roof FORD SIERRA 1983 1.G Fuel And Exhaust Systems Carburettor Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 20, PDF Size: 0.83 MB

Page 4 of 20

2.0 litre DOHC models

Inlet manifold nuts and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2415 to 18

Exhaust manifold nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2515 to 18

Carburettor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

General information

The fuel system on carburettor models

may comprise a fuel tank, a fuel pump, a fuel

pressure regulator and/or vapour separator, a

downdraught carburettor and a

thermostatically-controlled air cleaner.

On Saloon, Hatchback and Estate models,

the fuel tank is mounted under the rear of the

vehicle, on the right-hand side. On P100

models, the fuel tank is mounted behind the

cab, between the chassis frame and the load

area. The tank is ventilated, and has a simple

filler pipe and a fuel gauge sender unit.

The mechanical fuel pump is a diaphragm

type, actuated by a pushrod bearing on an

eccentric cam on the auxiliary shaft on SOHC

models, or on the camshaft on CVH models.

DOHC models and models with air

conditioning have an electric fuel pump

mounted under the rear of the vehicle, next to

the fuel tank. DOHC models have a combined

pump and fuel level sender unit.

The fuel pressure regulator and/or vapour

separator is used to stabilise the fuel supply

to the carburettor. The pressure regulator

provides a constant fuel pressure, and hence

maintains a constant float level in the

carburettor which reduces exhaust emission

levels. The vapour separator purges vapour

from the carburettor fuel supply, thus

improving hot starting qualities. All models up

to 1985 are fitted with a fuel pressure

regulator. All models from 1985 except 2.0

litre SOHC models and CVH models are fitted

with a combined fuel pressure regu-

lator/vapour separator. 2.0 litre models from

1985 and CVH models are fitted with a vapour

separator only. DOHC models have no

pressure regulator or vapour separator fitted.

The carburettor may be either a Ford

variable venturi (VV) type, a Weber twin venturi

(2V or 2V TLD) type, or a Pierburg twin venturi

(2V) type, depending on model. Each type ofcarburettor is available in several versions to

suit particular engine and equipment

combinations.

The air cleaner has a vacuum or waxstat

controlled air inlet supplying a blend of hot

and cold air to suit the prevailing engine

operating conditions.

Precautions

Tamperproof adjustment screws -

caution

Certain adjustment points in the fuel system

(and elsewhere) are protected by

“tamperproof” caps, plugs or seals. The

purpose of such tamperproofing is to

discourage, and to detent, adjustment by

unqualified operators.

In some EEC countries (though not yet in the

UK) it is an offence to drive a vehicle with

missing or broken tamperproof seals. Before

disturbing a tamperproof seal, satisfy yourself

that you will not be breaking local or national

anti-pollution regulations by doing so. Fit a

new seal when adjustment is complete when

this is required by law.

Do not break tamperproof seals on a vehicle

which is still under warranty.

Work proceedures

When working on fuel system components,

scrupulous cleanliness must be observed,

and care must be taken not to introduce any

foreign matter into fuel lines or components.

Carburettors in particular are delicateinstruments, and care should be taken not to

disturb any components unnecessarily.

Before attempting work on a carburettor,

ensure that the relevant spares are available.

Full overhaul procedures for carburettors have

not been given in this Chapter, as complete

strip-down of a carburettor is unlikely to cure

a fault which is not immediately obvious,

without introducing new problems. If

persistent problems are encountered, it is

recommended that the advice of a Ford dealer

or carburettor specialist is sought. Most

dealers will be able to provide carburettor re-

jetting and servicing facilities, and if necessary

it should be possible to purchase a

reconditioned carburettor of the relevant type.

Refer to Chapter 1, Section 38.

Removal

1On CVH models, disconnect the battery

negative lead.

2Remove the screws from the top of the air

cleaner cover (see illustration).

3Disconnect the cold air inlet hose from the

air cleaner spout or the inlet on the front body

panel. The hose is secured by toggle clips

(see illustration).

4Disconnect the hot air inlet hose from the

air cleaner spout or the hot air shroud on the

exhaust manifold (see illustration).

5Disconnect the vacuum hose from the inlet

manifold (see illustration).

6On DOHC models, disconnect the

camshaft cover breather hose

7Where applicable, on OHC models remove

the screw securing the air cleaner body to the

camshaft cover.

