wiring FORD SIERRA 1983 1.G Braking System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 22, PDF Size: 1.11 MB

Page 3 of 22

8Open the bleed screw half a turn and have

your assistant depress the brake pedal slowly

to the floor and then, after the bleed screw is

retightened, quickly remove his foot to allow

the pedal to return unimpeded. Repeat the

procedure.

9Observe the submerged end of the tube in

the jar. When air bubbles cease to appear,

tighten the bleed screw when the pedal is

being held fully down by your assistant.

10Top-up the fluid reservoir. It must be kept

topped up throughout the bleeding

operations. If the connecting holes to the

master cylinder are exposed at any time due

to low fluid level, then air will be drawn into

the system and work will have to start all over

again.

11Assuming that the complete system is

being bled, the procedure described in the

preceding paragraphs should be repeated on

the front right-hand caliper followed by the

rear right-hand and left-hand wheel cylinders.

12On completion, remove the bleed tube,

and discard the fluid which has been bled

from the system unless it is required for bleed

jar purposes. Never re-use old fluid.

13On completion of bleeding, top-up the

fluid level in the reservoir. Check the action of

the brake pedal, which should be firm and free

from any “sponginess” which would indicate

that air is still present in the system.

With one-way valve

14There are a number of one-man brake

bleeding kits currently available from motor

accessory shops. It is recommended that one

of these kits should be used whenever

possible, as they greatly simplify the bleeding

operation and also reduce the risk of expelled

air or fluid being drawn back into the system.

15Proceed as described in paragraphs 5

and 6.

16Open the bleed screw half a turn then

depress the brake pedal to the floor and

slowly release it. The one-way valve in the

bleeder device will prevent expelled air from

returning to the system at the completion of

each stroke. Repeat this operation until clear

hydraulic fluid, free from air bubbles, can be

seen coming through the tube. Tighten the

bleed screw.

17Proceed as shown in paragraphs 11 to 13.

With pressure bleeding kit

18These too are available from motor

accessory shops and are usually operated by

air pressure from the spare tyre.

19By connecting a pressurised container to

the master cylinder fluid reservoir, bleeding is

then carried out by simply opening each bleed

screw in turn and allowing the fluid to run out,

rather like turning on a tap, until no air bubbles

are visible in the fluid being expelled.

20Using this system, the large reserve of

fluid provides a safeguard against air being

drawn into the master cylinder during the

bleeding operations.21This method is particularly effective when

bleeding “difficult” systems or when bleeding

the entire system at time of routine fluid

renewal.

22Begin bleeding with reference to

paragraphs 5 and 6 and proceed as described

in paragraphs 11 to 13.

1Keep the fluid reservoir replenished

throughout the bleeding operations.

2Remove the dust cap where fitted, and

clean around the bleed screw on the left-hand

front caliper. Fit a bleed tube to the screw and

immerse the open end in a jar containing

clean hydraulic fluid.

3Open the bleed valve one full turn and have

an assistant depress the brake pedal fully and

hold it down.

4Close the bleed valve and release the brake

pedal. Repeat the procedure until fluid ejected

from the end of the tube is free from air

bubbles.

5Repeat the operations on the right-hand

front caliper.

6Fit the bleed tube to the left-hand rear

caliper and open the bleed valve one full turn.

7Have an assistant depress the brake pedal

fully and hold it down.

8Switch on the ignition to position ll.

9Allow the fluid to bleed from the tube for at

least 15 seconds, when the fluid should be

free from air bubbles.

10Close the bleed valve.

11Release the brake pedal and wait for the

hydraulic pump to stop.

12Fit the bleed tube to the right-hand rear

caliper and open the bleed valve one full turn.

13Have your assistant depress the brake

pedal through half its travel and hold it there.

Allow the fluid to bleed from the tube for at

least 15 seconds, when the fluid should be

free from air bubbles.

14Close the bleed valve.

15Release the brake pedal and wait for the

hydraulic pump to stop then switch off the

ignition.

16Top-up the reservoir with clean fluid.

17When the hydraulic system is being bled

for the purpose of renewing the fluid at the

specified interval, as each caliper is bled,

operate the brake pedal continuously until

clean fluid is seen to enter the jar.

18When the hydraulic pump is running its

note will be heard to change once fluid has

purged through it. Do not allow the pump torun continuously for more than two minutes. If

it does run for a longer period, switch off the

ignition and allow the motor to cool for ten

minutes.

19On completion, discard the fluid which

has been bled from the system unless it is

required for bleed jar purposes. Never re-use

old fluid.

20Check the action of the brake pedal,

which should be firm and free from any

“sponginess”, which would indicate that air is

still present in the system.

Front disc pads

1The disc pad friction material can be

inspected for wear without removing the

roadwheels. Working beneath the vehicle,

insert a mirror between the caliper and the

roadwheel and check that the friction material

thickness is not less than the minimum given

in the Specifications.

2If any one of the pads has worn below the

specified limit, the front pads must be

renewed as an axle set (4 pads).

3To renew the pads, slacken the front

roadwheel nuts, apply the handbrake, then

jack up the front of the vehicle and support on

axle stands (see “Jacking and Vehicle

Support”). Remove the roadwheels. On P100

models, mark the position of the roadwheels

in relation to the wheel studs before removal.

4Proceed as follows according to model:

Girling caliper (1.3 and early 1.6 litre

models)

5Where applicable, disconnect the wiring to

the disc pad wear sensor.

