wheel FORD SIERRA 1985 1.G Bodywork And Fittings Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: SIERRA, Model: FORD SIERRA 1985 1.GPages: 22, PDF Size: 1.2 MB

Page 1 of 22

Torque wrench settingsNm lbf ft

Front seat belt stalk-to-seat bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 to 28 18 to 22

Seat belt anchor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat belt inertia reel securing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 to 41 22 to 30

Seat mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Cab safety grille securing bolts (P100 models) . . . . . . . . . . . . . . . . . . . 20 to 27 15 to 20

Rear bump stop securing nuts (P100 models) . . . . . . . . . . . . . . . . . . . . 8 to 11 6 to 8

Cargo area-to-chassis bolts (P100 models) . . . . . . . . . . . . . . . . . . . . . . 40 to 50 29 to 37

Tailboard hinge securing screws (P100 models) . . . . . . . . . . . . . . . . . . 20 to 25 15 to 18

Chapter 12

Bodywork and fittings

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Bonnet lock release cable - removal and refitting . . . . . . . . . . . . . . . .7

Boot lid (Saloon models) - removal and refitting . . . . . . . . . . . . . . . . .9

Boot lid lock (Saloon models) - removal and refitting . . . . . . . . . . . . .10

Bumper - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Bumper trim moulding - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Cab air vent panel (P100 models) - removal and refitting . . . . . . . . .35

Cab interior trim panels (P100 models) - removal and refitting . . . . .42

Cargo area (P100 models) - removal and refitting . . . . . . . . . . . . . . .23

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .44

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Door check arm - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .22

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .19

Door inner trim panel - removal and refitting . . . . . . . . . . . . . . . . . . .17

Door interior handle - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Door lock - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .20

Door mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Door window - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .27

Door window regulator - removal and refitting . . . . . . . . . . . . . . . . . .28

Exterior rear pillar trim panel (Saloon models) - removal and refitting .34

Facia panels - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .43

Front seat air cushion assembly - removal and refitting . . . . . . . . . .49

Fuel filler flap - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .37

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Inner gutter weatherstrip (Saloon, Hatchback and Estate models)-

removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Interior pillar trim panels - removal and refitting . . . . . . . . . . . . . . . . .41

Interior trim panels - general information . . . . . . . . . . . . . . . . . . . . . .40

Maintenance - bodywork, underside and fittings . . . . . . . . . . . . . . . . .2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . . .3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . . .45

Opening rear quarter window - removal and refitting . . . . . . . . . . . . .26

Radiator grille panel - removal and refitting . . . . . . . . . . . . . . . . . . . .32

Rear seat catch - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .48

Seats - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Sunroof - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .39

Tailboard (P100 models) - removal and refitting . . . . . . . . . . . . . . . .24

Tailgate/boot lid/fuel filler flap release cable - removal and refitting .14

Tailgate/boot lid spoiler - removal and refitting . . . . . . . . . . . . . . . . .15

Tailgate (Hatchback and Estate models) - removal and refitting . . . .11

Tailgate lock (Hatchback and Estate models) - removal and refitting . .12

Tailgate strut (Hatchback and Estate models) - removal and refitting .13

Wheel arch liners - removal and refitting . . . . . . . . . . . . . . . . . . . . . .36

Windscreen cowl panel - removal and refitting . . . . . . . . . . . . . . . . .33

Windscreen, rear window and fixed rear quarter windows - removal

and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

12•1

Specifications Contents

12

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 2 of 22

The model range includes 4-door Saloon, 3

and 5-door Hatchback, 5-door Estate, and 2-

door Pick-up body styles.

Each body is of all-steel welded energy-

absorbing monocoque construction, with a

separate load-bearing rear chassis frame on

P100 Pick-up models. Corrosion protection is

applied to all new vehicles, and includes zinc

phosphate dipping of the body panels, and

wax injection of box sections and doors.

All models have flush direct-glazed fixed glass

panels, and integrated polycarbonate bumpers.

All body panels are welded, including the

front wings, so it is recommended that major

body damage repairs are entrusted to a dealer.

A wide range of interior equipment and trim

options are available depending on model.

The procedures given in this Chapter apply to

original equipment fitments, and do not cover

after-market products.

The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

important also to keep watch on those parts of

the vehicle not immediately visible, for instance

the underside, inside all the wheel arches and

the lower part of the engine compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way to remove any

accumulated mud which will retain moisture

and tend to encourage rust. Oddly enough,

the best time to clean the underframe and

wheel arches is in wet weather when the mud

is thoroughly wet and soft. In very wet

weather the underframe is usually cleaned of

large accumulations automatically and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the underframe

of the vehicle steam cleaned, engine

compartment included, so that a thorough

inspection can be carried out to see what

minor repairs and renovations are necessary.

Steam cleaning is available at many garages

and is necessary for removal of the

accumulation of oily grime which sometimes is

allowed to become thick in certain areas. If

steam cleaning facilities are not available,

there are one or two excellent grease solvents

available, which can be brush applied. The dirt

can then be simply hosed off. Note that thesemethods should not be used on vehicles with

wax-based underbody protective coating or

the coating will be removed. Such vehicles

should be inspected annually, preferably just

prior to winter, when the underbody should be

washed down and any damage to the wax

coating repaired using a proprietry brand

undershield. Ideally, a completely fresh coat

should be applied. It would also be worth

considering the use of such wax-based

protection for injection into door panels, sills,

box sections, etc, as an additional safeguard

against rust damage where such protection is

not provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish, will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to be

taken with metallic paintwork, as special non-

abrasive cleaner/polisher is required to avoid

damage to the finish. Always check that the

door and ventilator opening drain holes and

pipes are completely clear so that water can be

drained out. Bright work should be treated in

the same way as paint work. Windscreens and

windows can be kept clear of the smeary film

which often appears by the use of a proprietary

glass cleaner. Never use any form of wax or

other body or chromium polish on glass.

At the specified intervals, check the

operation of the door locks and check straps

and lubricate the hinges with a little oil. Also

lubricate the hinges of the bonnet and boot lid

or tailgate, as applicable, and the bonnet

release mechanism.

Mats and carpets should be brushed or

vacuum cleaned regularly to keep them free of

grit. If they are badly stained remove them

from the vehicle for scrubbing or sponging and

make quite sure they are dry before refitting.

Seats and interior trim panels can be kept

clean by wiping with a damp cloth and a

proprietry wax polish. If they do become

stained (which can be more apparent on light

coloured upholstery) use a little liquid

detergent and a soft nail brush to scour the

grime out of the grain of the material. Do not

forget to keep the headlining clean in the same

way as the upholstery. When using liquid

cleaners inside the vehicle do not over-wet the

surfaces being cleaned. Excessive damp

could get into the seams and padded interior

causing stains, offensive odours or even rot. If

the inside of the vehicle gets wet accidentally it

is worthwhile taking some trouble to dry it out

properly, particularly where carpets are

involved. Do not leave oil or electric heaters

inside the vehicle for this purpose.Repair of minor scratches in

bodywork

If the scratch is very superficial, and does not

penetrate to the metal of the bodywork, repair is

very simple. Lightly rub the area of the scratch

with a paintwork renovator, or a very fine cutting

paste, to remove loose paint from the scratch

and to clear the surrounding bodywork of wax

polish. Rinse the area with clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden: then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply a good wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique is

required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust inhibiting paint, to prevent the

formation of rust in the future. Using a rubber or

nylon applicator fill the scratch with bodystopper

paste. If required, this paste can be mixed with

cellulose thinners to provide a very thin paste

which is ideal for filling narrow scratches. Before

the stopper-paste in the scratch hardens, wrap

a piece of smooth cotton rag around the top of a

finger. Dip the finger in cellulose thinners; and

then quickly sweep it across the surface of the

stopper-paste in the scratch; this will ensure that

the surface of the stopper-paste is slightly

hollowed. The scratch can now be painted over

as described earlier in this Section.

