tow FORD SIERRA 1983 1.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1983, Model line: SIERRA, Model: FORD SIERRA 1983 1.GPages: 26, PDF Size: 0.57 MB

Page 1 of 26

General dimensions and Weights . . . . . . . . . . . .REF•1

Buying Spare Parts . . . . . . . . . . . . . . . . . . . . . . .REF•3

Vehicle Identification Numbers . . . . . . . . . . . . . .REF•3

General Repair Procedures . . . . . . . . . . . . . . . . .REF•4

Tools and Working Facilities . . . . . . . . . . . . . . . .REF•5MOT Test Checks . . . . . . . . . . . . . . . . . . . . . . . .REF•7

Fault Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . .REF•11

Glossary of Technical Terms . . . . . . . . . . . . . . .REF•18

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .REF•23

ReferenceREF•1

REF

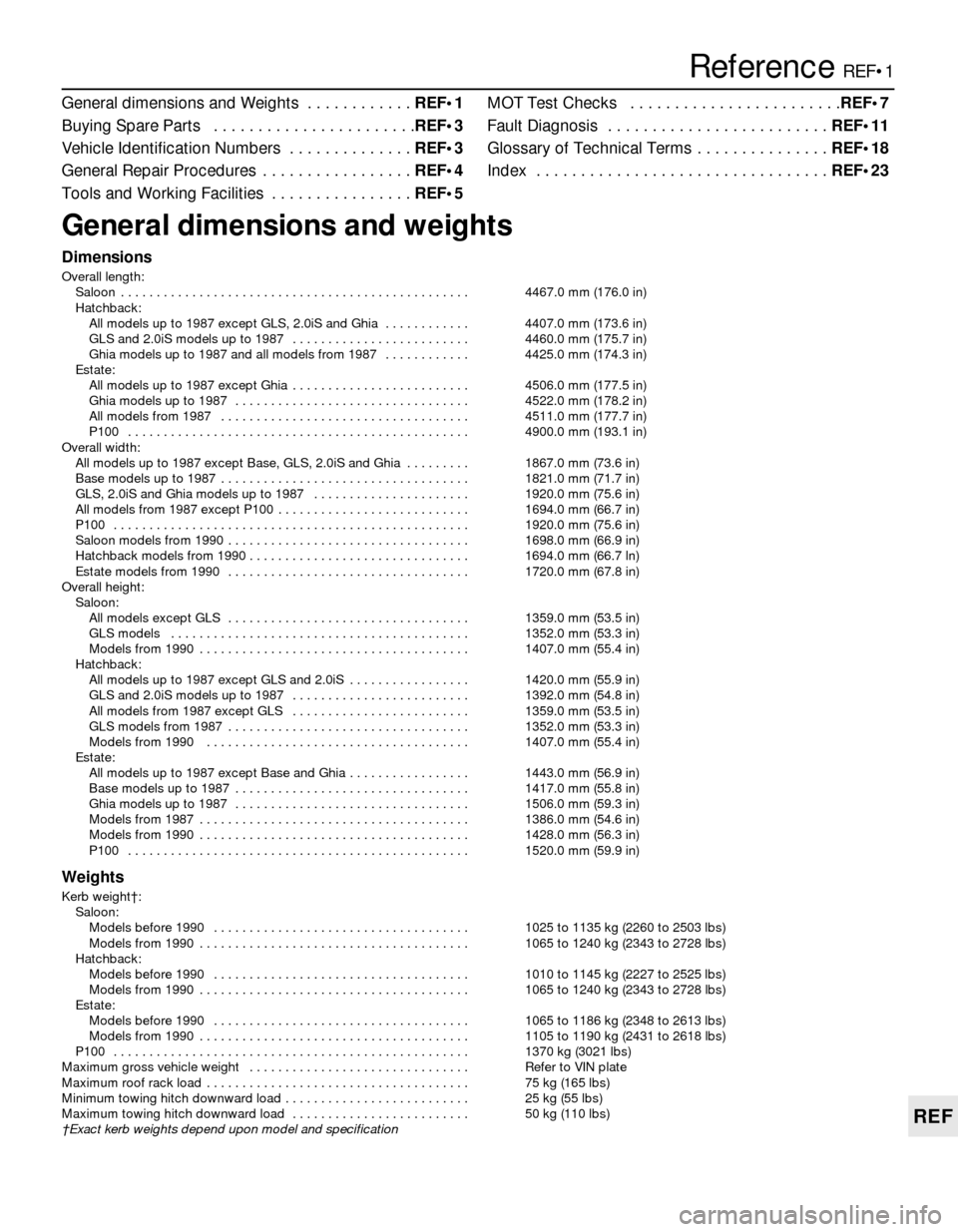

General dimensions and weights

Dimensions

Overall length:

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4467.0 mm (176.0 in)

Hatchback:

All models up to 1987 except GLS, 2.0iS and Ghia . . . . . . . . . . . . 4407.0 mm (173.6 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 4460.0 mm (175.7 in)

Ghia models up to 1987 and all models from 1987 . . . . . . . . . . . . 4425.0 mm (174.3 in)

Estate:

All models up to 1987 except Ghia . . . . . . . . . . . . . . . . . . . . . . . . . 4506.0 mm (177.5 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4522.0 mm (178.2 in)

All models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4511.0 mm (177.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4900.0 mm (193.1 in)

Overall width:

All models up to 1987 except Base, GLS, 2.0iS and Ghia . . . . . . . . . 1867.0 mm (73.6 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1821.0 mm (71.7 in)

GLS, 2.0iS and Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

All models from 1987 except P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

Saloon models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1698.0 mm (66.9 in)

Hatchback models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 ln)

Estate models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1720.0 mm (67.8 in)

Overall height:

Saloon:

All models except GLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Hatchback:

All models up to 1987 except GLS and 2.0iS . . . . . . . . . . . . . . . . . 1420.0 mm (55.9 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 1392.0 mm (54.8 in)

All models from 1987 except GLS . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Estate:

