torque FORD SIERRA 1984 1.G Braking System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1984, Model line: SIERRA, Model: FORD SIERRA 1984 1.GPages: 22, PDF Size: 1.11 MB

Page 2 of 22

Torque wrench settingsNmlbf ft

Caliper carrier bracket-to-hub carrier bolts . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Front caliper guide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear caliper guide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Rear brake backplate nuts - P100 models . . . . . . . . . . . . . . . . . . . . . . .45 to 5433 to 40

Servo-to-bulkhead nuts (conventional braking system) . . . . . . . . . . . . .35 to 4526 to 33

Master cylinder-to-servo nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Hydraulic unit-to-bulkhead nuts (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Hydraulic unit accumulator (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 to 4625 to 34

Pump mounting bolt (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 95 to 7

High pressure hose-to-pump union (ABS) . . . . . . . . . . . . . . . . . . . . . . .7 to 125 to 9

Wheel sensor mounting bolts (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

General information

The braking system is of the dual circuit

hydraulic type. The front and rear circuits are

operated independently from a tandem

master cylinder, so that in the event of a

hydraulic failure in one circuit, full braking

force will still be available to two wheels

through the remaining circuit.

A deceleration sensitive valve on Saloon,

Hatchback and Estate models not fitted with

an Anti-lock Braking System (ABS), and a load

apportioning valve on P100 models, is

incorporated in the rear brake hydraulic

circuit. The valve regulates the pressure

applied to the rear brakes and reduces the

possibility of the rear wheels locking under

heavy braking.

All models are fitted with front disc brakes,

with solid or ventilated discs depending on

model. The calipers are of single piston sliding

type, which ensures that equal pressure is

applied to each disc pad.

Non-ABS models are fitted with rear disc

brakes or rear drum brakes, incorporating

leading and trailing shoes operated by

double-acting wheel cylinders. A self-adjuster

mechanism is fitted which consists of a

toothed quadrant which is kept in contact with

a toothed pin attached to the shoe strut by

means of a spring. The quadrant incorporates

an arm which locates in a slot in the leading

shoe. As the shoe linings wear the quadrant is

pulled from the pin when the footbrake is

operated, and automatically repositioned to

effectively lengthen the shoe strut.

ABS is available as an option for all models

except the P100. The system comprises an

electronic control unit, roadwheel sensors,

hydraulic actuator with electrically-driven

hydraulic pump, and the necessary valves and

switches. Disc brakes are fitted to all four

wheels. The front disc brakes are similar to

those fitted to non-ABS models, but the rear

brakes incorporate a self-adjusting

mechanism, and a mechanical handbrake

mechanism. The purpose of the system is to

prevent wheel(s) locking during heavy brake

applications. This is achieved by automatic

release of the brake on the locked wheel,followed by reapplication of the brake. This

procedure is carried out four times per second

by the control valves in the valve block. The

valves are controlled by the electronic control

unit which itself receives signals from the

wheel sensors, which monitor the locked or

unlocked state of the wheels. A pressure

regulating valve is incorporated in the rear

hydraulic circuit to maintain the desired

pressure ratio between the front and rear

circuits.

Precautions

Note: Hydraulic fluid is poisonous; wash off

immediately and thoroughly in the case of skin

contact and seek immediate medical advice if

any fluid is swallowed or gets into the eyes.

Certain types of hydraulic fluid are

inflammable and may ignite when allowed into

contact with hot components; when servicing

any hydraulic system it is safest to assume

that the fluid is inflammable and to take

precautions against the risk of fire as though it

is petrol that is being handled. Hydraulic fluid

is also an effective paint stripper and will

attack plastics; if any is spilt, it should be

washed off immediately using copious

quantities of fresh water. Finally, it is

hygroscopic (it absorbs moisture from the air)

old fluid may be contaminated and unfit for

further use. When topping-up or renewing the

fluid, always use the recommended type and

ensure that it comes from a freshly-opened

sealed container

Note: When working on the brake

components, take care not to disperse brake

dust into the air, or to inhale it, since it may

contain asbestos which is injurious to health.