Repair of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact and cannot be

reshaped fully to its original contour. It is better

to bring the level of the dent up to a point which

is about 1/8 in (3 mm) below the level of the

surrounding bodywork. In cases where the dent

is very shallow anyway, it is not worth trying to

pull it out at all. If the underside of the dent is

accessible, it can be hammered out gently from

behind, using a mallet with a wooden or plastic

head. Whilst doing this, hold a suitable block of

wood firmly against the outside of the panel to

absorb the impact from the hammer blows and

thus prevent a large area of the bodywork from

being “belled-out”.

Should the dent be in a section of the

bodywork which has a double skin or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area particularly in the deeper section.

4Minor body damage - repair

3Maintenance - upholstery and

carpets

2Maintenance - bodywork,

underside and fittings

1General information

12•2Bodywork and fittings

Page 6 of 22

Removal

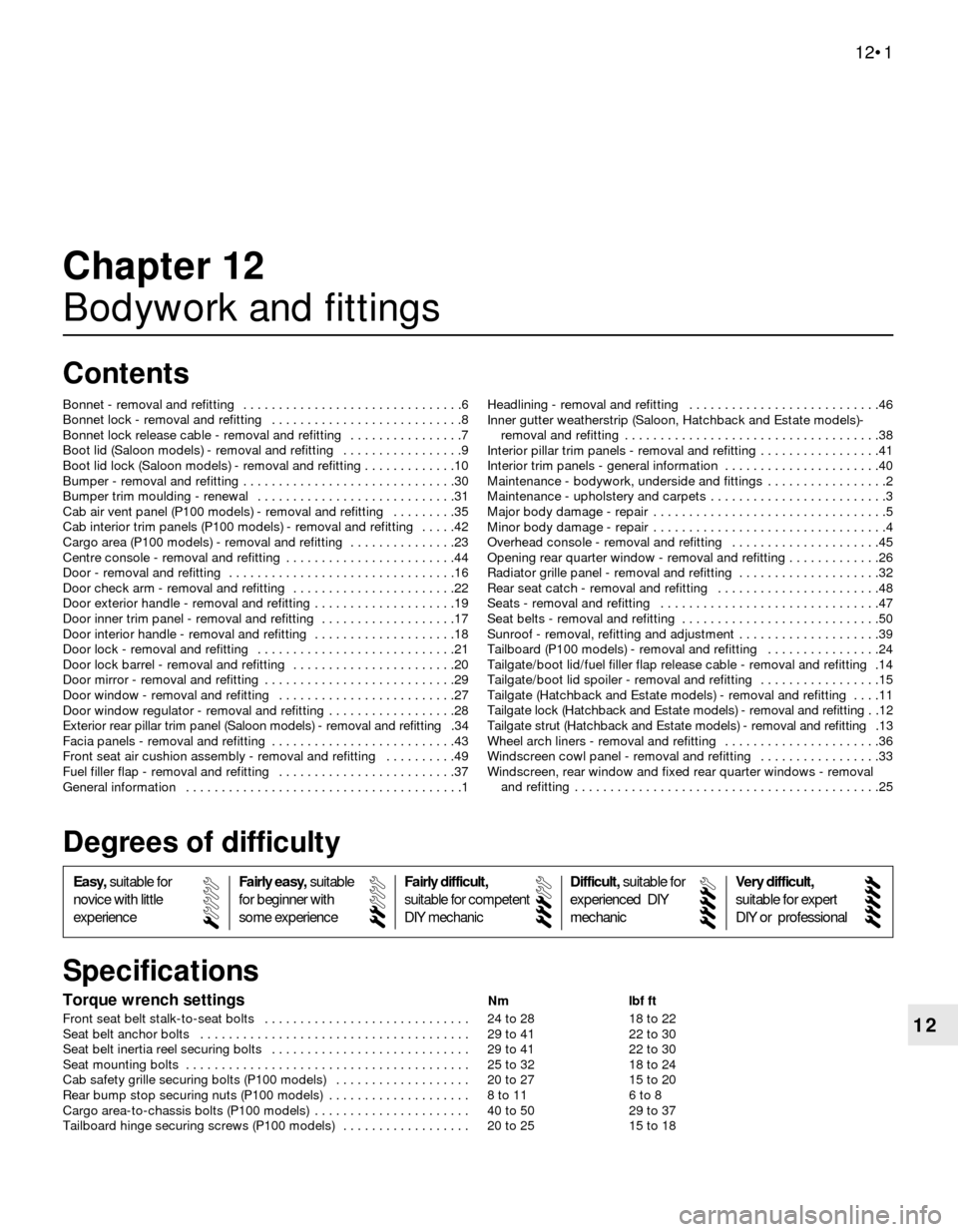

1Open the tailgate and prise out the trim

panel using a wide-bladed screwdriver(see

illustration).