All models up to 1987 except Base and Ghia . . . . . . . . . . . . . . . . . 1443.0 mm (56.9 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1417.0 mm (55.8 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1506.0 mm (59.3 in)

Models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1386.0 mm (54.6 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1428.0 mm (56.3 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1520.0 mm (59.9 in)

Weights

Kerb weight†:

Saloon:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1025 to 1135 kg (2260 to 2503 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Hatchback:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1010 to 1145 kg (2227 to 2525 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Estate:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1186 kg (2348 to 2613 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1105 to 1190 kg (2431 to 2618 lbs)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1370 kg (3021 lbs)

Maximum gross vehicle weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to VIN plate

Maximum roof rack load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg (165 lbs)

Minimum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . . 25 kg (55 lbs)

Maximum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . 50 kg (110 lbs)

†Exact kerb weights depend upon model and specification

Page 4 of 26

Whenever servicing, repair or overhaul work

is carried out on the car or its components, it

is necessary to observe the following

procedures and instructions. This will assist in

carrying out the operation efficiently and to a

professional standard of workmanship.

Joint mating faces and gaskets

When separating components at their

mating faces, never insert screwdrivers or

similar implements into the joint between the

faces in order to prise them apart. This can

cause severe damage which results in oil

leaks, coolant leaks, etc upon reassembly.

Separation is usually achieved by tapping

along the joint with a soft-faced hammer in

order to break the seal. However, note that

this method may not be suitable where

dowels are used for component location.

Where a gasket is used between the mating

faces of two components, ensure that it is

renewed on reassembly, and fit it dry unless

otherwise stated in the repair procedure.

Make sure that the mating faces are clean and

dry, with all traces of old gasket removed.

When cleaning a joint face, use a tool which is

not likely to score or damage the face, and

remove any burrs or nicks with an oilstone or

fine file.