General

1If any of the hydraulic components in the

braking system have been removed or

disconnected, or if the fluid level in the

reservoir has been allowed to fall appreciably,

it is inevitable that air will have been

introduced into the system. The removal of all

this air from the hydraulic system is essential

if the brakes are to function correctly, and the

process of removing it is known as bleeding.

2Where an operation has only affected one

circuit (front or rear) of the hydraulic system,

then it will only be necessary to bleed the

relevant circuit. If the master cylinder has

been disconnected and reconnected, or the

fluid level has been allowed to fall

appreciably, then the complete system must

be bled.

3One of three methods can be used to bleed

the system.

Bleeding

Two-man method

4Gather together a clean jar and a length of

rubber or plastic bleed tubing which will fit the

bleed screws tightly. The help of an assistant

will be required.

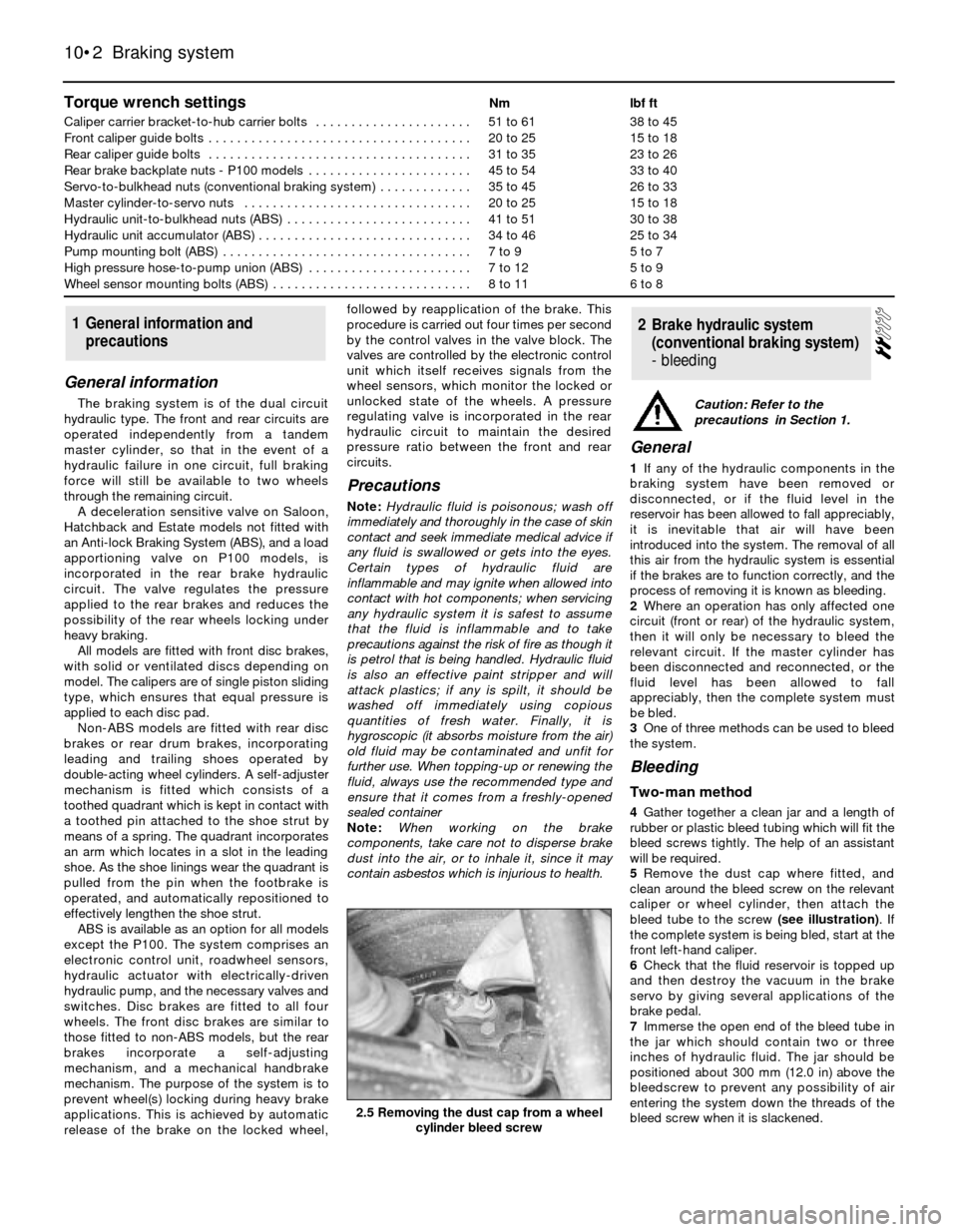

5Remove the dust cap where fitted, and

clean around the bleed screw on the relevant

caliper or wheel cylinder, then attach the

bleed tube to the screw (see illustration). If

the complete system is being bled, start at the

front left-hand caliper.

6Check that the fluid reservoir is topped up

and then destroy the vacuum in the brake

servo by giving several applications of the

brake pedal.

7Immerse the open end of the bleed tube in

the jar which should contain two or three

inches of hydraulic fluid. The jar should be

positioned about 300 mm (12.0 in) above the

bleedscrew to prevent any possibility of air

entering the system down the threads of the

bleed screw when it is slackened.

2Brake hydraulic system

(conventional braking system)

- bleeding1General information and

precautions

10•2Braking system

2.5 Removing the dust cap from a wheel

cylinder bleed screw

Caution: Refer to the

precautions in Section 1.

Page 9 of 22

neck with a rubber band, or by refitting the

cap. This will reduce the loss of fluid during

the following procedure.

3Disconnect the flexible fluid hose from the

rigid brake pipe under the wing of the vehicle,

or alternatively unscrew the flexible hose from

the union on the caliper. Take care not to twist

the hose, and plug the open ends to prevent

fluid loss and dirt ingress.

4Remove the disc pads.

