torque FORD SIERRA 1985 1.G Fuel And Exhaust Systems Carburettor Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: SIERRA, Model: FORD SIERRA 1985 1.GPages: 20, PDF Size: 0.83 MB

Page 3 of 20

Pierburg 2V (2E3) carburettor - SOHC models (Part No 85HF 9510 AB)

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .800 ±20 rpm

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.3%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .830 ±30 rpm

Automatic choke vacuum pull-down . . . . . . . . . . . . . . . . . . . . . . . . . . .3.0 mm (0.12 in)

Idle fuel jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Idle air bleed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

PrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.0 mm26.0 mm

Main jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107.5130

Pierburg 2V (2E3) carburettor - SOHC models (Part Nos 85HF 9510 JB and KC)

Idle speed:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .850 to 900 rpm

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .775 to 825 rpm

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0 to 1.5%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1850 to 1950 rpm

Automatic choke vacuum pull-down:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.0 mm (0.16 in)

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.7 mm (0.15 in)

Idle fuel jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Idle air bleed:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

PrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.0 mm26.0 mm

Main jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102.5130

Pierburg 2V (2E3) carburettor- CVH models

Idle speed:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .850 to 900 rpm

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .775 to 825 rpm

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.75 to 1.25%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 rpm

Automatic choke vacuum pull-down:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.3 mm (0.09 in)

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.5 mm (0.10 in)

Idle fuel jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47.5

Idle air bleed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

PrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22.0 mm23.0 mm

Main jet:

Manual gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100105

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97.5105

Weber 2V (TLD) carburettor

Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .850 ±25 rpm

Idle mixture (CO content) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0 ±0.25%

Fast idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1800 ±50 rpm

Float level (with gasket) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29.0 ±0.5 mm

Automatic choke vacuum pull-down . . . . . . . . . . . . . . . . . . . . . . . . . . .5.0 ±0.5 mm

Throttle kicker speed (see text) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 ±50 rpm

PrimarySecondary

Venturi diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23.0 mm25.0 mm

Main jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115157

Air correction jet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175145

Emulsion tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F114F3

Torque wrench settingsNmlbf ft

All models except 2.0 litre DOHC

Fuel pump bolts (mechanical pump) . . . . . . . . . . . . . . . . . . . . . . . . . . .14 to 1810 to 13

Inlet manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2012 to 15

Exhaust manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Exhaust manifold-to-downpipe nuts . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Exhaust downpipe-to-main system nuts . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Exhaust U-bolt clamp nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38 to 4528 to 33

Fuel and exhaust systems - carburettor 4A•3

4A

Page 6 of 20

5On some early pumps, the top cover can be

removed for access to the filter. Removing the

pump and cleaning the filter may cure the

problem. On models with a sealed pump, or

where cleaning the interior of the pump and

filter does not solve the problem, the pump

should be renewed, as no spares are

available. Check that there is petrol in the fuel

tank before condemning the pump!

6On completion of the test, reconnect the

outlet hose to the pump. If the hose was

originally secured with a crimped type clip,

discard this and use a new worm drive clip.

Reconnect the coil LT lead.