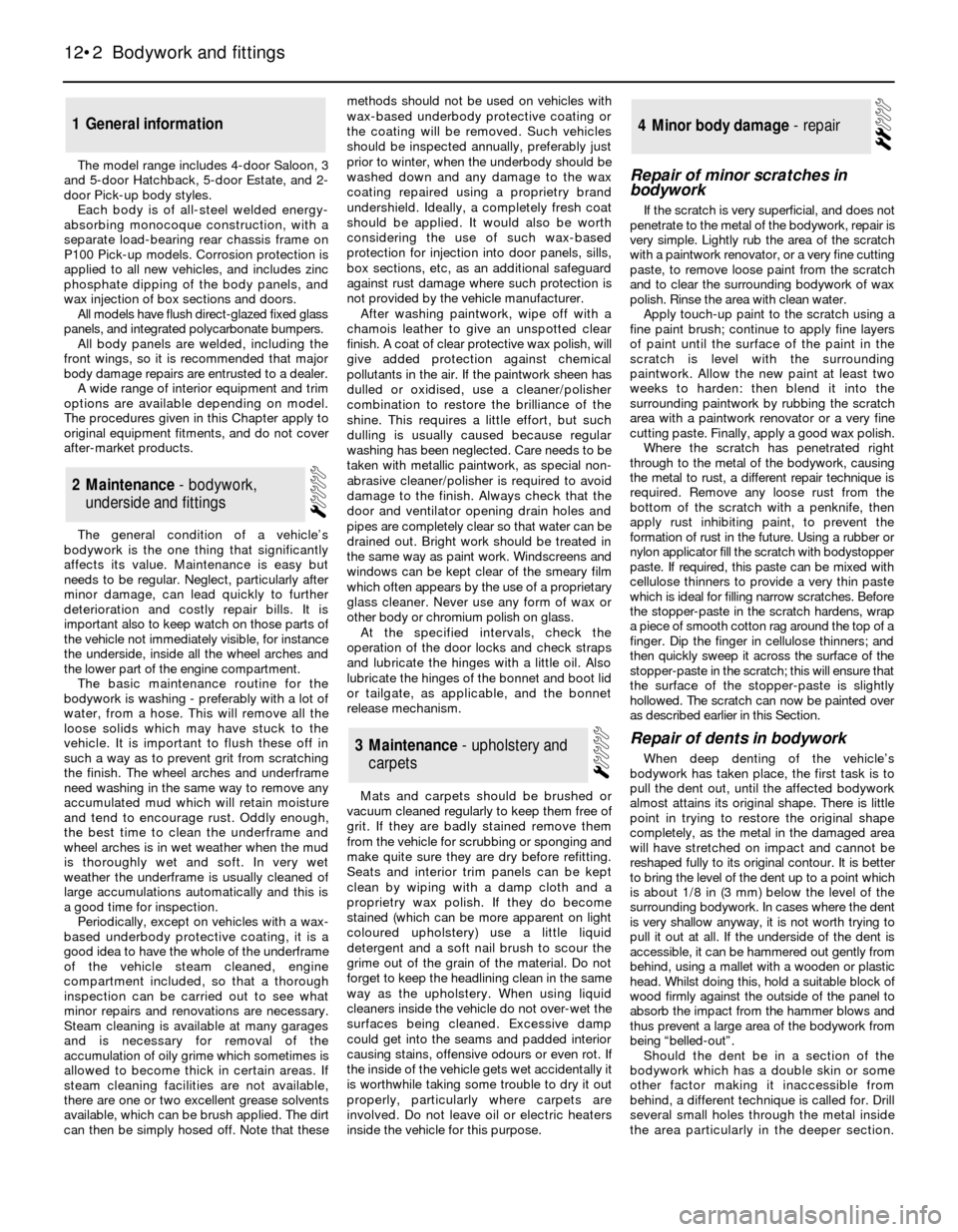

2Remove the lock barrel retaining clip, and

where applicable disconnect the operating

lever from the central locking solenoid/motor,

then withdraw the lock barrel (see

illustration). Central locking solenoid/motor

removal and refitting is covered in Chapter 13.

3Remove the two securing screws and

detach the lock barrel support bracket from

the tailgate.

4Where applicable, disconnect the battery

negative lead, the earth lead from the tailgate

and the “tailgate ajar” sensor wiring plug.

Unclip the luggage compartment light switch

from the lock assembly, where applicable.

5Remove the securing screws and withdraw

the lock assembly.

Refitting

6Refitting is a reversal of removal, but do not

tighten the lock barrel support bracket screws

until the lock barrel has been fitted.

Removal

1Support the tailgate in the open position

using a prop, or with the aid of an assistant.

2Disconnect the strut from the tailgate by

prising out the retaining clip. Do not remove

the clip completely, just raise it by a maximum

of 4.0 mm (0.16 in) and then pull the strut off

its mounting.

3Pull the strut from the pivot stud on the

body.

Refitting

4Refitting is a reversal of removal.

Removal

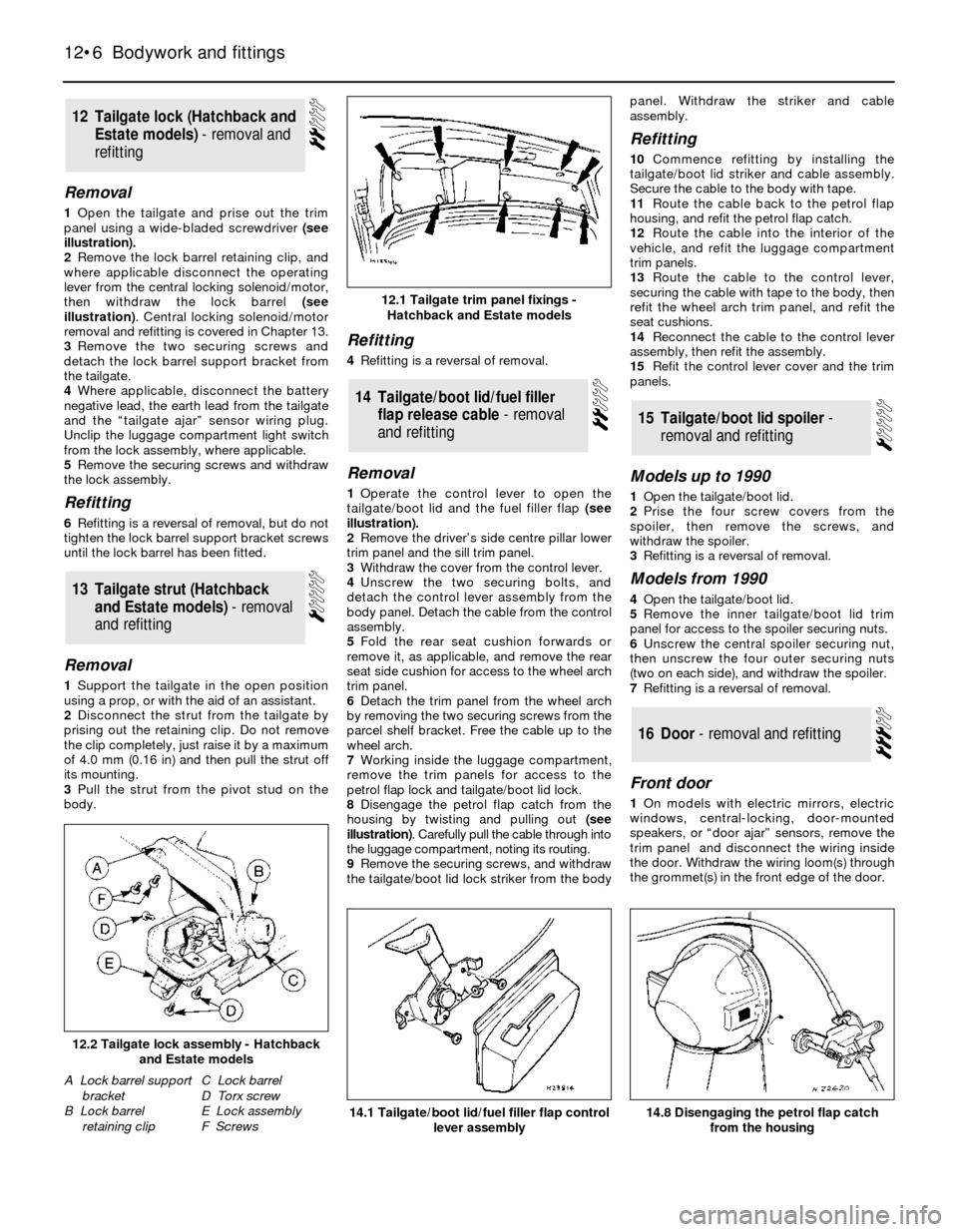

1Operate the control lever to open the

tailgate/boot lid and the fuel filler flap (see

illustration).

2Remove the driver’s side centre pillar lower

trim panel and the sill trim panel.

3Withdraw the cover from the control lever.

4Unscrew the two securing bolts, and

detach the control lever assembly from the

body panel. Detach the cable from the control

assembly.

5Fold the rear seat cushion forwards or

remove it, as applicable, and remove the rear

seat side cushion for access to the wheel arch

trim panel.

6Detach the trim panel from the wheel arch

by removing the two securing screws from the

parcel shelf bracket. Free the cable up to the

wheel arch.

7Working inside the luggage compartment,

remove the trim panels for access to the

petrol flap lock and tailgate/boot lid lock.

8Disengage the petrol flap catch from the

housing by twisting and pulling out (see

illustration). Carefully pull the cable through into

the luggage compartment, noting its routing.

9Remove the securing screws, and withdraw

the tailgate/boot lid lock striker from the bodypanel. Withdraw the striker and cable

assembly.

Refitting

10Commence refitting by installing the

tailgate/boot lid striker and cable assembly.

Secure the cable to the body with tape.

11Route the cable back to the petrol flap

housing, and refit the petrol flap catch.

12Route the cable into the interior of the

vehicle, and refit the luggage compartment

trim panels.

13Route the cable to the control lever,

securing the cable with tape to the body, then

refit the wheel arch trim panel, and refit the

seat cushions.

14Reconnect the cable to the control lever

assembly, then refit the assembly.

15Refit the control lever cover and the trim

panels.

