wheel FORD SIERRA 1985 1.G Routine Manintenance And Servicing Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: SIERRA, Model: FORD SIERRA 1985 1.GPages: 22, PDF Size: 1.26 MB

Page 1 of 22

Engine

Oil filter type:

SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C102

CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Valve clearances (cold):

SOHC:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 ± 0.03 mm (0.008 ± 0.001 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 ± 0.03 mm (0.010 ± 0.001 in)

DOHC and CVH:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not applicable (hydraulic cam followers)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Not applicable (hydraulic cam followers)

Chapter 1

Routine maintenance and servicing

Air cleaner filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Air cleaner inlet air temperature control check . . . . . . . . . . . . . . . . . .36

Air conditioner refrigerant charge check . . . . . . . . . . . . . . . . . . . . . .26

Automatic transmission brake band adjustment . . . . . . . . . . . . . . . .40

Automatic transmission fluid level check . . . . . . . . . . . . . . . . . . . . . .17

Automatic transmission selector lubrication . . . . . . . . . . . . . . . . . . .28

Auxiliary drivebelt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Battery electrolyte level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Battery terminal check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Brake fluid renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Brake system seal and hose renewal . . . . . . . . . . . . . . . . . . . . . . . . .43

Brake pipe and hose check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Camshaft drivebelt renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Crankcase ventilation system check . . . . . . . . . . . . . . . . . . . . . . . . .35

Crankcase ventilation vent valve renewal . . . . . . . . . . . . . . . . . . . . . .42

Driveshaft check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Electrical system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine coolant renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Engine idle speed check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Engine oil and filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Engine valve clearance check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Exhaust system check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Final drive oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27Fluid leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Fluid level checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Ford Sierra maintenance schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Front and rear brake pad/shoe check . . . . . . . . . . . . . . . . . . . . . . . . .9

Fuel filter renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Handbrake check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Hinge and lock check and lubrication . . . . . . . . . . . . . . . . . . . . . . . .19

Idle speed linkage clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Ignition system component check . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manual gearbox oil level check . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Mixture adjustment check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Oil filler cap check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pulse air filter element renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Radiator matrix and air conditioner condenser clean . . . . . . . . . . . . .25

Road test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Roadwheel security check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Seat belt check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Spark plug renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Steering and suspension security check . . . . . . . . . . . . . . . . . . . . . .29

Tyre checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Underbody inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Wiper blade check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

1

Page 2 of 22

Cooling system

Drivebelt tensions:

Air conditioning system compressor . . . . . . . . . . . . . . . . . . . . . . . . .10.0 mm (0.4 in) deflection at the midpoint of the belt’s longest run

under firm thumb pressure

Coolant pump/alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10.0 mm (0.4 in) deflection midway between coolant pump and

alternator (or power steering pump) pulleys under firm thumb pressure

Fuel system

Air filter element:

Carburettor type:

1.3 and 1.6 litre (SOHC - Ford carburettor) . . . . . . . . . . . . . . . . . .Champion W110

1.6 litre (SOHC - Weber carburettor) and 1.8 litre SOHC . . . . . . . .Champion W118

1.6 litre (SOHC - 1984-on) and 2.0 litre SOHC . . . . . . . . . . . . . . . .Champion W152

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W219

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W152

Fuel injection type:

2.0 litre SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion U507

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W219

Fuel filter:

All fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion L204

Ignition system

Spark plugs:

Make and type:

All except 1.8 CVH, CVH (R6A), 2.0 DOHC and P100 . . . . . . . . . . . .Champion RF7YCC or RF7YC

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC or RC7YC

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RF7YC or F7YC

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC

Electrode gap*:

Champion F7YCC or RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm (0.032 in)

Champion RF7YC, F7YC or RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm (0.028 in)

Ignition HT leads

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 k ohms maximum per lead

Type:

All SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-09 or LS-10 boxed set

1.8 litre CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-10 boxed set

1.6 and 1.8 litre (R6A type) CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-30 boxed set

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-29 boxed set

*The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to be

fitted, refer to their manufacturer’s recommendations.

Brakes

Brake pad friction material minimum thickness . . . . . . . . . . . . . . . . . . .1.5 mm (0.06 in)

Brake shoe friction material minimum thickness . . . . . . . . . . . . . . . . . .1.0 mm (0.04 in)

Torque wrench settingsNmlbf ft

Engine oil drain plug:

SOHC and DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

CVH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 3015 to 22

Engine block coolant drain plug (where fitted) . . . . . . . . . . . . . . . . . . . .21 to 25 16 to 18

Manual gearbox:

Oil filler/level plug:

A,B,C and N types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 to 4124 to 30

MT75 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

Oil drain plug:

MT75 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

Final drive oil filler plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Roadwheel nuts:

Saloon, Hatchback and Estate models (steel and alloy wheels) . . . .70 to 10052 to 74

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 to 9063 to 66

Spark plugs:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2815 to 21

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 to 3313 to 24

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 15

Brake caliper guide bolts:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

1•2Servicing specifications

Page 4 of 22

1•4Maintenance schedule

Every 250 miles (400 km) or weekly

m mCheck the engine oil level (Section 3)

m mCheck the engine coolant level (Section 3)

m mCheck the brake fluid level (Section 3)

m mCheck the power steering fluid level (Section 3)

m mCheck the screen washer fluid level (Section 3)

m mVisually examine the tyres for tread depth, and wear

or damage (Section 4)

m mCheck and if necessary adjust the tyre pressures

(Section 4)

m mCheck and if necessary top-up the battery electrolyte

level - where applicable (Section 6)

m mCheck the operation of the horn, all lights, and the

wipers and washers (Sections 5 and 7)

Every 6000 miles (10 000 km) or

6 months - whichever comes sooner

m mRenew engine oil and filter (Section 8)

m mCheck brake pads or shoes for wear (front and rear)

(Section 9)

m mCheck operation of brake fluid level warning indicator

(Section 9)

m mInspect engine bay and underside of vehicle for fluid

leaks or other signs of damage (Section 10)

m mCheck function and condition of seat belts

(Section 11)

m mCheck condition and security of exhaust system

(Section 12)

m mCheck tightness of wheel nuts (Section 13)

m mClean oil filler cap (Section 14)

m mCheck idle speed (where applicable) (Section 15)

m mCheck mixture adjustment (where applicable)

(Section 16)

Every 12 000 miles (20 000 km) or

12 months - whichever comes sooner

m mCheck automatic transmission fluid level (engine hot)

(Section 17)

m mCheck manual gearbox oil level (Section 18)

m mCheck operation of latches, check straps and locks;

lubricate if necessary (Section 19)

m mRenew spark plugs (Section 20)

m mCheck condition and tension of auxiliary drivebelt(s);

adjust or renew as necessary (Section 21)

m mCheck tightness of battery terminals, clean and

neutralise corrosion if necessary (Section 22)

m mCheck engine valve clearances - SOHC only

(Section 23)

m mCheck handbrake mechanism (Section 24)

Every 24 000 miles (40 000 km) or

2 years - whichever comes sooner

m mCheck air cleaner inlet air temperature control

operation (carburettor models) (Section 36)

m mRenew pulse air filter element (1.6 litre CVH)

(Section 37)

m mRenew air cleaner element (Section 38)

m mClean and inspect distributor cap and HT leads

(Section 39)

m mCheck automatic transmission brake band

adjustment (Section 40)

m mRenew fuel filter (fuel-injection models only)

(Section 41)

m mRenew crankcase ventilation vent valve (SOHC and

DOHC) (Section 42)

m mClean radiator matrix and air conditioning condenser

fins (where applicable) (Section 25)

m mCheck air conditioning refrigerant charge (where

applicable) (Section 26)

m mCheck final drive oil level (Section 27)

m mLubricate automatic transmission selector/kickdown

linkage (Section 28)

m mCheck security and condition of steering and

suspension components, gaiters and boots

(Section 29)

m mCheck condition and security of driveshaft joints and

gaiters (Section 30)

m mInspect underbody and panels for corrosion or other

damage (Section 31)

m mInspect brake pipes and hoses (Section 32)

m mClean idle speed control linkage at throttle (where

applicable) (Section 33)

m mRoad test and check operation of ABS (Section 34)

m mCheck crankcase ventilation system (Section 35)

Every 36 000 miles (60 000 km) or

3 years - whichever comes sooner

m mRenew brake hydraulic system seals and hoses if

necessary (Section 43)

m mRenew brake hydraulic fluid (Section 44)

m mRenew camshaft drivebelt (optional on SOHC

models - compulsory on CVH) (Section 45)

m mRenew coolant (Section 46)

Every 12 000 miles (20 000 km) or

12 months - whichever comes sooner

(continued)

Page 10 of 22

3Slacken the drain plug about half a turn.