Electric pump

SOHC and CVH models with air

conditioning

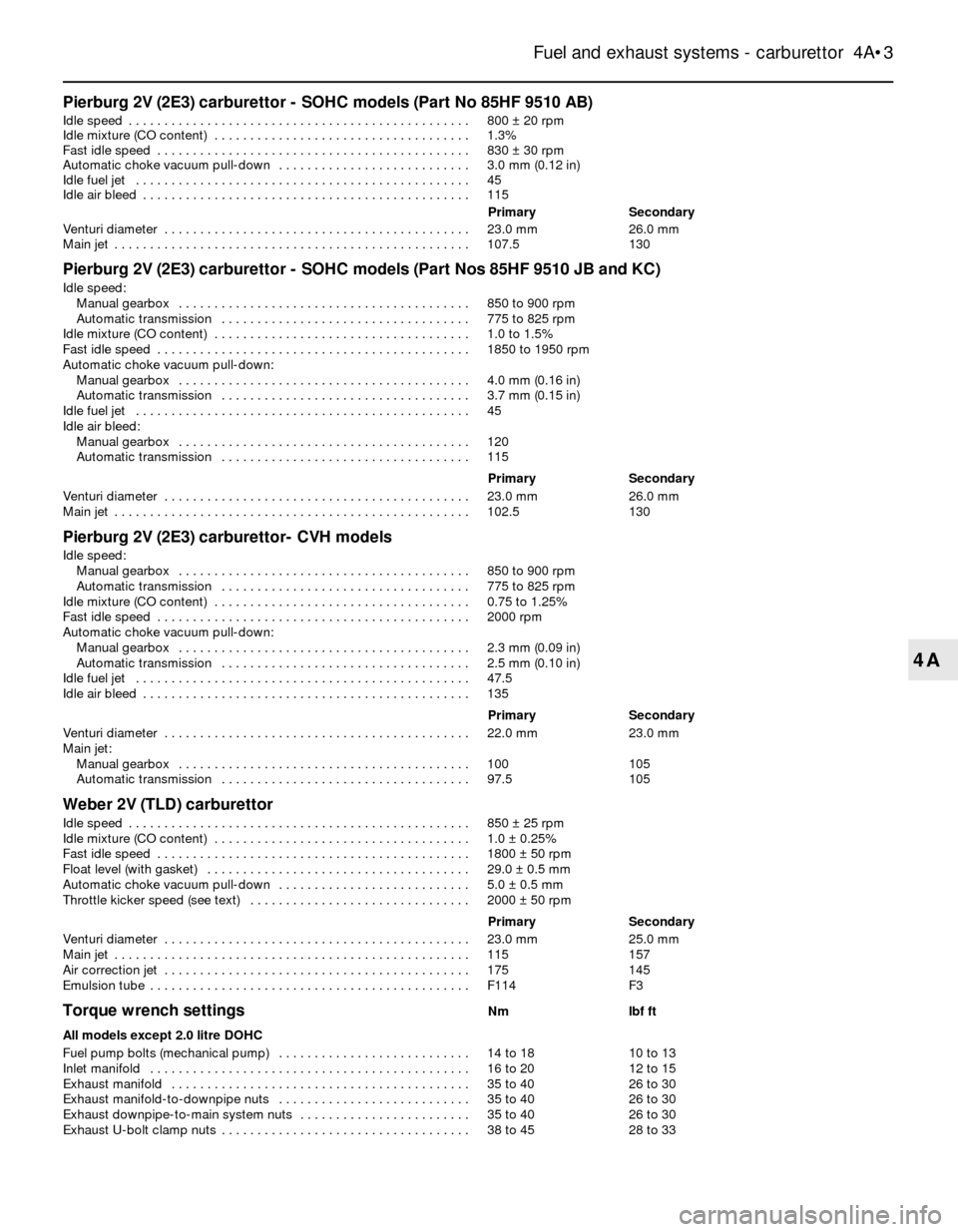

7The fuel pump is located under the rear of

the vehicle, next to the fuel tank (see

illustration).

8If the pump is functioning, it should be

possible to hear it “buzzing” by listening

under the rear of the vehicle when the ignition

is switched on.

9If the pump appears to have failed

completely, check the fuse and relay.

10To test the pump, disconnect the fuel

supply hose from the pressure regulator or

vapour separator (as applicable) in the engine

compartment. Lead the hose into a measuring

cylinder.

11Take appropriate fire precautions, then

switch on the ignition for 30 seconds (do notstart the engine), and measure the quantity of

petrol delivered: it should be at least 400 ml

(0.7 pint). If not, the pump is faulty and should

be renewed, as no spares are available.

12On completion of the test, reconnect the

hose to the pressure regulator or vapour

separator, as applicable, and if the hose was

originally secured with a crimped type clip,

discard this and fit a new worm drive clip.

2.0 litre DOHC models

13If the fuel pump is functioning, it should

be possible to hear it “buzzing” by listening

under the rear of the vehicle when the ignition

is switched on. Unless the engine is started,

the fuel pump should switch off after

approximately one second.

14If the pump appears to have failed

completely, check the appropriate fuse and

relay, and where applicable check the state of

the fuel pump inertia cut-off switch as follows.

15The inertia cut-off switch is located in the

spare wheel well. The switch incorporates a

reset button, which should normally be in the

depressed position. Check the position of the

reset button before assuming that a fault

exists in the fuel pump.

16To test the fuel pump, special equipment

is required, and it is recommended that any

suspected faults are referred to a Ford dealer.

Mechanical pump

Note: A new gasket must be used when

refitting the pump.

1Disconnect the battery negative lead.

2For improved access on CVH models,

remove the air cleaner.

3Identify the hose locations as an aid to

refitting, then disconnect the hoses from the

pump and plug them.

