wheel FORD SIERRA 1983 1.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 24, PDF Size: 1.09 MB

Page 1 of 24

1.6 litre engine

Note: Unless otherwise stated, the Specifications for the 1.6 litre CVH engine are as given for the 1.8 litre (R2A type) which follow.

General

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L6B

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.960 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.520 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1596 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 :1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 12.2 to 14.3 bars

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6000 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 kW at 5500 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 Nm at 3500 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.940 to 79.950 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.950 to 79.960 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.960 to 79.970 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.970 to 79.980 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.230 to 80.240 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.240 to 80.250 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.250 to 80.260 mm

Chapter 2 Part C:

CVH engines

Camshaft and cam followers - removal, inspection and refitting . . . .23

Compression test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Crankcase ventilation system - inspection and maintenance . . . . . . .3

Crankshaft and bearings - examination and renovation . . . . . . . . . .33

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .32

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Cylinder block and bores - examination and renovation . . . . . . . . . .34

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .21

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .22

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .19

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .20

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .13

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . .12

Engine - removal leaving automatic transmission in vehicle . . . . . . . .9

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .8

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Engine/automatic transmission assembly - removal and separation .11Engine dismantling, examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine/manual gearbox assembly - reconnection and refitting . . . . .14

Engine/manual gearbox assembly - removal and separation . . . . . .10

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .24

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .35

Major operations possible with the engine in the vehicle . . . . . . . . . . .5

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .6

Method of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .29

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Pistons and connecting rods - examination and renovation . . . . . . .31

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .30

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Timing belt and sprockets - removal and refitting . . . . . . . . . . . . . . .18

2C•1

Specifications Contents

2C

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 3 of 24

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10066 to 74

Connecting rod (big-end bearing cap) bolts . . . . . . . . . . . . . . . . . . . . . .30 to 3622 to 27

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 to 11574 to 85

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54 to 5940 to 44

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82 to 9261 to 68

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Sump bolts (in two stages) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 to 84 to 6

Rocker arm nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25 to 2918 to 21

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 4015 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 6030 to 44

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Timing cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Timing belt tensioner bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Oil pick-up tube/strainer-to-oil pump bolts . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Oil pick-up tube/strainer-to-cylinder block bolt . . . . . . . . . . . . . . . . . . .17 to 2313 to 17

Camshaft thrustplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

1.8 litre (R2A type) engine

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Four-cylinder, in-line, single overhead camshaft

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3-4-2

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .R2A

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1769 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.3:1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . .11 to 13 bar

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .5850 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66 kW at 5250 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147 Nm at 3000 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.940 to 79.950 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.950 to 79.960 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.960 to 79.970 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.970 to 79.980 mm

Standard class 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.980 to 79.990 mm

Standard class 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.990 to 80.000 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.000 to 80.010 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.010 to 80.020 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80.020 to 80.030 mm

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.10 to 0.20 mm (0.004 to 0.008 in)

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.067 mm

Main bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.980 to 54.000 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.730 to 54.750 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.480 to 53.500 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.230 to 53.250 mm

Centre main thrust bearing shell width:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.825 to 28.875 mm

Undersize 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28.675 to 28.725 mm

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.065 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.890 to 43.910 mm

Undersize 0.25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.640 to 43.660 mm

Undersize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.390 to 43.410 mm

Undersize 0.75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43.140 to 43.160 mm

Undersize 1.00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42.890 to 42.910 mm

CVH engines 2C•3

2C

Page 4 of 24

Pistons and piston rings

Piston diameter:

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.910 to 79.920 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.920 to 79.930 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.930 to 79.940 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.940 to 79.950 mm

Standard class 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.950 to 79.960 mm

Standard class 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.960 to 79.970 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.970 to 79.980 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.980 to 79.990 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79.990 to 80.000 mm

Camshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.15 to 0.20 mm (0.006 to 0.008 in)

Thrustplate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.99 to 5.01 mm (0.1966 to 0.1974 in)

Bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45.7625 to 45.7375 mm

Valves

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22º BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54º ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64º BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12º ATDC

Valve spring free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47.20 mm (1.86 in)

Inlet valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.025 to 8.043 mm

Oversize 0.38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.405 to 8.423 mm

Oversize 0.76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.825 to 8.843 mm

Exhaust valve stem diameter (standard) . . . . . . . . . . . . . . . . . . . . . . . .7.996 to 8.017 mm

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Multigrade engine oil, viscosity range SAE 10W/30 to 20W/50, to API

SG/CD or better

Oil capacity:

With filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.0 litres (7.0 pints)

Without filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.5 litres (6.2 pints)

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion C104

Oil pump clearances:

Outer rotor to body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.074 to 0.161 mm (0.003 to 0.006 in)

Inner rotor to outer rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.050 to 0.180 mm (0.002 to 0.007 in)

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.013 to 0.070 mm (0.0005 to 0.0028 in)

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10866 to 80

Big-end bearing caps:

With retaining nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 to 3419 to 25

With retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4126 to 30

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110 to 13081 to 96

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95 to 11570 to 85

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73 to 9154 to 67

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 to 168 to 12

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 127 to 9

Sump bolts:

M6 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3015 to 22

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3015 to 22

Rocker arm bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 3017 to 22

Cylinder head bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 6030 to 44

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Slacken bolts by half a turn

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 6030 to 44

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten through a further 90º

Stage 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten through a further 90º

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Timing cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Timing cover nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 to 74 to 5

Timing belt tensioner bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 3017 to 22

Oil pick-up tube/strainer-to-oil pump bolts . . . . . . . . . . . . . . . . . . . . . .10 to 137 to 9

Camshaft thrustplate bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 136 to 9

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3015 to 22

2C•4CVH engines

Page 6 of 24

a)Removal of the cylinder head

b)Removal of the camshaft

c)Removal of the timing belt and sprockets

d)Removal of the engine mountings

e)Removal of the clutch and flywheel

f)Removal of the crankshaft oil seals

a)Removal of the sump

b)Removal of the oil pump

c)Removal of the pistons/connecting rods

d)Removal of the big-end bearings

e)Removal of the crankshaft main bearings

f)Removal of the crankshaft

Refer to Section 8, Chapter 2, Part A.