Position the draining container under the drain

plug, then remove the plug completely. If

possible, try to keep the plug pressed into the

sump while unscrewing it by hand the last

couple of turns. As the plug releases from the

threads, move it away sharply so the stream

of oil issuing from the sump runs into the

container, not up your sleeve! Recover the

sealing washer from the drain plug.

4Allow some time for the old oil to drain,

noting that it may be necessary to reposition

the container as the oil flow slows to a trickle.

5After all the oil has drained, wipe off the

drain plug with a clean rag. Check the sealing

washer for condition, and renew it if

necessary. Clean the area around the drain

plug opening, and refit the plug. Tighten the

plug to the specified torque.

6Move the container into position under the

oil filter.

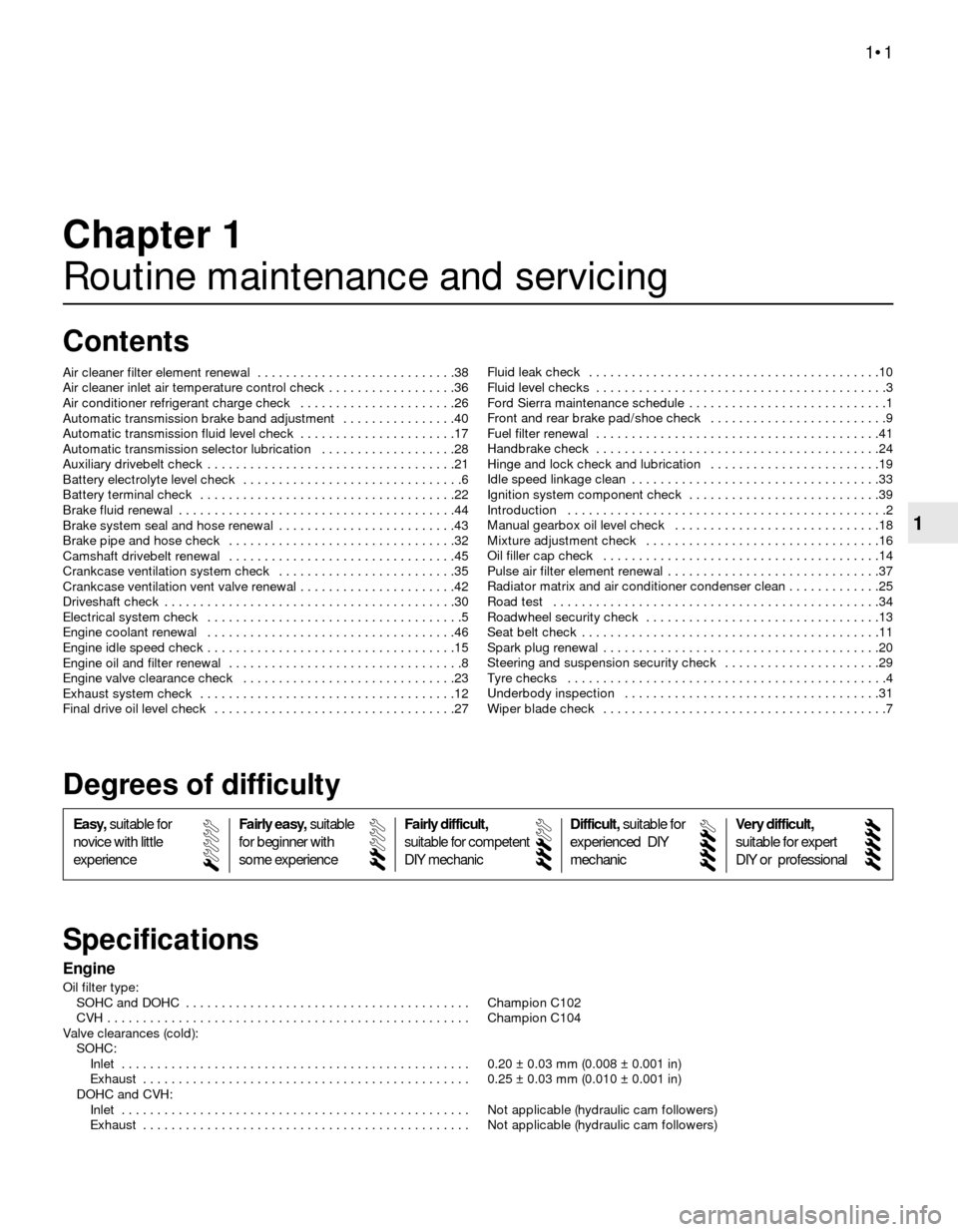

7Using an oil filter removal tool if necessary,

slacken the filter initially, then unscrew it by

hand the rest of the way (see illustration).

Empty the oil from the old filter into the

container, and discard the filter.

8Use a clean rag to remove all oil, dirt and

sludge from the filter sealing area on the

engine. Check the old filter to make sure that

the rubber sealing ring hasn’t stuck to the

engine. If it has, carefully remove it.

9Apply a light coating of clean engine oil to

the sealing ring on the new filter, then screw it

into position on the engine. Tighten the filter

firmly by hand only - do notuse any tools.

Wipe clean the filter and sump drain plug.10Remove the old oil and all tools from

under the car, then lower the car to the

ground (if applicable).

11Remove the oil filler cap and withdraw the

dipstick. Fill the engine, using the correct

grade and type of oil (see “Lubricants and

fluids”). An oil can spout or funnel may help to

reduce spillage. Pour in half the specified

quantity of oil first, then wait a few minutes for

the oil to fall to the sump. Continue adding oil

a small quantity at a time until the level is up to

the lower mark on the dipstick. Finally, bring

the level up to the upper mark on the dipstick.

Insert the dipstick, and refit the filler cap.

12Start the engine and run it for a few

minutes; check for leaks around the oil filter

seal and the sump drain plug. Note that there

may be a delay of a few seconds before the oil

pressure warning light goes out when the

engine is first started, as the oil circulates

through the engine oil galleries and the new oil

filter, before the pressure builds up.

13Switch off the engine, and wait a few

minutes for the oil to settle in the sump once

more. With the new oil circulated and the filter

completely full, recheck the level on the

dipstick, and add more oil as necessary.

14Dispose of the used engine oil safely, with

reference to “General repair procedures”in

the Reference section of this manual.

1Firmly apply the handbrake, then jack up

the front and rear of the car and support it

securely on axle stands (see “Jacking and

vehicle support”).

