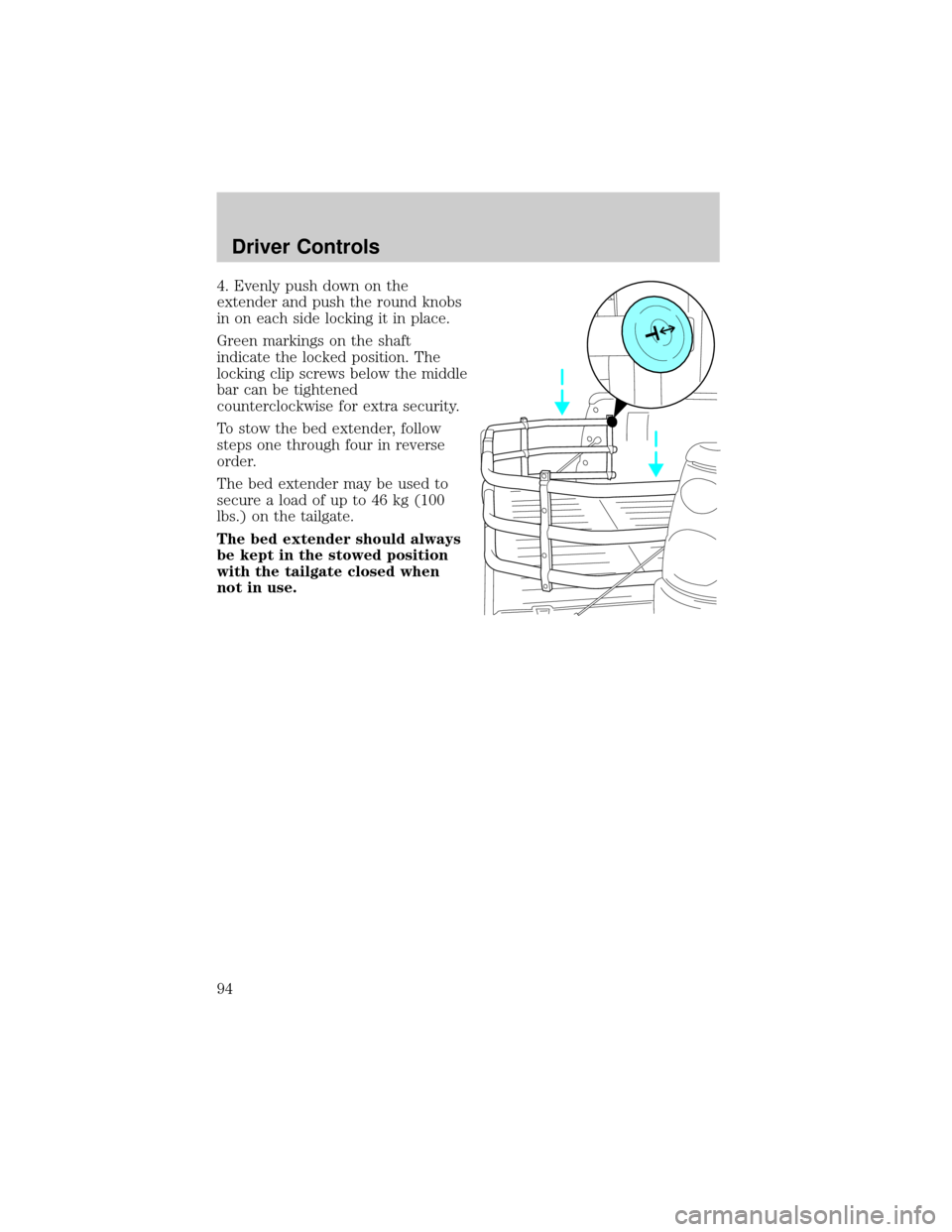

4. Evenly push down on the

extender and push the round knobs

in on each side locking it in place.

Green markings on the shaft

indicate the locked position. The

locking clip screws below the middle

bar can be tightened

counterclockwise for extra security.

To stow the bed extender, follow

steps one through four in reverse

order.

The bed extender may be used to

secure a load of up to 46 kg (100

lbs.) on the tailgate.

The bed extender should always

be kept in the stowed position

with the tailgate closed when

not in use.