Note: A suitable hoist and lifting tackle will be

required for this operation.

1.8 litre (R2A type)

1Disconnect the battery negative lead.

2Remove the bonnet.

3Remove the air cleaner.

4Disconnect the cooling fan wiring plug, then

unscrew the retaining nuts and washers and

withdraw the fan shroud and cooling fan

assembly.

5Drain the cooling system.

6Disconnect the coolant hoses from the

coolant pump elbow, and detach the heater

hose from the clip on the front of the timing

cover.

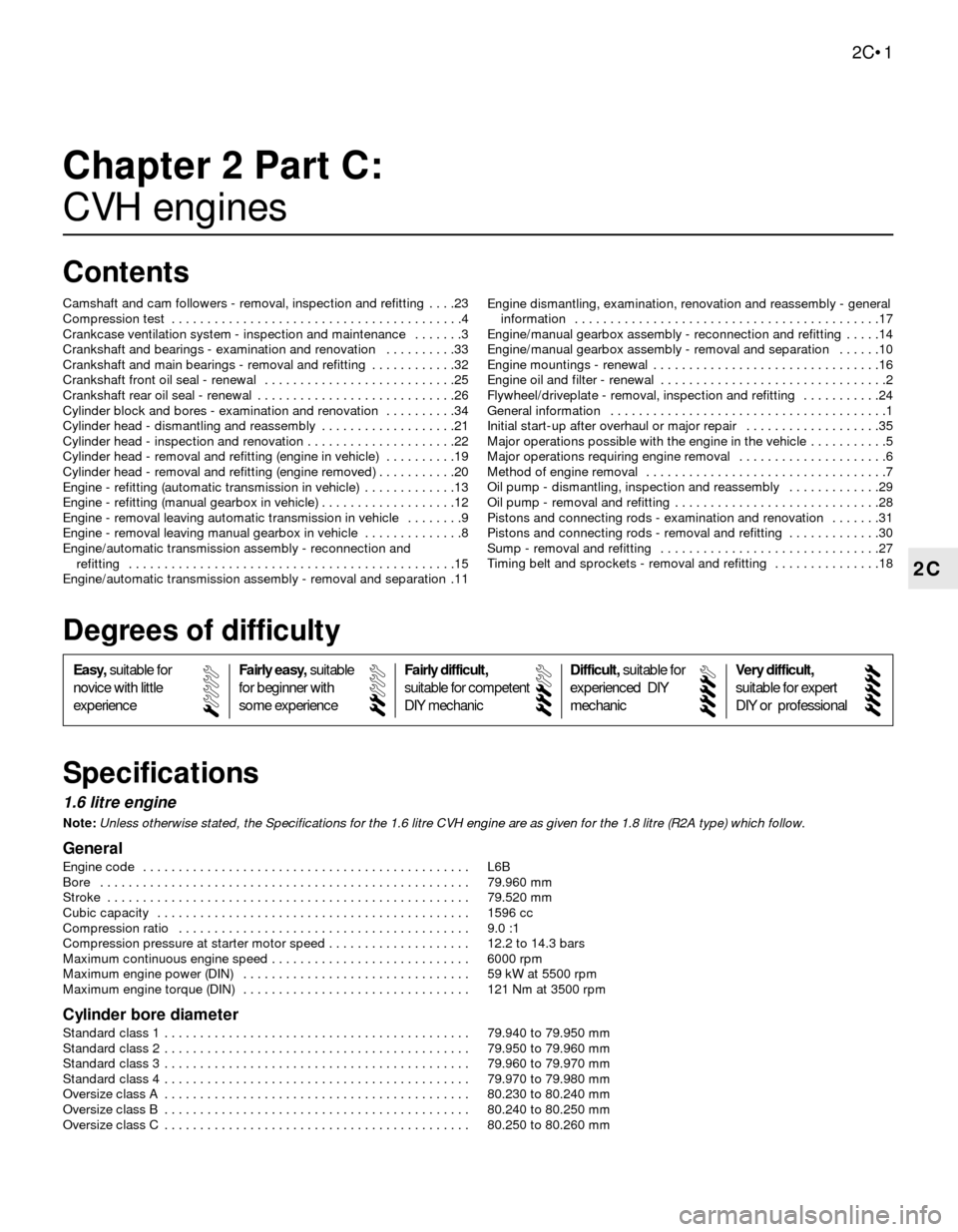

7Disconnect the upper radiator hose and the

expansion tank hose from the thermostat

housing (see illustration).8Disconnect the heater hose from the

automatic choke.