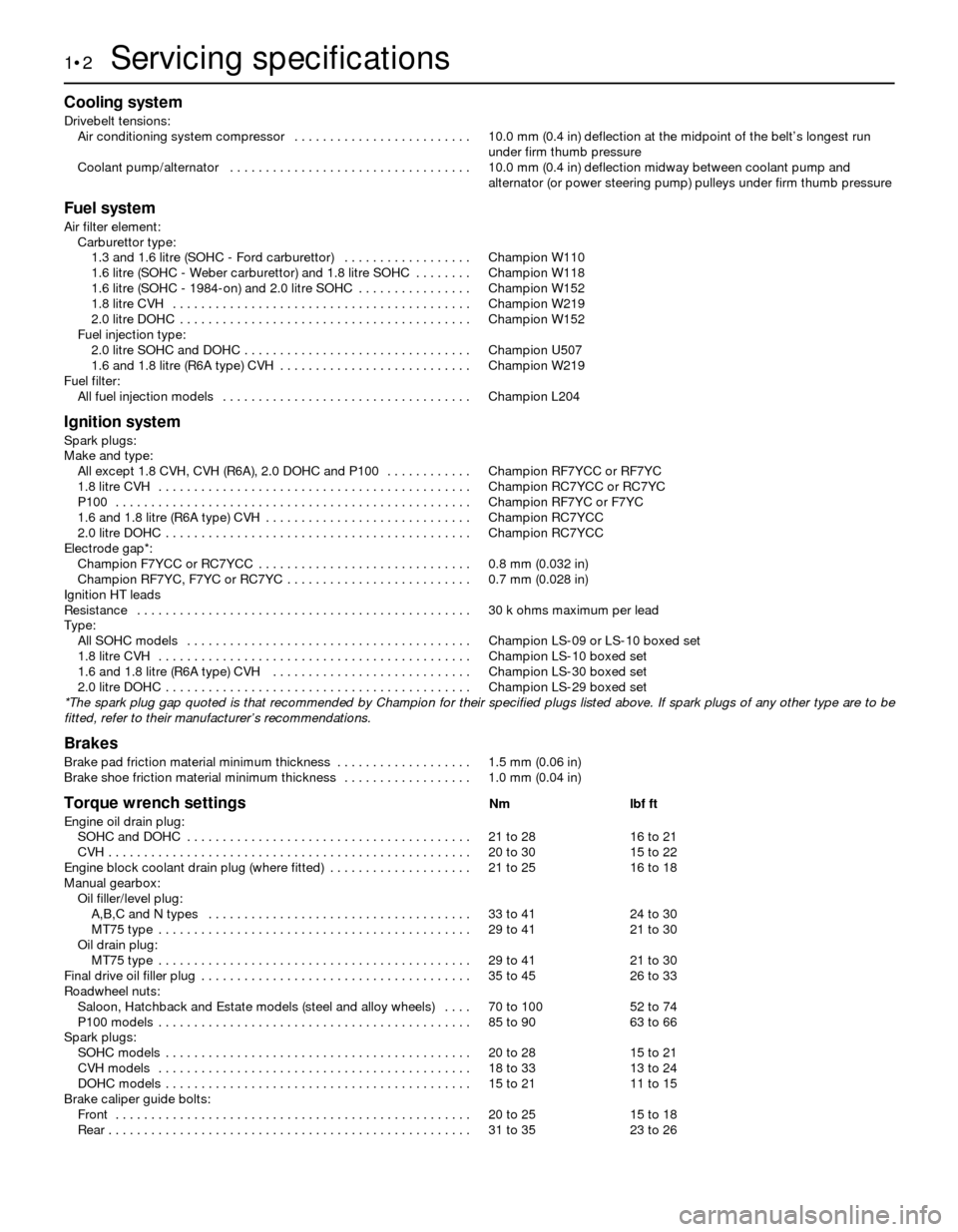

2For a quick check, the front brake disc pads

can be inspected without removing the front

wheels by inserting a mirror between each

caliper and roadwheel(see illustration).If any

one pad is worn down to the minimum

specified thickness, all four pads (on both

front wheels) must be renewed.

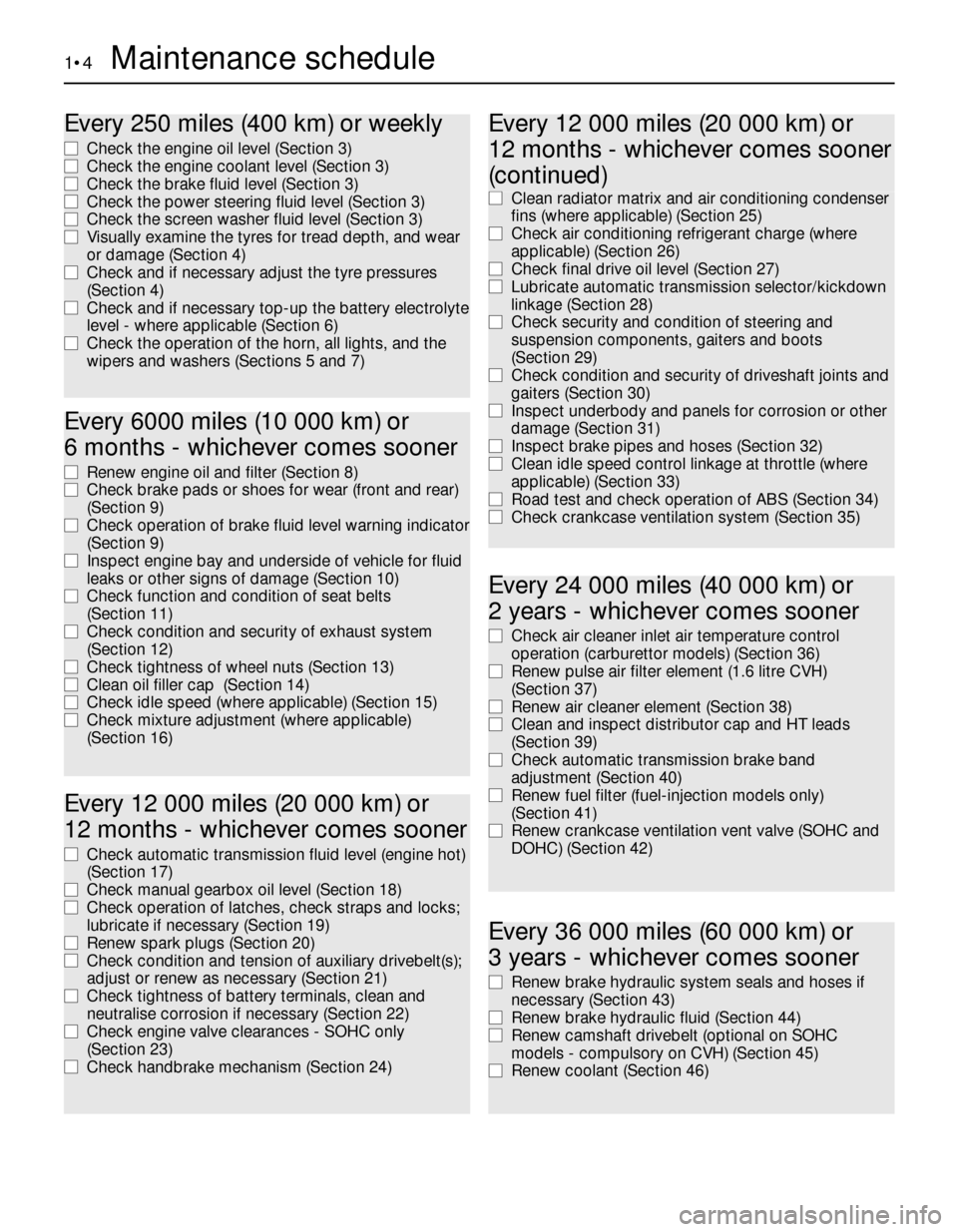

3It is necessary to remove the rear wheels in

order to inspect the rear disc pads. The pads

can be viewed through the top of the caliper

after removing the blanking spring clip(see

illustration).If any one pad is worn down to

the minimum specified, all four pads (on both

rear wheels) must be renewed.4For a comprehensive check, the brake disc

pads should be removed and cleaned. The

operation of the caliper can then also be

checked, and the condition of the brake discs

can be fully examined on both sides. Refer to

Chapter 10 for further information.