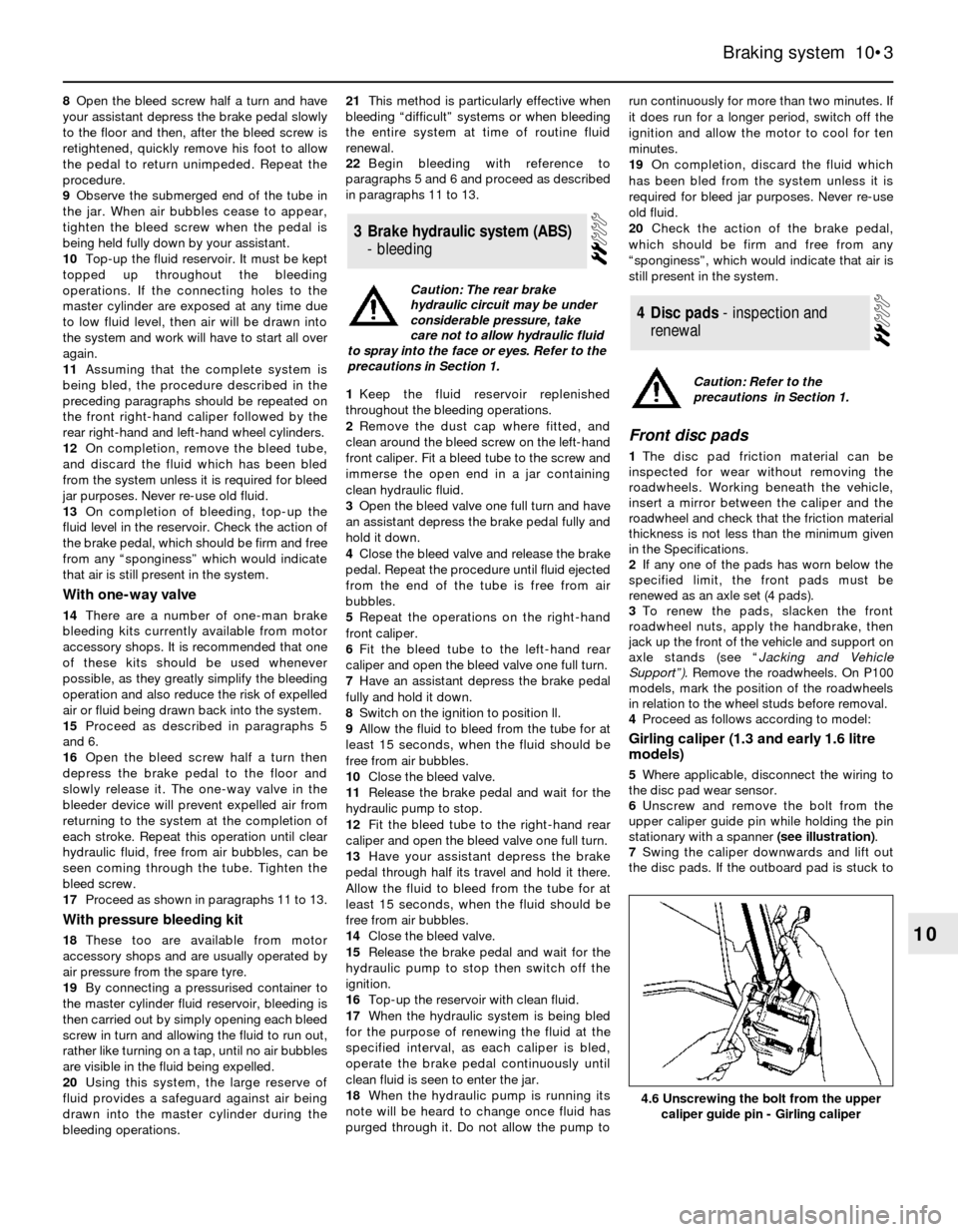

6Unscrew and remove the bolt from the

upper caliper guide pin while holding the pin

stationary with a spanner (see illustration).

7Swing the caliper downwards and lift out

the disc pads. If the outboard pad is stuck to

4Disc pads -inspectionand

renewal

3Brake hydraulic system (ABS)

- bleeding

Braking system 10•3

10

4.6 Unscrewing the bolt from the upper

caliper guide pin - Girling caliper

Caution: Refer to the

precautions in Section 1.

Caution: The rear brake

hydraulic circuit may be under

considerable pressure, take

care not to allow hydraulic fluid

to spray into the face or eyes. Refer to the

precautions in Section 1.

Page 4 of 22

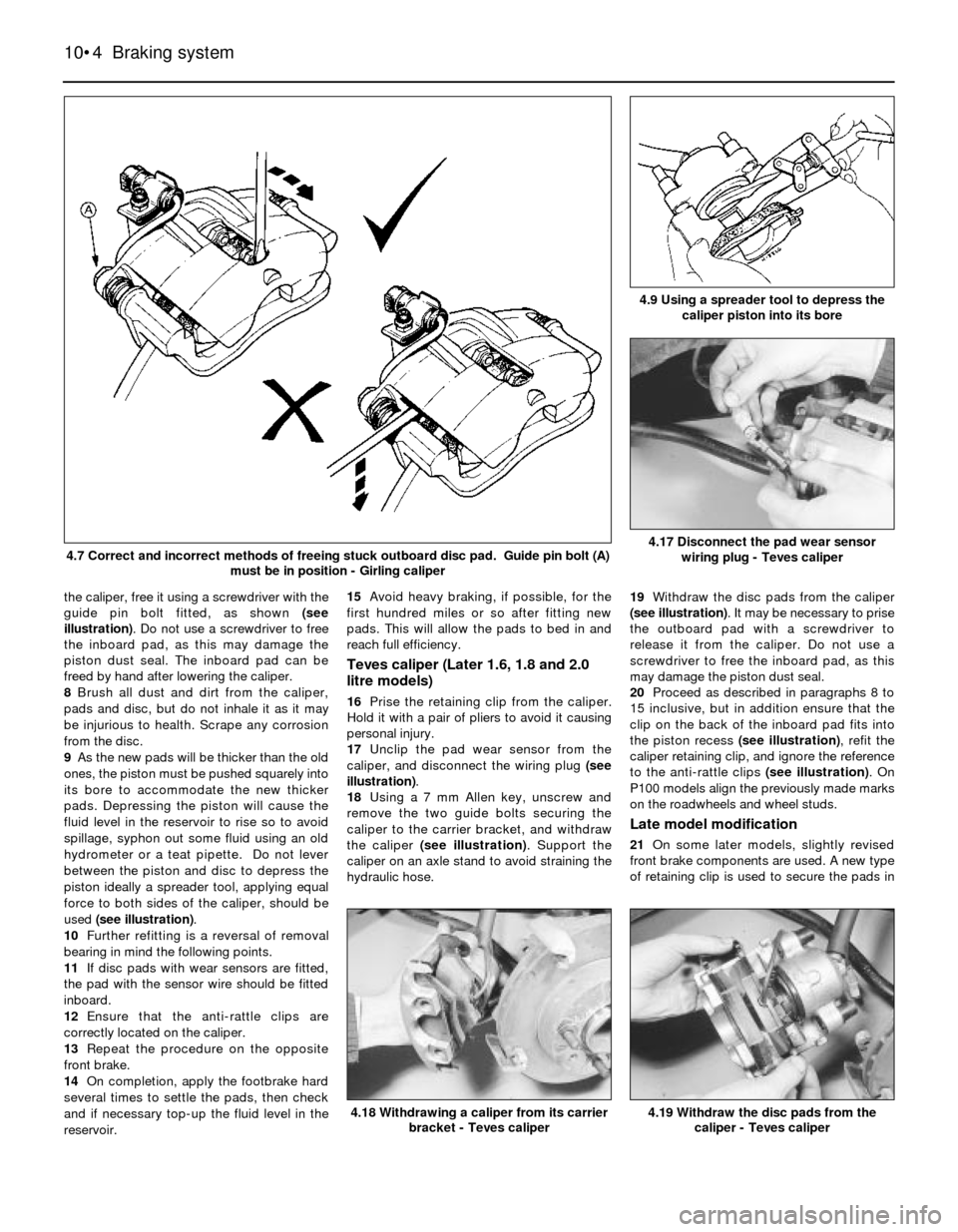

the caliper, free it using a screwdriver with the

guide pin bolt fitted, as shown (see

illustration). Do not use a screwdriver to free

the inboard pad, as this may damage the

piston dust seal. The inboard pad can be

freed by hand after lowering the caliper.

8Brush all dust and dirt from the caliper,

pads and disc, but do not inhale it as it may

be injurious to health. Scrape any corrosion

from the disc.

