dimensions FORD SIERRA 1987 2.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1987, Model line: SIERRA, Model: FORD SIERRA 1987 2.GPages: 18, PDF Size: 0.9 MB

Page 16 of 18

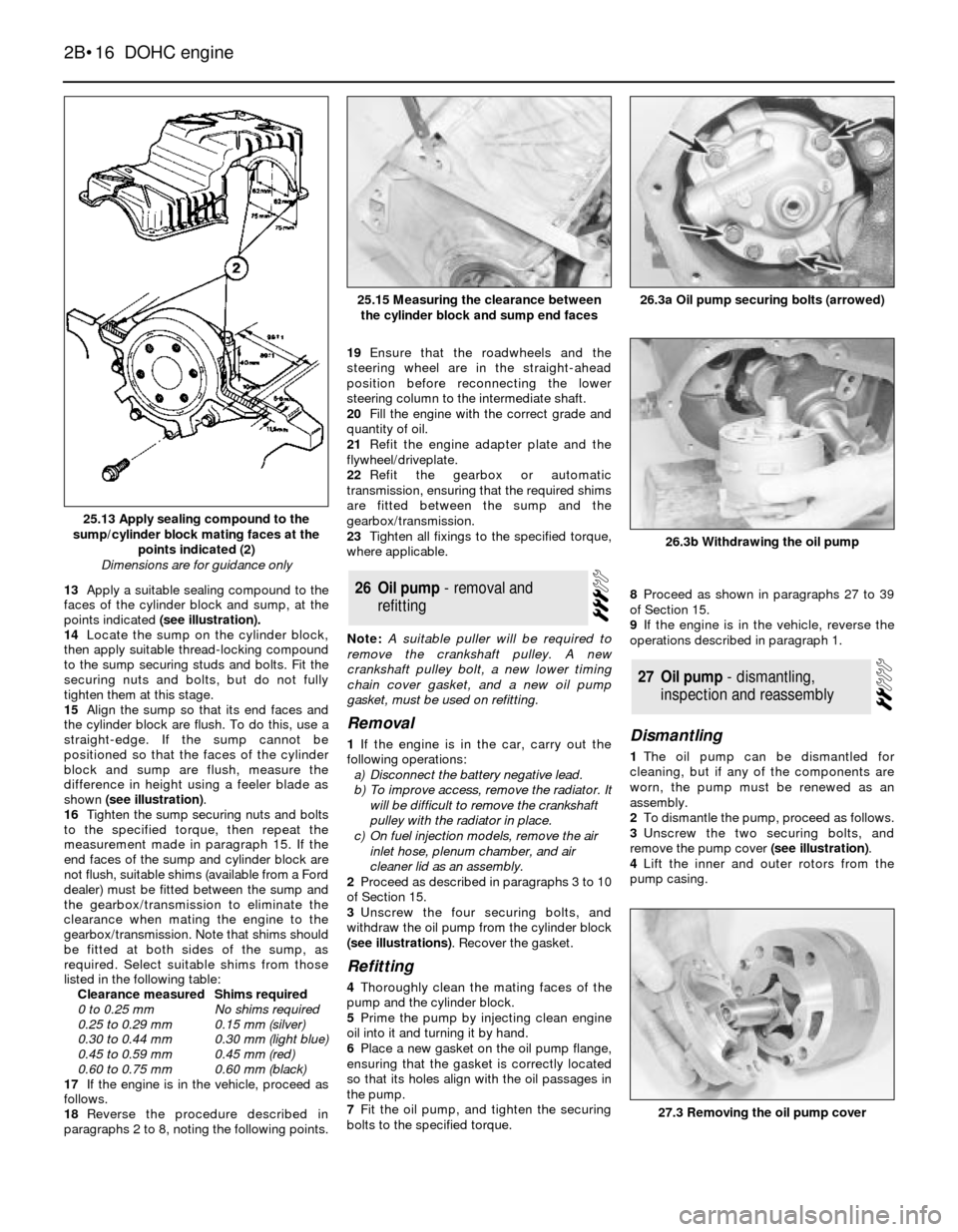

13Apply a suitable sealing compound to the

faces of the cylinder block and sump, at the

points indicated (see illustration).

14Locate the sump on the cylinder block,

then apply suitable thread-locking compound

to the sump securing studs and bolts. Fit the

securing nuts and bolts, but do not fully

tighten them at this stage.

15Align the sump so that its end faces and

the cylinder block are flush. To do this, use a

straight-edge. If the sump cannot be

positioned so that the faces of the cylinder

block and sump are flush, measure the

difference in height using a feeler blade as

shown (see illustration).

16Tighten the sump securing nuts and bolts

to the specified torque, then repeat the

measurement made in paragraph 15. If the

end faces of the sump and cylinder block are

not flush, suitable shims (available from a Ford

dealer) must be fitted between the sump and

the gearbox/transmission to eliminate the

clearance when mating the engine to the

gearbox/transmission. Note that shims should

be fitted at both sides of the sump, as

required. Select suitable shims from those

listed in the following table:

Clearance measuredShims required

0 to 0.25 mmNo shims required

0.25 to 0.29 mm0.15 mm (silver)

0.30 to 0.44 mm0.30 mm (light blue)

0.45 to 0.59 mm0.45 mm (red)

0.60 to 0.75 mm0.60 mm (black)

17If the engine is in the vehicle, proceed as

follows.

18Reverse the procedure described in

paragraphs 2 to 8, noting the following points.19Ensure that the roadwheels and the

steering wheel are in the straight-ahead

position before reconnecting the lower

steering column to the intermediate shaft.

20Fill the engine with the correct grade and

quantity of oil.

21Refit the engine adapter plate and the

flywheel/driveplate.

22Refit the gearbox or automatic

transmission, ensuring that the required shims

are fitted between the sump and the

gearbox/transmission.

23Tighten all fixings to the specified torque,

where applicable.

Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, a new lower timing

chain cover gasket, and a new oil pump

gasket, must be used on refitting.

Removal

1If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

2Proceed as described in paragraphs 3 to 10

of Section 15.

3Unscrew the four securing bolts, and

withdraw the oil pump from the cylinder block

(see illustrations). Recover the gasket.

Refitting

4Thoroughly clean the mating faces of the

pump and the cylinder block.

5Prime the pump by injecting clean engine

oil into it and turning it by hand.

6Place a new gasket on the oil pump flange,

ensuring that the gasket is correctly located

so that its holes align with the oil passages in

the pump.

7Fit the oil pump, and tighten the securing

bolts to the specified torque.8Proceed as shown in paragraphs 27 to 39

of Section 15.

9If the engine is in the vehicle, reverse the

operations described in paragraph 1.

Dismantling

1The oil pump can be dismantled for

cleaning, but if any of the components are

worn, the pump must be renewed as an

assembly.

2To dismantle the pump, proceed as follows.

3Unscrew the two securing bolts, and

remove the pump cover (see illustration).

4Lift the inner and outer rotors from the

pump casing.

27Oil pump - dismantling,

inspection and reassembly

26Oil pump - removal and

refitting

2B•16DOHC engine

25.13 Apply sealing compound to the

sump/cylinder block mating faces at the

points indicated (2)

Dimensions are for guidance only

26.3b Withdrawing the oil pump

26.3a Oil pump securing bolts (arrowed)25.15 Measuring the clearance between

the cylinder block and sump end faces

27.3 Removing the oil pump cover