Make sure that tapped holes are cleaned

with a pipe cleaner, and keep them free of

jointing compound, if this is being used,

unless specifically instructed otherwise.

Ensure that all orifices, channels or pipes

are clear, and blow through them, preferably

using compressed air.

Oil seals

Oil seals can be removed by levering them

out with a wide flat-bladed screwdriver or

similar implement. Alternatively, a number of

self-tapping screws may be screwed into the

seal, and these used as a purchase for pliers or

some similar device in order to pull the seal free.

Whenever an oil seal is removed from its

working location, either individually or as part

of an assembly, it should be renewed.

The very fine sealing lip of the seal is easily

damaged, and will not seal if the surface it

contacts is not completely clean and free from

scratches, nicks or grooves. If the original

sealing surface of the component cannot be

restored, and the manufacturer has not made

provision for slight relocation of the seal

relative to the sealing surface, the component

should be renewed.

Protect the lips of the seal from any surface

which may damage them in the course of

fitting. Use tape or a conical sleeve where

possible. Lubricate the seal lips with oil before

fitting and, on dual-lipped seals, fill the space

between the lips with grease.

Unless otherwise stated, oil seals must be

fitted with their sealing lips toward the

lubricant to be sealed.

Use a tubular drift or block of wood of the

appropriate size to install the seal and, if the

seal housing is shouldered, drive the seal

down to the shoulder. If the seal housing is

unshouldered, the seal should be fitted withits face flush with the housing top face (unless

otherwise instructed).

Screw threads and fastenings

Seized nuts, bolts and screws are quite a

common occurrence where corrosion has set

in, and the use of penetrating oil or releasing

fluid will often overcome this problem if the

offending item is soaked for a while before

attempting to release it. The use of an impact

driver may also provide a means of releasing

such stubborn fastening devices, when used

in conjunction with the appropriate

screwdriver bit or socket. If none of these

methods works, it may be necessary to resort

to the careful application of heat, or the use of

a hacksaw or nut splitter device.

Studs are usually removed by locking two

nuts together on the threaded part, and then

using a spanner on the lower nut to unscrew the

stud. Studs or bolts which have broken off

below the surface of the component in which

they are mounted can sometimes be removed

using a proprietary stud extractor. Always

ensure that a blind tapped hole is completely

free from oil, grease, water or other fluid before

installing the bolt or stud. Failure to do this could

cause the housing to crack due to the hydraulic

action of the bolt or stud as it is screwed in.

When tightening a castellated nut to accept

a split pin, tighten the nut to the specified

torque, where applicable, and then tighten

further to the next split pin hole. Never

slacken the nut to align the split pin hole,

unless stated in the repair procedure.

When checking or retightening a nut or bolt

to a specified torque setting, slacken the nut

or bolt by a quarter of a turn, and then

retighten to the specified setting. However,

this should not be attempted where angular

tightening has been used.

For some screw fastenings, notably

cylinder head bolts or nuts, torque wrench

settings are no longer specified for the latter

stages of tightening, “angle-tightening” being

called up instead. Typically, a fairly low torque

wrench setting will be applied to the

bolts/nuts in the correct sequence, followed

by one or more stages of tightening through

specified angles.

Locknuts, locktabs and washers

Any fastening which will rotate against a

component or housing in the course of tightening

should always have a washer between it and the

relevant component or housing.

Spring or split washers should always be

renewed when they are used to lock a critical

component such as a big-end bearing

retaining bolt or nut. Locktabs which are

folded over to retain a nut or bolt should

always be renewed.

Self-locking nuts can be re-used in non-

critical areas, providing resistance can be felt

when the locking portion passes over the bolt or

stud thread. However, it should be noted that

self-locking stiffnuts tend to lose their

effectiveness after long periods of use, and insuch cases should be renewed as a matter of

course.

