check engine FORD SIERRA 1988 2.G Routine Manintenance And Servicing User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1988, Model line: SIERRA, Model: FORD SIERRA 1988 2.GPages: 22, PDF Size: 1.26 MB

Page 17 of 22

system immediately if the charge is low and

do not use it again until it has been recharged.

4Inspect the refrigerant pipes, hoses and

unions for security and good condition. Refit

the radiator grille.

5The air conditioning system will lose a

proportion of its charge through normal

seepage typically up to 100 g (4 oz) per year -

so it is as well to regard periodic recharging

as a maintenance operation.

1Check the final drive oil level as follows.

2Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands. The

vehicle must be level.

3Wipe clean around the final drive filler/level

plug (see illustrations) and unscrew the

plug. Using a piece of bent wire as a dipstick,

check that the oil is no more than 10 mm (0.4

in) below the plug hole.

4If topping-up is necessary, use clean gear

oil of the specified type. Do not overfill.

Frequent need for topping-up can only be due

to leaks, which should be rectified.

5When the level is correct, refit the filler/level

plug and tighten it to the specified torque

loading.

6There is no requirement for periodic oil

changing, and no drain plug is provided.

Lubricate the transmission selector and

kickdown linkages with engine oil or aerosol

lubricant.

1Check the shock absorbers by bouncing

the vehicle up and down at each corner in

turn. When released, it should come to rest

within one complete oscillation. Continued

movement, or squeaking and groaning noises

from the shock absorber suggests that

renewal is required .

2Raise and support the vehicle. Examine all

steering and suspension components for

wear and damage. Pay particular attention to

dust covers and gaiters, which if renewed

promptly when damaged can save further

damage to the component protected.

3At the same intervals, check the front

suspension lower arm balljoints for wear by

levering up the arms(see illustration).

Balljoint free movement must not exceed 0.5

mm (0.02 in). The track rod end balljoints can

be checked in a similar manner, or by

observing them whilst an assistant rocks the

steering wheel back and forth. If the lower arm

balljoint is worn, the complete lower arm must

be renewed .4Wheel bearings can be checked for wear by

spinning the relevant roadwheel. Any

roughness or excessive noise indicates worn

bearings, which must be renewed, as no

adjustment is possible. It is unlikely that any

wear will be evident unless the vehicle has

covered a very high mileage. It should be

noted that it is normal for the bearings to

exhibit slight endfloat, which is perceptible as

wheel rock at the wheel rim.

1Position the vehicle over a pit, or raise it at

front and rear on ramps or axle stands (see

“Jacking and vehicle support”).

2Examine the driveshaft joint rubber gaiters.

Flex the gaiters by hand and inspect the folds

and clips. Damaged or leaking gaiters must

be renewed without delay to avoid damage

occurring to the joint itself

3Check the tightness of the final drive

mounting bolts and the driveshaft flange screws.

1Except on vehicles with a wax-based

underbody protective coating, have the whole

of the underframe of the vehicle steam-

cleaned, engine compartment included, so

that a thorough inspection can be carried out

to see what minor repairs and renovations are

necessary. 2Steam-cleaning is available at many

garages and is necessary for the removal of

the accumulation of oily grime which

sometimes is allowed to become thick in

certain areas. If steam-cleaning facilities are

not available, there are some excellent grease

solvents available which can be brush-

applied; the dirt can then be simply hosed off.

3After cleaning, position the vehicle over a

pit, or raise it at front and rear on ramps or axle

stands (see “Jacking and vehicle support”).

4Using a strong light, work around the

underside of the vehicle, inspecting it for

corrosion or damage. If either is found, refer

to Chapter 12 for details of repair.

Periodically inspect the rigid brake pipes for

rust and other damage, and the flexible hoses

for cracks, splits or “ballooning”. Have an

assistant depress the brake pedal (ignition on)

and inspect the hose and pipe unions for leaks.

Renew any defective item without delay.

On carburettor models which incorporate a

stepper motor (ie. Weber 2V from 1985), good

electrical contact between the motor plunger

and the adjusting screw is essential to

maintain a regular idle speed.

Clean the plunger and adjusting screw

contact faces with abrasive paper followed by

switch cleaning fluid. Switch cleaning fluid is

available from electronic component shops.