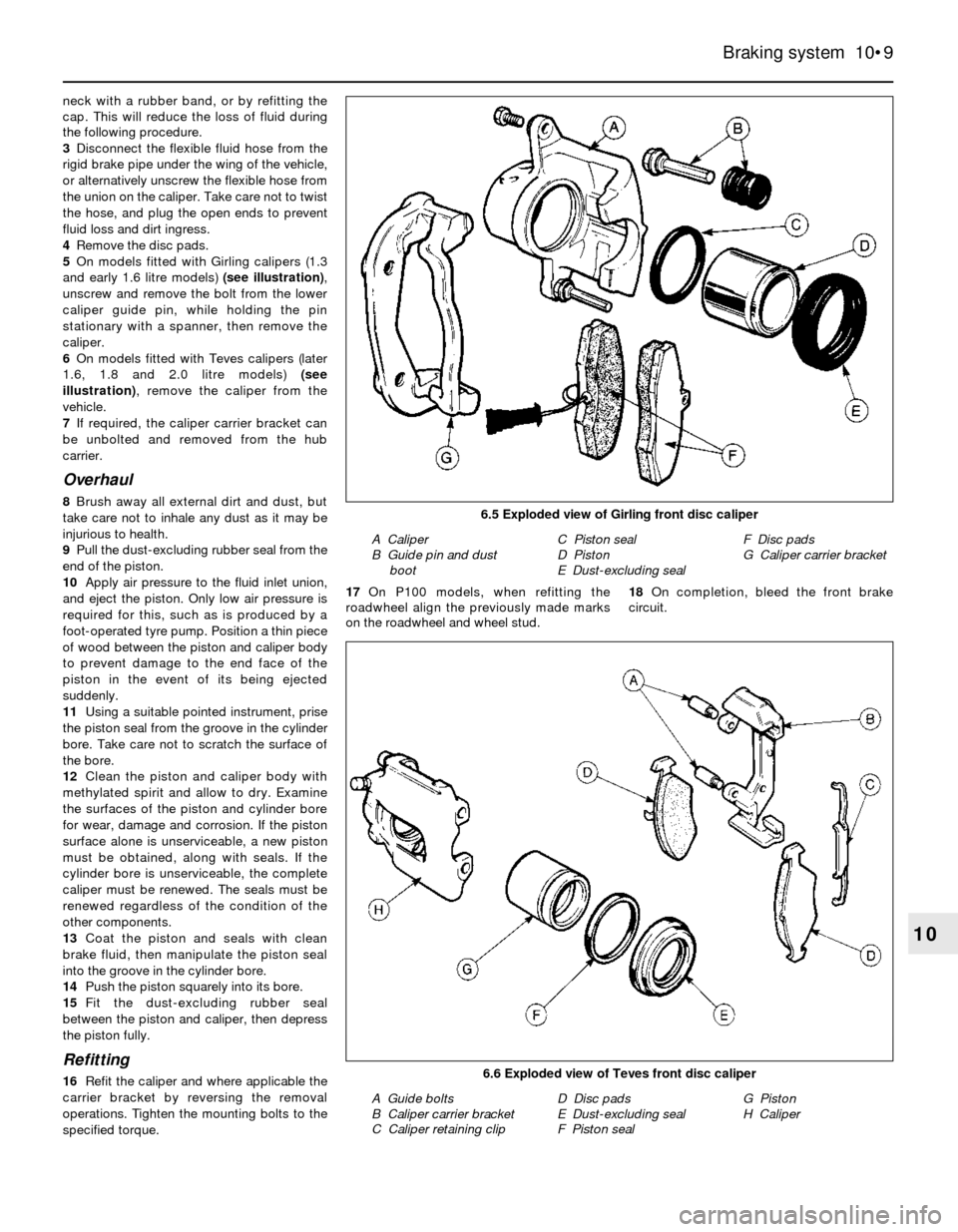

5On models fitted with Girling calipers (1.3

and early 1.6 litre models) (see illustration),

unscrew and remove the bolt from the lower

caliper guide pin, while holding the pin

stationary with a spanner, then remove the

caliper.

6On models fitted with Teves calipers (later

1.6, 1.8 and 2.0 litre models) (see

illustration), remove the caliper from the

vehicle.

7If required, the caliper carrier bracket can

be unbolted and removed from the hub

carrier.

Overhaul

8Brush away all external dirt and dust, but

take care not to inhale any dust as it may be

injurious to health.

9Pull the dust-excluding rubber seal from the

end of the piston.

10Apply air pressure to the fluid inlet union,

and eject the piston. Only low air pressure is

required for this, such as is produced by a

foot-operated tyre pump. Position a thin piece

of wood between the piston and caliper body

to prevent damage to the end face of the

piston in the event of its being ejected

suddenly.

11Using a suitable pointed instrument, prise

the piston seal from the groove in the cylinder

bore. Take care not to scratch the surface of

the bore.

12Clean the piston and caliper body with

methylated spirit and allow to dry. Examine

the surfaces of the piston and cylinder bore

for wear, damage and corrosion. If the piston

surface alone is unserviceable, a new piston

must be obtained, along with seals. If the

cylinder bore is unserviceable, the complete

caliper must be renewed. The seals must be

renewed regardless of the condition of the

other components.

13Coat the piston and seals with clean

brake fluid, then manipulate the piston seal

into the groove in the cylinder bore.

14Push the piston squarely into its bore.

15Fit the dust-excluding rubber seal

between the piston and caliper, then depress

the piston fully.

Refitting

16Refit the caliper and where applicable the

carrier bracket by reversing the removal

operations. Tighten the mounting bolts to the

specified torque.17On P100 models, when refitting the

roadwheel align the previously made marks

on the roadwheel and wheel stud.18On completion, bleed the front brake

circuit.

Braking system 10•9

10

6.6 Exploded view of Teves front disc caliper

A Guide bolts

B Caliper carrier bracket

C Caliper retaining clipD Disc pads

E Dust-excluding seal

F Piston sealG Piston

H Caliper

6.5 Exploded view of Girling front disc caliper

A Caliper

B Guide pin and dust

bootC Piston seal

D Piston

E Dust-excluding sealF Disc pads

G Caliper carrier bracket

Page 13 of 22

3Remove the wheel cylinder.