Models up to 1990

1Open the tailgate/boot lid.

2Prise the four screw covers from the

spoiler, then remove the screws, and

withdraw the spoiler.

3Refitting is a reversal of removal.

Models from 1990

4Open the tailgate/boot lid.

5Remove the inner tailgate/boot lid trim

panel for access to the spoiler securing nuts.

6Unscrew the central spoiler securing nut,

then unscrew the four outer securing nuts

(two on each side), and withdraw the spoiler.

7Refitting is a reversal of removal.

Front door

1On models with electric mirrors, electric

windows, central-locking, door-mounted

speakers, or “door ajar” sensors, remove the

trim panel and disconnect the wiring inside

the door. Withdraw the wiring loom(s) through

the grommet(s) in the front edge of the door.

16Door - removal and refitting

15Tailgate/boot lid spoiler -

removal and refitting

14Tailgate/boot lid/fuel filler

flap release cable - removal

and refitting

13Tailgate strut (Hatchback

and Estate models) - removal

and refitting

12Tailgate lock (Hatchback and

Estate models) - removal and

refitting

12•6Bodywork and fittings

14.1 Tailgate/boot lid/fuel filler flap control

lever assembly14.8 Disengaging the petrol flap catch

from the housing

12.2 Tailgate lock assembly - Hatchback

and Estate models

A Lock barrel support

bracket

B Lock barrel

retaining clipC Lock barrel

D Torx screw

E Lock assembly

F Screws

12.1 Tailgate trim panel fixings -

Hatchback and Estate models

Page 13 of 22

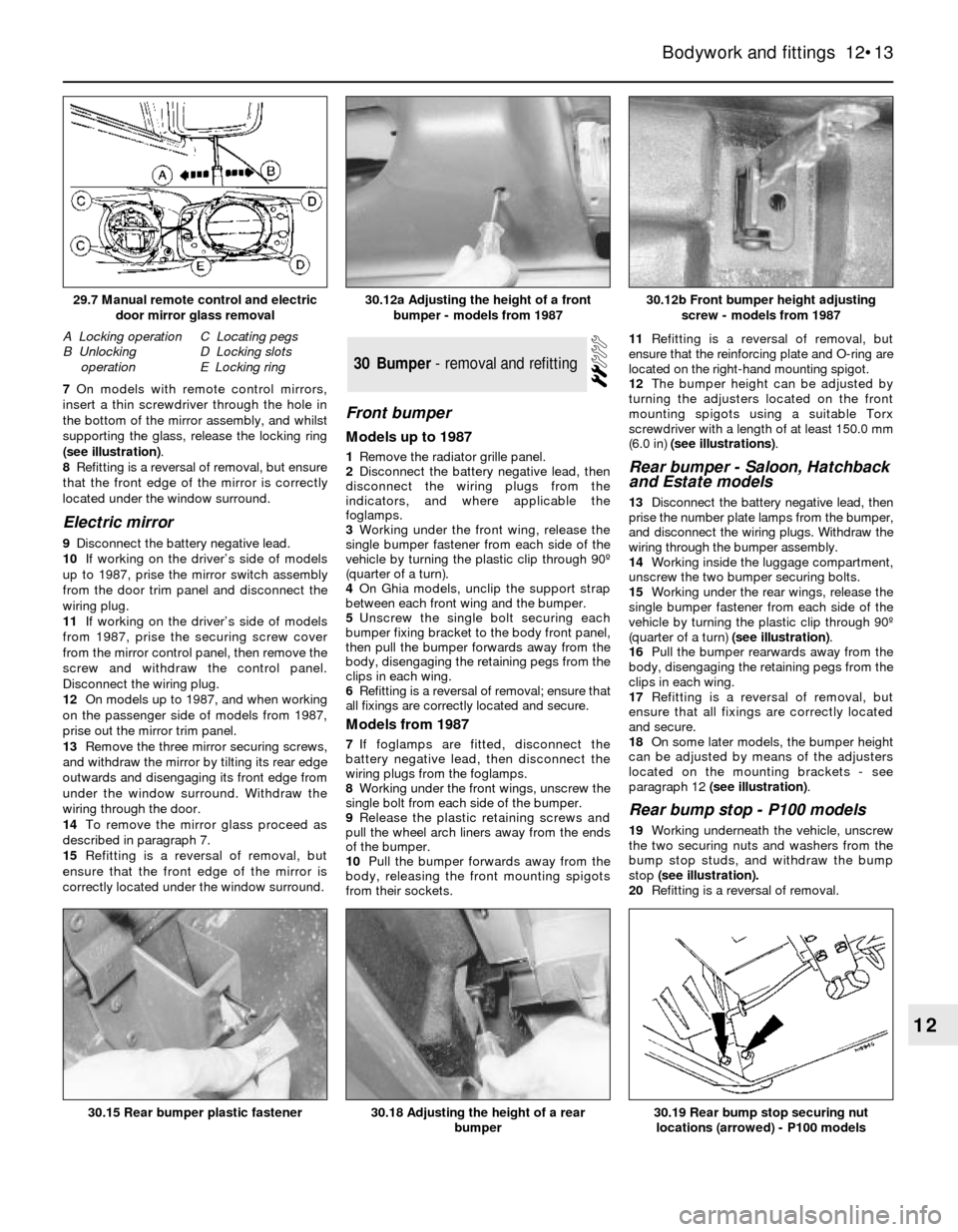

7On models with remote control mirrors,

insert a thin screwdriver through the hole in

the bottom of the mirror assembly, and whilst

supporting the glass, release the locking ring

(see illustration).

8Refitting is a reversal of removal, but ensure

that the front edge of the mirror is correctly

located under the window surround.

Electric mirror

9Disconnect the battery negative lead.

10If working on the driver’s side of models

up to 1987, prise the mirror switch assembly

from the door trim panel and disconnect the

wiring plug.

11If working on the driver’s side of models

from 1987, prise the securing screw cover

from the mirror control panel, then remove the

screw and withdraw the control panel.

Disconnect the wiring plug.

12On models up to 1987, and when working

on the passenger side of models from 1987,

prise out the mirror trim panel.

13Remove the three mirror securing screws,

and withdraw the mirror by tilting its rear edge

outwards and disengaging its front edge from

under the window surround. Withdraw the

wiring through the door.

14To remove the mirror glass proceed as

described in paragraph 7.

15Refitting is a reversal of removal, but

ensure that the front edge of the mirror is

correctly located under the window surround.

Front bumper

Models up to 1987

1Remove the radiator grille panel.

2Disconnect the battery negative lead, then

disconnect the wiring plugs from the

indicators, and where applicable the

foglamps.

3Working under the front wing, release the

single bumper fastener from each side of the

vehicle by turning the plastic clip through 90º

(quarter of a turn).

4On Ghia models, unclip the support strap

between each front wing and the bumper.

5Unscrew the single bolt securing each

bumper fixing bracket to the body front panel,

then pull the bumper forwards away from the

body, disengaging the retaining pegs from the

clips in each wing.

6Refitting is a reversal of removal; ensure that

all fixings are correctly located and secure.

Models from 1987

7If foglamps are fitted, disconnect the

battery negative lead, then disconnect the

wiring plugs from the foglamps.

8Working under the front wings, unscrew the

single bolt from each side of the bumper.

9Release the plastic retaining screws and

pull the wheel arch liners away from the ends

of the bumper.

10Pull the bumper forwards away from the

body, releasing the front mounting spigots

from their sockets.11Refitting is a reversal of removal, but

ensure that the reinforcing plate and O-ring are

located on the right-hand mounting spigot.

12The bumper height can be adjusted by

turning the adjusters located on the front

mounting spigots using a suitable Torx

screwdriver with a length of at least 150.0 mm

(6.0 in) (see illustrations).