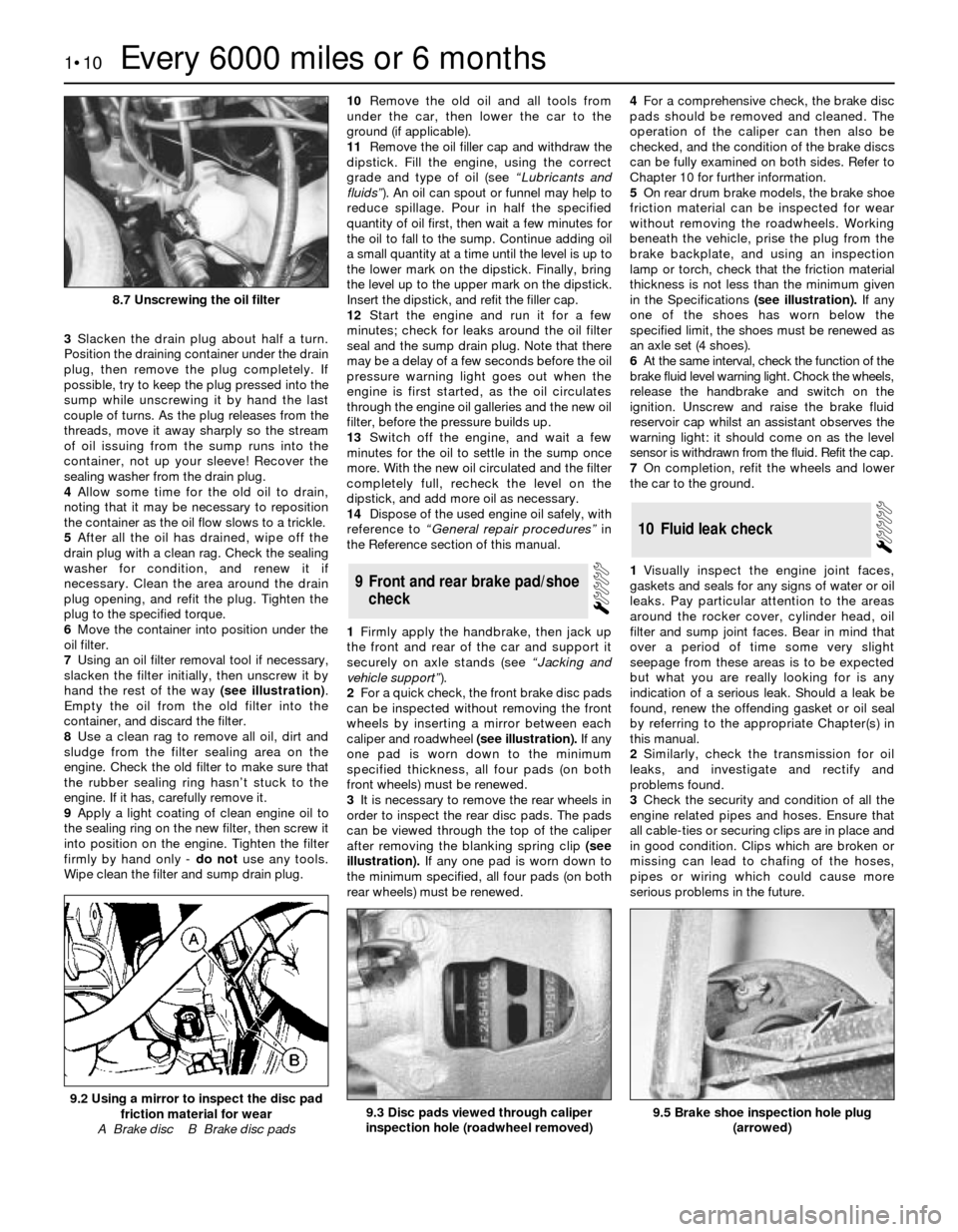

5On rear drum brake models, the brake shoe

friction material can be inspected for wear

without removing the roadwheels. Working

beneath the vehicle, prise the plug from the

brake backplate, and using an inspection

lamp or torch, check that the friction material

thickness is not less than the minimum given

in the Specifications(see illustration).If any

one of the shoes has worn below the

specified limit, the shoes must be renewed as

an axle set (4 shoes).

6At the same interval, check the function of the

brake fluid level warning light. Chock the wheels,

release the handbrake and switch on the

ignition. Unscrew and raise the brake fluid

reservoir cap whilst an assistant observes the

warning light: it should come on as the level

sensor is withdrawn from the fluid. Refit the cap.

7On completion, refit the wheels and lower

the car to the ground.

1Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the rocker cover, cylinder head, oil

filter and sump joint faces. Bear in mind that

over a period of time some very slight

seepage from these areas is to be expected

but what you are really looking for is any

indication of a serious leak. Should a leak be

found, renew the offending gasket or oil seal

by referring to the appropriate Chapter(s) in

this manual.

2Similarly, check the transmission for oil

leaks, and investigate and rectify and

problems found.

3Check the security and condition of all the

engine related pipes and hoses. Ensure that

all cable-ties or securing clips are in place and

in good condition. Clips which are broken or

missing can lead to chafing of the hoses,

pipes or wiring which could cause more

serious problems in the future.

10Fluid leak check

9Front and rear brake pad/shoe

check

1•10Every 6000 miles or 6 months

8.7 Unscrewing the oil filter

9.3 Disc pads viewed through caliper

inspection hole (roadwheel removed)9.5 Brake shoe inspection hole plug

(arrowed)9.2 Using a mirror to inspect the disc pad

friction material for wear

A Brake disc B Brake disc pads

Page 11 of 22

4Carefully check the condition of all coolant,

fuel, power steering and brake hoses. Renew

any hose which is cracked, swollen or

deteriorated. Cracks will show up better if the

hose is squeezed. Pay close attention to the

hose clips that secure the hoses to the system

components. Hose clips can pinch and

puncture hoses, resulting in leaks. If wire type

hose clips are used, it may be a good idea to

replace them with screw-type clips.

5With the vehicle raised, inspect the fuel

tank and filler neck for punctures, cracks and

other damage. The connection between the

filler neck and tank is especially critical.

Sometimes a rubber filler neck or connecting

hose will leak due to loose retaining clamps or

deteriorated rubber.

6Similarly, inspect all brake hoses and metal

pipes. If any damage or deterioration is

discovered, do not drive the vehicle until the

necessary repair work has been carried out.

Renew any damaged sections of hose or pipe.

7Carefully check all rubber hoses and metal

fuel lines leading away from the petrol tank.

Check for loose connections, deteriorated

hoses, crimped lines and other damage. Pay

particular attention to the vent pipes and

hoses which often loop up around the filler

neck and can become blocked or crimped.

Follow the lines to the front of the vehicle

carefully inspecting them all the way. Renew

damaged sections as necessary.

8From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

9Where applicable, check the condition of

the oil cooler hoses and pipes.

10Check the condition of all exposed wiring

harnesses.

1Periodically check the belts for fraying or

other damage. If evident, renew the belt.

2If the belts become dirty, wipe them with a

damp cloth using a little detergent only.

3Check the tightness of the anchor bolts and

if they are ever disconnected, make quite sure

that the original sequence of fitting of

washers, bushes and anchor plates is

retained.

With the vehicle raised on a hoist or

supported on axle stands, check the exhaust

system for signs of leaks, corrosion or

damage and check the rubber mountings for

condition and security. Where damage or

corrosion are evident, renew the system

complete or in sections, as applicable, using

the information given in Chapter 4.With the wheels on the ground, slacken each

wheel nut by a quarter turn, then retighten it

immediately to the specified torque.

Remove and clean the oil filler cap of any

sludge build-up using paraffin.

Inspect the vent hose for blockage or

damage. A blocked hose can cause a build-

up of crankcase pressure, which in turn can

cause oil leaks.

Ford VV carburettor

1Ensure that the air cleaner is correctly fitted,

and that all vacuum hoses and pipes are

securely connected and free from restrictions,

then run the engine until it is at normal

operating temperature.

2Stop the engine, and connect a tachometer

and an exhaust gas analyser in accordance

with the manufacturer’s instructions.

3Start the engine and run it at 3000 rpm for

30 seconds, ensuring that all electrical loads

are switched off (headlamps, heater blower

etc), then allow the engine to idle and check

the idle speed and CO content. Note that the

CO reading will initially rise, then fall and finally

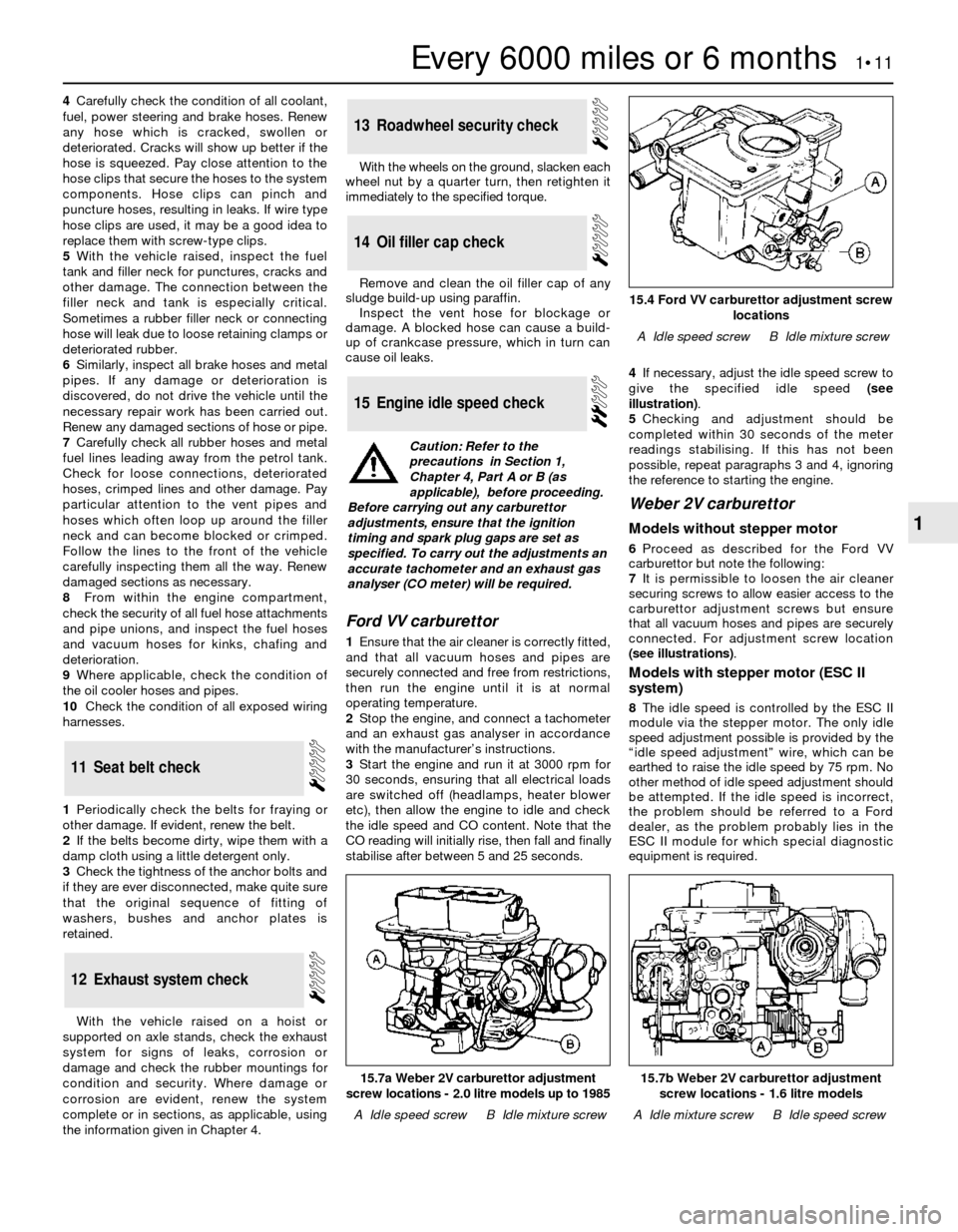

stabilise after between 5 and 25 seconds.4If necessary, adjust the idle speed screw to

give the specified idle speed (see

illustration).

