gas type FORD SIERRA 1982 1.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1982, Model line: SIERRA, Model: FORD SIERRA 1982 1.GPages: 26, PDF Size: 0.57 MB

Page 10 of 26

REF•10MOTtest checks

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test

can be carried out later to check that the

vehicle pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-

bearing areas. (These include chassis box

sections, side sills, cross-members, pillars,

and all suspension, steering, braking system

and seat belt mountings and anchorages.)

Any corrosion which has seriously reduced

the thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allow

the engine speed to return to idle, and watchfor smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000

rpm; if the HC level is then 1200 ppm or less,

this counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

Page 13 of 26

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

MFuel injection system fault (Chapter 4).

Engine lacks power

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MUneven or low cylinder compressions (Chapter 2).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

MBrakes binding (Chapters 1 and 10).

MClutch slipping (Chapter 6).

Engine backfires

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

Oil pressure warning light illuminated with engine

running

MLow oil level, or incorrect oil grade (Chapter 1).

MFaulty oil pressure sensor (Chapter 2).

MWorn engine bearings and/or oil pump (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

MOil pressure relief valve defective (Chapter 2).

MOil pick-up strainer clogged (Chapter 2).

Note:Low oil pressure in a high-mileage engine at tickover is not

necessarily a cause for concern. Sudden pressure loss at speed is far

more significant. In any event, check the gauge or warning light sender

before condemning the engine.

Engine runs-on after switching off

MExcessive carbon build-up in engine (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

Engine noises

Pre-ignition (pinking) or knocking during acceleration or

under load

MIgnition timing incorrect/ignition system fault (Chapters 1 and 5).

MIncorrect grade of spark plug (Chapter 1).

MIncorrect grade of fuel (Chapter 1).

MVacuum leak at throttle body, inlet manifold or associated hoses

(Chapter 4).

MExcessive carbon build-up in engine (Chapter 2).

MFuel injection system fault (Chapter 4).

Whistling or wheezing noises

MLeaking inlet manifold or throttle body gasket (Chapter 4).

MLeaking exhaust manifold gasket (Chapter 4).

MLeaking vacuum hose (Chapters 4 and 10).

MBlowing cylinder head gasket (Chapter 2).

Tapping or rattling noises

MWorn valve gear, timing chain, camshaft or hydraulic tappets

(Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Knocking or thumping noises

MWorn big-end bearings (regular heavy knocking, perhaps less

under load) (Chapter 2).

MWorn main bearings (rumbling and knocking, perhaps worsening

under load) (Chapter 2).

MPiston slap (most noticeable when cold) (Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Overheating

MAuxiliary drivebelt broken or incorrectly adjusted (Chapter 1).

MInsufficient coolant in system (Chapter 1).

MThermostat faulty (Chapter 3).

MRadiator core blocked, or grille restricted (Chapter 3).

MElectric cooling fan or thermostatic switch faulty (Chapter 3).

MViscous-coupled fan faulty (Chapter 3).

MIgnition timing incorrect, or ignition system fault (Chapters 1 and 5).

MInaccurate temperature gauge sender unit (Chapter 3).

MAirlock in cooling system (Chapter 3).

Overcooling

MThermostat faulty (Chapter 3).

MInaccurate temperature gauge sender unit (Chapter 3).

External coolant leakage

MDeteriorated or damaged hoses or hose clips (Chapter 1).

MRadiator core or heater matrix leaking (Chapter 3).

MPressure cap faulty (Chapter 3).

MWater pump internal seal leaking (Chapter 3).

MWater pump-to-block seal leaking (Chapter 3).

MBoiling due to overheating (Chapter 3).

MCore plug leaking (Chapter 2).

Internal coolant leakage

MLeaking cylinder head gasket (Chapter 2).

MCracked cylinder head or cylinder block (Chapter 2).

Corrosion

MInfrequent draining and flushing (Chapter 1).

MIncorrect coolant mixture or inappropriate coolant type (Chapter 1).

Fault diagnosisREF•13

REF

Cooling system

Excessive fuel consumption

MAir filter element dirty or clogged (Chapter 1).