Split pins must always be replaced with

new ones of the correct size for the hole.

When thread-locking compound is found

on the threads of a fastener which is to be re-

used, it should be cleaned off with a wire

brush and solvent, and fresh compound

applied on reassembly.

Special tools

Some repair procedures in this manual

entail the use of special tools such as a press,

two or three-legged pullers, spring

compressors, etc. Wherever possible, suitable

readily-available alternatives to the

manufacturer’s special tools are described,

and are shown in use. In some instances,

where no alternative is possible, it has been

necessary to resort to the use of a

manufacturer’s tool, and this has been done

for reasons of safety as well as the efficient

completion of the repair operation. Unless you

are highly-skilled and have a thorough

understanding of the procedures described,

never attempt to bypass the use of any

special tool when the procedure described

specifies its use. Not only is there a very great

risk of personal injury, but expensive damage

could be caused to the components involved.

Environmental considerations

When disposing of used engine oil, brake

fluid, antifreeze, etc, give due consideration to

any detrimental environmental effects. Do not,

for instance, pour any of the above liquids

down drains into the general sewage system,

or onto the ground to soak away. Many local

council refuse tips provide a facility for waste

oil disposal, as do some garages. If none of

these facilities are available, consult your local

Environmental Health Department for further

advice.

With the universal tightening-up of

legislation regarding the emission of

environmentally-harmful substances from

motor vehicles, most current vehicles have

tamperproof devices fitted to the main

adjustment points of the fuel system. These

devices are primarily designed to prevent

unqualified persons from adjusting the fuel/air

mixture, with the chance of a consequent

increase in toxic emissions. If such devices

are encountered during servicing or overhaul,

they should, wherever possible, be renewed

or refitted in accordance with the vehicle

manufacturer’s requirements or current

legislation.

REF•4General Repair Procedures

Note: It is

antisocial and

illegal to dump oil

down the drain. To

find the location of

your local oil

recycling bank,

call this number

free.