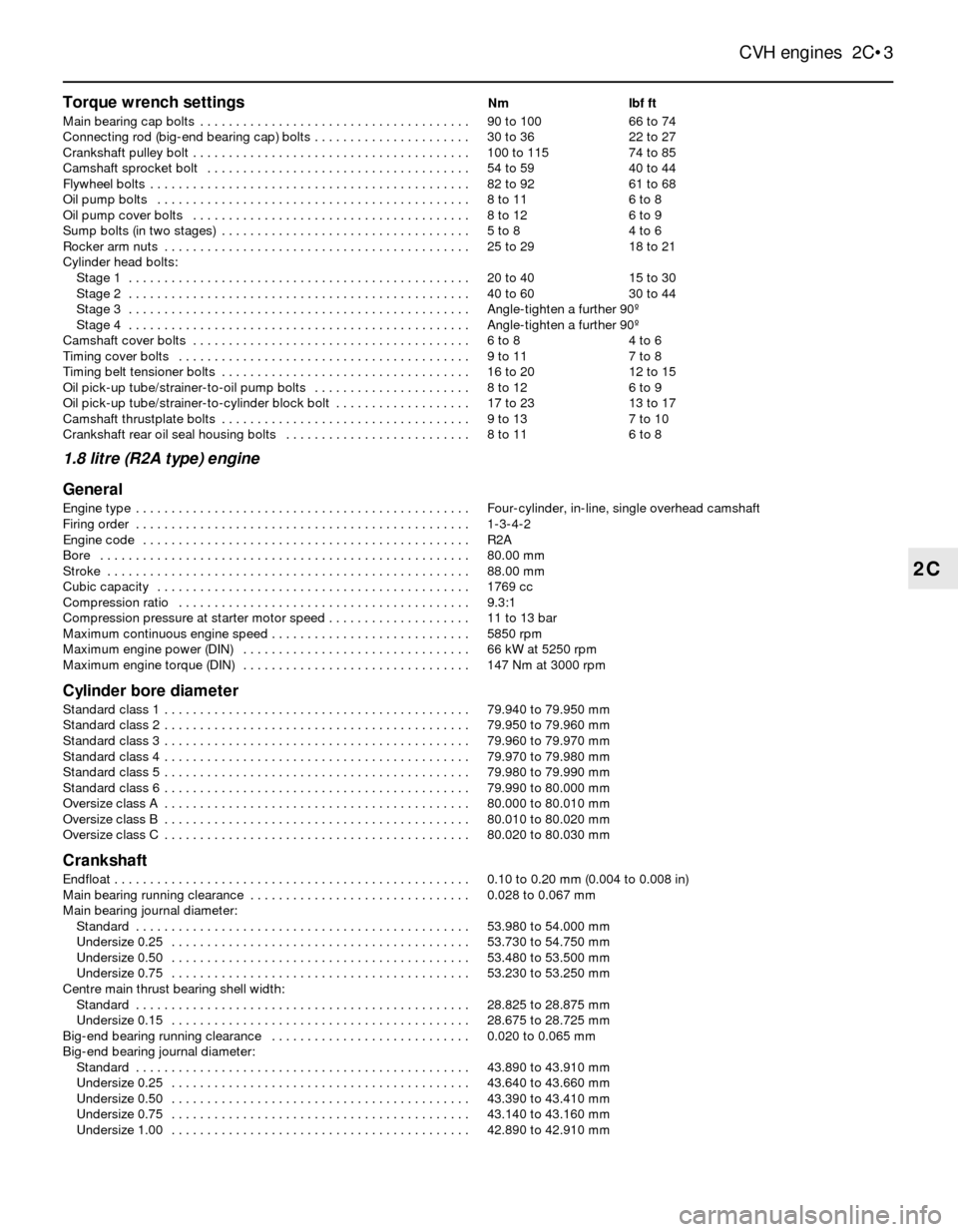

9Disconnect the brake servo vacuum hose

from the inlet manifold (see illustration).

10Disconnect the throttle damper solenoid

vacuum pipes (noting their locations) from the

throttle damper and the carburettor “T”-piece

connector.

11Disconnect the engine management

module vacuum pipe from the inlet manifold.

12Disconnect the fuel hoses from the

carburettor and fuel pump, and plug the ends

of the hoses to minimise petrol spillage. Take

adequate fire precautions.

13Disconnect the throttle cable.

14Disconnect the HT leads from the coil and

spark plugs, unclip the leads from the

camshaft cover, and remove the distributor

cap, rotor arm and housing.

15Disconnect the wiring from the following

components:

Alternator

Starter motor

Oil pressure warning lamp switch

Temperature gauge sender

Engine coolant temperature sensor

Automatic choke

Cooling fan switch

Crankshaft speed/position sensor

Engine earth strap to battery tray16Unscrew and remove the top engine-to-

gearbox bolts which are accessible from the

engine compartment.

17Apply the handbrake (if not already done),

jack up the front of the vehicle and support on

axle stands (see “Jacking and Vehicle

Support”).

18Drain the engine oil into a container.

19Remove the starter motor.

20Remove the exhaust downpipe.

21Unscrew the two nuts securing the engine

mountings to the crossmember. Recover the

washers.