4Remove the driveshaft but do not refit the

securing bolts to the backplate.

5Remove the backplate.

6If required, prise out the handbrake stop

button.

7Refitting is a reversal of removal.

P 100 models

Note: When refitting the backplate, a new rear

hub nut and driveshaft O-ring must be used.

8Proceed as described in paragraphs 1 to 3

inclusive.

9Remove the driveshaft.

10Relieve the staking on the rear hub nut,

and using a 50 mm socket and a suitable

extension bar, unscrew the nut. Note that the

nut is extremely tight.

11Pull off the hub.

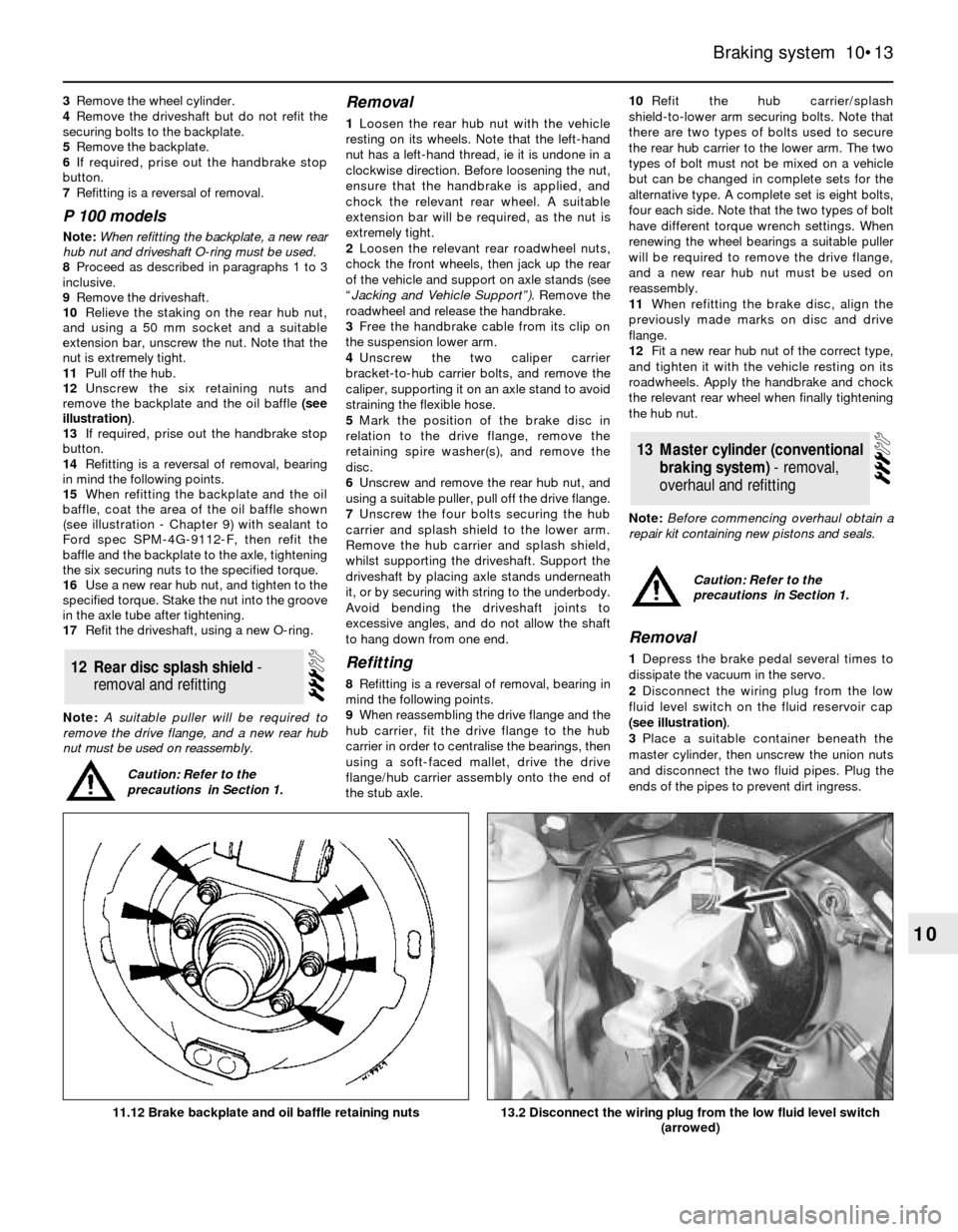

12Unscrew the six retaining nuts and

remove the backplate and the oil baffle (see

illustration).