Rear bumper - Saloon, Hatchback

and Estate models

13Disconnect the battery negative lead, then

prise the number plate lamps from the bumper,

and disconnect the wiring plugs. Withdraw the

wiring through the bumper assembly.

14Working inside the luggage compartment,

unscrew the two bumper securing bolts.

15Working under the rear wings, release the

single bumper fastener from each side of the

vehicle by turning the plastic clip through 90º

(quarter of a turn) (see illustration).

16Pull the bumper rearwards away from the

body, disengaging the retaining pegs from the

clips in each wing.

17Refitting is a reversal of removal, but

ensure that all fixings are correctly located

and secure.

18On some later models, the bumper height

can be adjusted by means of the adjusters

located on the mounting brackets - see

paragraph 12 (see illustration).

Rear bump stop - P100 models

19Working underneath the vehicle, unscrew

the two securing nuts and washers from the

bump stop studs, and withdraw the bump

stop (see illustration).

20Refitting is a reversal of removal.

30Bumper - removal and refitting

Bodywork and fittings 12•13

12

30.15 Rear bumper plastic fastener30.19 Rear bump stop securing nut

locations (arrowed) - P100 models30.18 Adjusting the height of a rear

bumper

30.12b Front bumper height adjusting

screw - models from 198730.12a Adjusting the height of a front

bumper - models from 198729.7 Manual remote control and electric

door mirror glass removal

A Locking operation

B Unlocking

operationC Locating pegs

D Locking slots

E Locking ring

Page 14 of 22

New bumpers are supplied without the trim

moulding fitted. Special primer and adhesive

tape are specified by the manufacturer to

retain the moulding: it is suggested that a

Ford dealer is consulted for further details.

A damaged moulding can be removed by

prising it from the bumper using a screwdriver.

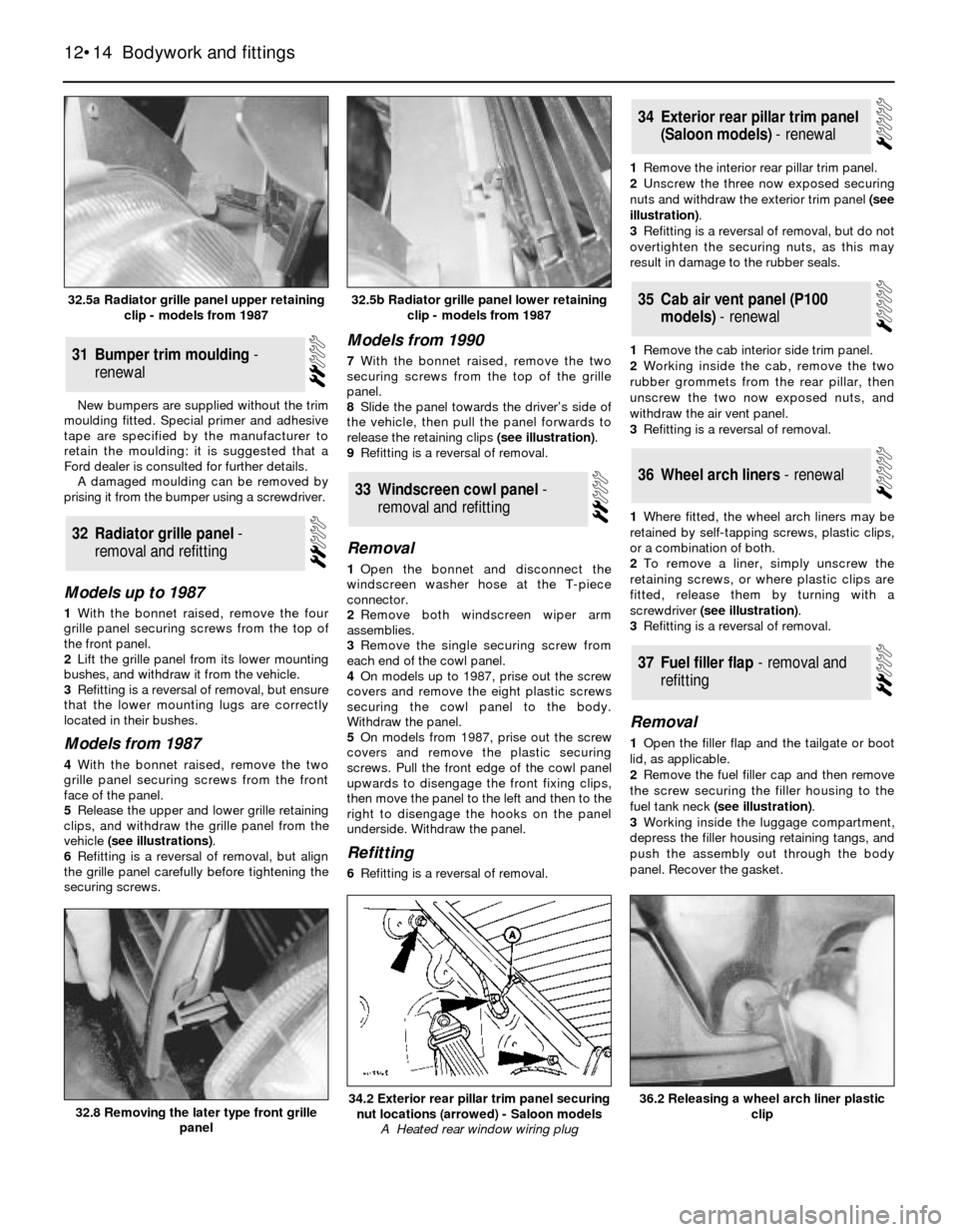

Models up to 1987

1With the bonnet raised, remove the four

grille panel securing screws from the top of

the front panel.

2Lift the grille panel from its lower mounting

bushes, and withdraw it from the vehicle.

3Refitting is a reversal of removal, but ensure

that the lower mounting lugs are correctly

located in their bushes.

Models from 1987

4With the bonnet raised, remove the two

grille panel securing screws from the front

face of the panel.

5Release the upper and lower grille retaining

clips, and withdraw the grille panel from the

vehicle (see illustrations).

6Refitting is a reversal of removal, but align

the grille panel carefully before tightening the

securing screws.

Models from 1990

7With the bonnet raised, remove the two

securing screws from the top of the grille

panel.

8Slide the panel towards the driver’s side of

the vehicle, then pull the panel forwards to

release the retaining clips (see illustration).

9Refitting is a reversal of removal.

Removal

1Open the bonnet and disconnect the

windscreen washer hose at the T-piece

connector.

2Remove both windscreen wiper arm

assemblies.

3Remove the single securing screw from

each end of the cowl panel.

4On models up to 1987, prise out the screw

covers and remove the eight plastic screws

securing the cowl panel to the body.

Withdraw the panel.

5On models from 1987, prise out the screw

covers and remove the plastic securing

screws. Pull the front edge of the cowl panel

upwards to disengage the front fixing clips,

then move the panel to the left and then to the

right to disengage the hooks on the panel

underside. Withdraw the panel.

Refitting

6Refitting is a reversal of removal.1Remove the interior rear pillar trim panel.

2Unscrew the three now exposed securing

nuts and withdraw the exterior trim panel (see

illustration).

3Refitting is a reversal of removal, but do not

overtighten the securing nuts, as this may

result in damage to the rubber seals.

1Remove the cab interior side trim panel.

2Working inside the cab, remove the two

rubber grommets from the rear pillar, then

unscrew the two now exposed nuts, and

withdraw the air vent panel.

3Refitting is a reversal of removal.