MFuel injection system fault (Chapter 4).

MIgnition timing incorrect or ignition system fault (Chapters 1 and 5).

MBrakes binding (Chapter 10).

MTyres under-inflated (Chapter 1).

Fuel leakage and/or fuel odour

MDamaged fuel tank, pipes or connections (Chapters 1 and 4).

Excessive noise or fumes from exhaust system

MLeaking exhaust system or manifold joints (Chapters 1 and 4).

MLeaking, corroded or damaged silencers or pipe (Chapters 1 and 4).

MBroken mountings causing body or suspension contact (Chapter 4).

Fuel and exhaust systems

Page 19 of 26

Glossary of Technical termsREF•19

REF

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

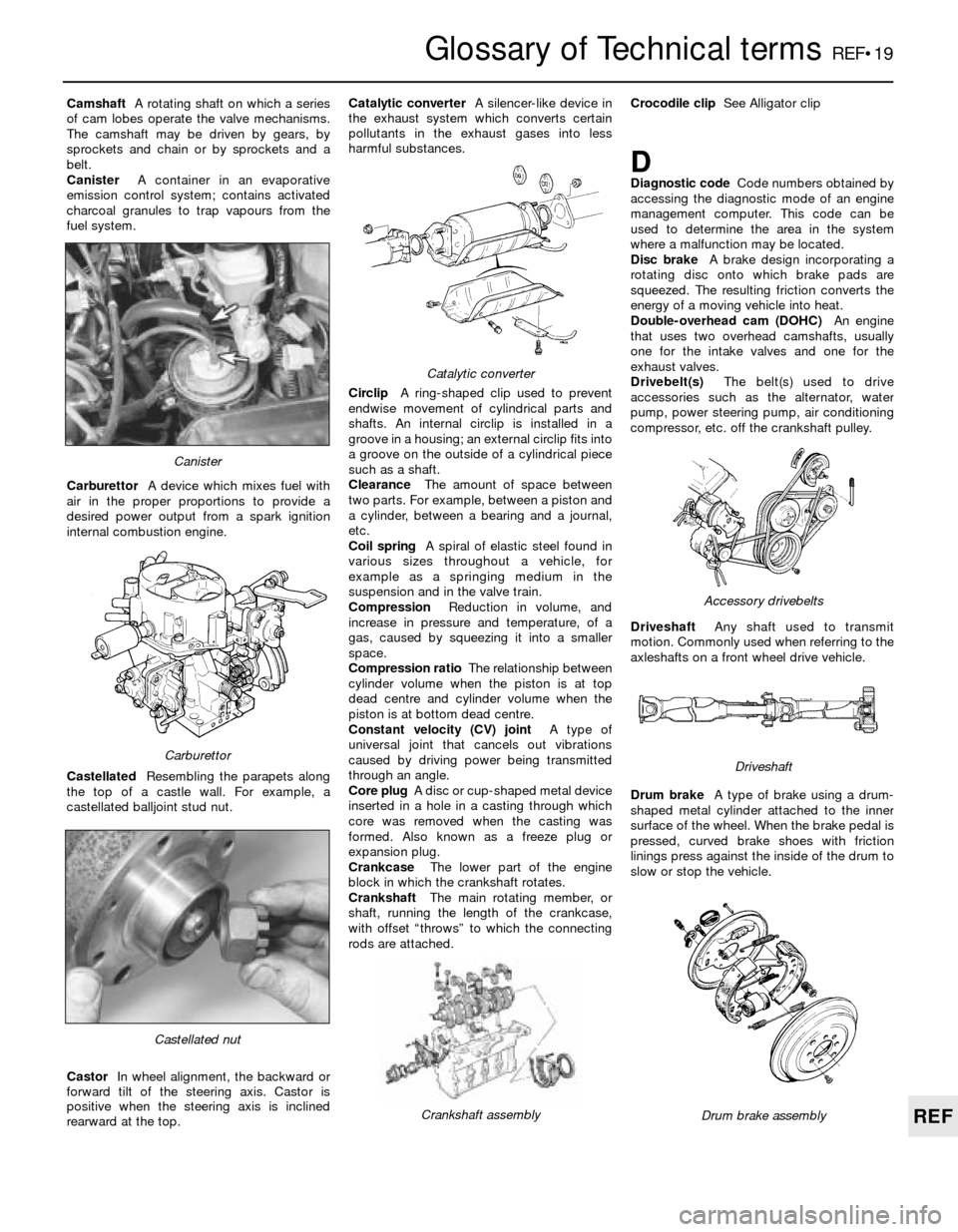

rearward at the top.Catalytic converterA silencer-like device in

the exhaust system which converts certain

pollutants in the exhaust gases into less

harmful substances.

CirclipA ring-shaped clip used to prevent

endwise movement of cylindrical parts and

shafts. An internal circlip is installed in a

groove in a housing; an external circlip fits into

a groove on the outside of a cylindrical piece

such as a shaft.

ClearanceThe amount of space between

two parts. For example, between a piston and

a cylinder, between a bearing and a journal,

etc.

Coil springA spiral of elastic steel found in

various sizes throughout a vehicle, for

example as a springing medium in the

suspension and in the valve train.

CompressionReduction in volume, and

increase in pressure and temperature, of a

gas, caused by squeezing it into a smaller

space.

Compression ratioThe relationship between

cylinder volume when the piston is at top

dead centre and cylinder volume when the

piston is at bottom dead centre.

Constant velocity (CV) jointA type of

universal joint that cancels out vibrations

caused by driving power being transmitted

through an angle.

Core plugA disc or cup-shaped metal device

inserted in a hole in a casting through which

core was removed when the casting was

formed. Also known as a freeze plug or

expansion plug.

CrankcaseThe lower part of the engine

block in which the crankshaft rotates.

CrankshaftThe main rotating member, or

shaft, running the length of the crankcase,

with offset “throws” to which the connecting

rods are attached.Crocodile clipSee Alligator clip