5Checking and adjustment should be

completed within 30 seconds of the meter

readings stabilising. If this has not been

possible, repeat paragraphs 3 and 4, ignoring

the reference to starting the engine.

Weber 2V carburettor

Models without stepper motor

6Proceed as described for the Ford VV

carburettor but note the following:

7It is permissible to loosen the air cleaner

securing screws to allow easier access to the

carburettor adjustment screws but ensure

that all vacuum hoses and pipes are securely

connected. For adjustment screw location

(see illustrations).

Models with stepper motor (ESC II

system)

8The idle speed is controlled by the ESC II

module via the stepper motor. The only idle

speed adjustment possible is provided by the

“idle speed adjustment” wire, which can be

earthed to raise the idle speed by 75 rpm. No

other method of idle speed adjustment should

be attempted. If the idle speed is incorrect,

the problem should be referred to a Ford

dealer, as the problem probably lies in the

ESC II module for which special diagnostic

equipment is required.

15Engine idle speed check

14Oil filler cap check

13Roadwheel security check

12Exhaust system check

11Seat belt check

Every 6000 miles or 6 months 1•11

1

15.7b Weber 2V carburettor adjustment

screw locations - 1.6 litre models

A Idle mixture screwB Idle speed screw

15.7a Weber 2V carburettor adjustment

screw locations - 2.0 litre models up to 1985

A Idle speed screwB Idle mixture screw

15.4 Ford VV carburettor adjustment screw

locations

A Idle speed screwB Idle mixture screw

Caution: Refer to the

precautions in Section 1,

Chapter 4, Part A or B (as

applicable), before proceeding.

Before carrying out any carburettor

adjustments, ensure that the ignition

timing and spark plug gaps are set as

specified. To carry out the adjustments an

accurate tachometer and an exhaust gas

analyser (CO meter) will be required.

Page 16 of 22

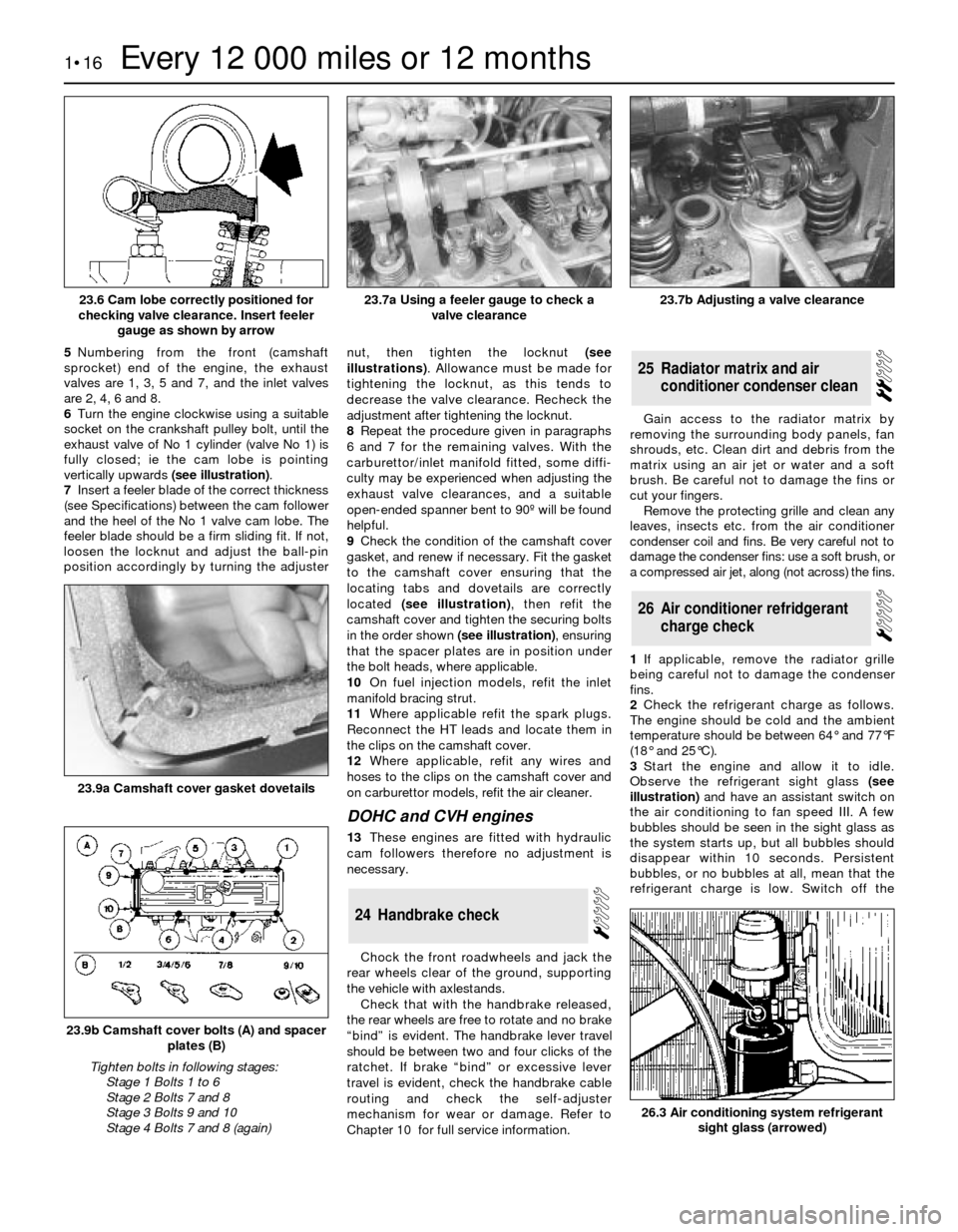

5Numbering from the front (camshaft

sprocket) end of the engine, the exhaust

valves are 1, 3, 5 and 7, and the inlet valves

are 2, 4, 6 and 8.

6Turn the engine clockwise using a suitable

socket on the crankshaft pulley bolt, until the

exhaust valve of No 1 cylinder (valve No 1) is

fully closed; ie the cam lobe is pointing

vertically upwards (see illustration).

7Insert a feeler blade of the correct thickness

(see Specifications) between the cam follower

and the heel of the No 1 valve cam lobe. The

feeler blade should be a firm sliding fit. If not,

loosen the locknut and adjust the ball-pin

position accordingly by turning the adjusternut, then tighten the locknut (see

illustrations). Allowance must be made for

tightening the locknut, as this tends to

decrease the valve clearance. Recheck the

adjustment after tightening the locknut.

8Repeat the procedure given in paragraphs

6 and 7 for the remaining valves. With the

carburettor/inlet manifold fitted, some diffi-

culty may be experienced when adjusting the

exhaust valve clearances, and a suitable

open-ended spanner bent to 90º will be found

helpful.