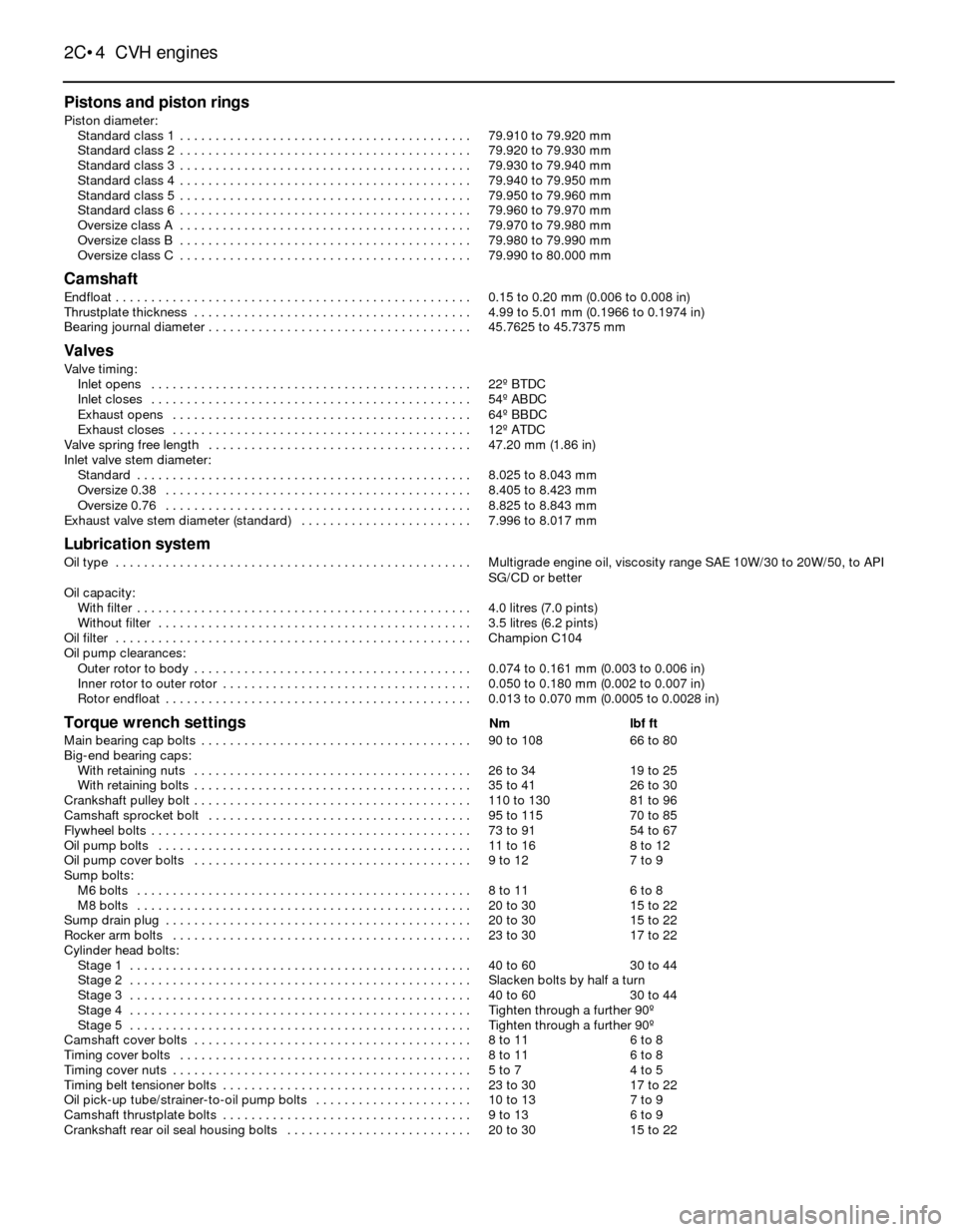

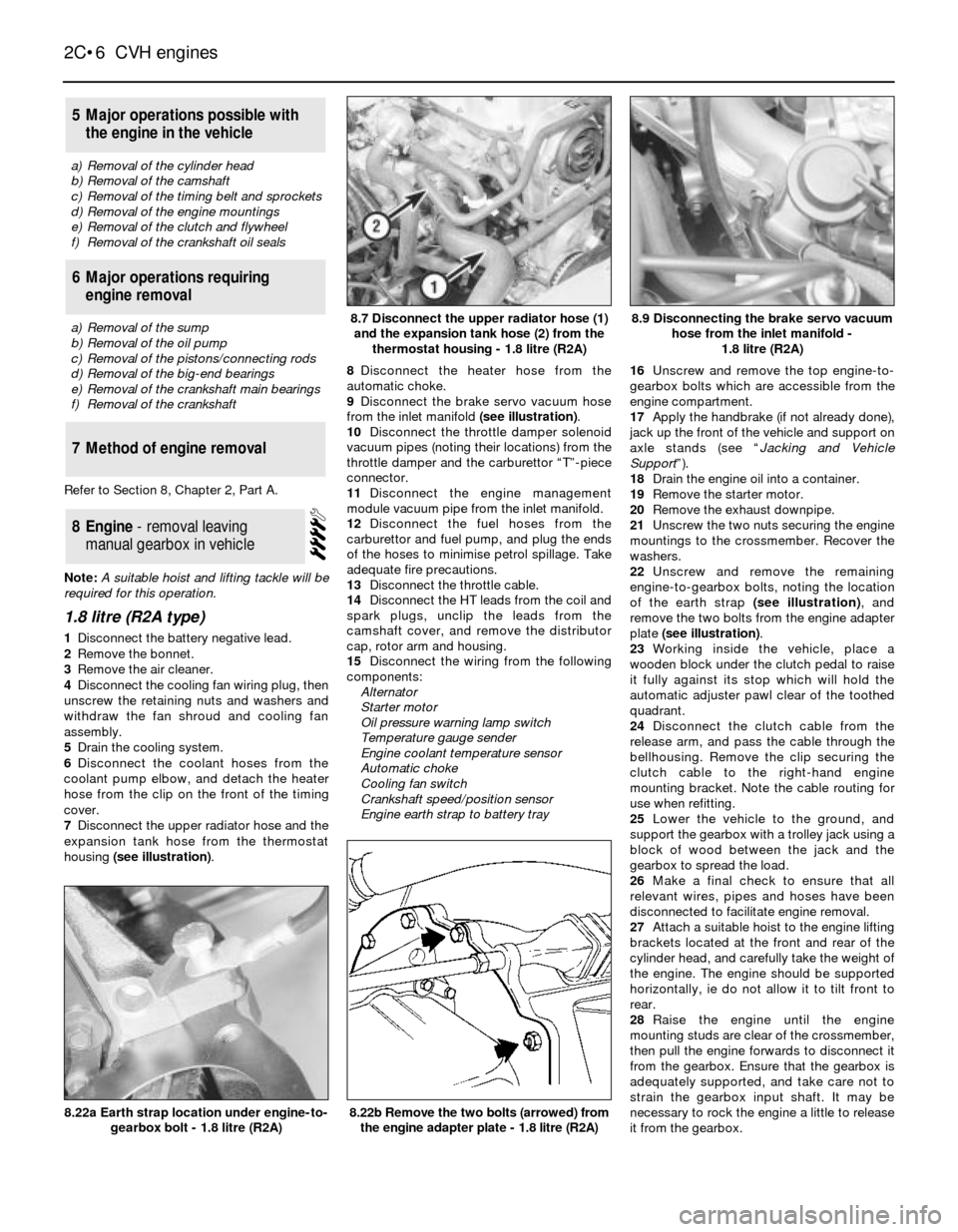

22Unscrew and remove the remaining

engine-to-gearbox bolts, noting the location

of the earth strap (see illustration), and

remove the two bolts from the engine adapter

plate (see illustration).

23Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against its stop which will hold the

automatic adjuster pawl clear of the toothed

quadrant.

24Disconnect the clutch cable from the

release arm, and pass the cable through the

bellhousing. Remove the clip securing the

clutch cable to the right-hand engine

mounting bracket. Note the cable routing for

use when refitting.

25Lower the vehicle to the ground, and

support the gearbox with a trolley jack using a

block of wood between the jack and the

gearbox to spread the load.

26Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate engine removal.

27Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine. The engine should be supported

horizontally, ie do not allow it to tilt front to

rear.

28Raise the engine until the engine

mounting studs are clear of the crossmember,

then pull the engine forwards to disconnect it

from the gearbox. Ensure that the gearbox is

adequately supported, and take care not to

strain the gearbox input shaft. It may be

necessary to rock the engine a little to release

it from the gearbox.