8Withdraw the air cleaner, and on CVH

models, disconnect the wiring plug from the

3Air cleaner - removal and

refitting

2Air cleaner element - renewal

1General information and

precautions

4A•4Fuel and exhaust systems - carburettor

3.4 Hot air intake hose on hot air shroud3.3 Disconnecting the cold air intake hose

from the air cleaner spout3.2 Air cleaner securing screws (arrowed)

Warning - Fuel - Many of the

procedures given in this

Chapter involve the

disconnection of fuel pipes and

system components which may result in

some fuel spillage. Before carrying out

any operation on the fuel system, refer to

the precautions given in the “Safety first”

Section at the beginning of this manual

and follow them implicitly. Petrol Is a

highly dangerous and volatile substance,

and the precautions necessary when

handling it cannot be over stressed.

Page 15 of 20

Refer to Chapter 1, Sections 15 and 16.

1Check the idle speed and mixture

adjustment. The idle speed must be correct

before attempting to check or adjust the fast

idle speed.

2With the engine at normal operating

temperature, and a tachometer connected in

accordance with the manufacturer’s

instructions proceed as follows.

3Remove the air cleaner.

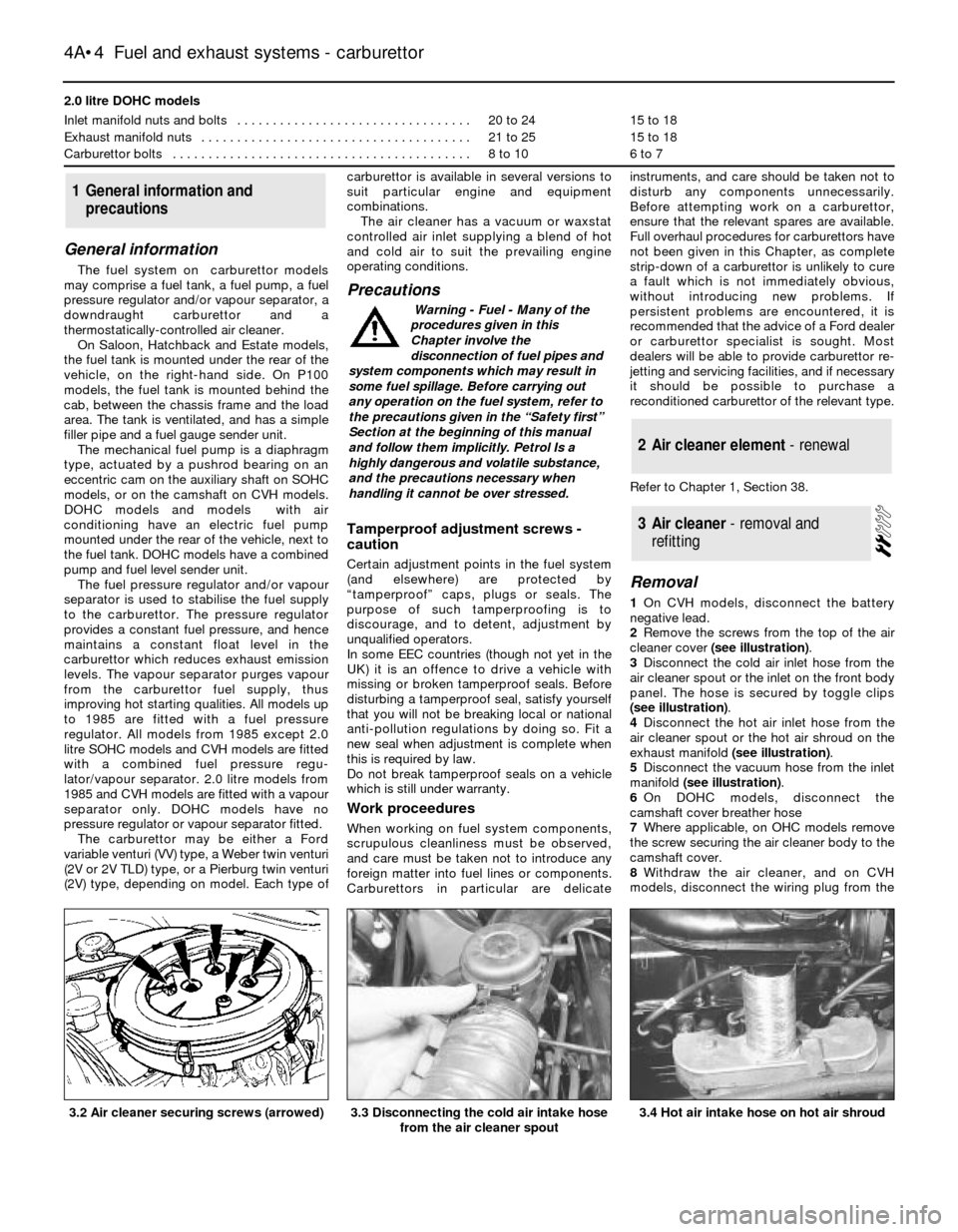

4Position the fast idle speed adjustment

screw on the lowest (6th) step of the fast idle

cam (see illustration).

5Check that the fast idle speed is as

specified. If adjustment is required, stop the

engine and proceed as follows.

6Remove the tamperproof cap from the fast

idle speed adjustment screw.

7Ensure that the adjustment screw is still

resting on the lowest step of the fast idle cam,

then open the throttle so that a small

screwdriver can be used to adjust the screw