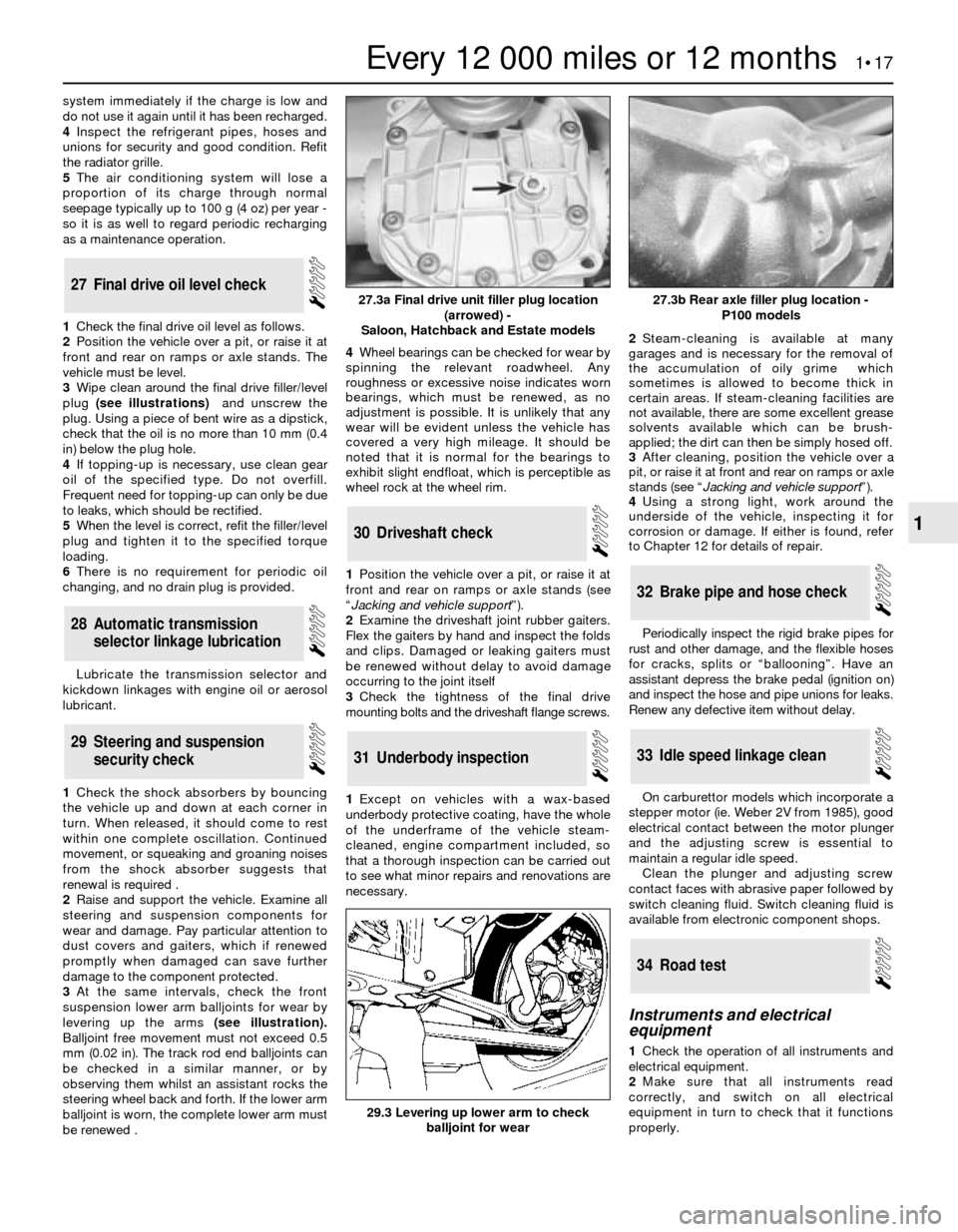

9Check the condition of the camshaft cover

gasket, and renew if necessary. Fit the gasket

to the camshaft cover ensuring that the

locating tabs and dovetails are correctly

located (see illustration), then refit the

camshaft cover and tighten the securing bolts

in the order shown (see illustration), ensuring

that the spacer plates are in position under

the bolt heads, where applicable.

10On fuel injection models, refit the inlet

manifold bracing strut.

11Where applicable refit the spark plugs.

Reconnect the HT leads and locate them in

the clips on the camshaft cover.

12Where applicable, refit any wires and

hoses to the clips on the camshaft cover and

on carburettor models, refit the air cleaner.

DOHCand CVH engines

13These engines are fitted with hydraulic

cam followers therefore no adjustment is

necessary.

Chock the front roadwheels and jack the

rear wheels clear of the ground, supporting

the vehicle with axlestands.

Check that with the handbrake released,

the rear wheels are free to rotate and no brake

“bind” is evident. The handbrake lever travel

should be between two and four clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing and check the self-adjuster

mechanism for wear or damage. Refer to

Chapter 10 for full service information. Gain access to the radiator matrix by

removing the surrounding body panels, fan

shrouds, etc. Clean dirt and debris from the

matrix using an air jet or water and a soft

brush. Be careful not to damage the fins or

cut your fingers.

Remove the protecting grille and clean any

leaves, insects etc. from the air conditioner

condenser coil and fins. Be very careful not to

damage the condenser fins: use a soft brush, or

a compressed air jet, along (not across) the fins.

1If applicable, remove the radiator grille

being careful not to damage the condenser

fins.

2Check the refrigerant charge as follows.

The engine should be cold and the ambient

temperature should be between 64°and 77°F

(18°and 25°C).

3Start the engine and allow it to idle.

Observe the refrigerant sight glass(see

illustration)and have an assistant switch on

the air conditioning to fan speed III. A few

bubbles should be seen in the sight glass as

the system starts up, but all bubbles should

disappear within 10 seconds. Persistent

bubbles, or no bubbles at all, mean that the

refrigerant charge is low. Switch off the

26Air conditioner refridgerant

charge check

25Radiator matrix and air

conditioner condenser clean

24Handbrake check

1•16Every 12 000 miles or 12 months

23.6 Cam lobe correctly positioned for

checking valve clearance. Insert feeler

gauge as shown by arrow23.7b Adjusting a valve clearance

26.3 Air conditioning system refrigerant

sight glass (arrowed)

23.9b Camshaft cover bolts (A) and spacer

plates (B)

Tighten bolts in following stages:

Stage 1 Bolts 1 to 6

Stage 2 Bolts 7 and 8

Stage 3 Bolts 9 and 10

Stage 4 Bolts 7 and 8 (again)

23.9a Camshaft cover gasket dovetails

23.7a Using a feeler gauge to check a

valve clearance

Page 17 of 22

system immediately if the charge is low and

do not use it again until it has been recharged.

4Inspect the refrigerant pipes, hoses and

unions for security and good condition. Refit

the radiator grille.

5The air conditioning system will lose a

proportion of its charge through normal

seepage typically up to 100 g (4 oz) per year -

so it is as well to regard periodic recharging

as a maintenance operation.

1Check the final drive oil level as follows.

2Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands. The

vehicle must be level.

3Wipe clean around the final drive filler/level

plug (see illustrations) and unscrew the

plug. Using a piece of bent wire as a dipstick,

check that the oil is no more than 10 mm (0.4

in) below the plug hole.

4If topping-up is necessary, use clean gear

oil of the specified type. Do not overfill.

Frequent need for topping-up can only be due

to leaks, which should be rectified.

5When the level is correct, refit the filler/level

plug and tighten it to the specified torque

loading.

6There is no requirement for periodic oil

changing, and no drain plug is provided.

Lubricate the transmission selector and

kickdown linkages with engine oil or aerosol

lubricant.

1Check the shock absorbers by bouncing

the vehicle up and down at each corner in

turn. When released, it should come to rest

within one complete oscillation. Continued

movement, or squeaking and groaning noises

from the shock absorber suggests that

renewal is required .

2Raise and support the vehicle. Examine all

steering and suspension components for

wear and damage. Pay particular attention to

dust covers and gaiters, which if renewed

promptly when damaged can save further

damage to the component protected.

3At the same intervals, check the front

suspension lower arm balljoints for wear by

levering up the arms(see illustration).

Balljoint free movement must not exceed 0.5

mm (0.02 in). The track rod end balljoints can

be checked in a similar manner, or by

observing them whilst an assistant rocks the

steering wheel back and forth. If the lower arm

balljoint is worn, the complete lower arm must

be renewed .4Wheel bearings can be checked for wear by

spinning the relevant roadwheel. Any

roughness or excessive noise indicates worn

bearings, which must be renewed, as no

adjustment is possible. It is unlikely that any

wear will be evident unless the vehicle has

covered a very high mileage. It should be

noted that it is normal for the bearings to

exhibit slight endfloat, which is perceptible as

wheel rock at the wheel rim.

1Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands (see

“Jacking and vehicle support”).

2Examine the driveshaft joint rubber gaiters.

Flex the gaiters by hand and inspect the folds

and clips. Damaged or leaking gaiters must

be renewed without delay to avoid damage

occurring to the joint itself

3Check the tightness of the final drive

mounting bolts and the driveshaft flange screws.