Page 25 of 26

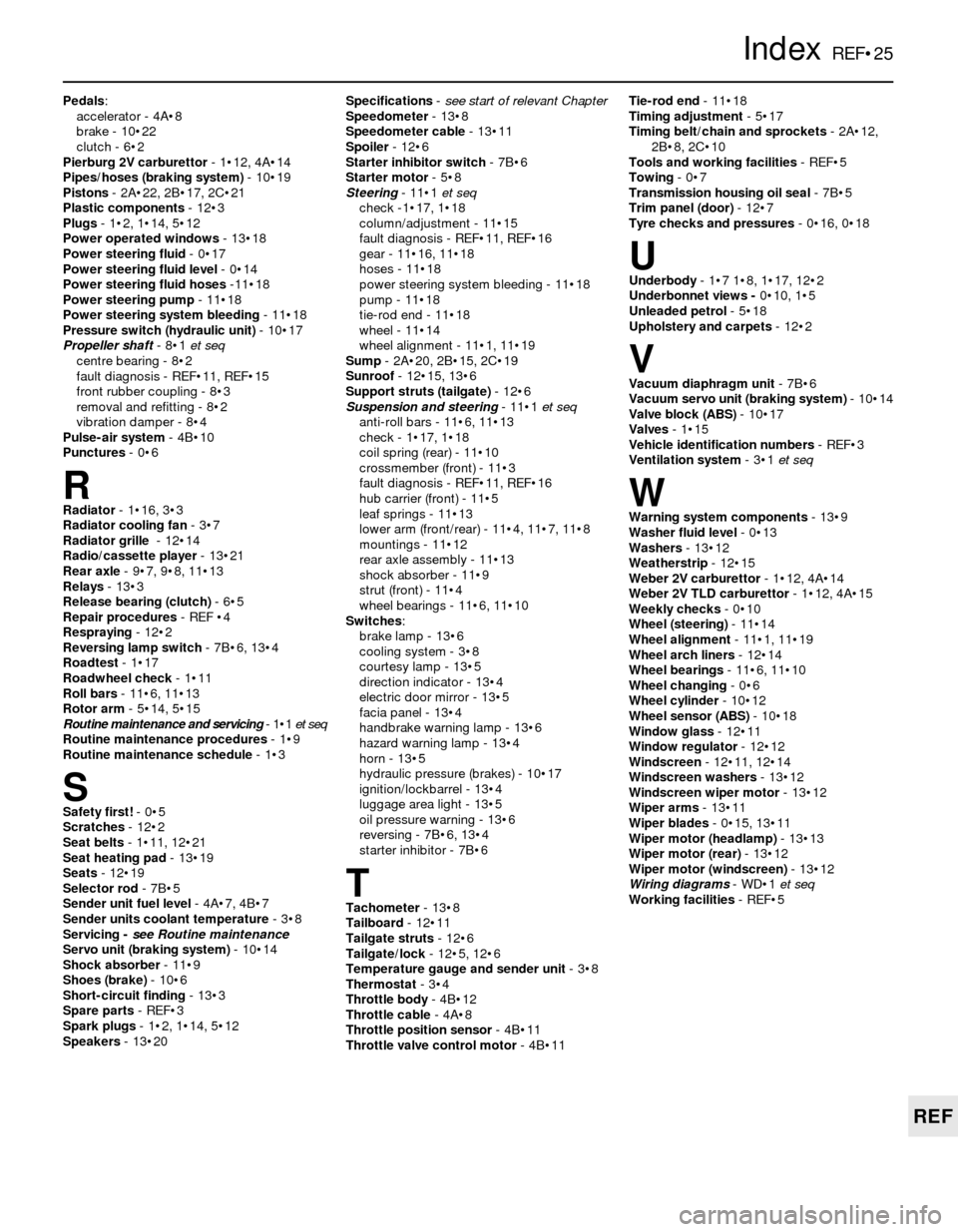

Pedals:

accelerator - 4A•8

brake - 10•22

clutch - 6•2

Pierburg 2V carburettor- 1•12, 4A•14

Pipes/hoses (braking system)- 10•19

Pistons- 2A•22, 2B•17, 2C•21

Plastic components- 12•3

Plugs- 1•2, 1•14, 5•12

Power operated windows- 13•18

Power steering fluid- 0•17

Power steering fluid level- 0•14

Power steering fluid hoses-11•18

Power steering pump- 11•18

Power steering system bleeding- 11•18

Pressure switch (hydraulic unit)- 10•17

Propeller shaft- 8•1 et seq

centre bearing - 8•2

fault diagnosis - REF•11, REF•15

front rubber coupling - 8•3

removal and refitting - 8•2

vibration damper - 8•4

Pulse-air system- 4B•10

Punctures- 0•6

RRadiator- 1•16, 3•3

Radiator cooling fan- 3•7

Radiator grille- 12•14

Radio/cassette player- 13•21

Rear axle- 9•7, 9•8, 11•13

Relays- 13•3

Release bearing (clutch)- 6•5

Repair procedures- REF •4

Respraying- 12•2

Reversing lamp switch- 7B•6, 13•4

Roadtest- 1•17

Roadwheel check- 1•11

Roll bars- 11•6, 11•13

Rotor arm- 5•14, 5•15

Routine maintenance and servicing- 1•1 et seq

Routine maintenance procedures- 1•9

Routine maintenance schedule- 1•3

SSafety first!- 0•5

Scratches- 12•2

Seat belts- 1•11, 12•21

Seat heating pad- 13•19

Seats- 12•19

Selector rod- 7B•5

Sender unit fuel level- 4A•7, 4B•7

Sender units coolant temperature- 3•8

Servicing -see Routine maintenance

Servo unit (braking system)- 10•14

Shock absorber- 11•9

Shoes (brake)- 10•6

Short-circuit finding- 13•3

Spare parts- REF•3

Spark plugs- 1•2, 1•14, 5•12

Speakers- 13•20Specifications- see start of relevant Chapter

Speedometer- 13•8

Speedometer cable- 13•11

Spoiler- 12•6

Starter inhibitor switch- 7B•6

Starter motor- 5•8

Steering- 11•1 et seq

check -1•17, 1•18

column/adjustment - 11•15

fault diagnosis - REF•11, REF•16

gear - 11•16, 11•18

hoses - 11•18

power steering system bleeding - 11•18

pump - 11•18

tie-rod end - 11•18

wheel - 11•14

wheel alignment - 11•1, 11•19

Sump- 2A•20, 2B•15, 2C•19

Sunroof- 12•15, 13•6

Support struts (tailgate)- 12•6

Suspension and steering- 11•1 et seq

anti-roll bars - 11•6, 11•13

check - 1•17, 1•18

coil spring (rear) - 11•10

crossmember (front) - 11•3

fault diagnosis - REF•11, REF•16

hub carrier (front) - 11•5

leaf springs - 11•13

lower arm (front/rear) - 11•4, 11•7, 11•8

mountings - 11•12

rear axle assembly - 11•13

shock absorber - 11•9

strut (front) - 11•4

wheel bearings - 11•6, 11•10

Switches:

brake lamp - 13•6

cooling system - 3•8

courtesy lamp - 13•5

direction indicator - 13•4

electric door mirror - 13•5

facia panel - 13•4

handbrake warning lamp - 13•6

hazard warning lamp - 13•4

horn - 13•5

hydraulic pressure (brakes) - 10•17

ignition/lockbarrel - 13•4

luggage area light - 13•5

oil pressure warning - 13•6

reversing - 7B•6, 13•4

starter inhibitor - 7B•6

TTachometer- 13•8

Tailboard- 12•11

Tailgate struts- 12•6

Tailgate/lock- 12•5, 12•6

Temperature gauge and sender unit- 3•8

Thermostat- 3•4

Throttle body- 4B•12

Throttle cable- 4A•8

Throttle position sensor- 4B•11

Throttle valve control motor- 4B•11Tie-rod end- 11•18

Timing adjustment- 5•17

Timing belt/chain and sprockets- 2A•12,

2B•8, 2C•10

Tools and working facilities- REF•5

Towing- 0•7

Transmission housing oil seal- 7B•5

Trim panel (door)- 12•7

Tyre checks and pressures- 0•16, 0•18

UUnderbody- 1•7 1•8, 1•17, 12•2

Underbonnet views -0•10, 1•5

Unleaded petrol- 5•18

Upholstery and carpets- 12•2

VVacuum diaphragm unit- 7B•6

Vacuum servo unit (braking system)- 10•14

Valve block (ABS)- 10•17

Valves- 1•15

Vehicle identification numbers- REF•3

Ventilation system- 3•1 et seq

WWarning system components- 13•9

Washer fluid level- 0•13

Washers- 13•12

Weatherstrip- 12•15

Weber 2V carburettor- 1•12, 4A•14

Weber 2V TLD carburettor- 1•12, 4A•15

Weekly checks- 0•10

Wheel (steering) - 11•14

Wheel alignment- 11•1, 11•19

Wheel arch liners- 12•14

Wheel bearings- 11•6, 11•10

Wheel changing- 0•6

Wheel cylinder- 10•12

Wheel sensor(ABS)- 10•18

Window glass- 12•11

Window regulator- 12•12

Windscreen- 12•11, 12•14

Windscreen washers- 13•12

Windscreen wiper motor- 13•12

Wiper arms- 13•11

Wiper blades- 0•15, 13•11

Wiper motor (headlamp)- 13•13

Wiper motor (rear)- 13•12

Wiper motor (windscreen)- 13•12

Wiring diagrams- WD•1 et seq

Working facilities- REF•5

IndexREF•25

REF