8Engine - removal leaving

manual gearbox in vehicle

7Method of engine removal

6Major operations requiring

engine removal

5Major operations possible with

the engine in the vehicle

2C•6CVH engines

8.9 Disconnecting the brake servo vacuum

hose from the inlet manifold -

1.8 litre (R2A)

8.22b Remove the two bolts (arrowed) from

the engine adapter plate - 1.8 litre (R2A)8.22a Earth strap location under engine-to-

gearbox bolt - 1.8 litre (R2A)

8.7 Disconnect the upper radiator hose (1)

and the expansion tank hose (2) from the

thermostat housing - 1.8 litre (R2A)

Page 10 of 24

1.8 litre (R2A type)

Dismantling

1It is best to mount the engine on a

dismantling stand, but if this is not available,

stand the engine on a strong bench at a

comfortable working height. Failing this, it will

have to stripped down on the floor.

2Cleanliness is most important, and if the

engine is dirty, it should be cleaned with

paraffin while keeping it in an upright position.

3Avoid working with the engine directly on a

concrete floor, as grit presents a real source

of trouble.

4As parts are removed, clean them in a

paraffin bath. However, do not immerse parts

with internal oilways in paraffin as it is difficult

to remove, usually requiring a high pressure

hose. Clean oilways with nylon pipe cleaners.

5It is advisable to have suitable containers

available to hold small items according to

their use, as this will help when reassembling

the engine and also prevent possible losses.

6Always obtain a complete set of new

gaskets for use during engine reassembly, but

retain the old gaskets with a view to using

them as a pattern to make a replacement if a

new one is not available.

7Where possible, refit securing nuts, bolts

and washers to their locations after removing

the relevant components. This will help to

protect the threads and will also prevent

possible losses.

8Retain unserviceable components in order

to compare them with the new components

supplied.

9A suitable Torx socket will be required to

remove the oil pump cover securing screws.

10Before dismantling the main engine

components, the following externally mounted

ancillary components can be removed:

Inlet manifold and carburettor

Exhaust manifold

Fuel pump and operating pushrod

Alternator

Spark plugs

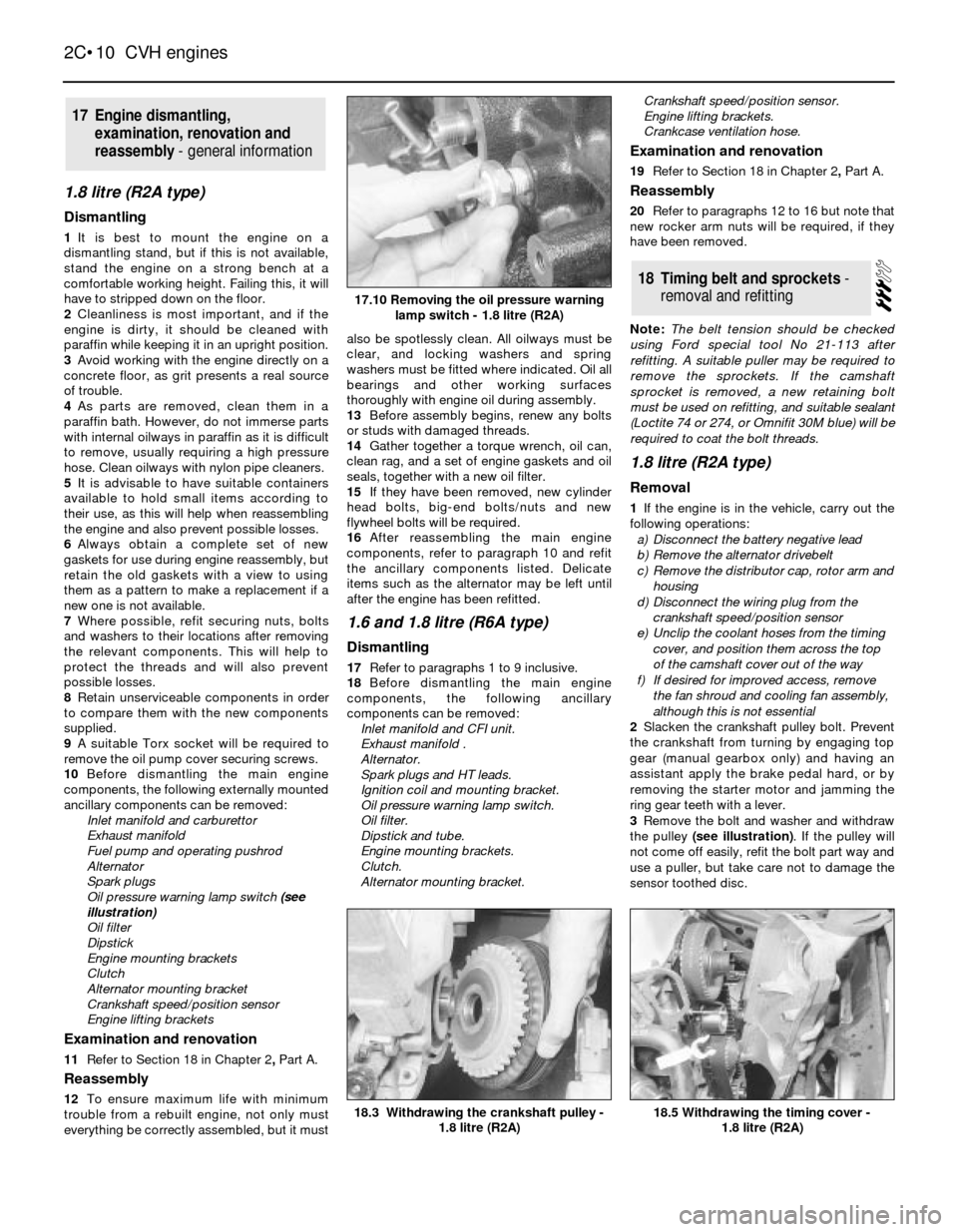

Oil pressure warning lamp switch (see

illustration)

Oil filter

Dipstick

Engine mounting brackets

Clutch

Alternator mounting bracket

Crankshaft speed/position sensor

Engine lifting brackets

Examination and renovation

11Refer to Section 18 in Chapter 2, PartA.

Reassembly

12To ensure maximum life with minimum

trouble from a rebuilt engine, not only must

everything be correctly assembled, but it mustalso be spotlessly clean. All oilways must be

clear, and locking washers and spring

washers must be fitted where indicated. Oil all

bearings and other working surfaces

thoroughly with engine oil during assembly.