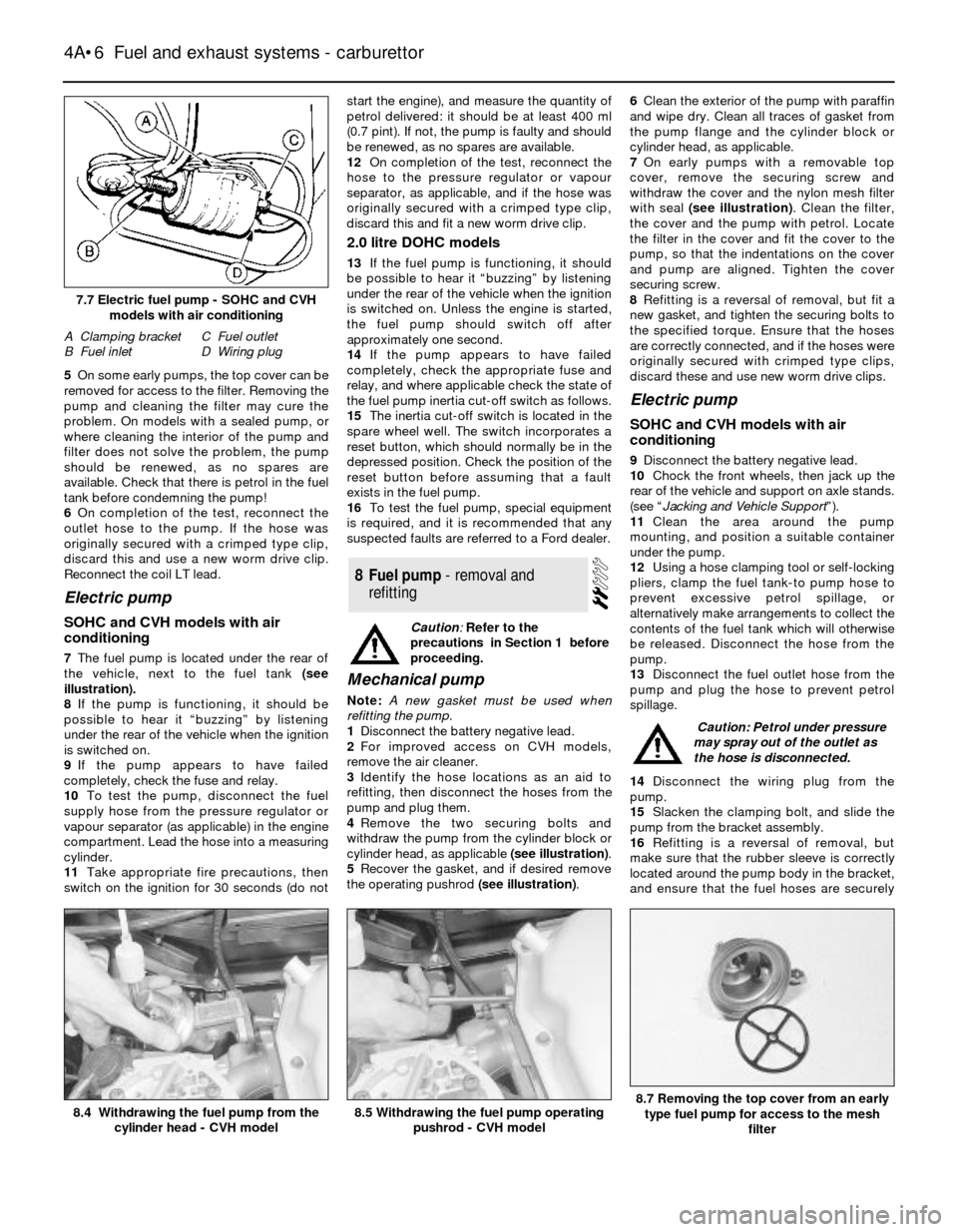

4Remove the two securing bolts and

withdraw the pump from the cylinder block or

cylinder head, as applicable (see illustration).

5Recover the gasket, and if desired remove

the operating pushrod (see illustration).6Clean the exterior of the pump with paraffin

and wipe dry. Clean all traces of gasket from

the pump flange and the cylinder block or

cylinder head, as applicable.

7On early pumps with a removable top

cover, remove the securing screw and

withdraw the cover and the nylon mesh filter

with seal (see illustration). Clean the filter,

the cover and the pump with petrol. Locate

the filter in the cover and fit the cover to the

pump, so that the indentations on the cover

and pump are aligned. Tighten the cover

securing screw.

8Refitting is a reversal of removal, but fit a

new gasket, and tighten the securing bolts to

the specified torque. Ensure that the hoses

are correctly connected, and if the hoses were

originally secured with crimped type clips,

discard these and use new worm drive clips.