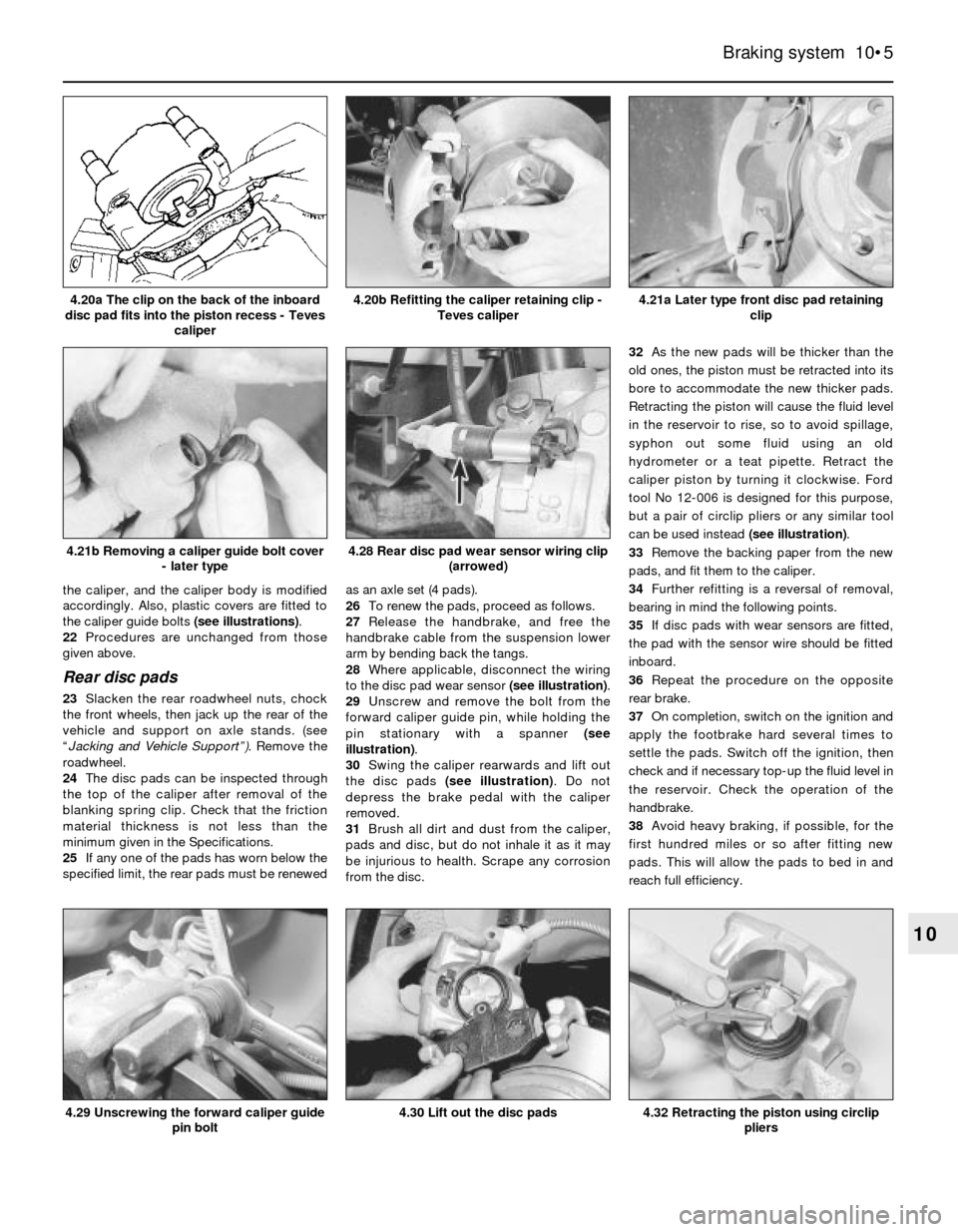

9As the new pads will be thicker than the old

ones, the piston must be pushed squarely into

its bore to accommodate the new thicker

pads. Depressing the piston will cause the

fluid level in the reservoir to rise so to avoid

spillage, syphon out some fluid using an old

hydrometer or a teat pipette. Do not lever

between the piston and disc to depress the

piston ideally a spreader tool, applying equal

force to both sides of the caliper, should be

used (see illustration).

10Further refitting is a reversal of removal

bearing in mind the following points.

11If disc pads with wear sensors are fitted,

the pad with the sensor wire should be fitted

inboard.

12Ensure that the anti-rattle clips are

correctly located on the caliper.

13Repeat the procedure on the opposite

front brake.

14On completion, apply the footbrake hard

several times to settle the pads, then check

and if necessary top-up the fluid level in the

reservoir. 15Avoid heavy braking, if possible, for the

first hundred miles or so after fitting new

pads. This will allow the pads to bed in and

reach full efficiency.

Teves caliper (Later 1.6, 1.8 and 2.0

litre models)

16Prise the retaining clip from the caliper.

Hold it with a pair of pliers to avoid it causing

personal injury.

17Unclip the pad wear sensor from the

caliper, and disconnect the wiring plug (see

illustration).

18Using a 7 mm Allen key, unscrew and

remove the two guide bolts securing the

caliper to the carrier bracket, and withdraw

the caliper (see illustration). Support the

caliper on an axle stand to avoid straining the

hydraulic hose.19Withdraw the disc pads from the caliper

(see illustration). It may be necessary to prise

the outboard pad with a screwdriver to

release it from the caliper. Do not use a

screwdriver to free the inboard pad, as this

may damage the piston dust seal.

20Proceed as described in paragraphs 8 to

15 inclusive, but in addition ensure that the

clip on the back of the inboard pad fits into

the piston recess (see illustration), refit the

caliper retaining clip, and ignore the reference

to the anti-rattle clips (see illustration). On

P100 models align the previously made marks

on the roadwheels and wheel studs.

Late model modification

21On some later models, slightly revised

front brake components are used. A new type

of retaining clip is used to secure the pads in

10•4Braking system

4.7 Correct and incorrect methods of freeing stuck outboard disc pad. Guide pin bolt (A)

must be in position - Girling caliper

4.9 Using a spreader tool to depress the

caliper piston into its bore

4.19 Withdraw the disc pads from the

caliper - Teves caliper4.18 Withdrawing a caliper from its carrier

bracket - Teves caliper

4.17 Disconnect the pad wear sensor

wiring plug - Teves caliper

Page 5 of 22

the caliper, and the caliper body is modified

accordingly. Also, plastic covers are fitted to

the caliper guide bolts (see illustrations).

22Procedures are unchanged from those

given above.

Rear disc pads

23Slacken the rear roadwheel nuts, chock

the front wheels, then jack up the rear of the

vehicle and support on axle stands. (see

“Jacking and Vehicle Support”). Remove the

roadwheel.

24The disc pads can be inspected through

the top of the caliper after removal of the

blanking spring clip. Check that the friction

material thickness is not less than the

minimum given in the Specifications.

25If any one of the pads has worn below the

specified limit, the rear pads must be renewedas an axle set (4 pads).

26To renew the pads, proceed as follows.

27Release the handbrake, and free the

handbrake cable from the suspension lower

arm by bending back the tangs.

28Where applicable, disconnect the wiring

to the disc pad wear sensor (see illustration).

29Unscrew and remove the bolt from the

forward caliper guide pin, while holding the

pin stationary with a spanner (see

illustration).

30Swing the caliper rearwards and lift out

the disc pads (see illustration). Do not

depress the brake pedal with the caliper

removed.