DDiagnostic codeCode numbers obtained by

accessing the diagnostic mode of an engine

management computer. This code can be

used to determine the area in the system

where a malfunction may be located.

Disc brakeA brake design incorporating a

rotating disc onto which brake pads are

squeezed. The resulting friction converts the

energy of a moving vehicle into heat.

Double-overhead cam (DOHC)An engine

that uses two overhead camshafts, usually

one for the intake valves and one for the

exhaust valves.

Drivebelt(s)The belt(s) used to drive

accessories such as the alternator, water

pump, power steering pump, air conditioning

compressor, etc. off the crankshaft pulley.

DriveshaftAny shaft used to transmit

motion. Commonly used when referring to the

axleshafts on a front wheel drive vehicle.

Drum brakeA type of brake using a drum-

shaped metal cylinder attached to the inner

surface of the wheel. When the brake pedal is

pressed, curved brake shoes with friction

linings press against the inside of the drum to

slow or stop the vehicle.

Castellated nut

Catalytic converter

Crankshaft assembly

Carburettor

Canister

Drum brake assembly

Accessory drivebelts

Driveshaft

Page 20 of 26

REF•20Glossary of Technical terms

EEGR valveA valve used to introduce exhaust

gases into the intake air stream.

Electronic control unit (ECU)A computer

which controls (for instance) ignition and fuel

injection systems, or an anti-lock braking

system. For more information refer to the

Haynes Automotive Electrical and Electronic

Systems Manual.

Electronic Fuel Injection (EFI)A computer

controlled fuel system that distributes fuel

through an injector located in each intake port

of the engine.

Emergency brakeA braking system,

independent of the main hydraulic system,

that can be used to slow or stop the vehicle if

the primary brakes fail, or to hold the vehicle

stationary even though the brake pedal isn’t

depressed. It usually consists of a hand lever

that actuates either front or rear brakes

mechanically through a series of cables and

linkages. Also known as a handbrake or

parking brake.

EndfloatThe amount of lengthwise

movement between two parts. As applied to a

crankshaft, the distance that the crankshaft

can move forward and back in the cylinder

block.

