FORD SIERRA 1982 1.G Braking System Owner's Manual

Manufacturer: FORD, Model Year: 1982, Model line: SIERRA, Model: FORD SIERRA 1982 1.GPages: 22, PDF Size: 1.11 MB

Page 21 of 22

Note: Where fitted, the adjuster locking pin

must be renewed on completion of

adjustment.

Conventional braking system

(except P100 models)

1The handbrake cable is normally

self-adjusting in use, however adjustment

may be required to compensate for cable

stretch over a long period, and is also

necessary after fitting a new cable.

2Chock the front wheels, jack up the rear of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Release the

handbrake.

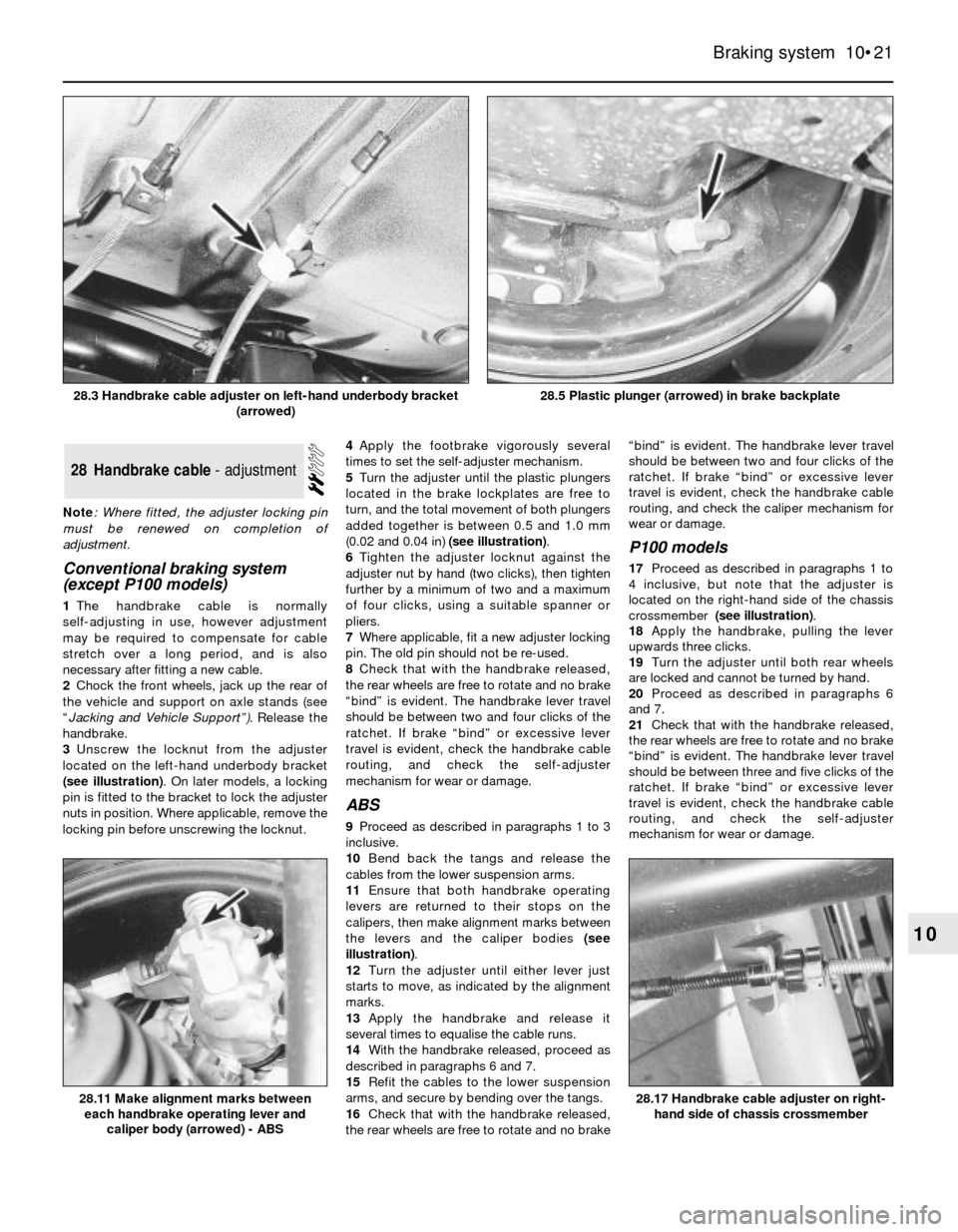

3Unscrew the locknut from the adjuster

located on the left-hand underbody bracket

(see illustration). On later models, a locking

pin is fitted to the bracket to lock the adjuster

nuts in position. Where applicable, remove the

locking pin before unscrewing the locknut.4Apply the footbrake vigorously several

times to set the self-adjuster mechanism.