13If required, prise out the handbrake stop

button.

14Refitting is a reversal of removal, bearing

in mind the following points.

15When refitting the backplate and the oil

baffle, coat the area of the oil baffle shown

(see illustration - Chapter 9) with sealant to

Ford spec SPM-4G-9112-F, then refit the

baffle and the backplate to the axle, tightening

the six securing nuts to the specified torque.

16Use a new rear hub nut, and tighten to the

specified torque. Stake the nut into the groove

in the axle tube after tightening.

17Refit the driveshaft, using a new O-ring.

Note: A suitable puller will be required to

remove the drive flange, and a new rear hub

nut must be used on reassembly.

Removal

1Loosen the rear hub nut with the vehicle

resting on its wheels. Note that the left-hand

nut has a left-hand thread, ie it is undone in a

clockwise direction. Before loosening the nut,

ensure that the handbrake is applied, and

chock the relevant rear wheel. A suitable

extension bar will be required, as the nut is

extremely tight.

2Loosen the relevant rear roadwheel nuts,

chock the front wheels, then jack up the rear

of the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Remove the

roadwheel and release the handbrake.

3Free the handbrake cable from its clip on

the suspension lower arm.

4Unscrew the two caliper carrier

bracket-to-hub carrier bolts, and remove the

caliper, supporting it on an axle stand to avoid

straining the flexible hose.

5Mark the position of the brake disc in

relation to the drive flange, remove the

retaining spire washer(s), and remove the

disc.

6Unscrew and remove the rear hub nut, and

using a suitable puller, pull off the drive flange.

7Unscrew the four bolts securing the hub

carrier and splash shield to the lower arm.

Remove the hub carrier and splash shield,

whilst supporting the driveshaft. Support the

driveshaft by placing axle stands underneath

it, or by securing with string to the underbody.

Avoid bending the driveshaft joints to

excessive angles, and do not allow the shaft

to hang down from one end.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9When reassembling the drive flange and the

hub carrier, fit the drive flange to the hub

carrier in order to centralise the bearings, then

using a soft-faced mallet, drive the drive

flange/hub carrier assembly onto the end of

the stub axle.10Refit the hub carrier/splash

shield-to-lower arm securing bolts. Note that

there are two types of bolts used to secure

the rear hub carrier to the lower arm. The two

types of bolt must not be mixed on a vehicle

but can be changed in complete sets for the

alternative type. A complete set is eight bolts,

four each side. Note that the two types of bolt

have different torque wrench settings. When

renewing the wheel bearings a suitable puller

will be required to remove the drive flange,

and a new rear hub nut must be used on

reassembly.

11When refitting the brake disc, align the

previously made marks on disc and drive

flange.

12Fit a new rear hub nut of the correct type,

and tighten it with the vehicle resting on its

roadwheels. Apply the handbrake and chock

the relevant rear wheel when finally tightening

the hub nut.

Note: Before commencing overhaul obtain a

repair kit containing new pistons and seals.

Removal

1Depress the brake pedal several times to

dissipate the vacuum in the servo.

2Disconnect the wiring plug from the low

fluid level switch on the fluid reservoir cap

(see illustration).

3Place a suitable container beneath the

master cylinder, then unscrew the union nuts

and disconnect the two fluid pipes. Plug the

ends of the pipes to prevent dirt ingress.

13Master cylinder (conventional

braking system) - removal,

overhaul and refitting

12Rear disc splash shield -

removal and refitting

Braking system 10•13

10

13.2 Disconnect the wiring plug from the low fluid level switch

(arrowed)11.12 Brake backplate and oil baffle retaining nuts

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.