Driver Controls

94

Page 110 of 288

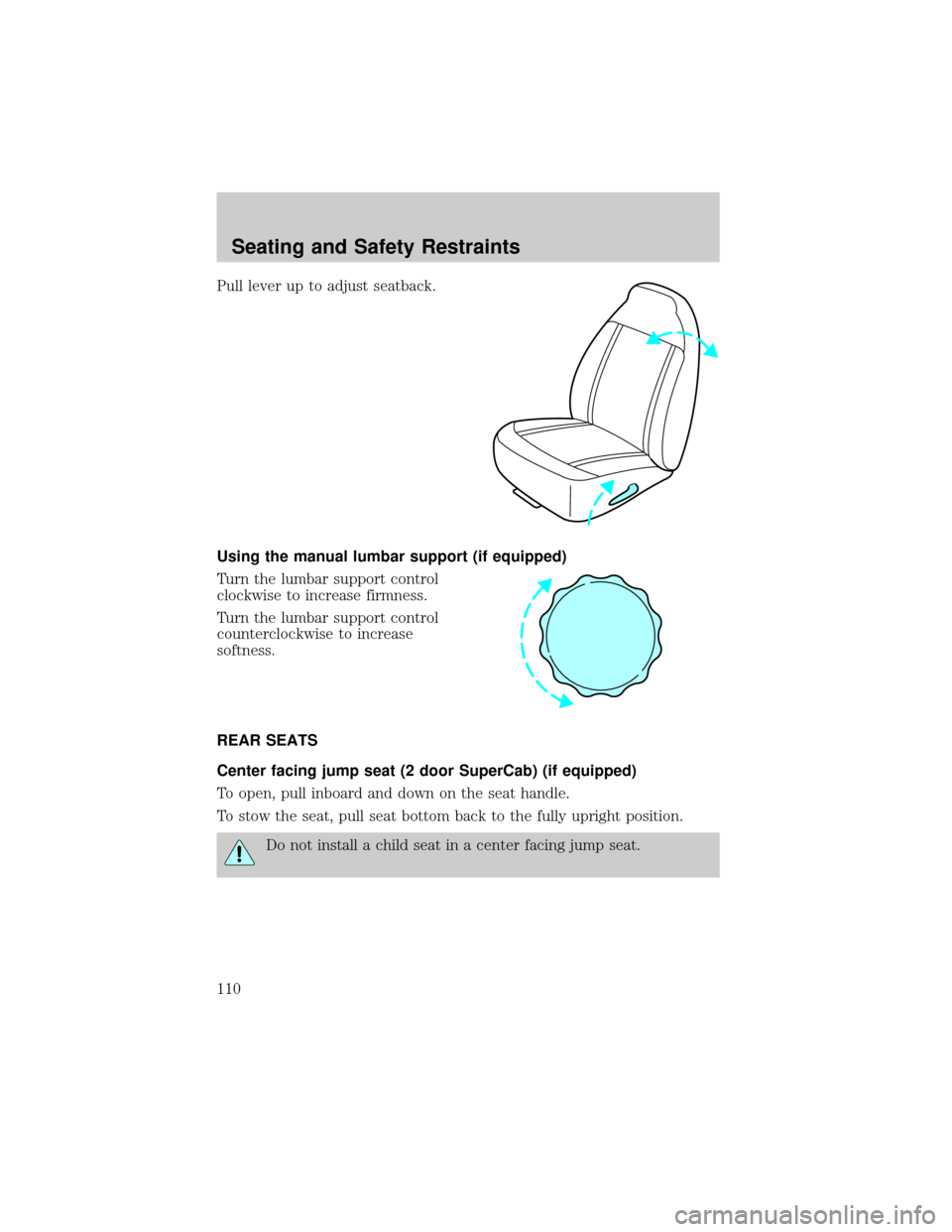

Pull lever up to adjust seatback.

Using the manual lumbar support (if equipped)

Turn the lumbar support control

clockwise to increase firmness.

Turn the lumbar support control

counterclockwise to increase

softness.

REAR SEATS

Center facing jump seat (2 door SuperCab) (if equipped)

To open, pull inboard and down on the seat handle.

To stow the seat, pull seat bottom back to the fully upright position.

Do not install a child seat in a center facing jump seat.