Electric pump

SOHC and CVH models with air

conditioning

9Disconnect the battery negative lead.

10Chock the front wheels, then jack up the

rear of the vehicle and support on axle stands.

(see “Jacking and Vehicle Support”).

11Clean the area around the pump

mounting, and position a suitable container

under the pump.

12Using a hose clamping tool or self-locking

pliers, clamp the fuel tank-to pump hose to

prevent excessive petrol spillage, or

alternatively make arrangements to collect the

contents of the fuel tank which will otherwise

be released. Disconnect the hose from the

pump.

13Disconnect the fuel outlet hose from the

pump and plug the hose to prevent petrol

spillage.

14Disconnect the wiring plug from the

pump.

15Slacken the clamping bolt, and slide the

pump from the bracket assembly.

16Refitting is a reversal of removal, but

make sure that the rubber sleeve is correctly

located around the pump body in the bracket,

and ensure that the fuel hoses are securely

8Fuel pump - removal and

refitting

4A•6Fuel and exhaust systems - carburettor

7.7 Electric fuel pump - SOHC and CVH

models with air conditioning

A Clamping bracket

B Fuel inletC Fuel outlet

D Wiring plug

8.5 Withdrawing the fuel pump operating

pushrod - CVH model8.4 Withdrawing the fuel pump from the

cylinder head - CVH model8.7 Removing the top cover from an early

type fuel pump for access to the mesh

filter

Caution: Refer to the

precautions in Section 1 before

proceeding.

Caution:Petrol under pressure

may spray out of the outlet as

the hose is disconnected.