Engine management system (EMS)A

computer controlled system which manages

the fuel injection and the ignition systems in

an integrated fashion.

Exhaust manifoldA part with several

passages through which exhaust gases leave

the engine combustion chambers and enter

the exhaust pipe.

FFan clutchA viscous (fluid) drive coupling

device which permits variable engine fan

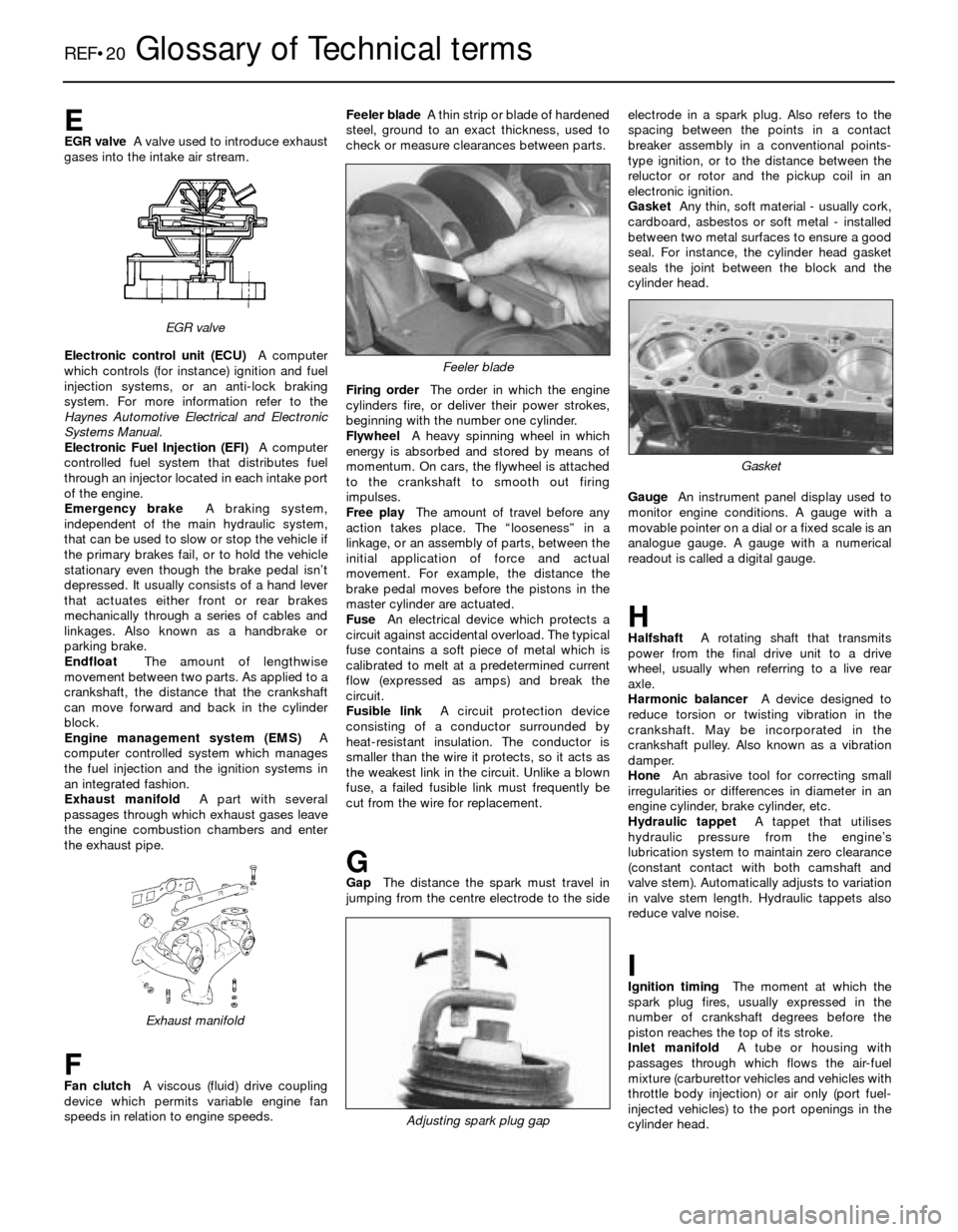

speeds in relation to engine speeds.Feeler bladeA thin strip or blade of hardened

steel, ground to an exact thickness, used to

check or measure clearances between parts.