from below the carburettor.

8Start the engine and recheck the fast idle

speed.

9If necessary, repeat the procedure given in

paragraphs 7 and 8 until the correct fast idle

speed is obtained.

10On completion of adjustment, stop the

engine and disconnect the tachometer, then

refit the tamperproof cap to the adjustment

screw, and refit the air cleaner.Note: A new gasket must be used when

refitting the carburettor. A tachometer and an

exhaust gas analyser will be required to check

the idle speed and mixture on completion.Removal

1Disconnect the battery negative lead.

2Remove the air cleaner.

3Disconnect the wiring from the anti-

dieselling (anti-run-on) valve.

4Disconnect the wiring from the automatic

choke heater.

5Disconnect the fuel supply and return

hoses, noting their locations to aid refitting.

Plug the ends of the hoses to minimise petrol

spillage.

6Disconnect the link arm from the throttle

linkage.

7Disconnect the vacuum pipe.

8Release the coolant hose from the bracket

under the automatic choke housing.

9Unscrew the four Torx screws, and lift the

carburettor from the inlet manifold. Recover

the gasket.

Refitting

11Refitting is a reversal of removal, bearing

in mind the following points.

12Ensure that the mating faces of the inlet

manifold and the carburettor are clean, and

use a new gasket.

13Ensure that all hoses, pipes and wiring are

correctly routed, and free from restrictions. If

any of the hoses were originally secured with

crimped-type clips, discard these, and use

new worm-drive clips on refitting.

14Make sure that the coolant hose is

correctly positioned in the bracket under the

automatic choke housing.

15On completion, check and if necessary

adjust the idle speed and mixture.