Seating and Safety Restraints

110

Page 203 of 288

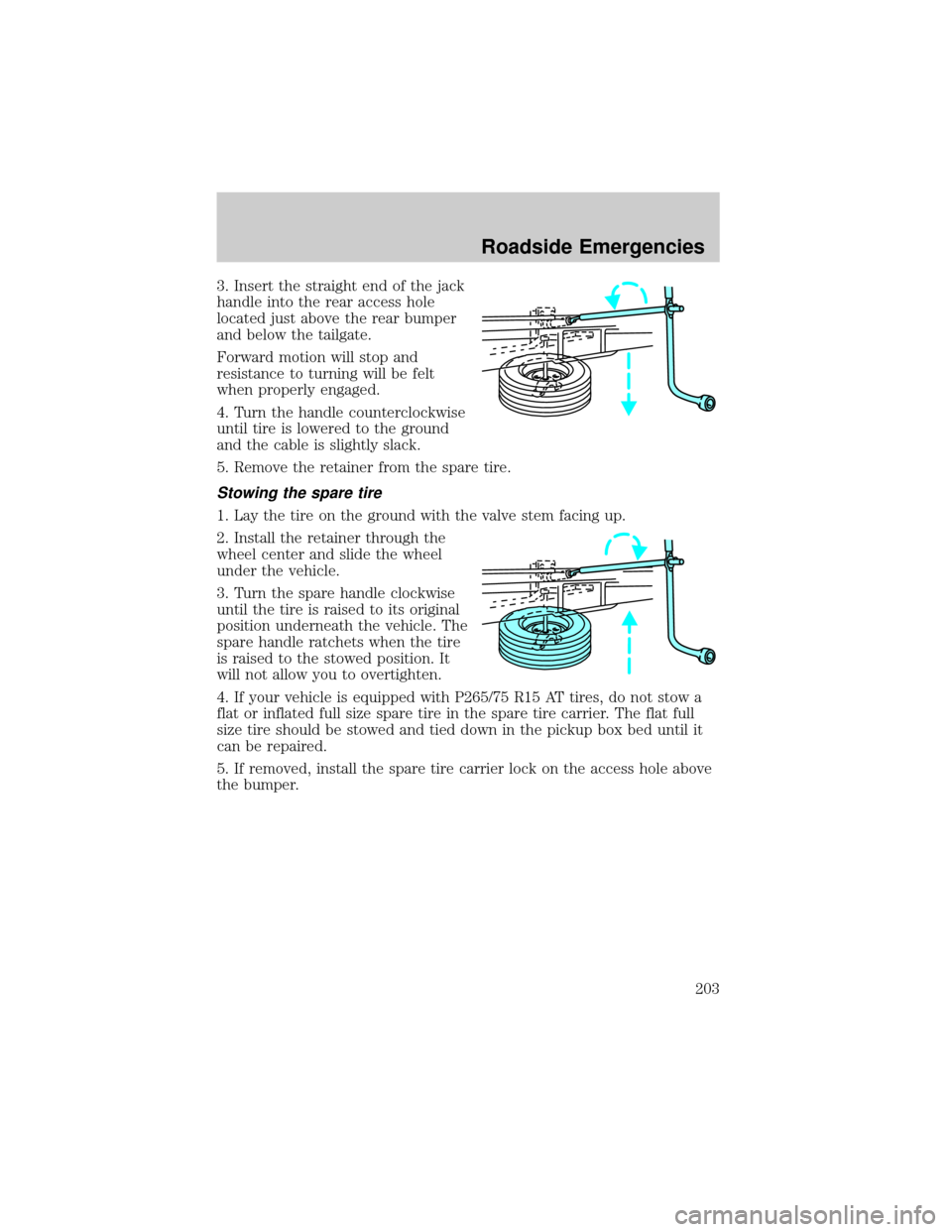

3. Insert the straight end of the jack

handle into the rear access hole

located just above the rear bumper

and below the tailgate.

Forward motion will stop and

resistance to turning will be felt

when properly engaged.

4. Turn the handle counterclockwise

until tire is lowered to the ground

and the cable is slightly slack.

5. Remove the retainer from the spare tire.

Stowing the spare tire

1. Lay the tire on the ground with the valve stem facing up.

2. Install the retainer through the

wheel center and slide the wheel

under the vehicle.

3. Turn the spare handle clockwise

until the tire is raised to its original

position underneath the vehicle. The

spare handle ratchets when the tire

is raised to the stowed position. It

will not allow you to overtighten.

4. If your vehicle is equipped with P265/75 R15 AT tires, do not stow a

flat or inflated full size spare tire in the spare tire carrier. The flat full

size tire should be stowed and tied down in the pickup box bed until it

can be repaired.

5. If removed, install the spare tire carrier lock on the access hole above

the bumper.