1Where fitted, the wheel arch liners may be

retained by self-tapping screws, plastic clips,

or a combination of both.

2To remove a liner, simply unscrew the

retaining screws, or where plastic clips are

fitted, release them by turning with a

screwdriver (see illustration).

3Refitting is a reversal of removal.

Removal

1Open the filler flap and the tailgate or boot

lid, as applicable.

2Remove the fuel filler cap and then remove

the screw securing the filler housing to the

fuel tank neck (see illustration).

3Working inside the luggage compartment,

depress the filler housing retaining tangs, and

push the assembly out through the body

panel. Recover the gasket.

37Fuel filler flap - removal and

refitting

36Wheel arch liners - renewal

35Cab air vent panel (P100

models) - renewal

34Exterior rear pillar trim panel

(Saloon models) - renewal

33Windscreen cowl panel -

removal and refitting

32Radiator grille panel -

removal and refitting

31Bumper trim moulding -

renewal

12•14Bodywork and fittings

32.8 Removing the later type front grille

panel36.2 Releasing a wheel arch liner plastic

clip34.2 Exterior rear pillar trim panel securing

nut locations (arrowed) - Saloon models

A Heated rear window wiring plug

32.5b Radiator grille panel lower retaining

clip - models from 198732.5a Radiator grille panel upper retaining

clip - models from 1987

Page 16 of 22

4Unscrew the upper seat belt anchor nut,

noting the fitted positions of any washers and

spacers so that they can be refitted in their

original positions.

5Remove the two securing screws, and

withdraw the upper trim panel.

6Remove the two or three securing screws

as applicable, and withdraw the lower trim

panel, passing the seat belt webbing through

the panel as it is removed.

7Refitting is a reversal of removal.

Rear pillar

Saloon models

8Remove the rear seat cushion.

9Unbolt the lower seat belt anchor.

10On models with fixed rear seats, remove

the backrest.

11On models with folding rear seats, remove

the side cushion.

12Remove the two securing screws from the

base of the pillar trim panel, then pull the trim

panel from the pillar, passing the seat belt

webbing through the panel as it is removed.

13Refitting is a reversal of removal.

Hatchback models

14Remove the rear seat side cushion.

15Remove the rear parcel shelf, and where

applicable unbolt the rear seat belt upper

anchor and spacer.

16On “high specification” models, lift the

seat catch release lever, push out the pin

securing the link rod to the lever and

disconnect the link rod.

17Remove the securing screws from the rear

parcel shelf support (nine screws on models

up to 1987, eight screws from 1987 onwards)

and on “high specification” models remove

the two bolts securing the rear seat catch

assembly to the wheel arch, then withdraw

the catch assembly. Remove the rear parcel

shelf support.

18Remove the five securing screws and

detach the rear pillar trim panel.

19Refitting is a reversal of removal, but

where applicable check the operation of the

rear seat catch on completion.

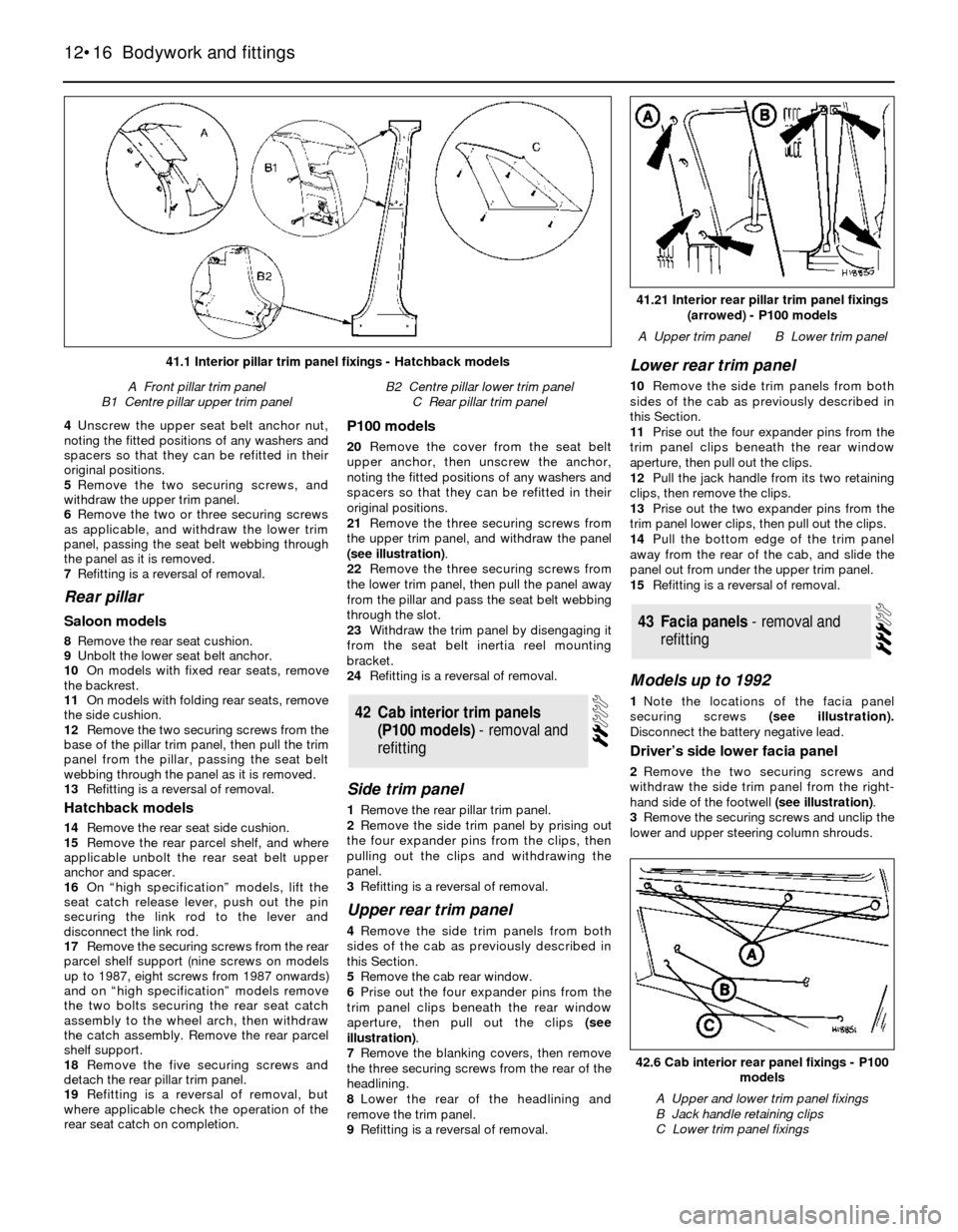

P100 models

20Remove the cover from the seat belt

upper anchor, then unscrew the anchor,

noting the fitted positions of any washers and

spacers so that they can be refitted in their

original positions.

21Remove the three securing screws from

the upper trim panel, and withdraw the panel

(see illustration).

22Remove the three securing screws from

the lower trim panel, then pull the panel away

from the pillar and pass the seat belt webbing

through the slot.

23Withdraw the trim panel by disengaging it

from the seat belt inertia reel mounting

bracket.

24Refitting is a reversal of removal.

Side trim panel

1Remove the rear pillar trim panel.

2Remove the side trim panel by prising out

the four expander pins from the clips, then

pulling out the clips and withdrawing the

panel.

3Refitting is a reversal of removal.

Upper rear trim panel

4Remove the side trim panels from both

sides of the cab as previously described in

this Section.

5Remove the cab rear window.

6Prise out the four expander pins from the

trim panel clips beneath the rear window

aperture, then pull out the clips (see

illustration).

7Remove the blanking covers, then remove

the three securing screws from the rear of the

headlining.