31Brush all dirt and dust from the caliper,

pads and disc, but do not inhale it as it may

be injurious to health. Scrape any corrosion

from the disc.32As the new pads will be thicker than the

old ones, the piston must be retracted into its

bore to accommodate the new thicker pads.

Retracting the piston will cause the fluid level

in the reservoir to rise, so to avoid spillage,

syphon out some fluid using an old

hydrometer or a teat pipette. Retract the

caliper piston by turning it clockwise. Ford

tool No 12-006 is designed for this purpose,

but a pair of circlip pliers or any similar tool

can be used instead (see illustration).

33Remove the backing paper from the new

pads, and fit them to the caliper.

34Further refitting is a reversal of removal,

bearing in mind the following points.

35If disc pads with wear sensors are fitted,

the pad with the sensor wire should be fitted

inboard.

36Repeat the procedure on the opposite

rear brake.

37On completion, switch on the ignition and

apply the footbrake hard several times to

settle the pads. Switch off the ignition, then

check and if necessary top-up the fluid level in

the reservoir. Check the operation of the

handbrake.

38Avoid heavy braking, if possible, for the

first hundred miles or so after fitting new

pads. This will allow the pads to bed in and

reach full efficiency.

Braking system 10•5

10

4.21a Later type front disc pad retaining

clip

4.32 Retracting the piston using circlip

pliers4.30 Lift out the disc pads

4.28 Rear disc pad wear sensor wiring clip

(arrowed)

4.29 Unscrewing the forward caliper guide

pin bolt

4.21b Removing a caliper guide bolt cover

- later type

4.20b Refitting the caliper retaining clip -

Teves caliper4.20a The clip on the back of the inboard

disc pad fits into the piston recess - Teves

caliper

Page 10 of 22

Note: Complete dismantling of the rear caliper

should not be attempted unless Ford spring

compressor (tool No 12-007) is available, or

unless the problems likely to arise in the

absence of the tool are understood. Renewal

of the piston seal dust-excluding seal and

piston adjuster nut seal requires no special

tools.

Removal

1With the ignition switched off, pump the

brake pedal at least 20 times, or until it

becomes hard, to depressurise the system.

2Chock the front wheels, slacken the

relevant roadwheel nuts, then jack up the rear

of the vehicle and support on axle stands (see

“Jacking and Vehicle Support”). Remove the

roadwheel and release the handbrake.

3Where applicable, disconnect the wiring to

the disc pad wear sensor.

4Proceed as described in Section 6,

paragraphs 2 and 3, but note that the rigid

brake pipe is clipped to the suspension lower

arm.

5Unscrew and remove the two guide bolts

securing the caliper to the carrier bracket,

while holding the pins with a spanner. Unhookthe handbrake cable from the lever, and

withdraw the caliper. Alternatively, the two

carrier bracket-to-hub carrier bolts can be

unscrewed, and the caliper and carrier can be

separated on the bench, but in this case the

handbrake cable must be disconnected from

the carrier bracket by removing the retaining

circlip.

Overhaul

6Clean the caliper, taking care not to inhale

any dust which may be injurious to health, and

mount it in a soft-jawed vice.

7Rotate the piston anti-clockwise, using

Ford tool No 12-006, or a pair of circlip pliers

or similar tool, until it protrudes from the

caliper bore by approximately 20.0 mm (0.8

in). Free the dust-excluding seal from the

groove in the piston, then continue

unscrewing the piston and remove it. Remove

and discard the dust-excluding seal.

8The piston and bore may now be cleaned

and examined as described in Section 6,

paragraph 12.

9The piston adjuster nut seal should be

renewed as follows.

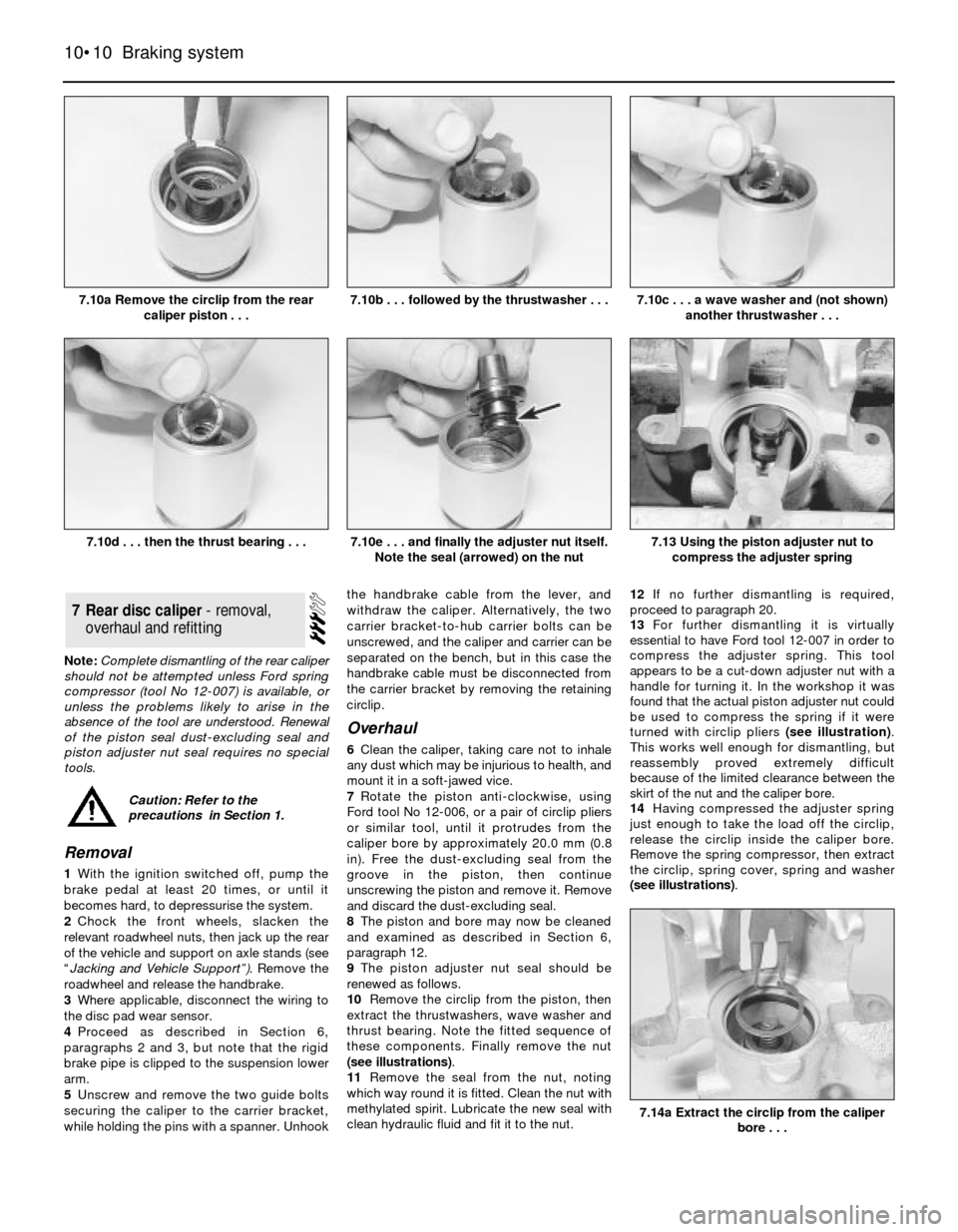

10Remove the circlip from the piston, then

extract the thrustwashers, wave washer and

thrust bearing. Note the fitted sequence of

these components. Finally remove the nut

(see illustrations).