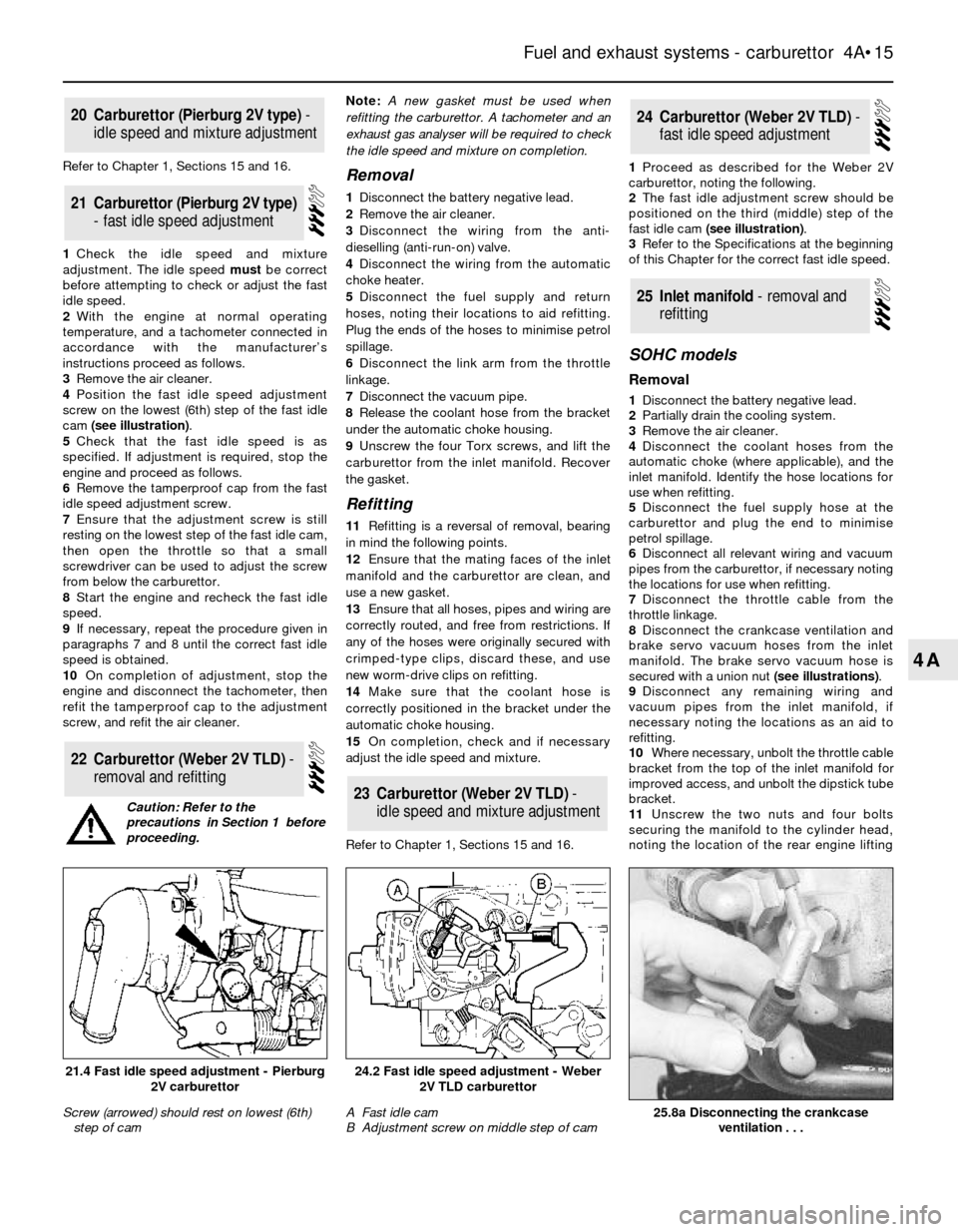

Refer to Chapter 1, Sections 15 and 16.1Proceed as described for the Weber 2V

carburettor, noting the following.

2The fast idle adjustment screw should be

positioned on the third (middle) step of the

fast idle cam (see illustration).

3Refer to the Specifications at the beginning

of this Chapter for the correct fast idle speed.

SOHC models

Removal

1Disconnect the battery negative lead.

2Partially drain the cooling system.

3Remove the air cleaner.

4Disconnect the coolant hoses from the

automatic choke (where applicable), and the

inlet manifold. Identify the hose locations for

use when refitting.

5Disconnect the fuel supply hose at the

carburettor and plug the end to minimise

petrol spillage.

6Disconnect all relevant wiring and vacuum

pipes from the carburettor, if necessary noting

the locations for use when refitting.

7Disconnect the throttle cable from the

throttle linkage.

8Disconnect the crankcase ventilation and

brake servo vacuum hoses from the inlet

manifold. The brake servo vacuum hose is

secured with a union nut (see illustrations).

9Disconnect any remaining wiring and

vacuum pipes from the inlet manifold, if

necessary noting the locations as an aid to

refitting.

10Where necessary, unbolt the throttle cable

bracket from the top of the inlet manifold for

improved access, and unbolt the dipstick tube

bracket.

11Unscrew the two nuts and four bolts

securing the manifold to the cylinder head,

noting the location of the rear engine lifting

25Inlet manifold - removal and

refitting

24Carburettor (Weber 2V TLD) -

fast idle speed adjustment

23Carburettor (Weber 2V TLD) -

idle speed and mixture adjustment

22Carburettor (Weber 2V TLD) -

removal and refitting

21Carburettor (Pierburg 2V type)

- fast idle speed adjustment

20Carburettor (Pierburg 2V type) -

idle speed and mixture adjustment

Fuel and exhaust systems - carburettor 4A•15

4A

25.8a Disconnecting the crankcase

ventilation . . .

24.2 Fast idle speed adjustment - Weber

2V TLD carburettor

A Fast idle cam

B Adjustment screw on middle step of cam21.4 Fast idle speed adjustment - Pierburg

2V carburettor

Screw (arrowed) should rest on lowest (6th)

step of cam

Caution: Refer to the

precautions in Section 1 before

proceeding.