Instruments and electrical

equipment

1Check the operation of all instruments and

electrical equipment.

2Make sure that all instruments read

correctly, and switch on all electrical

equipment in turn to check that it functions

properly.

34Road test

33Idle speed linkage clean

32Brake pipe and hose check

31Underbody inspection

30Driveshaft check

29Steering and suspension

security check

28Automatic transmission

selector linkage lubrication

27Final drive oil level check

Every 12 000 miles or 12 months 1•17

1

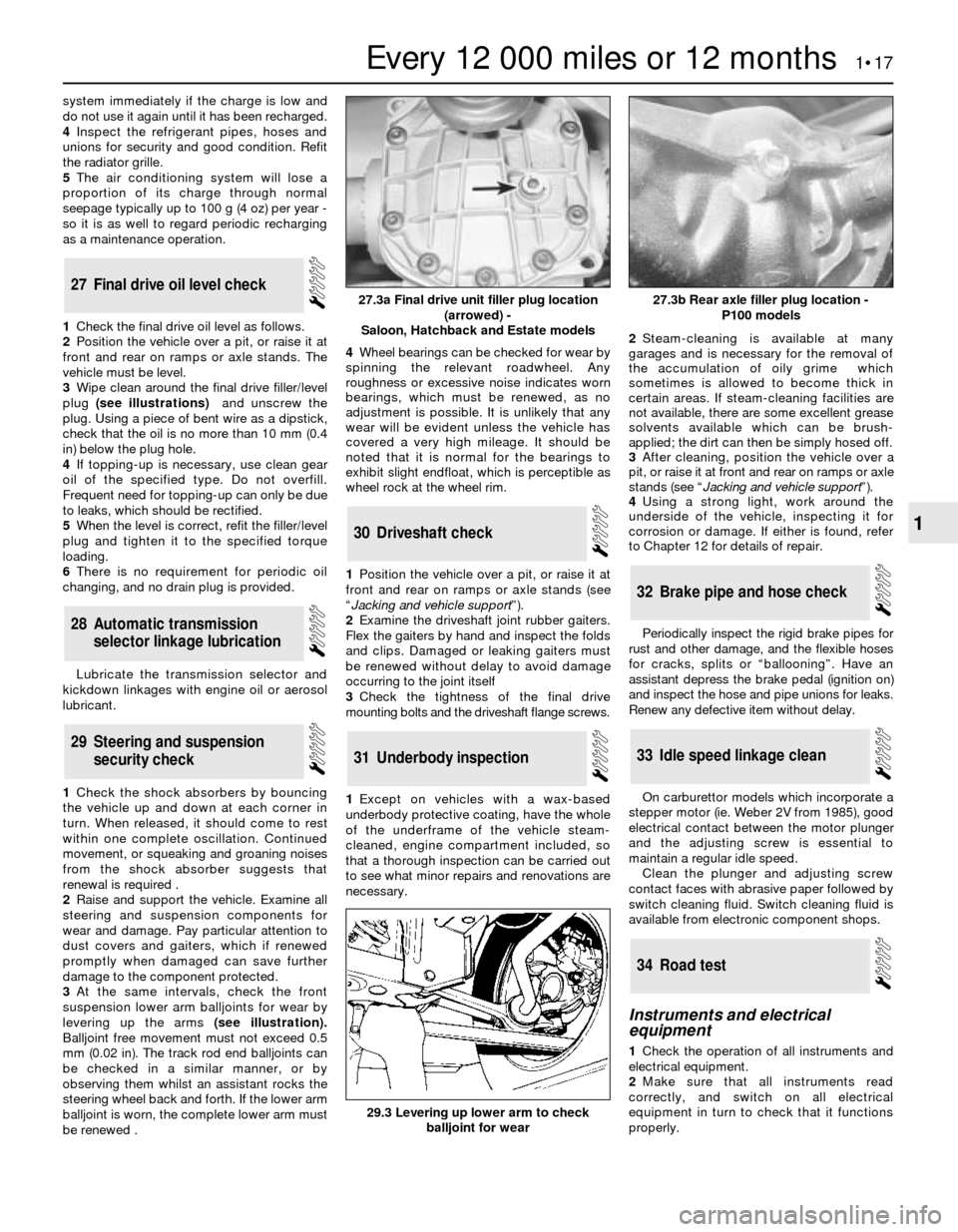

29.3 Levering up lower arm to check

balljoint for wear

27.3b Rear axle filler plug location -

P100 models27.3a Final drive unit filler plug location

(arrowed) -

Saloon, Hatchback and Estate models

Page 18 of 22

Steering and suspension

3Check for any abnormalities in the steering,

suspension, handling or road “feel”.