Page 16 of 20

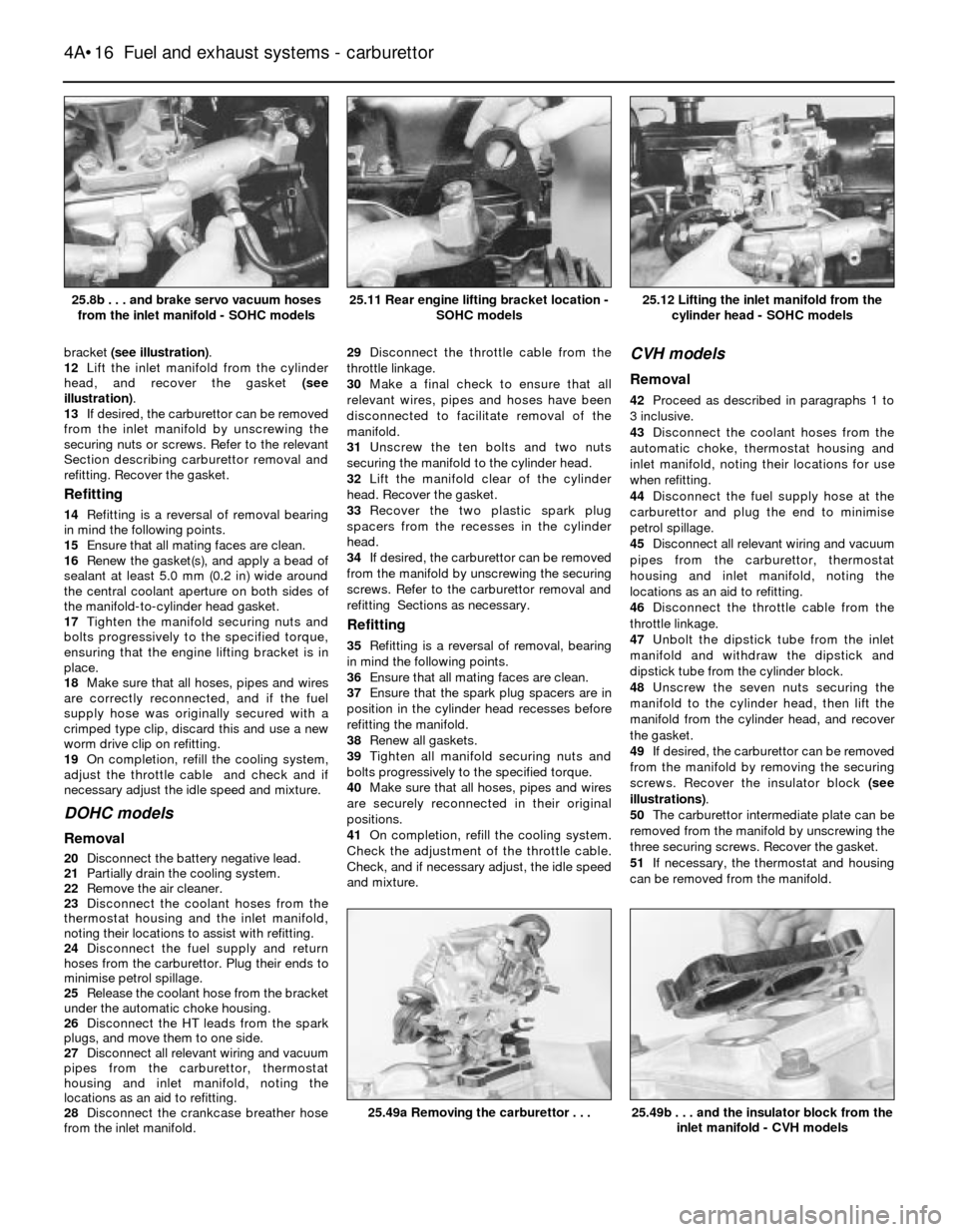

bracket (see illustration).

12Lift the inlet manifold from the cylinder

head, and recover the gasket (see

illustration).

13If desired, the carburettor can be removed

from the inlet manifold by unscrewing the

securing nuts or screws. Refer to the relevant

Section describing carburettor removal and

refitting. Recover the gasket.

Refitting

14Refitting is a reversal of removal bearing

in mind the following points.

15Ensure that all mating faces are clean.

16Renew the gasket(s), and apply a bead of

sealant at least 5.0 mm (0.2 in) wide around

the central coolant aperture on both sides of

the manifold-to-cylinder head gasket.

17Tighten the manifold securing nuts and

bolts progressively to the specified torque,

ensuring that the engine lifting bracket is in

place.

18Make sure that all hoses, pipes and wires

are correctly reconnected, and if the fuel

supply hose was originally secured with a

crimped type clip, discard this and use a new

worm drive clip on refitting.

19On completion, refill the cooling system,

adjust the throttle cable and check and if

necessary adjust the idle speed and mixture.

DOHC models

Removal

20Disconnect the battery negative lead.

21Partially drain the cooling system.

22Remove the air cleaner.

23Disconnect the coolant hoses from the

thermostat housing and the inlet manifold,

noting their locations to assist with refitting.

24Disconnect the fuel supply and return

hoses from the carburettor. Plug their ends to

minimise petrol spillage.

25Release the coolant hose from the bracket

under the automatic choke housing.

26Disconnect the HT leads from the spark

plugs, and move them to one side.

27Disconnect all relevant wiring and vacuum

pipes from the carburettor, thermostat

housing and inlet manifold, noting the

locations as an aid to refitting.

28Disconnect the crankcase breather hose

from the inlet manifold. 29Disconnect the throttle cable from the

throttle linkage.

30Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

manifold.

31Unscrew the ten bolts and two nuts

securing the manifold to the cylinder head.

32Lift the manifold clear of the cylinder

head. Recover the gasket.

33Recover the two plastic spark plug

spacers from the recesses in the cylinder

head.

34If desired, the carburettor can be removed

from the manifold by unscrewing the securing

screws. Refer to the carburettor removal and

refitting Sections as necessary.

Refitting

35Refitting is a reversal of removal, bearing

in mind the following points.

36Ensure that all mating faces are clean.

37Ensure that the spark plug spacers are in

position in the cylinder head recesses before

refitting the manifold.

38Renew all gaskets.

39Tighten all manifold securing nuts and

bolts progressively to the specified torque.

40Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions.

41On completion, refill the cooling system.

Check the adjustment of the throttle cable.

Check, and if necessary adjust, the idle speed

and mixture.

CVH models

Removal

42Proceed as described in paragraphs 1 to

3 inclusive.

43Disconnect the coolant hoses from the

automatic choke, thermostat housing and

inlet manifold, noting their locations for use

when refitting.

44Disconnect the fuel supply hose at the

carburettor and plug the end to minimise

petrol spillage.

45Disconnect all relevant wiring and vacuum

pipes from the carburettor, thermostat

housing and inlet manifold, noting the

locations as an aid to refitting.

46Disconnect the throttle cable from the

throttle linkage.

47Unbolt the dipstick tube from the inlet

manifold and withdraw the dipstick and

dipstick tube from the cylinder block.

48Unscrew the seven nuts securing the

manifold to the cylinder head, then lift the

manifold from the cylinder head, and recover

the gasket.

49If desired, the carburettor can be removed

from the manifold by removing the securing

screws. Recover the insulator block (see

illustrations).

50The carburettor intermediate plate can be

removed from the manifold by unscrewing the

three securing screws. Recover the gasket.