Roadside Emergencies

203

Page 204 of 288

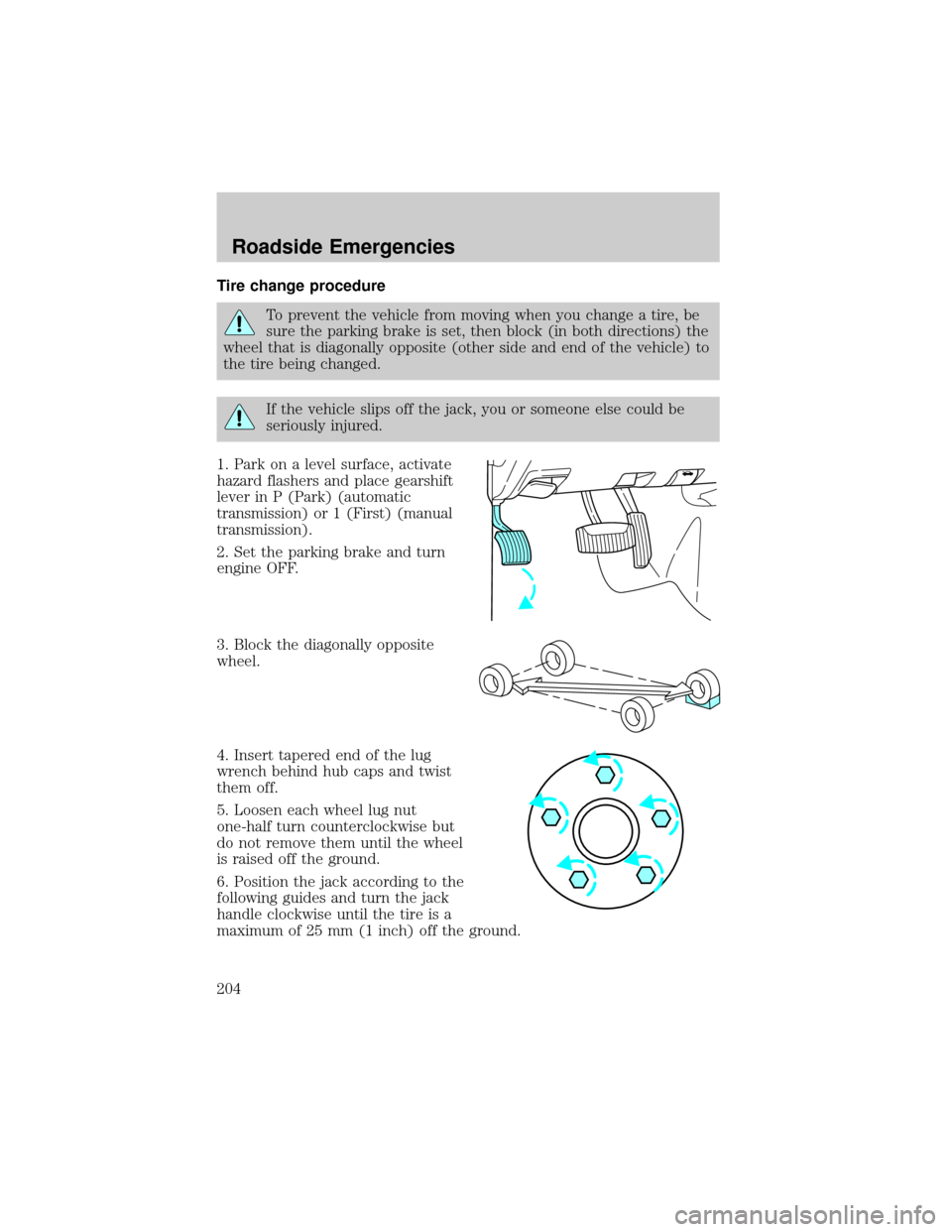

Tire change procedure

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block (in both directions) the

wheel that is diagonally opposite (other side and end of the vehicle) to

the tire being changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

1. Park on a level surface, activate

hazard flashers and place gearshift

lever in P (Park) (automatic

transmission) or 1 (First) (manual

transmission).

2. Set the parking brake and turn

engine OFF.

3. Block the diagonally opposite

wheel.

4. Insert tapered end of the lug

wrench behind hub caps and twist

them off.

5. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

6. Position the jack according to the

following guides and turn the jack

handle clockwise until the tire is a

maximum of 25 mm (1 inch) off the ground.

