mileage FORD SIERRA 1985 1.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: SIERRA, Model: FORD SIERRA 1985 1.GPages: 18, PDF Size: 0.9 MB

Page 15 of 18

Inspection

3Examine the surfaces of the camshaft

journals and lobes and the contact surfaces of

the cam followers for wear. If wear is

excessive considerable noise would have

been noticed from the top of the engine when

running, and new camshafts and followers

must be fitted. It is unlikely that this level of

wear will occur unless a considerable mileage

has been covered. Note that the cam

followers cannot be dismantled for renewal of

individual components.

4Check the camshaft bearing surfaces in the

cylinder head and the bearing caps for wear. If

excessive wear is evident, the only course of

action available is to renew the cylinder head

and bearing caps.

5Check the cam follower bores in the

cylinder head for wear. If excessive wear is

evident, the cylinder head must be renewed.

6Check the cam follower oil grooves and the

oil ports in the cylinder head for obstructions.

Refitting

7Refit the cam followers and the camshafts

as described in paragraphs 27 to 55 of

Section 18.

8If the engine is in the vehicle, reverse the

operations given in paragraph 1.

Note: New flywheel/driveplate securing bolts

must be used on refitting.

1Refer to Chapter 2, PartA, noting the

following points.

2If the engine is in the car, refer to Chapter 6

when removing and refitting the clutch.

3There is no need to make alignment marks

between the flywheel/driveplate and the end

of the crankshaft, as the securing bolt holes

are offset, so the flywheel/driveplate can only

be fitted to the crankshaft in one position.