Page 14 of 22

4Unscrew the two mounting nuts and spring

washers, and withdraw the master cylinder

from the servo. Cover the master cylinder with

rag or a plastic bag to prevent spillage of

hydraulic fluid on the vehicle paintwork. If fluid

is accidentally spilt on the paintwork, wash off

immediately with cold water.

Overhaul

5Drain the remaining fluid from the master

cylinder, and clean the exterior surfaces with

methylated spirit.

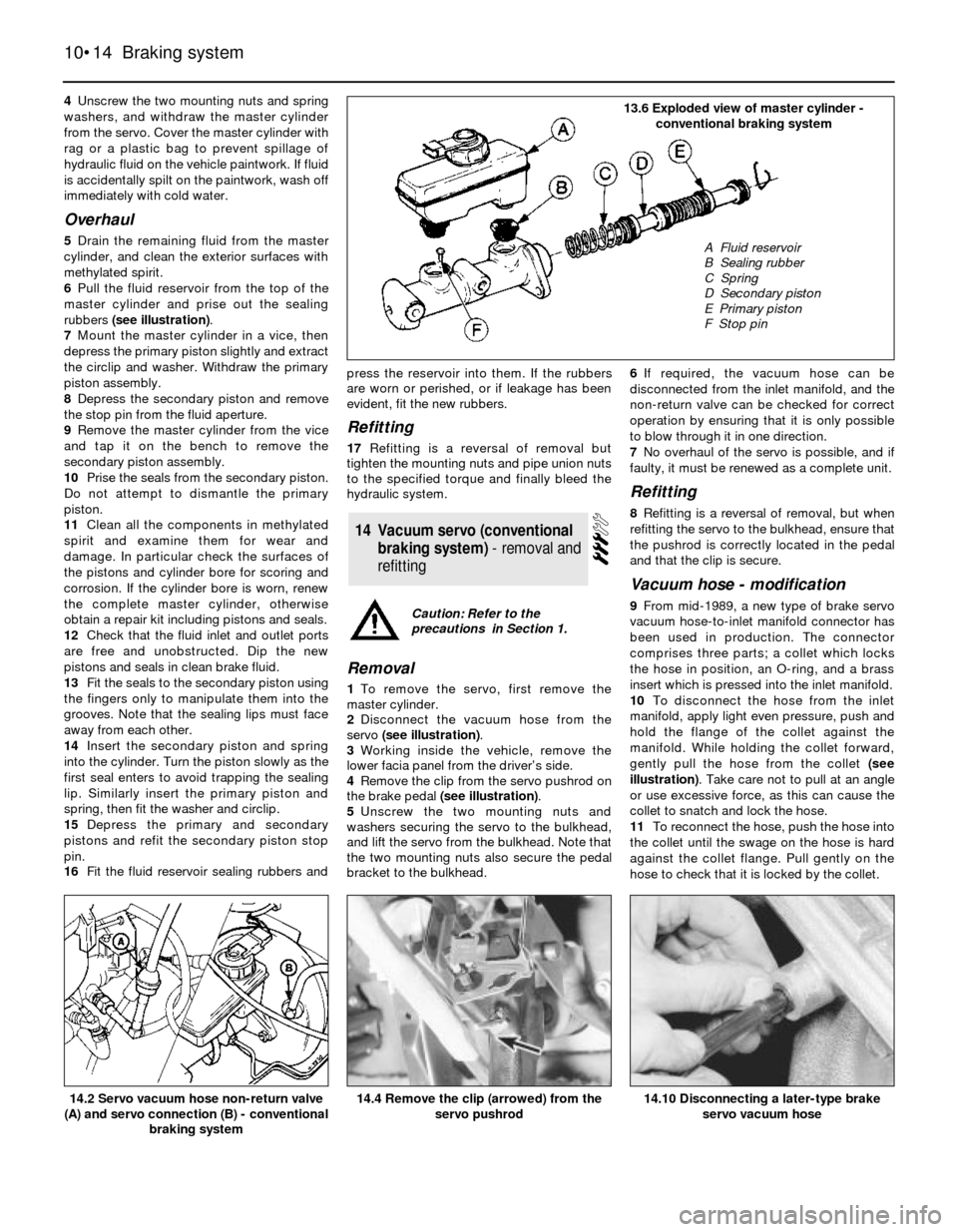

6Pull the fluid reservoir from the top of the

master cylinder and prise out the sealing

rubbers (see illustration).

