spare wheel FORD SIERRA 1985 1.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: SIERRA, Model: FORD SIERRA 1985 1.GPages: 18, PDF Size: 0.9 MB

Page 17 of 18

5Unscrew the pressure relief valve plug from

the pump cover, recover the washer, and

withdraw the spring and plunger (see

illustrations).

Inspection

6Thoroughly clean all components in petrol or

paraffin, and wipe dry using a non-fluffy rag.

7Examine the rotors and the pump casing for

signs of excessive wear on the machined

surfaces. If wear is evident, the complete

pump assembly must be renewed, as spare

parts are not available individually.

Reassembly

8Commence reassembly by lubricating the

relief valve plunger. Fit the plunger and the

spring, and screw the plug into place,

ensuring that the washer is in place under the

plug.

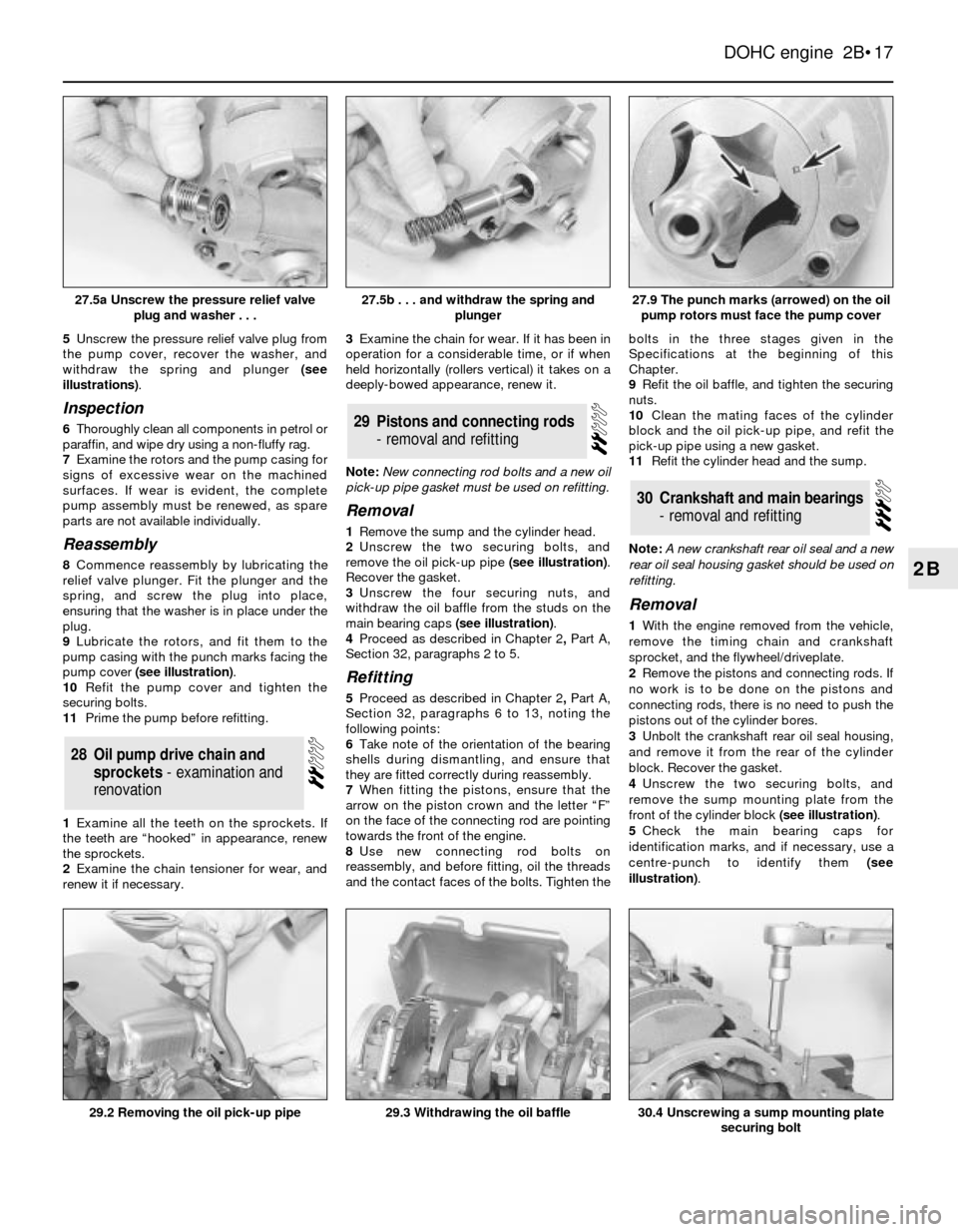

9Lubricate the rotors, and fit them to the

pump casing with the punch marks facing the

pump cover (see illustration).

10Refit the pump cover and tighten the

securing bolts.

11Prime the pump before refitting.

1Examine all the teeth on the sprockets. If

the teeth are “hooked” in appearance, renew

the sprockets.

2Examine the chain tensioner for wear, and

renew it if necessary.3Examine the chain for wear. If it has been in

operation for a considerable time, or if when

held horizontally (rollers vertical) it takes on a

deeply-bowed appearance, renew it.

Note: New connecting rod bolts and a new oil

pick-up pipe gasket must be used on refitting.

Removal

1Remove the sump and the cylinder head.

2Unscrew the two securing bolts, and

remove the oil pick-up pipe (see illustration).

Recover the gasket.

3Unscrew the four securing nuts, and

withdraw the oil baffle from the studs on the

main bearing caps (see illustration).

4Proceed as described in Chapter 2, PartA,

Section 32, paragraphs 2 to 5.

Refitting

5Proceed as described in Chapter 2, PartA,

Section 32, paragraphs 6 to 13, noting the

following points:

6Take note of the orientation of the bearing

shells during dismantling, and ensure that

they are fitted correctly during reassembly.

7When fitting the pistons, ensure that the

arrow on the piston crown and the letter “F”

on the face of the connecting rod are pointing

towards the front of the engine.

8Use new connecting rod bolts on

reassembly, and before fitting, oil the threads

and the contact faces of the bolts. Tighten thebolts in the three stages given in the

Specifications at the beginning of this

Chapter.

9Refit the oil baffle, and tighten the securing

nuts.

10Clean the mating faces of the cylinder

block and the oil pick-up pipe, and refit the

pick-up pipe using a new gasket.

11Refit the cylinder head and the sump.

Note: A new crankshaft rear oil seal and a new

rear oil seal housing gasket should be used on

refitting.

Removal

1With the engine removed from the vehicle,

remove the timing chain and crankshaft

sprocket, and the flywheel/driveplate.

2Remove the pistons and connecting rods. If

no work is to be done on the pistons and

connecting rods, there is no need to push the

pistons out of the cylinder bores.

3Unbolt the crankshaft rear oil seal housing,

and remove it from the rear of the cylinder

block. Recover the gasket.

4Unscrew the two securing bolts, and

remove the sump mounting plate from the

front of the cylinder block (see illustration).

5Check the main bearing caps for

identification marks, and if necessary, use a

centre-punch to identify them (see

illustration).

30Crankshaft and main bearings

- removal and refitting

29Pistons and connecting rods

- removal and refitting

28Oil pump drive chain and

sprockets - examination and

renovation

DOHC engine 2B•17

2B

27.5b . . . and withdraw the spring and

plunger

30.4 Unscrewing a sump mounting plate

securing bolt29.3 Withdrawing the oil baffle29.2 Removing the oil pick-up pipe

27.9 The punch marks (arrowed) on the oil

pump rotors must face the pump cover27.5a Unscrew the pressure relief valve

plug and washer . . .