Firing orderThe order in which the engine

cylinders fire, or deliver their power strokes,

beginning with the number one cylinder.

Flywheel A heavy spinning wheel in which

energy is absorbed and stored by means of

momentum. On cars, the flywheel is attached

to the crankshaft to smooth out firing

impulses.

Free playThe amount of travel before any

action takes place. The “looseness” in a

linkage, or an assembly of parts, between the

initial application of force and actual

movement. For example, the distance the

brake pedal moves before the pistons in the

master cylinder are actuated.

FuseAn electrical device which protects a

circuit against accidental overload. The typical

fuse contains a soft piece of metal which is

calibrated to melt at a predetermined current

flow (expressed as amps) and break the

circuit.

Fusible linkA circuit protection device

consisting of a conductor surrounded by

heat-resistant insulation. The conductor is

smaller than the wire it protects, so it acts as

the weakest link in the circuit. Unlike a blown

fuse, a failed fusible link must frequently be

cut from the wire for replacement.

GGapThe distance the spark must travel in

jumping from the centre electrode to the sideelectrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

Exhaust manifold

Feeler blade

Adjusting spark plug gap

Gasket

EGR valve

Page 21 of 26

Glossary of Technical termsREF•21

REF

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).

Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful tothe ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.

SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

O-ring

Serpentine drivebelt

Plastigage

Page 24 of 26

refitting - 2A•10, 2B•7, 2C•9

removal - 2A•8, 2B•4, 2C•6

SOHC engines- 2A•1et seq

spark plugs - 1•2, 1•14, 5•12

sump - 2A•20, 2B•15, 2C•19

timing belt/chain and sprockets - 2A•12,

2B•8, 2C•10

timing and sprockets - 2A•12, 2B•8, 2C•10

valves - 1•15

Engine electrical systems - 5•1 et seq

Environmental considerations- REF•4

Exhaust gas oxygen sensor (HEGO)- 4B•15

Exhaust gas recirculation valve- 4B•14

Exhaust manifold- 4A•17, 4B•15

Exhaust pressure transducer- 4B•14

Exhaust system- 1•11, 4A•18, 4B•15

Expansion tank/coolant sensor- 3•8

FFacia panel- 12•16

Facia panel switches- 13•4

Fan (radiator)- 3•7

Fault diagnosis- REF•11

automatic transmission - REF•14

braking system - REF•15

clutch - REF•14

cooling system - REF•13

driveshafts - REF•15

electrical system - REF•16

engine - REF•12

final drive - REF•15

fuel and exhaust systems - REF•13

manual gearbox - REF•14

propeller shaft - REF•15

steering - REF•16

suspension - REF•16

Final drive and driveshafts- 9•1 et seq

Final drive fault diagnosis- REF•11, REF•15

Final drive unit- 9•2, 9•3, 9•4

Fluids- 0•17

Flywheel/driveplate- 2A•18, 2B•15, 2C•19

Foglamps- 13•15

Ford VV carburettor- 1•12, 4A•13

Front suspension crossmember- 11•3

Front suspension strut- 11•4

Fuel systems- carburettor - 4A•1 et seq

Fuel systems- fuel injection - 4B•1 et seq

Fuel system:

accelerator cable - 4A•8

accelerator pedal - 4A•8

air cleaner - 1•18, 1•19, 4A•4, 4B•4

airflow meter - 4B•8

catalytic converter - 4B•3, 4B•14

CFI unit- 4B•10

depressurising fuel injection system - 4B•4

dismantling and reassembly - 4A•8

electronic vacuum regulator - 4B•11

exhaust gas recirculation valve - 4B•14

exhaust gas oxygen sensor (HEGO) - 4B•15

exhaust manifold - 4A•17, 4B•15

exhaust pressure transducer - 4B•14

exhaust system - 4A•18, 4B•15

fuel filler cap - 12•14

fuel filter - 1•2, 1•20

fuel level sender unit - 4A•7, 4B•7fuel pressure regulator - 4A•5, 4B•5

fuel pump - 4A•5, 4A•6, 4B•6

fuel tank - 4A•7

fuel vapour separator - 4A•5

fuel gauges - 13•8

idle speed control valve - 4B•7

injector(s) - 4B•8

inlet manifold - 4A•15, 4B•12

mixture adjustment potentiometer - 4B•7

pulse-air - 4B•10

throttle body - 4B•12

throttle control motor - 4B•11

throttle position sensor - 4B•11

throttle valve control motor - 4B•11

Fuses- 13•3

GGear linkage- 7A•4

Gear selector mechanism- 7B•5

Gearbox - see Manual gearbox or

Automatic transmission

Gearbox oil- 0•17, 1•3

Glass- 12•11

HHandbrake check/adjustment- 1•16, 10•21

Handbrake cables- 10•20, 10•21

Handbrake lever - 10•22

Handbrake warning lamp switch- 13•6

Handles (door)- 12•9

Hazard warning flasher switch- 13•4

Headlamp alignment- 13•14

Headlamp unit- 13•13

Headlamp washers- 13•12

Headlining - 12•19

Heated rear window- 13•20

Heated seat- 13•19

Heater- 3•9

Hinges and locks- 1•14

Horn- 13•11

Horn switch- 13•5

Hose and fluid leak check- 0•8, 1•10,

Hoses brake- 10•19

Hoses power steering- 11•18

HT coil- 5•13

HT leads- 5•12

Hub carrier (front) - 11•5

Hydraulic fluid- 0•17

Hydraulic system (brakes) bleeding- 10•2

Hydraulic unit, pump, motor (ABS)- 10•15,

10•16

IIdle speed control valve- 4B•7

Idle speed/mixture- 1•11, 1•12, see

Specifications in Chapter 4A, and refer to

specific carburettor type

Ignition electronic modules- 5•3, 5•19

Ignition HT coil- 5•13

Ignition switch- 13•4

Ignition system check- 1•20

Ignition timing adjustment- 5•17

Indicator lamps- 13•15Indicator switch/relay- 13•4

Injector(s)- 4B•8

Inlet manifold- 4A•15, 4B•12

Instrument panel- 13•7

Interior trim- 12•15

Introduction to the Ford Sierra- 0•4

JJacking and vehicle support- 0•6

Jump starting- 0•9

KKickdown cable - 7B•3

LLeaf springs- 11•13

Leak, checking- 0•8, 1•10

Lights- 13•14

Locks:

bootlid - 12•5

door - 12•9, 12•10

tailgate - 12•6

Loudspeakers- 13•20

Lower arm (suspension)- 11•4, 11•7, 11•8

Lubricants and fluids- 0•17

Luggage area light switch- 13•5

MMain bearings- 2A•23, 2B•17, 2C•23

Maintenance and servicing - see Routine

maintenance

Manifolds- 4A•15, 4A•17, 4B•12, 4B•15

Manual gearbox- 7A•1 et seq

fault diagnosis - REF•11, REF•14

gear linkage - 7A•4

gearbox oil - 0•17, 1•3

oil level check - 1•13

removal and refitting - 7A•2

Master cylinder (brake)- 10•13

Mirrors- 12•12

Mixture (CO)- see Idle speed/mixture

Mixture adjustment potentiometer- 4B•7

MOT test checks- REF•7

Mountings, engine-2A•11, 2B•7, 2C•9

NNumber plate lamp- 13•16

OOil change/filter- 1•1, 1•9,

Oil pressure warning switch- 13•6

Oil pump- 2A•21, 2B•16, 2C•20

Oil seals- REF •4

Oil seals crankshaft- 2A•19, 2B•15, 2C•19

Oils- engine and gearbox- 0•17, 1•3

PPads (brake) - 10•3

Paintwork damage- 12•2

Parts- REF•3

REF•24Index