5Turn the adjuster until the plastic plungers

located in the brake lockplates are free to

turn, and the total movement of both plungers

added together is between 0.5 and 1.0 mm

(0.02 and 0.04 in) (see illustration).

6Tighten the adjuster locknut against the

adjuster nut by hand (two clicks), then tighten

further by a minimum of two and a maximum

of four clicks, using a suitable spanner or

pliers.

7Where applicable, fit a new adjuster locking

pin. The old pin should not be re-used.

8Check that with the handbrake released,

the rear wheels are free to rotate and no brake

“bind” is evident. The handbrake lever travel

should be between two and four clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the self-adjuster

mechanism for wear or damage.

ABS

9Proceed as described in paragraphs 1 to 3

inclusive.

10Bend back the tangs and release the

cables from the lower suspension arms.

11Ensure that both handbrake operating

levers are returned to their stops on the

calipers, then make alignment marks between

the levers and the caliper bodies (see

illustration).

12Turn the adjuster until either lever just

starts to move, as indicated by the alignment

marks.

13Apply the handbrake and release it

several times to equalise the cable runs.

14With the handbrake released, proceed as

described in paragraphs 6 and 7.

15Refit the cables to the lower suspension

arms, and secure by bending over the tangs.

16Check that with the handbrake released,

the rear wheels are free to rotate and no brake“bind” is evident. The handbrake lever travel

should be between two and four clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the caliper mechanism for

wear or damage.

P100 models

17Proceed as described in paragraphs 1 to

4 inclusive, but note that the adjuster is

located on the right-hand side of the chassis

crossmember (see illustration).

18Apply the handbrake, pulling the lever

upwards three clicks.

19Turn the adjuster until both rear wheels

are locked and cannot be turned by hand.

20Proceed as described in paragraphs 6

and 7.

21Check that with the handbrake released,

the rear wheels are free to rotate and no brake

“bind” is evident. The handbrake lever travel

should be between three and five clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the self-adjuster

mechanism for wear or damage.

28Handbrake cable - adjustment

Braking system 10•21

10

28.5 Plastic plunger (arrowed) in brake backplate

28.17 Handbrake cable adjuster on right-

hand side of chassis crossmember28.11 Make alignment marks between

each handbrake operating lever and

caliper body (arrowed) - ABS

28.3 Handbrake cable adjuster on left-hand underbody bracket

(arrowed)