1Except on vehicles with a wax-based

underbody protective coating, have the whole

of the underframe of the vehicle steam-

cleaned, engine compartment included, so

that a thorough inspection can be carried out

to see what minor repairs and renovations are

necessary. 2Steam-cleaning is available at many

garages and is necessary for the removal of

the accumulation of oily grime which

sometimes is allowed to become thick in

certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

3After cleaning, position the vehicle over a

pit, or raise it at front and rear on ramps or axle

stands (see “Jacking and vehicle support”).

4Using a strong light, work around the

underside of the vehicle, inspecting it for

corrosion or damage. If either is found, refer

to Chapter 12 for details of repair.

Periodically inspect the rigid brake pipes for

rust and other damage, and the flexible hoses

for cracks, splits or “ballooning”. Have an

assistant depress the brake pedal (ignition on)

and inspect the hose and pipe unions for leaks.

Renew any defective item without delay.

On carburettor models which incorporate a

stepper motor (ie. Weber 2V from 1985), good

electrical contact between the motor plunger

and the adjusting screw is essential to

maintain a regular idle speed.

Clean the plunger and adjusting screw

contact faces with abrasive paper followed by

switch cleaning fluid. Switch cleaning fluid is

available from electronic component shops.

Instruments and electrical

equipment

1Check the operation of all instruments and

electrical equipment.

2Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn to check that it functions

properly.

34Road test

33Idle speed linkage clean

32Brake pipe and hose check

31Underbody inspection

30Driveshaft check

29Steering and suspension

security check

28Automatic transmission

selector linkage lubrication

27Final drive oil level check

Every 12 000 miles or 12 months 1•17

1

29.3 Levering up lower arm to check

balljoint for wear

27.3b Rear axle filler plug location -

P100 models27.3a Final drive unit filler plug location

(arrowed) -

Saloon, Hatchback and Estate models

Page 18 of 22

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the vehicle, and check that there are

no unusual vibrations or noises.

5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6Check the performance of the engine,

clutch, transmission and driveshafts.

7Listen for any unusual noises from the

engine, clutch and transmission.

8Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.9Where applicable, check that the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10Check that all gears can be engaged

smoothly, without noise, and that the gear lever

action is not abnormally vague or “notchy”.

Check the operation and

performance of the braking

system

11Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

12Check that there is no vibration through

the steering when braking.

13Check that the handbrake operates

correctly, without excessive movement of thelever, and that it holds the vehicle stationary

on a slope.

14Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Start the engine, holding the brake

pedal depressed. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then

switch it off. If the brake pedal is depressed

now, it should be possible to detect a hiss

from the servo as the pedal is depressed.

After about four or five applications, no further

hissing should be heard, and the pedal should

feel considerably firmer.

1Inspect the crankcase ventilation system

for blockage or damage. A blocked hose can

cause a build-up of crankcase pressure,

which in turn can cause oil leaks (see

illustration).

2On carburettor model SOHC engines, clean

the oil filler cap with paraffin and check that

the vent valve is not blocked by pulling it from

the oil separator and loosening the hose clip

(Section 42).

3On CVH engines, check that the oil

separator and mushroom valve are not

blocked, and clean if necessary (see

illustration).

35Crankcase ventilation system

check

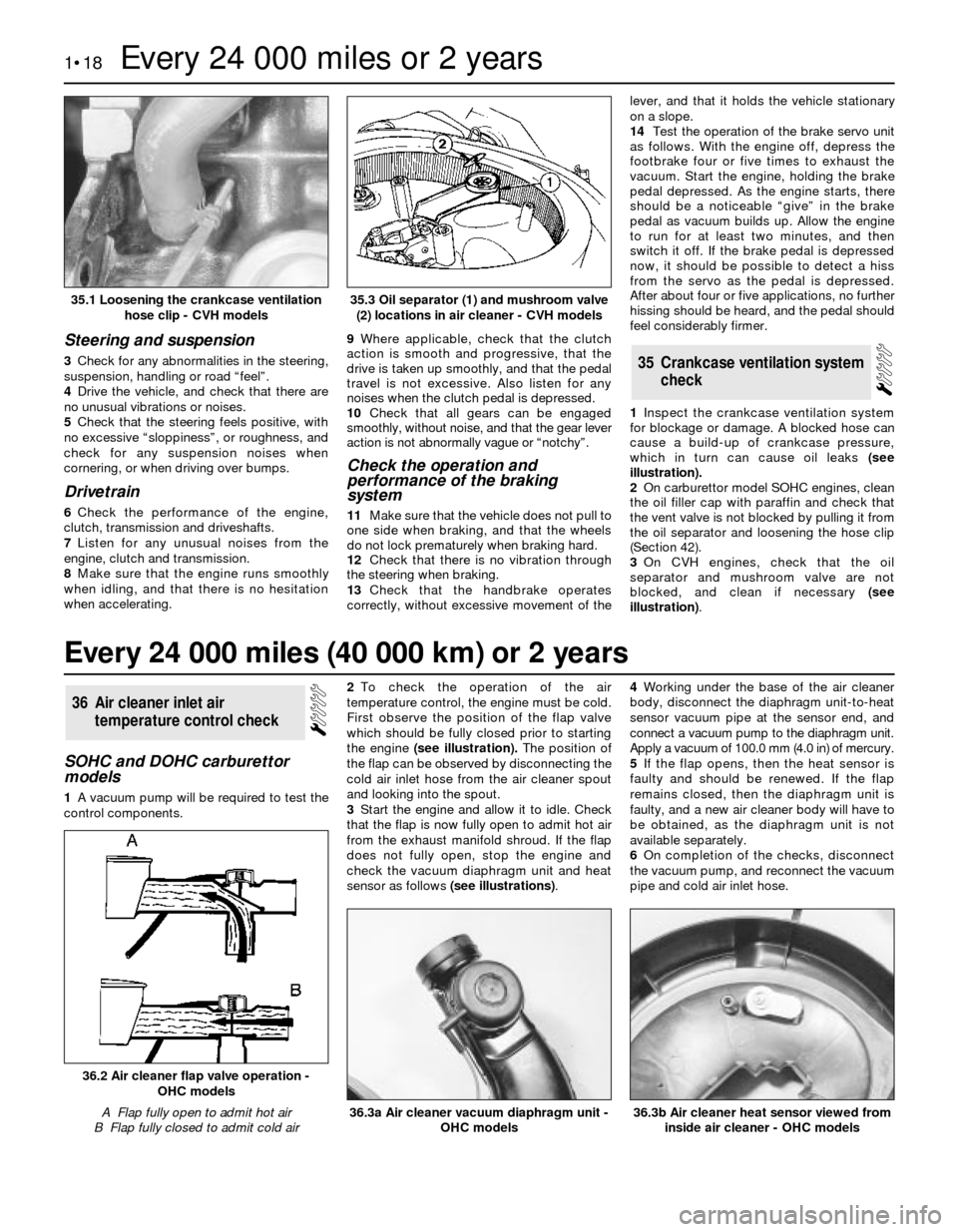

SOHC and DOHC carburettor

models

1A vacuum pump will be required to test the

control components.2To check the operation of the air

temperature control, the engine must be cold.

First observe the position of the flap valve

which should be fully closed prior to starting

the engine(see illustration).The position of

the flap can be observed by disconnecting the

cold air inlet hose from the air cleaner spout

and looking into the spout.

3Start the engine and allow it to idle. Check

that the flap is now fully open to admit hot air

from the exhaust manifold shroud. If the flap

does not fully open, stop the engine and

check the vacuum diaphragm unit and heat

sensor as follows (see illustrations).4Working under the base of the air cleaner

body, disconnect the diaphragm unit-to-heat

sensor vacuum pipe at the sensor end, and

connect a vacuum pump to the diaphragm unit.

Apply a vacuum of 100.0 mm (4.0 in) of mercury.

5If the flap opens, then the heat sensor is

faulty and should be renewed. If the flap

remains closed, then the diaphragm unit is

faulty, and a new air cleaner body will have to

be obtained, as the diaphragm unit is not

available separately.

6On completion of the checks, disconnect

the vacuum pump, and reconnect the vacuum

pipe and cold air inlet hose.