13Before assembly begins, renew any bolts

or studs with damaged threads.

14Gather together a torque wrench, oil can,

clean rag, and a set of engine gaskets and oil

seals, together with a new oil filter.

15If they have been removed, new cylinder

head bolts, big-end bolts/nuts and new

flywheel bolts will be required.

16After reassembling the main engine

components, refer to paragraph 10 and refit

the ancillary components listed. Delicate

items such as the alternator may be left until

after the engine has been refitted.

1.6 and 1.8 litre (R6A type)

Dismantling

17Refer to paragraphs 1 to 9 inclusive.

18Before dismantling the main engine

components, the following ancillary

components can be removed:

Inlet manifold and CFI unit.

Exhaust manifold .

Alternator.

Spark plugs and HT leads.

Ignition coil and mounting bracket.

Oil pressure warning lamp switch.

Oil filter.

Dipstick and tube.

Engine mounting brackets.

Clutch.

Alternator mounting bracket.Crankshaft speed/position sensor.

Engine lifting brackets.

Crankcase ventilation hose.

Examination and renovation

19Refer to Section 18 in Chapter 2, PartA.

Reassembly

20Refer to paragraphs 12 to 16 but note that

new rocker arm nuts will be required, if they

have been removed.

Note: The belt tension should be checked

using Ford special tool No 21-113 after

refitting. A suitable puller may be required to

remove the sprockets. If the camshaft

sprocket is removed, a new retaining bolt

must be used on refitting, and suitable sealant

(Loctite 74 or 274, or Omnifit 30M blue) will be

required to coat the bolt threads.

1.8 litre (R2A type)

Removal

1If the engine is in the vehicle, carry out the

following operations:

a)Disconnect the battery negative lead

b)Remove the alternator drivebelt

c)Remove the distributor cap, rotor arm and

housing

d)Disconnect the wiring plug from the

crankshaft speed/position sensor

e)Unclip the coolant hoses from the timing

cover, and position them across the top

of the camshaft cover out of the way

f)If desired for improved access, remove

the fan shroud and cooling fan assembly,

although this is not essential

2Slacken the crankshaft pulley bolt. Prevent

the crankshaft from turning by engaging top

gear (manual gearbox only) and having an

assistant apply the brake pedal hard, or by

removing the starter motor and jamming the

ring gear teeth with a lever.

3Remove the bolt and washer and withdraw

the pulley (see illustration). If the pulley will

not come off easily, refit the bolt part way and

use a puller, but take care not to damage the

sensor toothed disc.

18Timing belt and sprockets -

removal and refitting

17Engine dismantling,

examination, renovation and

reassembly - general information

2C•10CVH engines

17.10 Removing the oil pressure warning

lamp switch - 1.8 litre (R2A)

18.5 Withdrawing the timing cover -

1.8 litre (R2A)18.3 Withdrawing the crankshaft pulley -

1.8 litre (R2A)

Page 19 of 24

Note: New flywheel securing bolts must be

used on refitting.

1.8 litre (R2A type)

1Refer to Section 26, Chapter 2, PartA but

also note the following points.

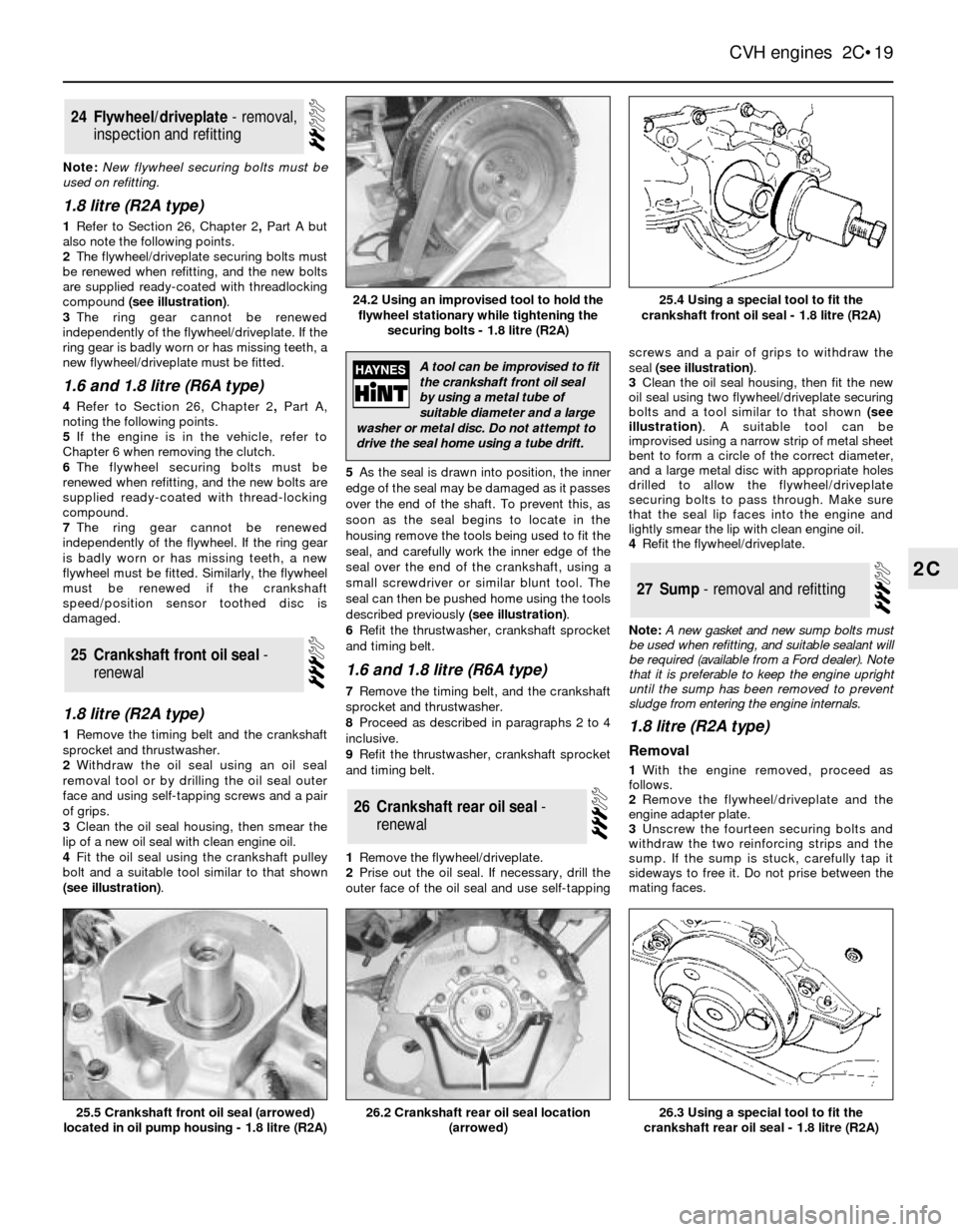

2The flywheel/driveplate securing bolts must

be renewed when refitting, and the new bolts

are supplied ready-coated with threadlocking

compound (see illustration).