4Drive the vehicle, and check that there are

no unusual vibrations or noises.

5Check that the steering feels positive, with

no excessive “sloppiness”, or roughness, and

check for any suspension noises when

cornering, or when driving over bumps.

Drivetrain

6Check the performance of the engine,

clutch, transmission and driveshafts.

7Listen for any unusual noises from the

engine, clutch and transmission.

8Make sure that the engine runs smoothly

when idling, and that there is no hesitation

when accelerating.9Where applicable, check that the clutch

action is smooth and progressive, that the

drive is taken up smoothly, and that the pedal

travel is not excessive. Also listen for any

noises when the clutch pedal is depressed.

10Check that all gears can be engaged

smoothly, without noise, and that the gear lever

action is not abnormally vague or “notchy”.

Check the operation and

performance of the braking

system

11Make sure that the vehicle does not pull to

one side when braking, and that the wheels

do not lock prematurely when braking hard.

12Check that there is no vibration through

the steering when braking.

13Check that the handbrake operates

correctly, without excessive movement of thelever, and that it holds the vehicle stationary

on a slope.

14Test the operation of the brake servo unit

as follows. With the engine off, depress the

footbrake four or five times to exhaust the

vacuum. Start the engine, holding the brake

pedal depressed. As the engine starts, there

should be a noticeable “give” in the brake

pedal as vacuum builds up. Allow the engine

to run for at least two minutes, and then

switch it off. If the brake pedal is depressed

now, it should be possible to detect a hiss

from the servo as the pedal is depressed.

After about four or five applications, no further

hissing should be heard, and the pedal should

feel considerably firmer.