51If necessary, the thermostat and housing

can be removed from the manifold.

4A•16Fuel and exhaust systems - carburettor

25.8b . . . and brake servo vacuum hoses

from the inlet manifold - SOHC models25.12 Lifting the inlet manifold from the

cylinder head - SOHC models

25.49b . . . and the insulator block from the

inlet manifold - CVH models25.49a Removing the carburettor . . .

25.11 Rear engine lifting bracket location -

SOHC models

Page 17 of 20

Refitting

52Refitting is a reversal of removal, bearing

in mind the following points.

53Ensure that all mating faces are clean and

renew the gasket(s).

54Tighten the manifold securing nuts

progressively to the specified torque.

55Make sure that all hoses, pipes and wires

are correctly reconnected, and if the fuel

supply hose was originally secured with a

crimped type clip, discard this and use a new

worm drive clip on refitting.

56On completion, refill the cooling system,

adjust the throttle cable and check and if

necessary adjust the idle speed and mixture.

Removal

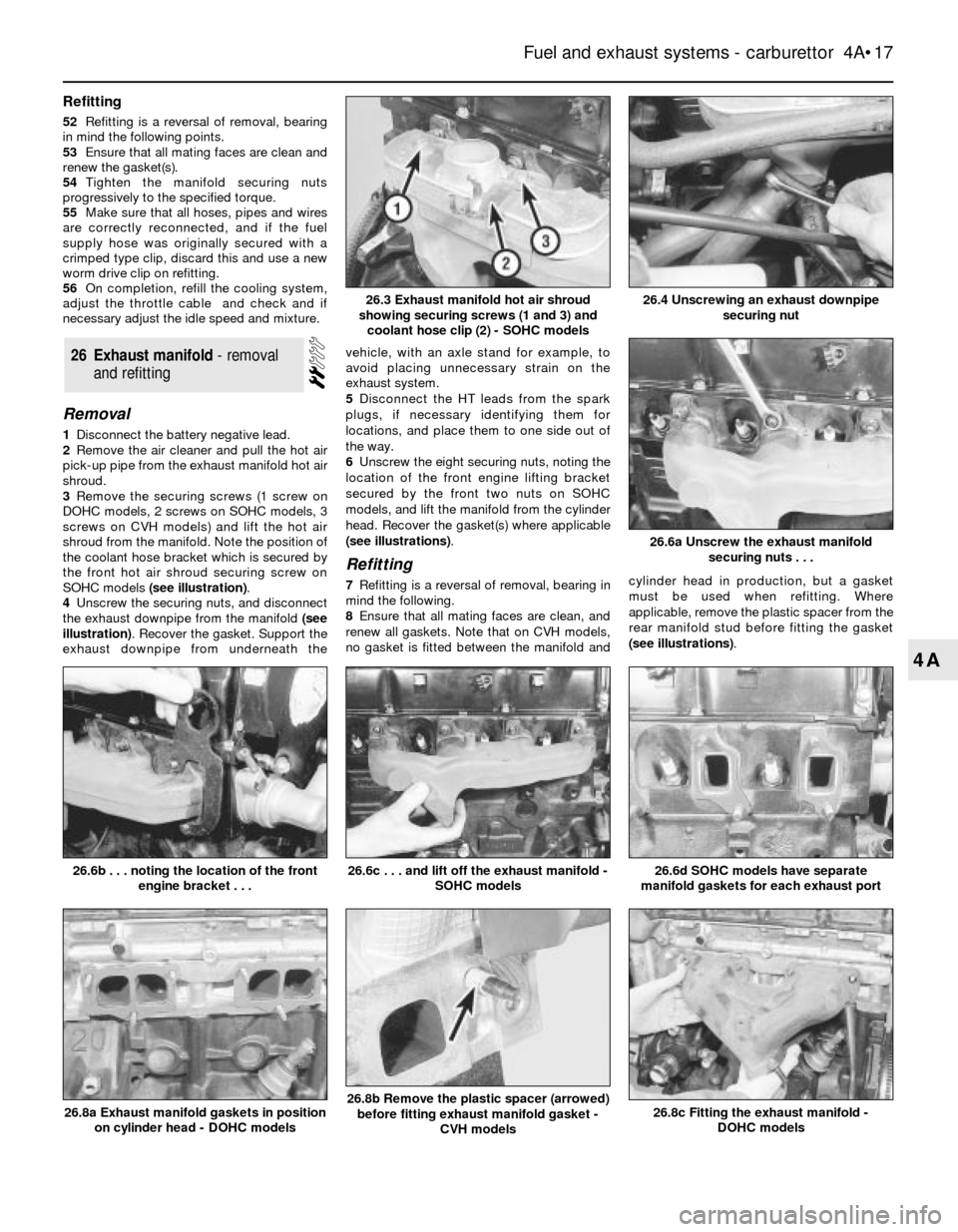

1Disconnect the battery negative lead.