8Lower the rear of the headlining and

remove the trim panel.

9Refitting is a reversal of removal.

Lower rear trim panel

10Remove the side trim panels from both

sides of the cab as previously described in

this Section.

11Prise out the four expander pins from the

trim panel clips beneath the rear window

aperture, then pull out the clips.

12Pull the jack handle from its two retaining

clips, then remove the clips.

13Prise out the two expander pins from the

trim panel lower clips, then pull out the clips.

14Pull the bottom edge of the trim panel

away from the rear of the cab, and slide the

panel out from under the upper trim panel.

15Refitting is a reversal of removal.

Models up to 1992

1Note the locations of the facia panel

securing screws (see illustration).

Disconnect the battery negative lead.

Driver’s side lower facia panel

2Remove the two securing screws and

withdraw the side trim panel from the right-

hand side of the footwell (see illustration).

3Remove the securing screws and unclip the

lower and upper steering column shrouds.

43Facia panels - removal and

refitting

42Cab interior trim panels

(P100 models) - removal and

refitting

12•16Bodywork and fittings

42.6 Cab interior rear panel fixings - P100

models

A Upper and lower trim panel fixings

B Jack handle retaining clips

C Lower trim panel fixings

41.21 Interior rear pillar trim panel fixings

(arrowed) - P100 models

A Upper trim panelB Lower trim panel

41.1 Interior pillar trim panel fixings - Hatchback models

A Front pillar trim panel

B1 Centre pillar upper trim panelB2 Centre pillar lower trim panel

C Rear pillar trim panel

Page 18 of 22

20On models with an adjustable steering

column, fully extend and lower the steering

column before attempting to remove any of

the panels on the driver’s side.

21The steering column shrouds are secured

by six screws - five through the lower shroud,

and one through the upper shroud.

22If necessary, remove the centre console.

23The driver’s side lower facia panel is

secured by five screws.

24The passenger’s side lower facia panel is

secured by eight screws.

25On models with an alarm, the alarm warning

light must be disconnected and removed before

removing the upper facia panel.

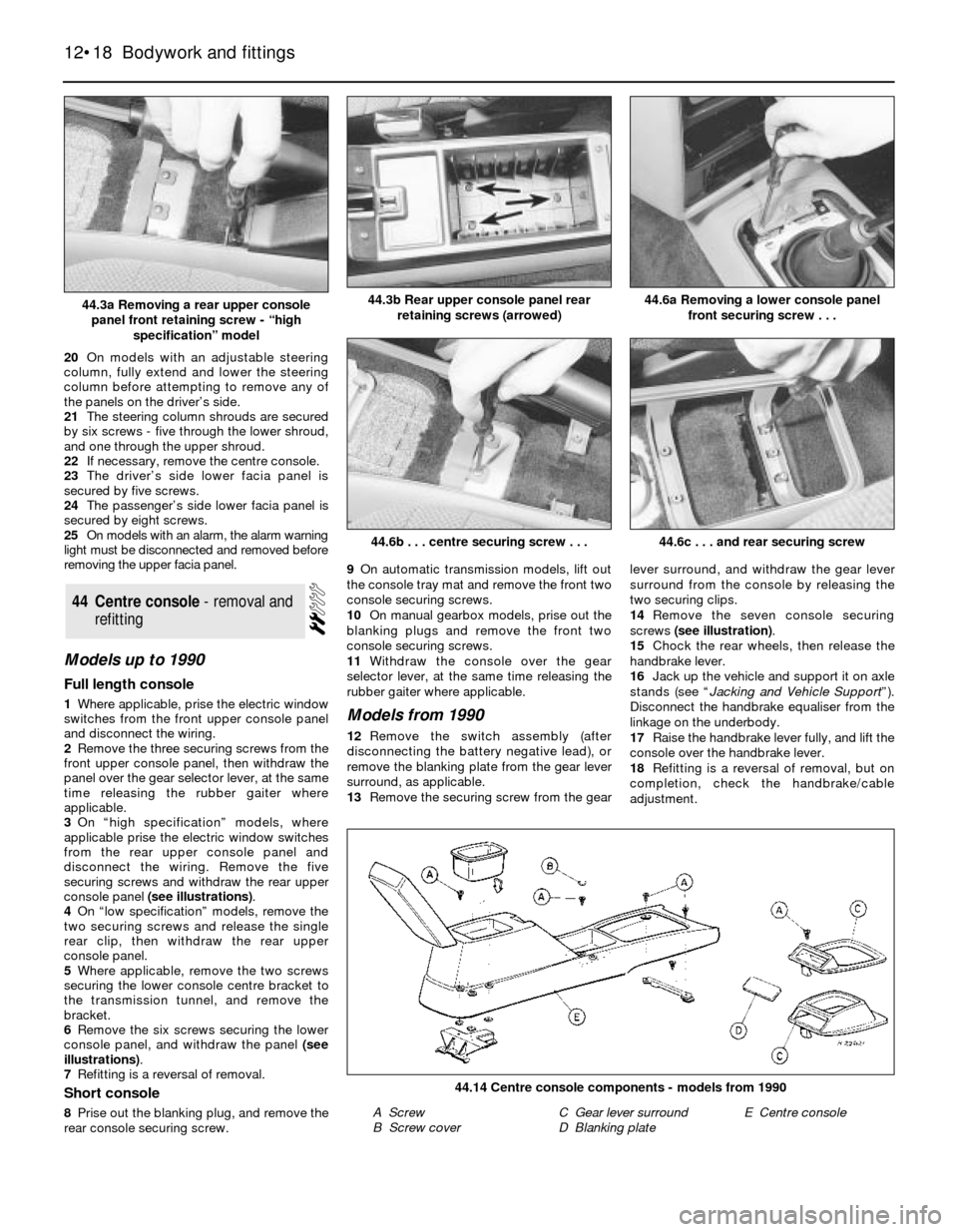

Models up to 1990

Full length console

1Where applicable, prise the electric window

switches from the front upper console panel

and disconnect the wiring.

2Remove the three securing screws from the

front upper console panel, then withdraw the

panel over the gear selector lever, at the same

time releasing the rubber gaiter where

applicable.

3On “high specification” models, where

applicable prise the electric window switches

from the rear upper console panel and

disconnect the wiring. Remove the five

securing screws and withdraw the rear upper

console panel (see illustrations).

4On “low specification” models, remove the

two securing screws and release the single

rear clip, then withdraw the rear upper

console panel.

5Where applicable, remove the two screws

securing the lower console centre bracket to

the transmission tunnel, and remove the

bracket.

6Remove the six screws securing the lower

console panel, and withdraw the panel (see

illustrations).

7Refitting is a reversal of removal.

Short console

8Prise out the blanking plug, and remove the

rear console securing screw.9On automatic transmission models, lift out

the console tray mat and remove the front two

console securing screws.

10On manual gearbox models, prise out the

blanking plugs and remove the front two

console securing screws.

11Withdraw the console over the gear

selector lever, at the same time releasing the

rubber gaiter where applicable.

Models from 1990

12Remove the switch assembly (after

disconnecting the battery negative lead), or

remove the blanking plate from the gear lever

surround, as applicable.

13Remove the securing screw from the gearlever surround, and withdraw the gear lever

surround from the console by releasing the

two securing clips.

14Remove the seven console securing

screws (see illustration).

15Chock the rear wheels, then release the

handbrake lever.

16Jack up the vehicle and support it on axle

stands (see “Jacking and Vehicle Support”).

Disconnect the handbrake equaliser from the

linkage on the underbody.

17Raise the handbrake lever fully, and lift the

console over the handbrake lever.

18Refitting is a reversal of removal, but on

completion, check the handbrake/cable

adjustment.