11Remove the seal from the nut, noting

which way round it is fitted. Clean the nut with

methylated spirit. Lubricate the new seal with

clean hydraulic fluid and fit it to the nut.12If no further dismantling is required,

proceed to paragraph 20.

13For further dismantling it is virtually

essential to have Ford tool 12-007 in order to

compress the adjuster spring. This tool

appears to be a cut-down adjuster nut with a

handle for turning it. In the workshop it was

found that the actual piston adjuster nut could

be used to compress the spring if it were

turned with circlip pliers (see illustration).

This works well enough for dismantling, but

reassembly proved extremely difficult

because of the limited clearance between the

skirt of the nut and the caliper bore.

14Having compressed the adjuster spring

just enough to take the load off the circlip,

release the circlip inside the caliper bore.

Remove the spring compressor, then extract

the circlip, spring cover, spring and washer

(see illustrations).

7Rear disc caliper - removal,

overhaul and refitting

10•10Braking system

7.10a Remove the circlip from the rear

caliper piston . . .7.10c . . . a wave washer and (not shown)

another thrustwasher . . .

7.14a Extract the circlip from the caliper

bore . . .

7.13 Using the piston adjuster nut to

compress the adjuster spring7.10e . . . and finally the adjuster nut itself.

Note the seal (arrowed) on the nut7.10d . . . then the thrust bearing . . .

7.10b . . . followed by the thrustwasher . . .

Caution: Refer to the

precautions in Section 1.

Page 13 of 22

3Remove the wheel cylinder.

4Remove the driveshaft but do not refit the

securing bolts to the backplate.

5Remove the backplate.

6If required, prise out the handbrake stop

button.

7Refitting is a reversal of removal.

P 100 models

Note: When refitting the backplate, a new rear

hub nut and driveshaft O-ring must be used.

8Proceed as described in paragraphs 1 to 3

inclusive.

9Remove the driveshaft.

10Relieve the staking on the rear hub nut,

and using a 50 mm socket and a suitable

extension bar, unscrew the nut. Note that the

nut is extremely tight.

11Pull off the hub.

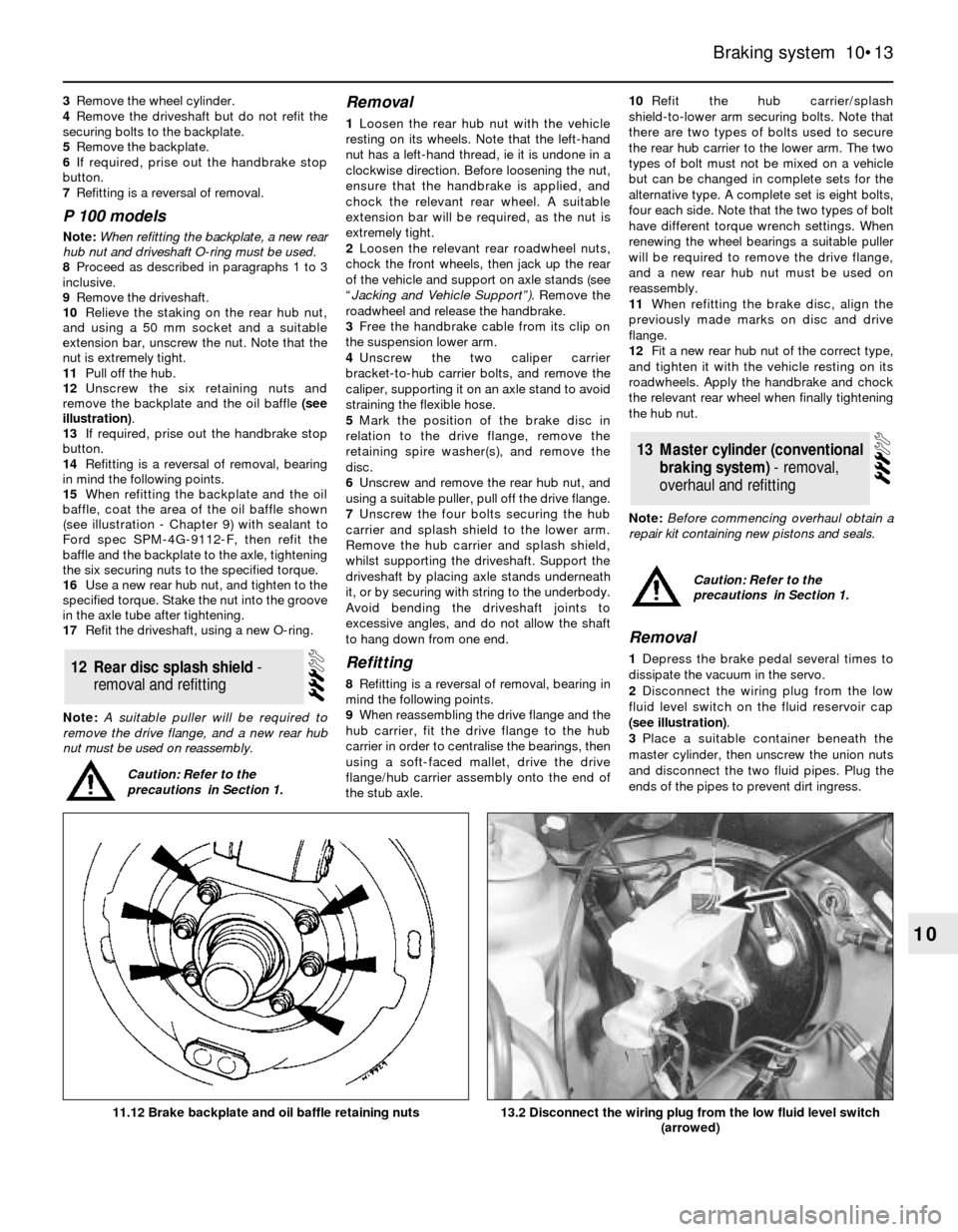

12Unscrew the six retaining nuts and

remove the backplate and the oil baffle (see

illustration).

13If required, prise out the handbrake stop

button.

14Refitting is a reversal of removal, bearing

in mind the following points.

15When refitting the backplate and the oil

baffle, coat the area of the oil baffle shown

(see illustration - Chapter 9) with sealant to

Ford spec SPM-4G-9112-F, then refit the

baffle and the backplate to the axle, tightening

the six securing nuts to the specified torque.

16Use a new rear hub nut, and tighten to the

specified torque. Stake the nut into the groove

in the axle tube after tightening.

17Refit the driveshaft, using a new O-ring.

Note: A suitable puller will be required to

remove the drive flange, and a new rear hub

nut must be used on reassembly.

Removal

1Loosen the rear hub nut with the vehicle

resting on its wheels. Note that the left-hand

nut has a left-hand thread, ie it is undone in a

clockwise direction. Before loosening the nut,

ensure that the handbrake is applied, and

chock the relevant rear wheel. A suitable

extension bar will be required, as the nut is

extremely tight.