2Remove the air cleaner and pull the hot air

pick-up pipe from the exhaust manifold hot air

shroud.

3Remove the securing screws (1 screw on

DOHC models, 2 screws on SOHC models, 3

screws on CVH models) and lift the hot air

shroud from the manifold. Note the position of

the coolant hose bracket which is secured by

the front hot air shroud securing screw on

SOHC models (see illustration).

4Unscrew the securing nuts, and disconnect

the exhaust downpipe from the manifold (see

illustration). Recover the gasket. Support the

exhaust downpipe from underneath thevehicle, with an axle stand for example, to

avoid placing unnecessary strain on the

exhaust system.

5Disconnect the HT leads from the spark

plugs, if necessary identifying them for

locations, and place them to one side out of

the way.

6Unscrew the eight securing nuts, noting the

location of the front engine lifting bracket

secured by the front two nuts on SOHC

models, and lift the manifold from the cylinder

head. Recover the gasket(s) where applicable

(see illustrations).

Refitting

7Refitting is a reversal of removal, bearing in

mind the following.

8Ensure that all mating faces are clean, and

renew all gaskets. Note that on CVH models,

no gasket is fitted between the manifold andcylinder head in production, but a gasket

must be used when refitting. Where

applicable, remove the plastic spacer from the

rear manifold stud before fitting the gasket

(see illustrations).

26Exhaust manifold - removal

and refitting

Fuel and exhaust systems - carburettor 4A•17

4A

26.6a Unscrew the exhaust manifold

securing nuts . . .

26.8c Fitting the exhaust manifold -

DOHC models26.8b Remove the plastic spacer (arrowed)

before fitting exhaust manifold gasket -

CVH models26.8a Exhaust manifold gaskets in position

on cylinder head - DOHC models

26.6d SOHC models have separate

manifold gaskets for each exhaust port26.6c . . . and lift off the exhaust manifold -

SOHC models26.6b . . . noting the location of the front

engine bracket . . .

26.4 Unscrewing an exhaust downpipe

securing nut26.3 Exhaust manifold hot air shroud

showing securing screws (1 and 3) and

coolant hose clip (2) - SOHC models

Page 18 of 20

9Tighten the manifold securing nuts

progressively to the specified torque, and

similarly tighten the exhaust downpipe

securing nuts. Do not forget to fit the engine

lifting bracket on SOHC models.

10Ensure that the HT leads are reconnected

to their correct cylinders.

