spark plugs FORD SIERRA 1983 1.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 18, PDF Size: 0.9 MB

Page 8 of 18

Dismantling

1Refer to Chapter 2, PartA, Section 18,

paragraphs 1 to 8 inclusive.

2A suitable selection of splined and Torx

sockets will be required to remove many of

the bolts when dismantling the engine.

3Before dismantling the main engine

components, the following externally-

mounted ancillary components can be

removed, with reference to the relevant

Chapters of this Manual and the relevant

Sections of this Chapter, where applicable.

Inlet manifold (and carburettor, if applicable)

Exhaust manifold

Alternator.

Coolant pump, and thermostat

Alternator/coolant pump drivebelt tensioner

Distributor cap, HT leads and spark plugs

Oil pressure warning lamp switch

Crankshaft speed/position sensor

Oil filter

Dipstick

Engine mounting brackets (if not already done)

Crankcase ventilation pipe and hoses

Clutch

Alternator mounting bracket.

Air conditioning compressor mounting

bracket (where applicable).

Engine lifting brackets.

Examination and renovation

4Refer to Chapter 2, PartA, Section 18, but

note that the connecting rod bolts should be

renewed on reassembly, and when renewing

the cylinder head bolts, the latest type bolts

with hexagonal heads should always be used.

Reassembly

5Proceed as described in Chapter 2, PartA,

Section 18, noting the following:

6If they have been removed, new cylinder

head bolts (both M11 and M8, of the latest

type with hexagonal heads), flywheel bolts,

and connecting rod bolts must be used.

Note: Refer to the warning at the beginning of

Section 5 before proceeding. A suitable puller

will be required to remove the crankshaft pulley.

A new crankshaft pulley bolt, a new timing chain

tensioner plunger assembly, new upper and

lower timing chain cover gaskets, and a new

camshaft cover gasket and reinforcing sleeve

sealing rings, must be used on refitting.

Removal

1If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.c)On carburettor models, remove the air

cleaner.

d)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

e)Disconnect the breather hose from the

camshaft cover.

f)Remove the distributor cap and HT leads,

and the rotor arm and housing.

2Proceed as described in paragraphs 2 to 11

inclusive of Section 18 (see illustration).

3Remove the alternator drivebelt.

4Slacken the crankshaft pulley bolt. Prevent

the crankshaft from turning by engaging top

gear (manual gearbox only) and having an

assistant press the brake pedal hard, or by

removing the starter motor and jamming the

ring gear teeth with a lever.

5Unscrew the bolt part-way, and use a puller

to remove the crankshaft pulley. The legs ofthe puller must be suitably shaped to enable

them to rest on the metal surfaces of the

pulley. Do not use a puller on the rubber

surface of the pulley (see illustrations).

15Timing chain and sprockets -

removal and refitting

14Engine dismantling,

examination, renovation and

reassembly - general information

2B•8DOHC engine

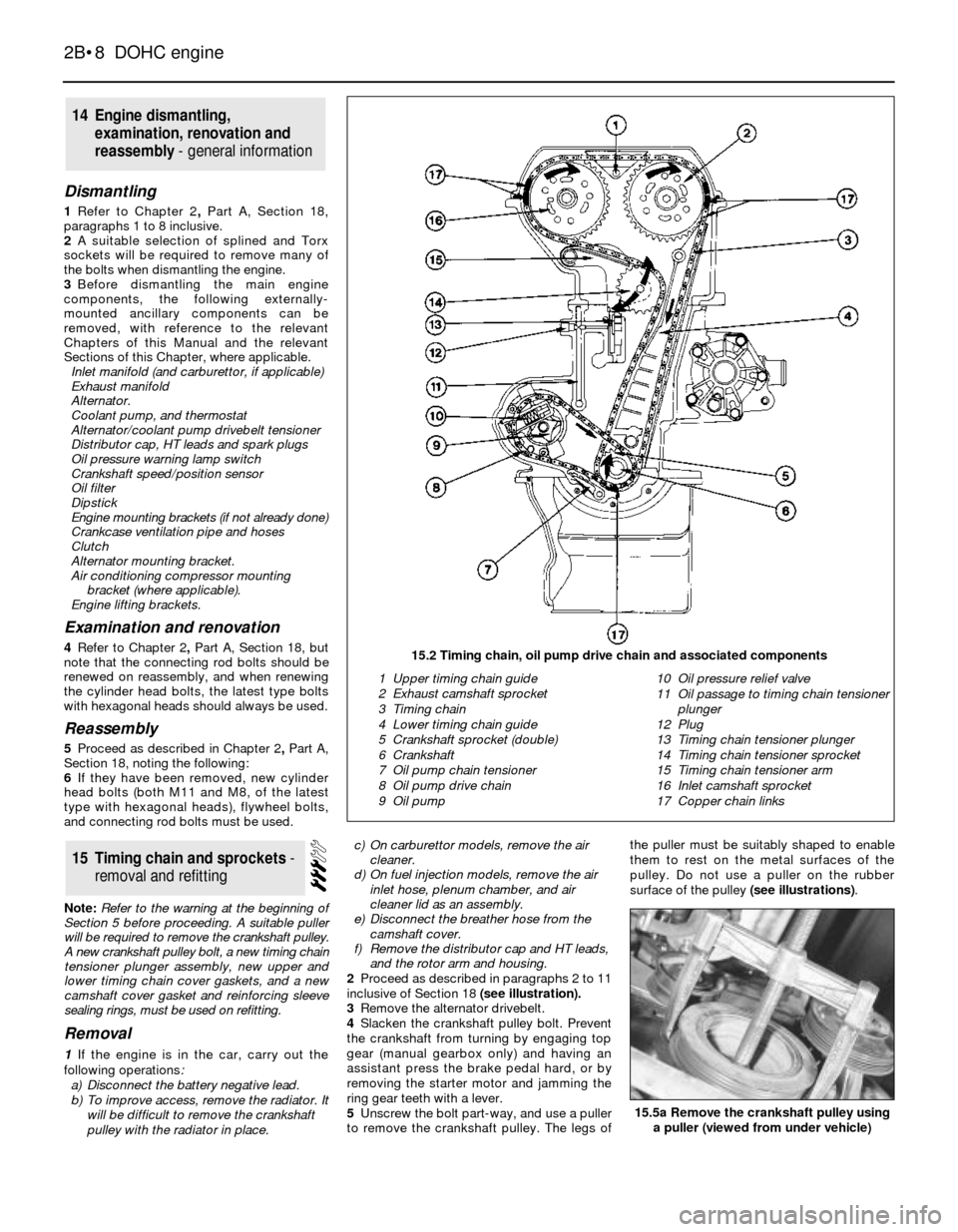

15.2 Timing chain, oil pump drive chain and associated components

1 Upper timing chain guide

2 Exhaust camshaft sprocket

3 Timing chain

4 Lower timing chain guide

5 Crankshaft sprocket (double)

6 Crankshaft

7 Oil pump chain tensioner

8 Oil pump drive chain

9 Oil pump10 Oil pressure relief valve

11 Oil passage to timing chain tensioner

plunger

12 Plug

13 Timing chain tensioner plunger

14 Timing chain tensioner sprocket

15 Timing chain tensioner arm

16 Inlet camshaft sprocket

17 Copper chain links

15.5a Remove the crankshaft pulley using

a puller (viewed from under vehicle)