2Loosen the relevant rear roadwheel nuts,

chock the front wheels, then jack up the rear

of the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Remove the

roadwheel and release the handbrake.

3Free the handbrake cable from its clip on

the suspension lower arm.

4Unscrew the two caliper carrier

bracket-to-hub carrier bolts, and remove the

caliper, supporting it on an axle stand to avoid

straining the flexible hose.

5Mark the position of the brake disc in

relation to the drive flange, remove the

retaining spire washer(s), and remove the

disc.

6Unscrew and remove the rear hub nut, and

using a suitable puller, pull off the drive flange.

7Unscrew the four bolts securing the hub

carrier and splash shield to the lower arm.

Remove the hub carrier and splash shield,

whilst supporting the driveshaft. Support the

driveshaft by placing axle stands underneath

it, or by securing with string to the underbody.

Avoid bending the driveshaft joints to

excessive angles, and do not allow the shaft

to hang down from one end.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9When reassembling the drive flange and the

hub carrier, fit the drive flange to the hub

carrier in order to centralise the bearings, then

using a soft-faced mallet, drive the drive

flange/hub carrier assembly onto the end of

the stub axle.10Refit the hub carrier/splash

shield-to-lower arm securing bolts. Note that

there are two types of bolts used to secure

the rear hub carrier to the lower arm. The two

types of bolt must not be mixed on a vehicle

but can be changed in complete sets for the

alternative type. A complete set is eight bolts,

four each side. Note that the two types of bolt

have different torque wrench settings. When

renewing the wheel bearings a suitable puller

will be required to remove the drive flange,

and a new rear hub nut must be used on

reassembly.

11When refitting the brake disc, align the

previously made marks on disc and drive

flange.

12Fit a new rear hub nut of the correct type,

and tighten it with the vehicle resting on its

roadwheels. Apply the handbrake and chock

the relevant rear wheel when finally tightening

the hub nut.

Note: Before commencing overhaul obtain a

repair kit containing new pistons and seals.

Removal

1Depress the brake pedal several times to

dissipate the vacuum in the servo.

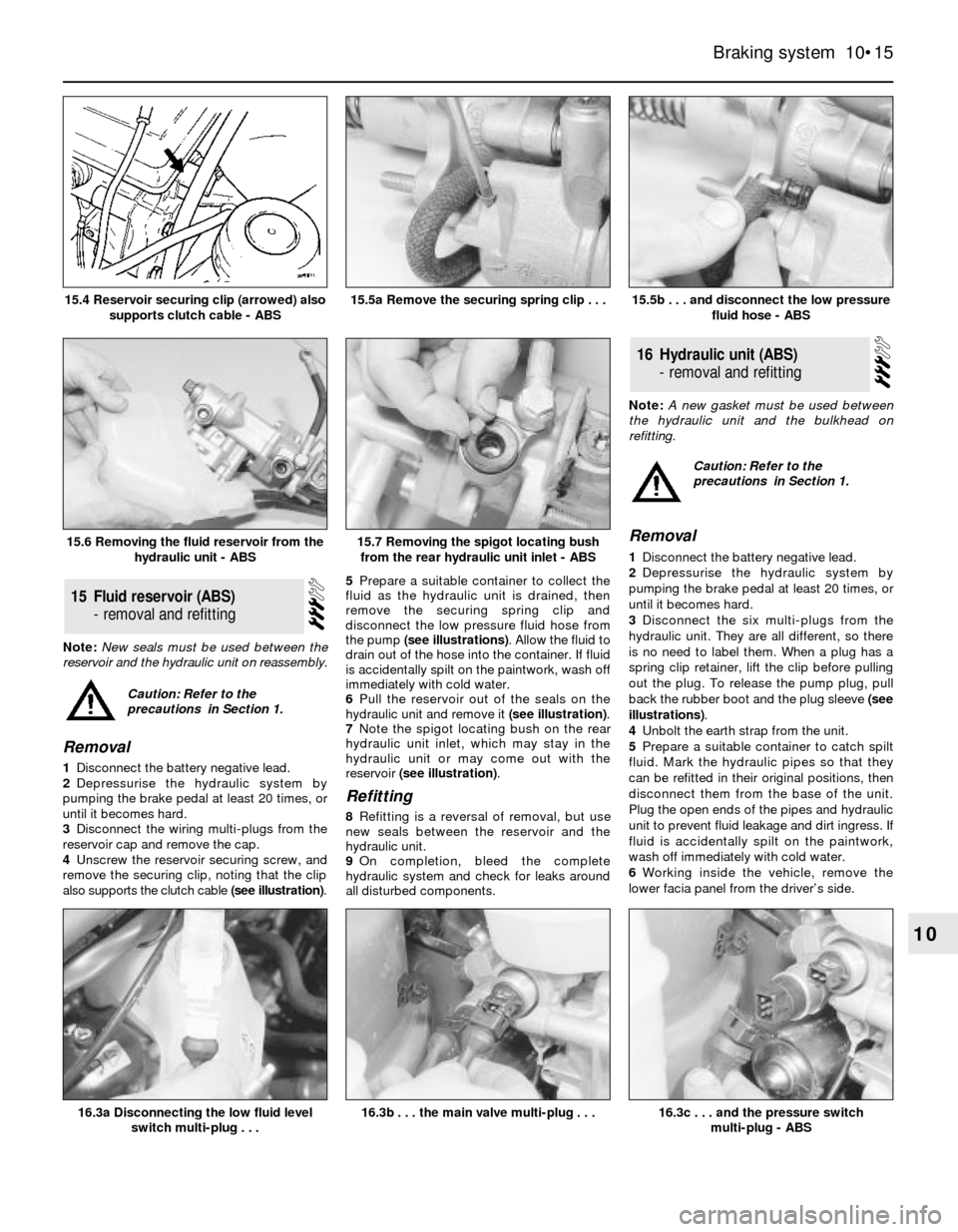

2Disconnect the wiring plug from the low

fluid level switch on the fluid reservoir cap

(see illustration).

3Place a suitable container beneath the

master cylinder, then unscrew the union nuts

and disconnect the two fluid pipes. Plug the

ends of the pipes to prevent dirt ingress.

13Master cylinder (conventional

braking system) - removal,

overhaul and refitting

12Rear disc splash shield -

removal and refitting

Braking system 10•13

10

13.2 Disconnect the wiring plug from the low fluid level switch

(arrowed)11.12 Brake backplate and oil baffle retaining nuts

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.

Page 15 of 22

Note: New seals must be used between the

reservoir and the hydraulic unit on reassembly.