Page 22 of 22

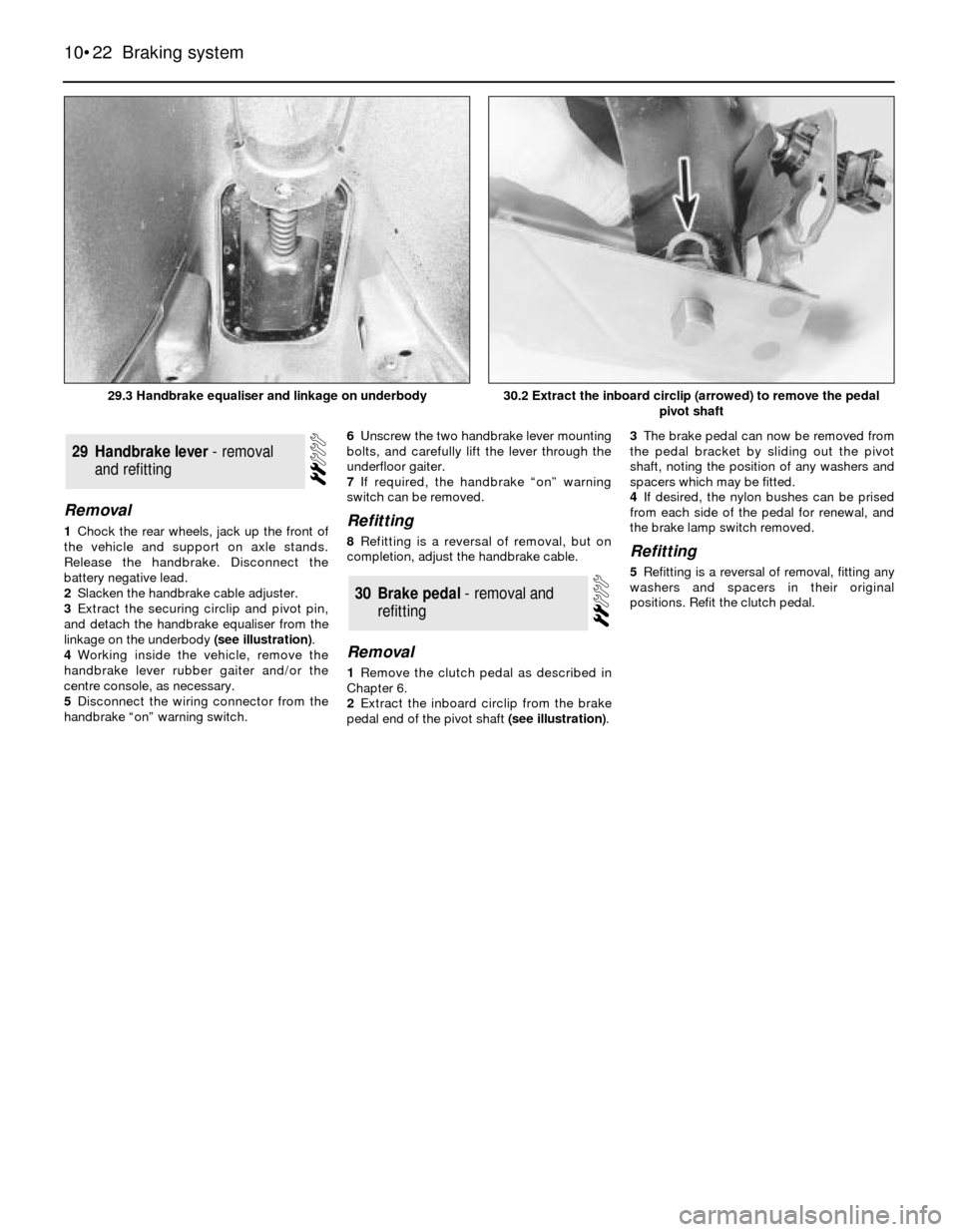

Removal

1Chock the rear wheels, jack up the front of

the vehicle and support on axle stands.

Release the handbrake. Disconnect the

battery negative lead.

2Slacken the handbrake cable adjuster.

3Extract the securing circlip and pivot pin,

and detach the handbrake equaliser from the

linkage on the underbody (see illustration).

4Working inside the vehicle, remove the

handbrake lever rubber gaiter and/or the

centre console, as necessary.

5Disconnect the wiring connector from the

handbrake “on” warning switch. 6Unscrew the two handbrake lever mounting

bolts, and carefully lift the lever through the

underfloor gaiter.

7If required, the handbrake “on” warning

switch can be removed.Refitting

8Refitting is a reversal of removal, but on

completion, adjust the handbrake cable.

Removal

1Remove the clutch pedal as described in

Chapter 6.

2Extract the inboard circlip from the brake

pedal end of the pivot shaft (see illustration).3The brake pedal can now be removed from

the pedal bracket by sliding out the pivot

shaft, noting the position of any washers and

spacers which may be fitted.

4If desired, the nylon bushes can be prised

from each side of the pedal for renewal, and

the brake lamp switch removed.

Refitting

5Refitting is a reversal of removal, fitting any

washers and spacers in their original

positions. Refit the clutch pedal.

30Brake pedal - removal and

refitting

29Handbrake lever -removal

andrefitting

10•22Braking system

29.3 Handbrake equaliser and linkage on underbody30.2 Extract the inboard circlip (arrowed) to remove the pedal

pivot shaft