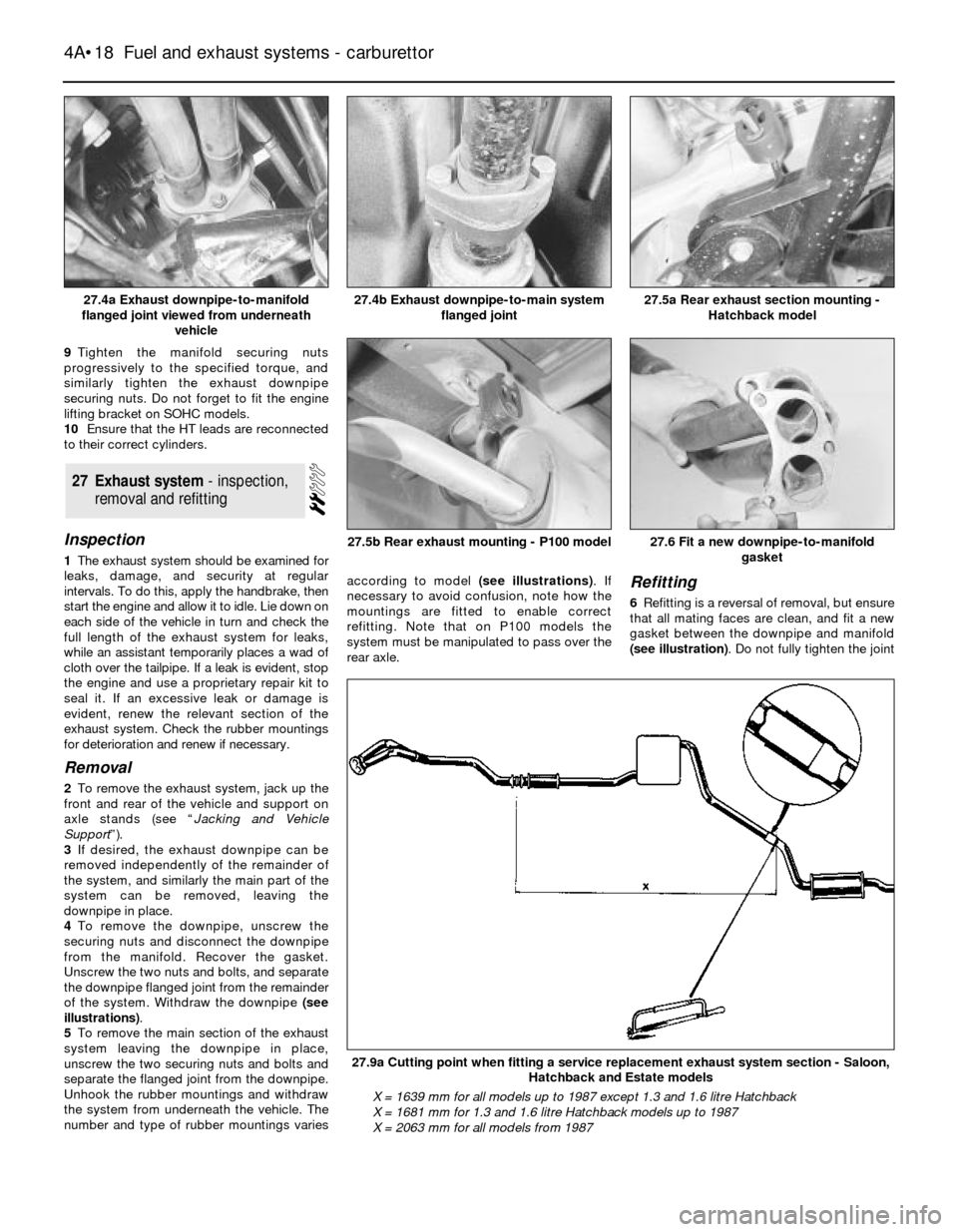

Inspection

1The exhaust system should be examined for

leaks, damage, and security at regular

intervals. To do this, apply the handbrake, then

start the engine and allow it to idle. Lie down on

each side of the vehicle in turn and check the

full length of the exhaust system for leaks,

while an assistant temporarily places a wad of

cloth over the tailpipe. If a leak is evident, stop

the engine and use a proprietary repair kit to

seal it. If an excessive leak or damage is

evident, renew the relevant section of the

exhaust system. Check the rubber mountings

for deterioration and renew if necessary.

Removal

2To remove the exhaust system, jack up the

front and rear of the vehicle and support on

axle stands (see “Jacking and Vehicle

Support”).

3If desired, the exhaust downpipe can be

removed independently of the remainder of

the system, and similarly the main part of the

system can be removed, leaving the

downpipe in place.

4To remove the downpipe, unscrew the

securing nuts and disconnect the downpipe

from the manifold. Recover the gasket.

Unscrew the two nuts and bolts, and separate

the downpipe flanged joint from the remainder

of the system. Withdraw the downpipe (see

illustrations).

5To remove the main section of the exhaust

system leaving the downpipe in place,

unscrew the two securing nuts and bolts and

separate the flanged joint from the downpipe.

Unhook the rubber mountings and withdraw

the system from underneath the vehicle. The

number and type of rubber mountings variesaccording to model (see illustrations). If

necessary to avoid confusion, note how the

mountings are fitted to enable correct

refitting. Note that on P100 models the

system must be manipulated to pass over the

rear axle.

Refitting

6Refitting is a reversal of removal, but ensure

that all mating faces are clean, and fit a new

gasket between the downpipe and manifold

(see illustration). Do not fully tighten the joint

27Exhaust system - inspection,

removal and refitting

4A•18Fuel and exhaust systems - carburettor

27.4a Exhaust downpipe-to-manifold

flanged joint viewed from underneath

vehicle27.5a Rear exhaust section mounting -

Hatchback model

27.9a Cutting point when fitting a service replacement exhaust system section - Saloon,

Hatchback and Estate models

X = 1639 mm for all models up to 1987 except 1.3 and 1.6 litre Hatchback

X = 1681 mm for 1.3 and 1.6 litre Hatchback models up to 1987

X = 2063 mm for all models from 1987

27.6 Fit a new downpipe-to-manifold

gasket27.5b Rear exhaust mounting - P100 model

27.4b Exhaust downpipe-to-main system

flanged joint