Roadside Emergencies

204

Page 206 of 288

8. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts until the wheel is snug against the

hub. Do not fully tighten the lug nuts until the wheel has been lowered.

9. Lower the wheel by turning the jack handle counterclockwise.

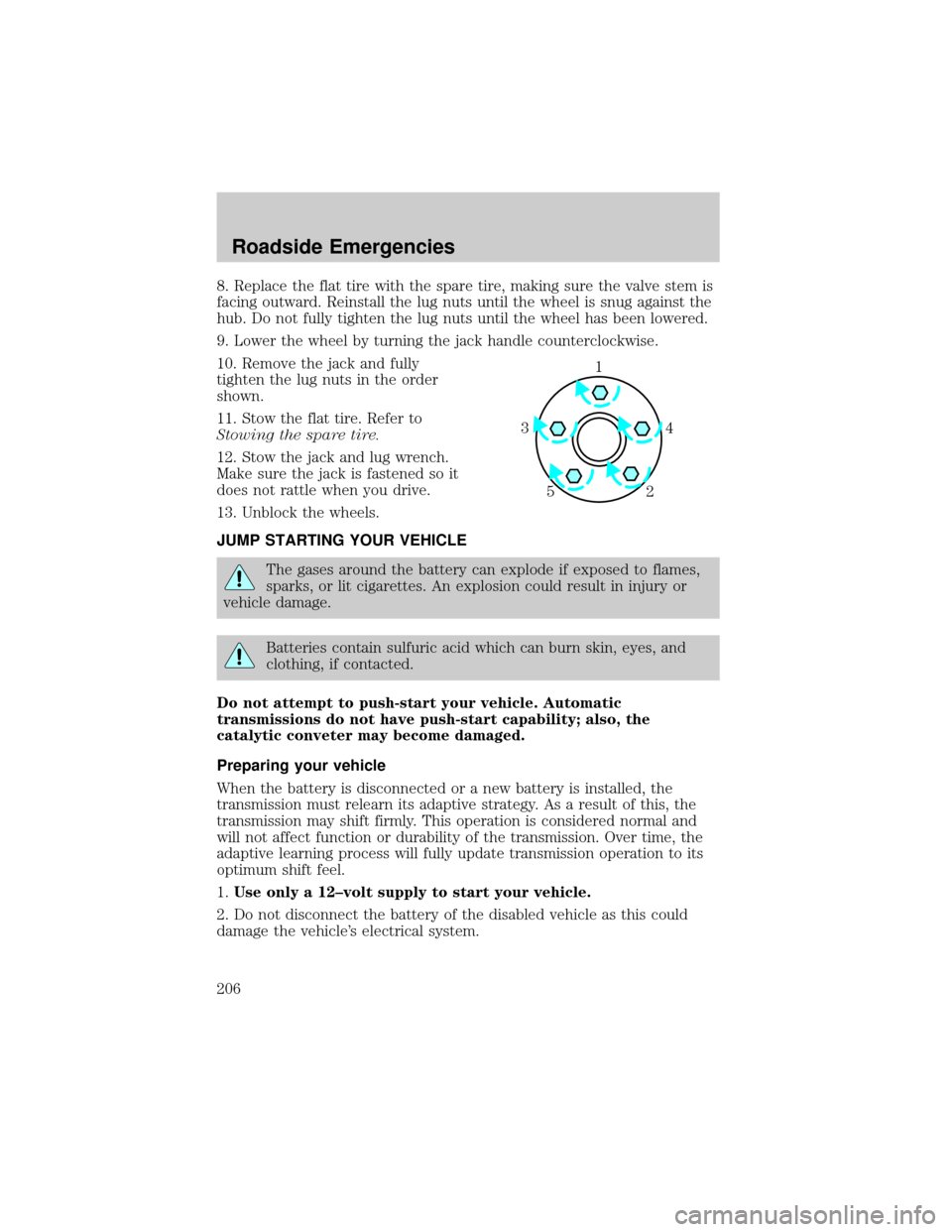

10. Remove the jack and fully

tighten the lug nuts in the order

shown.

11. Stow the flat tire. Refer to

Stowing the spare tire.

12. Stow the jack and lug wrench.

Make sure the jack is fastened so it

does not rattle when you drive.

13. Unblock the wheels.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes, and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic conveter may become damaged.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its adaptive strategy. As a result of this, the

transmission may shift firmly. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation to its

optimum shift feel.

1.Use only a 12±volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle's electrical system.