Removal

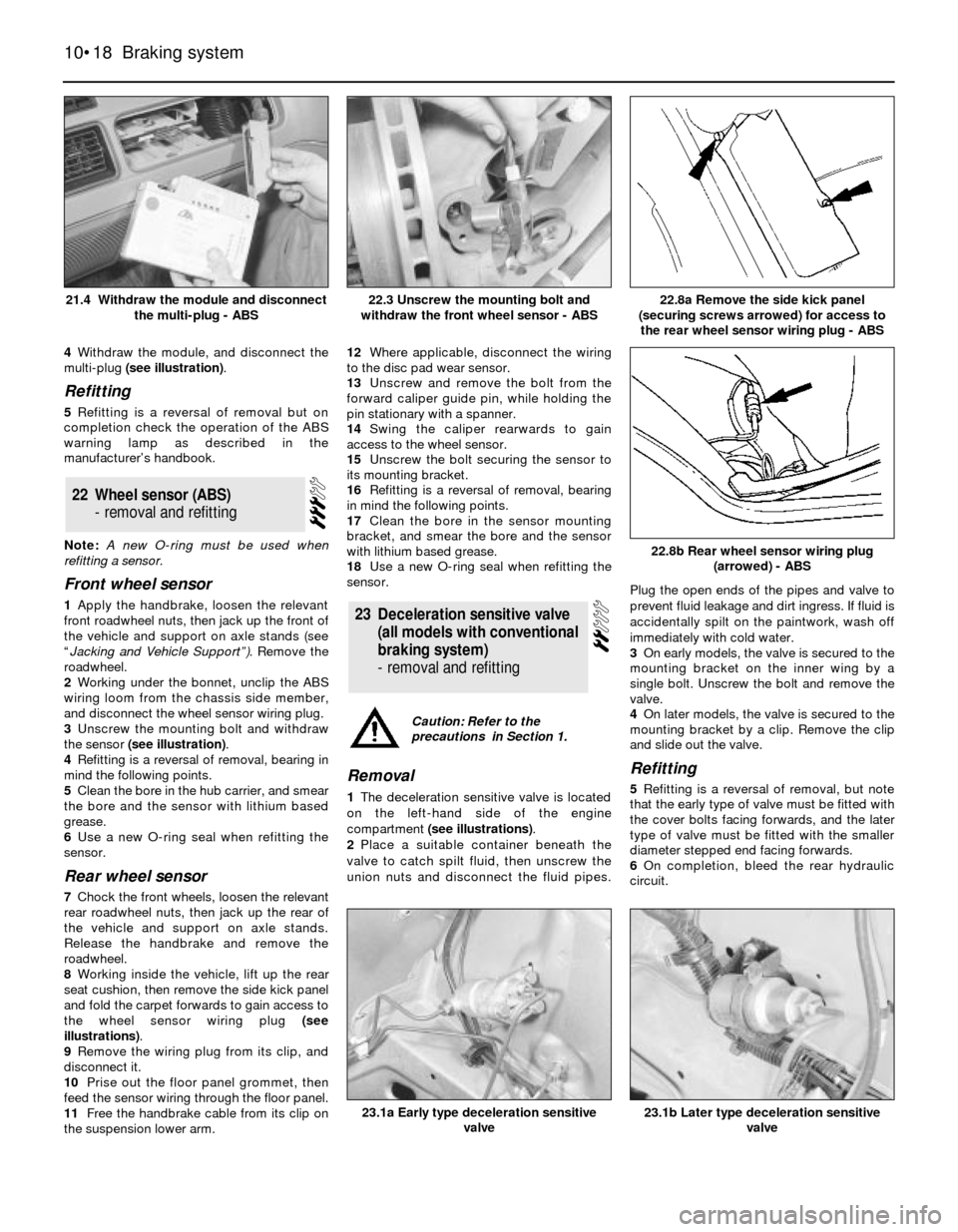

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the wiring multi-plugs from the

reservoir cap and remove the cap.

4Unscrew the reservoir securing screw, and

remove the securing clip, noting that the clip

also supports the clutch cable (see illustration).5Prepare a suitable container to collect the

fluid as the hydraulic unit is drained, then

remove the securing spring clip and

disconnect the low pressure fluid hose from

the pump (see illustrations). Allow the fluid to

drain out of the hose into the container. If fluid

is accidentally spilt on the paintwork, wash off

immediately with cold water.

6Pull the reservoir out of the seals on the

hydraulic unit and remove it (see illustration).

7Note the spigot locating bush on the rear

hydraulic unit inlet, which may stay in the

hydraulic unit or may come out with the

reservoir (see illustration).

Refitting

8Refitting is a reversal of removal, but use

new seals between the reservoir and the

hydraulic unit.

9On completion, bleed the complete

hydraulic system and check for leaks around

all disturbed components.Note: A new gasket must be used between

the hydraulic unit and the bulkhead on

refitting.

Removal

1Disconnect the battery negative lead.

2Depressurise the hydraulic system by

pumping the brake pedal at least 20 times, or

until it becomes hard.

3Disconnect the six multi-plugs from the

hydraulic unit. They are all different, so there

is no need to label them. When a plug has a

spring clip retainer, lift the clip before pulling

out the plug. To release the pump plug, pull

back the rubber boot and the plug sleeve (see

illustrations).

4Unbolt the earth strap from the unit.

5Prepare a suitable container to catch spilt

fluid. Mark the hydraulic pipes so that they

can be refitted in their original positions, then

disconnect them from the base of the unit.

Plug the open ends of the pipes and hydraulic

unit to prevent fluid leakage and dirt ingress. If

fluid is accidentally spilt on the paintwork,

wash off immediately with cold water.

6Working inside the vehicle, remove the

lower facia panel from the driver’s side.

16Hydraulic unit (ABS)

- removal and refitting

15Fluid reservoir (ABS)

- removal and refitting

Braking system 10•15

10

15.5b . . . and disconnect the low pressure

fluid hose - ABS

16.3c . . . and the pressure switch

multi-plug - ABS16.3b . . . the main valve multi-plug . . .16.3a Disconnecting the low fluid level

switch multi-plug . . .

15.7 Removing the spigot locating bush

from the rear hydraulic unit inlet - ABS15.6 Removing the fluid reservoir from the

hydraulic unit - ABS

15.5a Remove the securing spring clip . . .15.4 Reservoir securing clip (arrowed) also

supports clutch cable - ABS

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.

Page 18 of 22

4Withdraw the module, and disconnect the

multi-plug (see illustration).

Refitting

5Refitting is a reversal of removal but on

completion check the operation of the ABS

warning lamp as described in the

manufacturer’s handbook.

Note: A new O-ring must be used when

refitting a sensor.

Front wheel sensor

1Apply the handbrake, loosen the relevant

front roadwheel nuts, then jack up the front of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”). Remove the

roadwheel.

2Working under the bonnet, unclip the ABS

wiring loom from the chassis side member,

and disconnect the wheel sensor wiring plug.

3Unscrew the mounting bolt and withdraw

the sensor (see illustration).

4Refitting is a reversal of removal, bearing in

mind the following points.

5Clean the bore in the hub carrier, and smear

the bore and the sensor with lithium based

grease.

6Use a new O-ring seal when refitting the

sensor.

Rear wheel sensor

7Chock the front wheels, loosen the relevant

rear roadwheel nuts, then jack up the rear of

the vehicle and support on axle stands.

Release the handbrake and remove the

roadwheel.

8Working inside the vehicle, lift up the rear

seat cushion, then remove the side kick panel

and fold the carpet forwards to gain access to

the wheel sensor wiring plug (see

illustrations).

9Remove the wiring plug from its clip, and

disconnect it.

10Prise out the floor panel grommet, then

feed the sensor wiring through the floor panel.

11Free the handbrake cable from its clip on

the suspension lower arm.12Where applicable, disconnect the wiring

to the disc pad wear sensor.

13Unscrew and remove the bolt from the

forward caliper guide pin, while holding the

pin stationary with a spanner.