3The ring gear cannot be renewed

independently of the flywheel/driveplate. If the

ring gear is badly worn or has missing teeth, a

new flywheel/driveplate must be fitted.

1.6 and 1.8 litre (R6A type)

4Refer to Section 26, Chapter 2, PartA,

noting the following points.

5If the engine is in the vehicle, refer to

Chapter 6 when removing the clutch.

6The flywheel securing bolts must be

renewed when refitting, and the new bolts are

supplied ready-coated with thread-locking

compound.

7The ring gear cannot be renewed

independently of the flywheel. If the ring gear

is badly worn or has missing teeth, a new

flywheel must be fitted. Similarly, the flywheel

must be renewed if the crankshaft

speed/position sensor toothed disc is

damaged.

1.8 litre (R2A type)

1Remove the timing belt and the crankshaft

sprocket and thrustwasher.

2Withdraw the oil seal using an oil seal

removal tool or by drilling the oil seal outer

face and using self-tapping screws and a pair

of grips.

3Clean the oil seal housing, then smear the

lip of a new oil seal with clean engine oil.

4Fit the oil seal using the crankshaft pulley

bolt and a suitable tool similar to that shown

(see illustration).5As the seal is drawn into position, the inner

edge of the seal may be damaged as it passes

over the end of the shaft. To prevent this, as

soon as the seal begins to locate in the

housing remove the tools being used to fit the

seal, and carefully work the inner edge of the

seal over the end of the crankshaft, using a

small screwdriver or similar blunt tool. The

seal can then be pushed home using the tools

described previously (see illustration).

6Refit the thrustwasher, crankshaft sprocket

and timing belt.

1.6 and 1.8 litre (R6A type)

7Remove the timing belt, and the crankshaft

sprocket and thrustwasher.

8Proceed as described in paragraphs 2 to 4

inclusive.

9Refit the thrustwasher, crankshaft sprocket

and timing belt.

1Remove the flywheel/driveplate.

2Prise out the oil seal. If necessary, drill the

outer face of the oil seal and use self-tappingscrews and a pair of grips to withdraw the

seal (see illustration).

3Clean the oil seal housing, then fit the new

oil seal using two flywheel/driveplate securing

bolts and a tool similar to that shown (see

illustration). A suitable tool can be

improvised using a narrow strip of metal sheet

bent to form a circle of the correct diameter,

and a large metal disc with appropriate holes

drilled to allow the flywheel/driveplate

securing bolts to pass through. Make sure

that the seal lip faces into the engine and

lightly smear the lip with clean engine oil.

4Refit the flywheel/driveplate.

Note: A new gasket and new sump bolts must

be used when refitting, and suitable sealant will

be required (available from a Ford dealer). Note

that it is preferable to keep the engine upright

until the sump has been removed to prevent

sludge from entering the engine internals.

1.8 litre (R2A type)

Removal

1With the engine removed, proceed as

follows.

2Remove the flywheel/driveplate and the

engine adapter plate.

3Unscrew the fourteen securing bolts and

withdraw the two reinforcing strips and the

sump. If the sump is stuck, carefully tap it

sideways to free it. Do not prise between the

mating faces.

27Sump - removal and refitting

26Crankshaft rear oil seal -

renewal

25Crankshaft front oil seal -

renewal

24Flywheel/driveplate - removal,

inspection and refitting

CVH engines 2C•19

2C

25.5 Crankshaft front oil seal (arrowed)

located in oil pump housing - 1.8 litre (R2A)26.3 Using a special tool to fit the

crankshaft rear oil seal - 1.8 litre (R2A)26.2 Crankshaft rear oil seal location

(arrowed)

25.4 Using a special tool to fit the

crankshaft front oil seal - 1.8 litre (R2A)24.2 Using an improvised tool to hold the

flywheel stationary while tightening the

securing bolts - 1.8 litre (R2A)

A tool can be improvised to fit

the crankshaft front oil seal

by using a metal tube of

suitable diameter and a large

washer or metal disc. Do not attempt to

drive the seal home using a tube drift.

Page 20 of 24

4Recover the gasket.

5Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

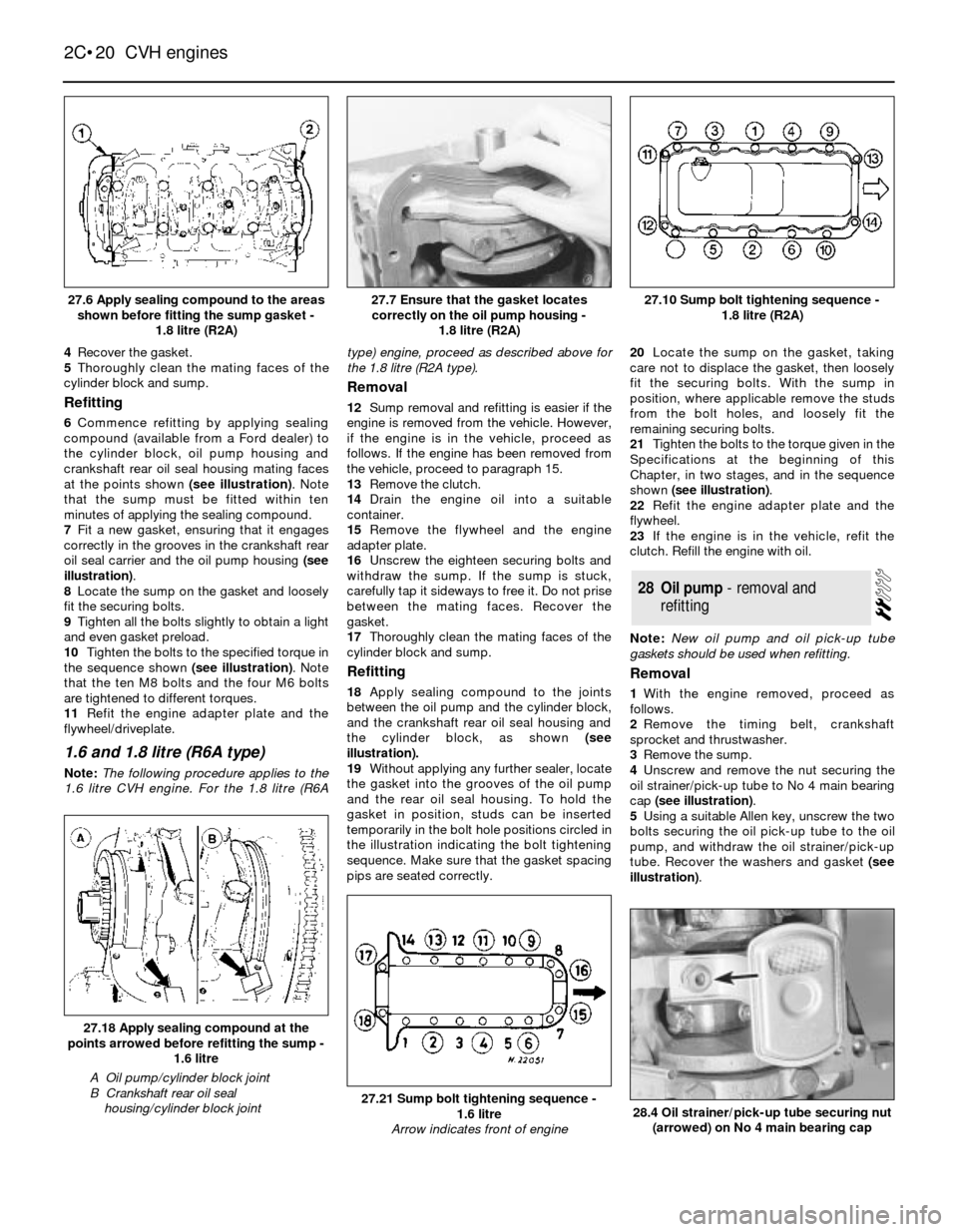

6Commence refitting by applying sealing

compound (available from a Ford dealer) to

the cylinder block, oil pump housing and

crankshaft rear oil seal housing mating faces

at the points shown (see illustration). Note

that the sump must be fitted within ten

minutes of applying the sealing compound.

7Fit a new gasket, ensuring that it engages

correctly in the grooves in the crankshaft rear

oil seal carrier and the oil pump housing (see

illustration).

8Locate the sump on the gasket and loosely

fit the securing bolts.

9Tighten all the bolts slightly to obtain a light

and even gasket preload.

10Tighten the bolts to the specified torque in

the sequence shown (see illustration). Note

that the ten M8 bolts and the four M6 bolts

are tightened to different torques.

11Refit the engine adapter plate and the

flywheel/driveplate.

1.6 and 1.8 litre (R6A type)

Note: The following procedure applies to the

1.6 litre CVH engine. For the 1.8 litre (R6Atype) engine, proceed as described above for

the 1.8 litre (R2A type).

Removal

12Sump removal and refitting is easier if the

engine is removed from the vehicle. However,

if the engine is in the vehicle, proceed as

follows. If the engine has been removed from

the vehicle, proceed to paragraph 15.

13Remove the clutch.

14Drain the engine oil into a suitable

container.

15Remove the flywheel and the engine

adapter plate.

16Unscrew the eighteen securing bolts and

withdraw the sump. If the sump is stuck,

carefully tap it sideways to free it. Do not prise

between the mating faces. Recover the

gasket.

17Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

18Apply sealing compound to the joints

between the oil pump and the cylinder block,

and the crankshaft rear oil seal housing and

the cylinder block, as shown (see

illustration).

19Without applying any further sealer, locate

the gasket into the grooves of the oil pump

and the rear oil seal housing. To hold the

gasket in position, studs can be inserted

temporarily in the bolt hole positions circled in

the illustration indicating the bolt tightening

sequence. Make sure that the gasket spacing

pips are seated correctly.20Locate the sump on the gasket, taking

care not to displace the gasket, then loosely

fit the securing bolts. With the sump in

position, where applicable remove the studs

from the bolt holes, and loosely fit the

remaining securing bolts.

21Tighten the bolts to the torque given in the

Specifications at the beginning of this

Chapter, in two stages, and in the sequence

shown (see illustration).

22Refit the engine adapter plate and the

flywheel.

23If the engine is in the vehicle, refit the

clutch. Refill the engine with oil.

Note: New oil pump and oil pick-up tube

gaskets should be used when refitting.

Removal

1With the engine removed, proceed as

follows.

2Remove the timing belt, crankshaft

sprocket and thrustwasher.

3Remove the sump.

4Unscrew and remove the nut securing the

oil strainer/pick-up tube to No 4 main bearing

cap (see illustration).

5Using a suitable Allen key, unscrew the two

bolts securing the oil pick-up tube to the oil

pump, and withdraw the oil strainer/pick-up

tube. Recover the washers and gasket (see

illustration).

28Oil pump - removal and

refitting

2C•20CVH engines

27.6 Apply sealing compound to the areas

shown before fitting the sump gasket -

1.8 litre (R2A)27.10 Sump bolt tightening sequence -

1.8 litre (R2A)

27.21 Sump bolt tightening sequence -

1.6 litre

Arrow indicates front of engine

27.18 Apply sealing compound at the

points arrowed before refitting the sump -

1.6 litre

A Oil pump/cylinder block joint

B Crankshaft rear oil seal

housing/cylinder block joint

27.7 Ensure that the gasket locates

correctly on the oil pump housing -

1.8 litre (R2A)

28.4 Oil strainer/pick-up tube securing nut

(arrowed) on No 4 main bearing cap