36Air cleaner inlet air

temperature control check

1•18Every 24 000 miles or 2 years

35.1 Loosening the crankcase ventilation

hose clip - CVH models

36.3b Air cleaner heat sensor viewed from

inside air cleaner - OHC models36.3a Air cleaner vacuum diaphragm unit -

OHC models

36.2 Air cleaner flap valve operation -

OHC models

A Flap fully open to admit hot air

B Flap fully closed to admit cold air

35.3 Oil separator (1) and mushroom valve

(2) locations in air cleaner - CVH models

Every 24 000 miles (40 000 km) or 2 years

Page 21 of 22

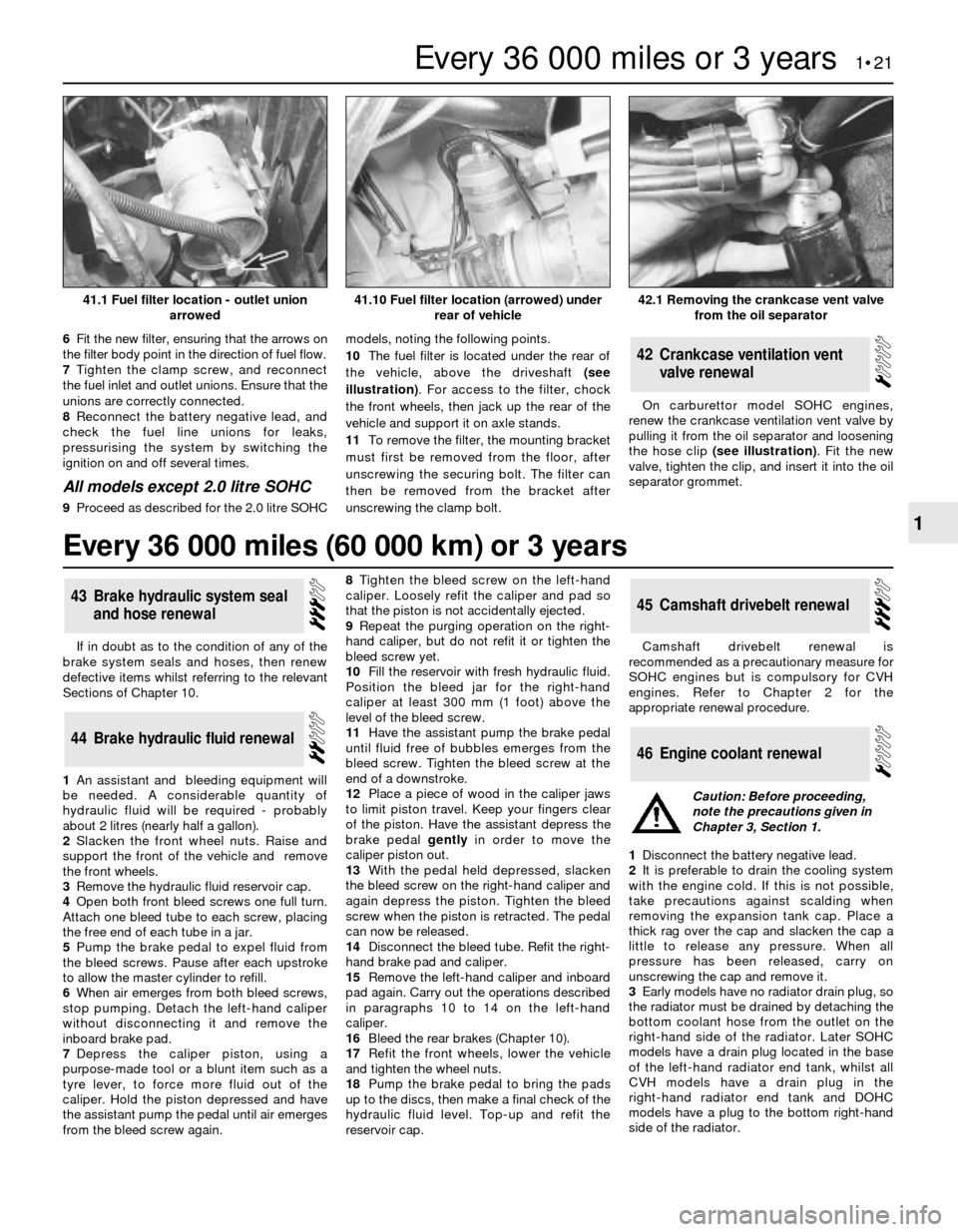

6Fit the new filter, ensuring that the arrows on

the filter body point in the direction of fuel flow.

7Tighten the clamp screw, and reconnect

the fuel inlet and outlet unions. Ensure that the

unions are correctly connected.

8Reconnect the battery negative lead, and

check the fuel line unions for leaks,

pressurising the system by switching the

ignition on and off several times.

All models except 2.0 litre SOHC

9Proceed as described for the 2.0 litre SOHCmodels, noting the following points.

10The fuel filter is located under the rear of

the vehicle, above the driveshaft (see

illustration). For access to the filter, chock

the front wheels, then jack up the rear of the

vehicle and support it on axle stands.

11To remove the filter, the mounting bracket

must first be removed from the floor, after

unscrewing the securing bolt. The filter can

then be removed from the bracket after

unscrewing the clamp bolt.On carburettor model SOHC engines,

renew the crankcase ventilation vent valve by

pulling it from the oil separator and loosening

the hose clip (see illustration). Fit the new

valve, tighten the clip, and insert it into the oil

separator grommet.

42Crankcase ventilation vent

valve renewal

If in doubt as to the condition of any of the

brake system seals and hoses, then renew

defective items whilst referring to the relevant

Sections of Chapter 10.

1An assistant and bleeding equipment will

be needed. A considerable quantity of

hydraulic fluid will be required - probably

about 2 litres (nearly half a gallon).

2Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheels.

3Remove the hydraulic fluid reservoir cap.

4Open both front bleed screws one full turn.

Attach one bleed tube to each screw, placing

the free end of each tube in a jar.

5Pump the brake pedal to expel fluid from

the bleed screws. Pause after each upstroke

to allow the master cylinder to refill.

6When air emerges from both bleed screws,

stop pumping. Detach the left-hand caliper

without disconnecting it and remove the

inboard brake pad.

7Depress the caliper piston, using a

purpose-made tool or a blunt item such as a

tyre lever, to force more fluid out of the

caliper. Hold the piston depressed and have

the assistant pump the pedal until air emerges

from the bleed screw again.8Tighten the bleed screw on the left-hand

caliper. Loosely refit the caliper and pad so

that the piston is not accidentally ejected.

9Repeat the purging operation on the right-

hand caliper, but do not refit it or tighten the

bleed screw yet.

10Fill the reservoir with fresh hydraulic fluid.

Position the bleed jar for the right-hand

caliper at least 300 mm (1 foot) above the

level of the bleed screw.

11Have the assistant pump the brake pedal

until fluid free of bubbles emerges from the

bleed screw. Tighten the bleed screw at the

end of a downstroke.

12Place a piece of wood in the caliper jaws

to limit piston travel. Keep your fingers clear

of the piston. Have the assistant depress the

brake pedal gentlyin order to move the

caliper piston out.

13With the pedal held depressed, slacken

the bleed screw on the right-hand caliper and

again depress the piston. Tighten the bleed

screw when the piston is retracted. The pedal

can now be released.

14Disconnect the bleed tube. Refit the right-

hand brake pad and caliper.

15Remove the left-hand caliper and inboard

pad again. Carry out the operations described

in paragraphs 10 to 14 on the left-hand

caliper.

16Bleed the rear brakes (Chapter 10).

17Refit the front wheels, lower the vehicle

and tighten the wheel nuts.

18Pump the brake pedal to bring the pads

up to the discs, then make a final check of the

hydraulic fluid level. Top-up and refit the

reservoir cap.Camshaft drivebelt renewal is

recommended as a precautionary measure for

SOHC engines but is compulsory for CVH

engines. Refer to Chapter 2 for the

appropriate renewal procedure.

1Disconnect the battery negative lead.

2It is preferable to drain the cooling system

with the engine cold. If this is not possible,

take precautions against scalding when

removing the expansion tank cap. Place a

thick rag over the cap and slacken the cap a

little to release any pressure. When all

pressure has been released, carry on

unscrewing the cap and remove it.

3Early models have no radiator drain plug, so

the radiator must be drained by detaching the

bottom coolant hose from the outlet on the

right-hand side of the radiator. Later SOHC

models have a drain plug located in the base

of the left-hand radiator end tank, whilst all

CVH models have a drain plug in the

right-hand radiator end tank and DOHC

models have a plug to the bottom right-hand

side of the radiator.

46Engine coolant renewal

45Camshaft drivebelt renewal

44Brake hydraulic fluid renewal

43Brake hydraulic system seal

and hose renewal

Every 36 000 miles or 3 years 1•21

1

42.1 Removing the crankcase vent valve

from the oil separator41.10 Fuel filter location (arrowed) under

rear of vehicle41.1 Fuel filter location - outlet union

arrowed

Caution: Before proceeding,

note the precautions given in

Chapter 3, Section 1.

Every 36 000 miles (60 000 km) or 3 years