14Swing the caliper rearwards to gain

access to the wheel sensor.

15Unscrew the bolt securing the sensor to

its mounting bracket.

16Refitting is a reversal of removal, bearing

in mind the following points.

17Clean the bore in the sensor mounting

bracket, and smear the bore and the sensor

with lithium based grease.

18Use a new O-ring seal when refitting the

sensor.

Removal

1The deceleration sensitive valve is located

on the left-hand side of the engine

compartment (see illustrations).

2Place a suitable container beneath the

valve to catch spilt fluid, then unscrew the

union nuts and disconnect the fluid pipes.Plug the open ends of the pipes and valve to

prevent fluid leakage and dirt ingress. If fluid is

accidentally spilt on the paintwork, wash off

immediately with cold water.

3On early models, the valve is secured to the

mounting bracket on the inner wing by a

single bolt. Unscrew the bolt and remove the

valve.

4On later models, the valve is secured to the

mounting bracket by a clip. Remove the clip

and slide out the valve.

Refitting

5Refitting is a reversal of removal, but note

that the early type of valve must be fitted with

the cover bolts facing forwards, and the later

type of valve must be fitted with the smaller

diameter stepped end facing forwards.

6On completion, bleed the rear hydraulic

circuit.

23Deceleration sensitive valve

(all models with conventional

braking system)

- removal and refitting

22Wheel sensor (ABS)

- removal and refitting

10•18Braking system

21.4 Withdraw the module and disconnect

the multi-plug - ABS22.8a Remove the side kick panel

(securing screws arrowed) for access to

the rear wheel sensor wiring plug - ABS

23.1b Later type deceleration sensitive

valve23.1a Early type deceleration sensitive

valve

22.8b Rear wheel sensor wiring plug

(arrowed) - ABS

22.3 Unscrew the mounting bolt and

withdraw the front wheel sensor - ABS

Caution: Refer to the

precautions in Section 1.

Page 22 of 22

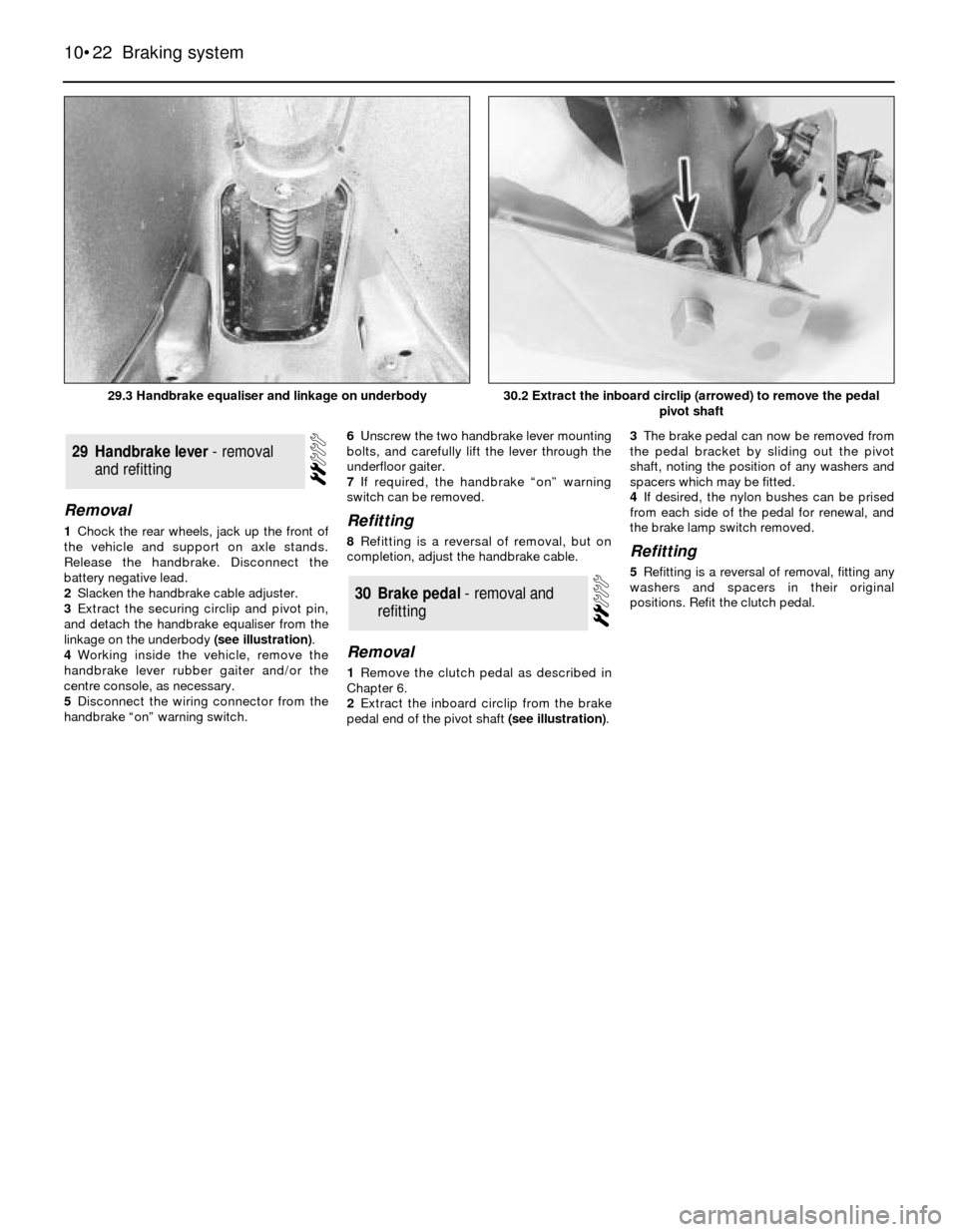

Removal

1Chock the rear wheels, jack up the front of

the vehicle and support on axle stands.

Release the handbrake. Disconnect the

battery negative lead.

2Slacken the handbrake cable adjuster.

3Extract the securing circlip and pivot pin,

and detach the handbrake equaliser from the

linkage on the underbody (see illustration).

4Working inside the vehicle, remove the

handbrake lever rubber gaiter and/or the

centre console, as necessary.

5Disconnect the wiring connector from the

handbrake “on” warning switch. 6Unscrew the two handbrake lever mounting

bolts, and carefully lift the lever through the

underfloor gaiter.

7If required, the handbrake “on” warning

switch can be removed.Refitting

8Refitting is a reversal of removal, but on

completion, adjust the handbrake cable.

Removal

1Remove the clutch pedal as described in

Chapter 6.

2Extract the inboard circlip from the brake

pedal end of the pivot shaft (see illustration).3The brake pedal can now be removed from

the pedal bracket by sliding out the pivot

shaft, noting the position of any washers and

spacers which may be fitted.

4If desired, the nylon bushes can be prised

from each side of the pedal for renewal, and

the brake lamp switch removed.

Refitting

5Refitting is a reversal of removal, fitting any

washers and spacers in their original

positions. Refit the clutch pedal.

30Brake pedal - removal and

refitting

29Handbrake lever -removal

andrefitting

10•22Braking system

29.3 Handbrake equaliser and linkage on underbody30.2 Extract the inboard circlip (arrowed) to remove the pedal

pivot shaft