44Centre console - removal and

refitting

12•18Bodywork and fittings

44.3b Rear upper console panel rear

retaining screws (arrowed)

44.6b . . . centre securing screw . . .

44.14 Centre console components - models from 1990

A Screw

B Screw coverC Gear lever surround

D Blanking plateE Centre console

44.6c . . . and rear securing screw

44.6a Removing a lower console panel

front securing screw . . .44.3a Removing a rear upper console

panel front retaining screw - “high

specification” model

Page 20 of 22

Rear seat armrest

26Fold the rear seat backrest forwards, and

remove the three armrest securing screws.

27Remove the armrest by prising out the

trim clips securing the cover material to the

seat backrest.

28Refitting is a reversal of removal.

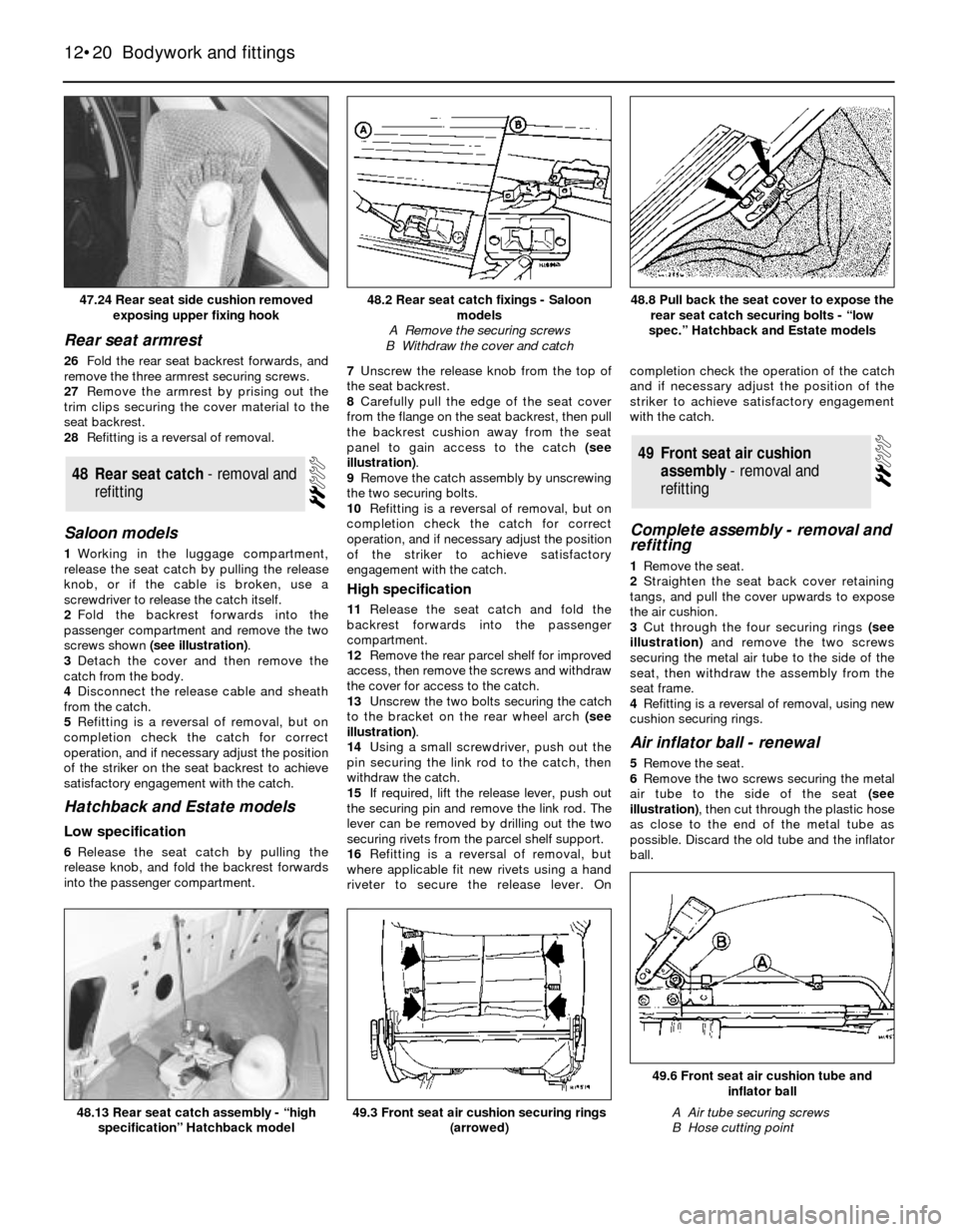

Saloon models

1Working in the luggage compartment,

release the seat catch by pulling the release

knob, or if the cable is broken, use a

screwdriver to release the catch itself.

2Fold the backrest forwards into the

passenger compartment and remove the two

screws shown (see illustration).

3Detach the cover and then remove the

catch from the body.

4Disconnect the release cable and sheath

from the catch.

5Refitting is a reversal of removal, but on

completion check the catch for correct

operation, and if necessary adjust the position

of the striker on the seat backrest to achieve

satisfactory engagement with the catch.

Hatchback and Estate models

Low specification

6Release the seat catch by pulling the

release knob, and fold the backrest forwards

into the passenger compartment.7Unscrew the release knob from the top of

the seat backrest.

8Carefully pull the edge of the seat cover

from the flange on the seat backrest, then pull

the backrest cushion away from the seat

panel to gain access to the catch (see

illustration).

9Remove the catch assembly by unscrewing

the two securing bolts.

10Refitting is a reversal of removal, but on

completion check the catch for correct

operation, and if necessary adjust the position

of the striker to achieve satisfactory

engagement with the catch.

High specification

11Release the seat catch and fold the

backrest forwards into the passenger

compartment.

12Remove the rear parcel shelf for improved

access, then remove the screws and withdraw

the cover for access to the catch.

13Unscrew the two bolts securing the catch

to the bracket on the rear wheel arch (see

illustration).

14Using a small screwdriver, push out the

pin securing the link rod to the catch, then

withdraw the catch.

15If required, lift the release lever, push out

the securing pin and remove the link rod. The

lever can be removed by drilling out the two

securing rivets from the parcel shelf support.

16Refitting is a reversal of removal, but

where applicable fit new rivets using a hand

riveter to secure the release lever. Oncompletion check the operation of the catch

and if necessary adjust the position of the

striker to achieve satisfactory engagement

with the catch.

Complete assembly - removal and

refitting

1Remove the seat.

2Straighten the seat back cover retaining

tangs, and pull the cover upwards to expose

the air cushion.

3Cut through the four securing rings (see

illustration)and remove the two screws

securing the metal air tube to the side of the

seat, then withdraw the assembly from the

seat frame.

4Refitting is a reversal of removal, using new

cushion securing rings.

Air inflator ball - renewal

5Remove the seat.

6Remove the two screws securing the metal

air tube to the side of the seat (see

illustration), then cut through the plastic hose

as close to the end of the metal tube as

possible. Discard the old tube and the inflator

ball.

49Front seat air cushion

assembly - removal and

refitting

48Rear seat catch - removal and

refitting

12•20Bodywork and fittings

48.8 Pull back the seat cover to expose the

rear seat catch securing bolts - “low

spec.” Hatchback and Estate models

49.3 Front seat air cushion securing rings

(arrowed)

49.6 Front seat air cushion tube and

inflator ball

A Air tube securing screws

B Hose cutting point48.13 Rear seat catch assembly - “high

specification” Hatchback model

48.2 Rear seat catch fixings - Saloon

models

A Remove the securing screws

B Withdraw the cover and catch47.24 Rear seat side cushion removed

exposing upper fixing hook