7Mount the master cylinder in a vice, then

depress the primary piston slightly and extract

the circlip and washer. Withdraw the primary

piston assembly.

8Depress the secondary piston and remove

the stop pin from the fluid aperture.

9Remove the master cylinder from the vice

and tap it on the bench to remove the

secondary piston assembly.

10Prise the seals from the secondary piston.

Do not attempt to dismantle the primary

piston.

11Clean all the components in methylated

spirit and examine them for wear and

damage. In particular check the surfaces of

the pistons and cylinder bore for scoring and

corrosion. If the cylinder bore is worn, renew

the complete master cylinder, otherwise

obtain a repair kit including pistons and seals.

12Check that the fluid inlet and outlet ports

are free and unobstructed. Dip the new

pistons and seals in clean brake fluid.

13Fit the seals to the secondary piston using

the fingers only to manipulate them into the

grooves. Note that the sealing lips must face

away from each other.

14Insert the secondary piston and spring

into the cylinder. Turn the piston slowly as the

first seal enters to avoid trapping the sealing

lip. Similarly insert the primary piston and

spring, then fit the washer and circlip.

15Depress the primary and secondary

pistons and refit the secondary piston stop

pin.

16Fit the fluid reservoir sealing rubbers andpress the reservoir into them. If the rubbers

are worn or perished, or if leakage has been

evident, fit the new rubbers.

Refitting

17Refitting is a reversal of removal but

tighten the mounting nuts and pipe union nuts

to the specified torque and finally bleed the

hydraulic system.

Removal

1To remove the servo, first remove the

master cylinder.

2Disconnect the vacuum hose from the

servo (see illustration).

3Working inside the vehicle, remove the

lower facia panel from the driver’s side.

4Remove the clip from the servo pushrod on

the brake pedal (see illustration).

5Unscrew the two mounting nuts and

washers securing the servo to the bulkhead,

and lift the servo from the bulkhead. Note that

the two mounting nuts also secure the pedal

bracket to the bulkhead.6If required, the vacuum hose can be

disconnected from the inlet manifold, and the

non-return valve can be checked for correct

operation by ensuring that it is only possible

to blow through it in one direction.

7No overhaul of the servo is possible, and if

faulty, it must be renewed as a complete unit.

Refitting

8Refitting is a reversal of removal, but when

refitting the servo to the bulkhead, ensure that

the pushrod is correctly located in the pedal

and that the clip is secure.

Vacuum hose - modification

9From mid-1989, a new type of brake servo

vacuum hose-to-inlet manifold connector has

been used in production. The connector

comprises three parts; a collet which locks

the hose in position, an O-ring, and a brass

insert which is pressed into the inlet manifold.

10To disconnect the hose from the inlet

manifold, apply light even pressure, push and

hold the flange of the collet against the

manifold. While holding the collet forward,

gently pull the hose from the collet (see

illustration). Take care not to pull at an angle

or use excessive force, as this can cause the

collet to snatch and lock the hose.

11To reconnect the hose, push the hose into

the collet until the swage on the hose is hard

against the collet flange. Pull gently on the

hose to check that it is locked by the collet.

14Vacuum servo (conventional

braking system) - removal and

refitting

10•14Braking system

14.10 Disconnecting a later-type brake

servo vacuum hose14.4 Remove the clip (arrowed) from the

servo pushrod14.2 Servo vacuum hose non-return valve

(A) and servo connection (B) - conventional

braking system

13.6 Exploded view of master cylinder -

conventional braking system

A Fluid reservoir

B Sealing rubber

C Spring

D Secondary piston

E Primary piston

F Stop pin

Caution: Refer to the

precautions in Section 1.