1

4 3

2 5

Roadside Emergencies

206

Page 239 of 288

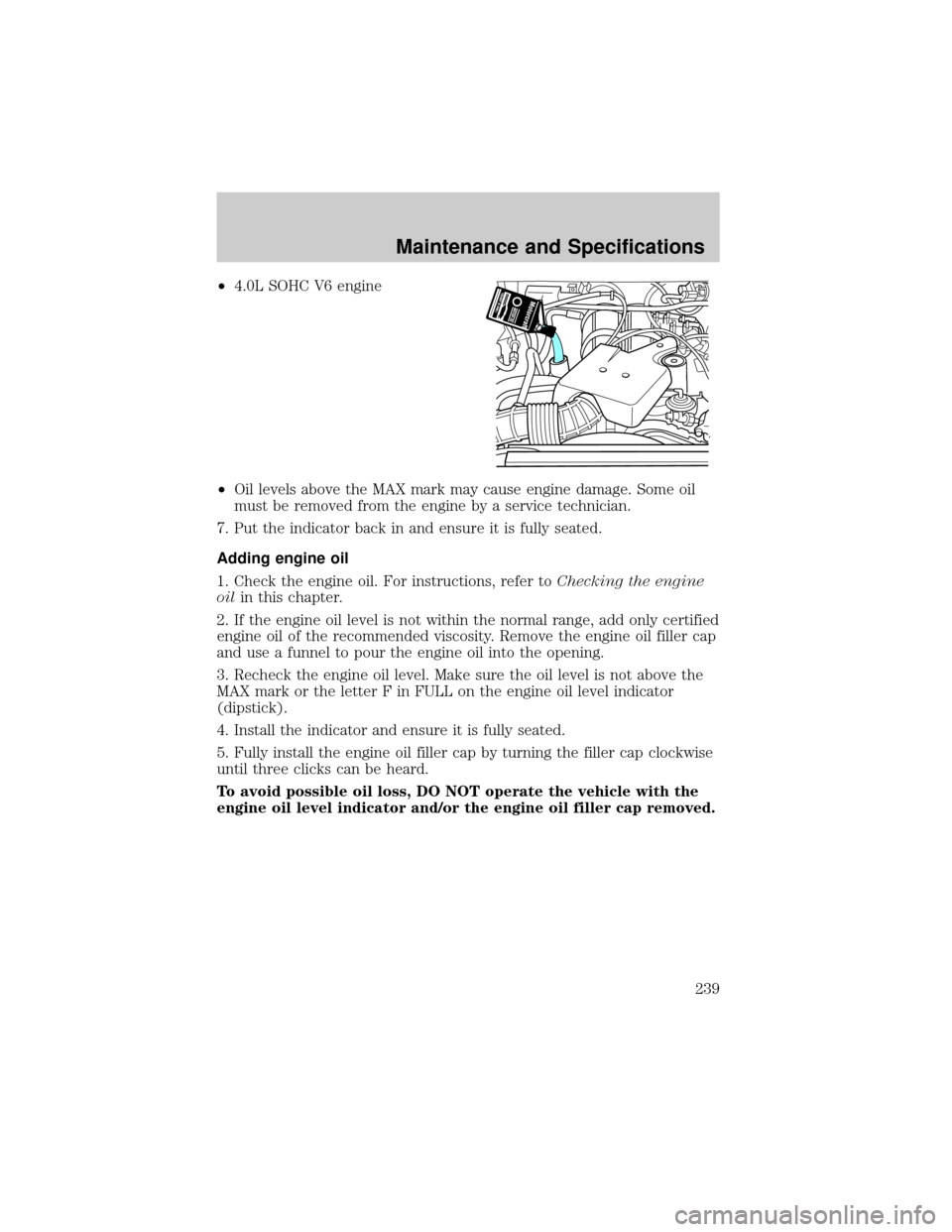

²4.0L SOHC V6 engine

²Oil levels above the MAX mark may cause engine damage. Some oil

must be removed from the engine by a service technician.

7. Put the indicator back in and ensure it is fully seated.

Adding engine oil

1. Check the engine oil. For instructions, refer toChecking the engine

oilin this chapter.

2. If the engine oil level is not within the normal range, add only certified

engine oil of the recommended viscosity. Remove the engine oil filler cap

and use a funnel to pour the engine oil into the opening.

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark or the letter F in FULL on the engine oil level indicator

(dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

until three clicks can be heard.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Maintenance and Specifications

239