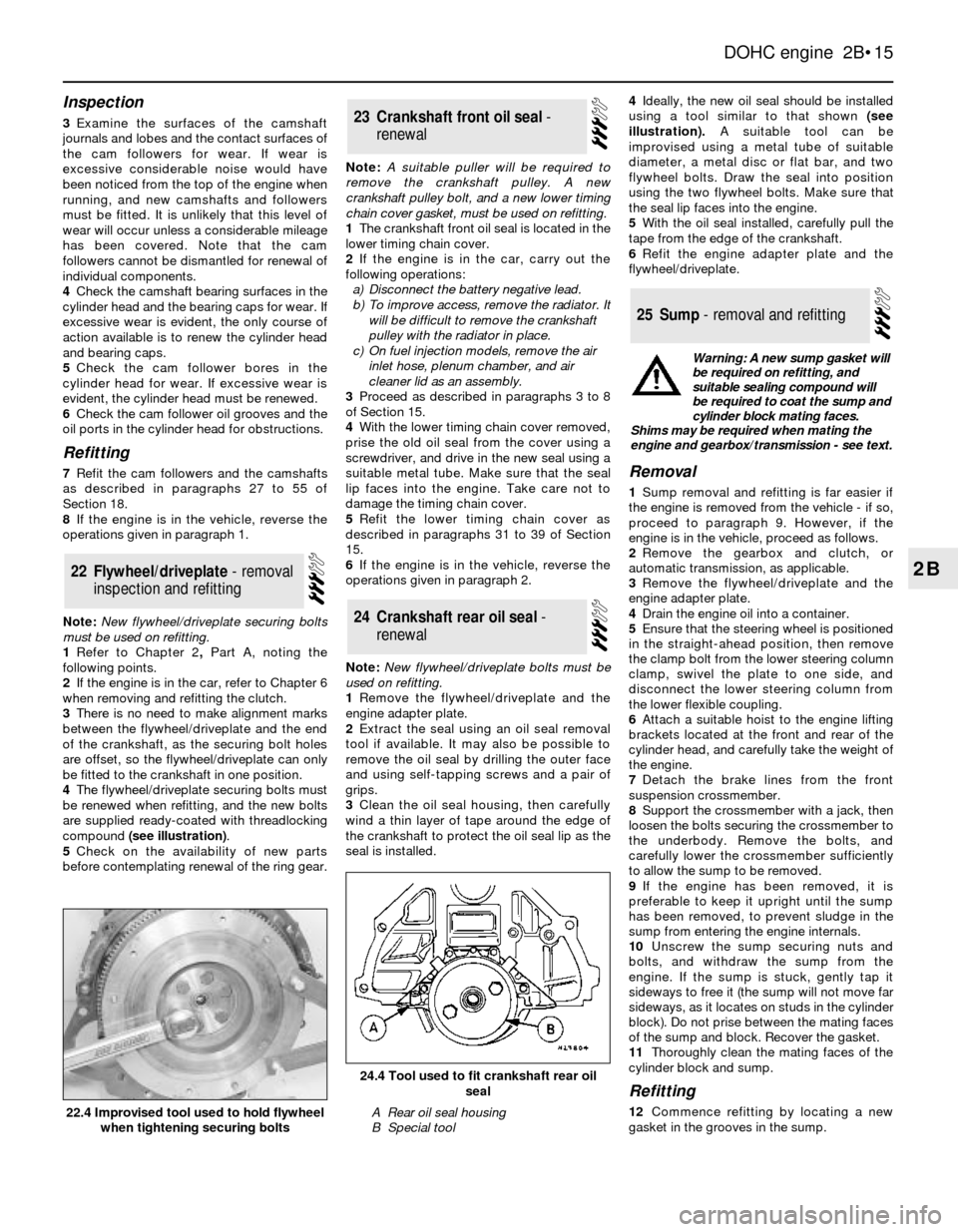

4The flywheel/driveplate securing bolts must

be renewed when refitting, and the new bolts

are supplied ready-coated with threadlocking

compound (see illustration).

5Check on the availability of new parts

before contemplating renewal of the ring gear.Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, and a new lower timing

chain cover gasket, must be used on refitting.

1The crankshaft front oil seal is located in the

lower timing chain cover.

2If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

3Proceed as described in paragraphs 3 to 8

of Section 15.

4With the lower timing chain cover removed,

prise the old oil seal from the cover using a

screwdriver, and drive in the new seal using a

suitable metal tube. Make sure that the seal

lip faces into the engine. Take care not to

damage the timing chain cover.

5Refit the lower timing chain cover as

described in paragraphs 31 to 39 of Section

15.

6If the engine is in the vehicle, reverse the

operations given in paragraph 2.

Note: New flywheel/driveplate bolts must be

used on refitting.

1Remove the flywheel/driveplate and the

engine adapter plate.

2Extract the seal using an oil seal removal

tool if available. It may also be possible to

remove the oil seal by drilling the outer face

and using self-tapping screws and a pair of

grips.

3Clean the oil seal housing, then carefully

wind a thin layer of tape around the edge of

the crankshaft to protect the oil seal lip as the

seal is installed.4Ideally, the new oil seal should be installed

using a tool similar to that shown (see

illustration).A suitable tool can be

improvised using a metal tube of suitable

diameter, a metal disc or flat bar, and two

flywheel bolts. Draw the seal into position

using the two flywheel bolts. Make sure that

the seal lip faces into the engine.

5With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

6Refit the engine adapter plate and the

flywheel/driveplate.Removal

1Sump removal and refitting is far easier if

the engine is removed from the vehicle - if so,

proceed to paragraph 9. However, if the

engine is in the vehicle, proceed as follows.

2Remove the gearbox and clutch, or

automatic transmission, as applicable.

3Remove the flywheel/driveplate and the

engine adapter plate.

4Drain the engine oil into a container.

5Ensure that the steering wheel is positioned

in the straight-ahead position, then remove

the clamp bolt from the lower steering column

clamp, swivel the plate to one side, and

disconnect the lower steering column from

the lower flexible coupling.

6Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

7Detach the brake lines from the front

suspension crossmember.

8Support the crossmember with a jack, then

loosen the bolts securing the crossmember to

the underbody. Remove the bolts, and

carefully lower the crossmember sufficiently

to allow the sump to be removed.

9If the engine has been removed, it is

preferable to keep it upright until the sump

has been removed, to prevent sludge in the

sump from entering the engine internals.

10Unscrew the sump securing nuts and

bolts, and withdraw the sump from the

engine. If the sump is stuck, gently tap it

sideways to free it (the sump will not move far

sideways, as it locates on studs in the cylinder

block). Do not prise between the mating faces

of the sump and block. Recover the gasket.

11Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

12Commence refitting by locating a new

gasket in the grooves in the sump.

25Sump - removal and refitting

24Crankshaft rear oil seal -

renewal

23Crankshaft front oil seal -

renewal

22Flywheel/driveplate - removal

inspection and refitting

DOHC engine 2B•15

2B

24.4 Tool used to fit crankshaft rear oil

seal

A Rear oil seal housing

B Special tool22.4 Improvised tool used to hold flywheel

when tightening securing bolts

Warning: A new sump gasket will

be required on refitting, and

suitable sealing compound will

be required to coat the sump and

cylinder block mating faces.

Shims may be required when mating the

engine and gearbox/transmission - see text.