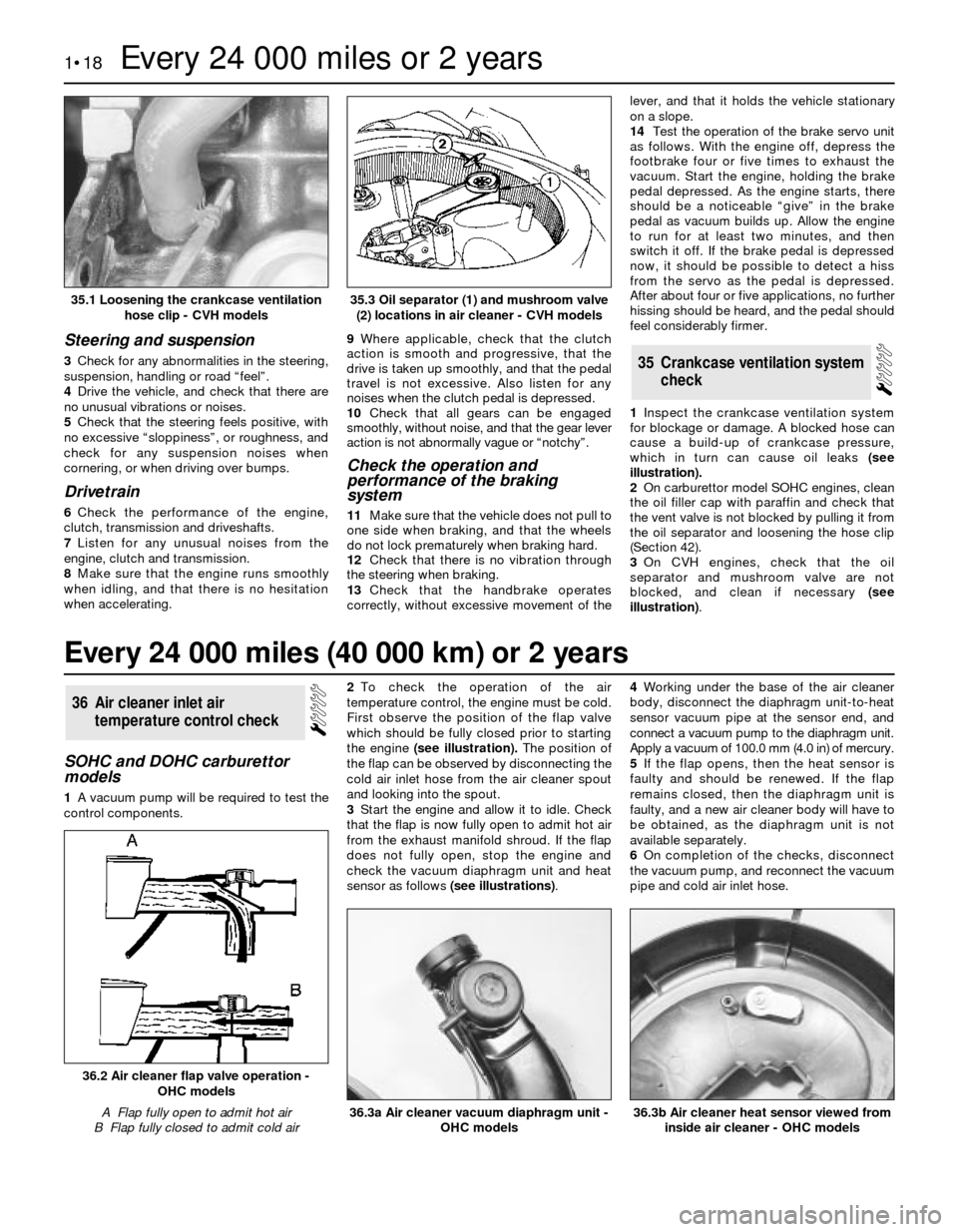

1Inspect the crankcase ventilation system

for blockage or damage. A blocked hose can

cause a build-up of crankcase pressure,

which in turn can cause oil leaks (see

illustration).

2On carburettor model SOHC engines, clean

the oil filler cap with paraffin and check that

the vent valve is not blocked by pulling it from

the oil separator and loosening the hose clip

(Section 42).

3On CVH engines, check that the oil

separator and mushroom valve are not

blocked, and clean if necessary (see

illustration).

35Crankcase ventilation system

check

SOHC and DOHC carburettor

models

1A vacuum pump will be required to test the

control components.2To check the operation of the air

temperature control, the engine must be cold.

First observe the position of the flap valve

which should be fully closed prior to starting

the engine(see illustration).The position of

the flap can be observed by disconnecting the

cold air inlet hose from the air cleaner spout

and looking into the spout.

3Start the engine and allow it to idle. Check

that the flap is now fully open to admit hot air

from the exhaust manifold shroud. If the flap

does not fully open, stop the engine and

check the vacuum diaphragm unit and heat

sensor as follows (see illustrations).4Working under the base of the air cleaner

body, disconnect the diaphragm unit-to-heat

sensor vacuum pipe at the sensor end, and

connect a vacuum pump to the diaphragm unit.

Apply a vacuum of 100.0 mm (4.0 in) of mercury.

5If the flap opens, then the heat sensor is

faulty and should be renewed. If the flap

remains closed, then the diaphragm unit is

faulty, and a new air cleaner body will have to

be obtained, as the diaphragm unit is not

available separately.

6On completion of the checks, disconnect

the vacuum pump, and reconnect the vacuum

pipe and cold air inlet hose.

36Air cleaner inlet air

temperature control check

1•18Every 24 000 miles or 2 years

35.1 Loosening the crankcase ventilation

hose clip - CVH models

36.3b Air cleaner heat sensor viewed from

inside air cleaner - OHC models36.3a Air cleaner vacuum diaphragm unit -

OHC models

36.2 Air cleaner flap valve operation -

OHC models

A Flap fully open to admit hot air

B Flap fully closed to admit cold air

35.3 Oil separator (1) and mushroom valve

(2) locations in air cleaner - CVH models

Every 24 000 miles (40 000 km) or 2 years

Page 19 of 22

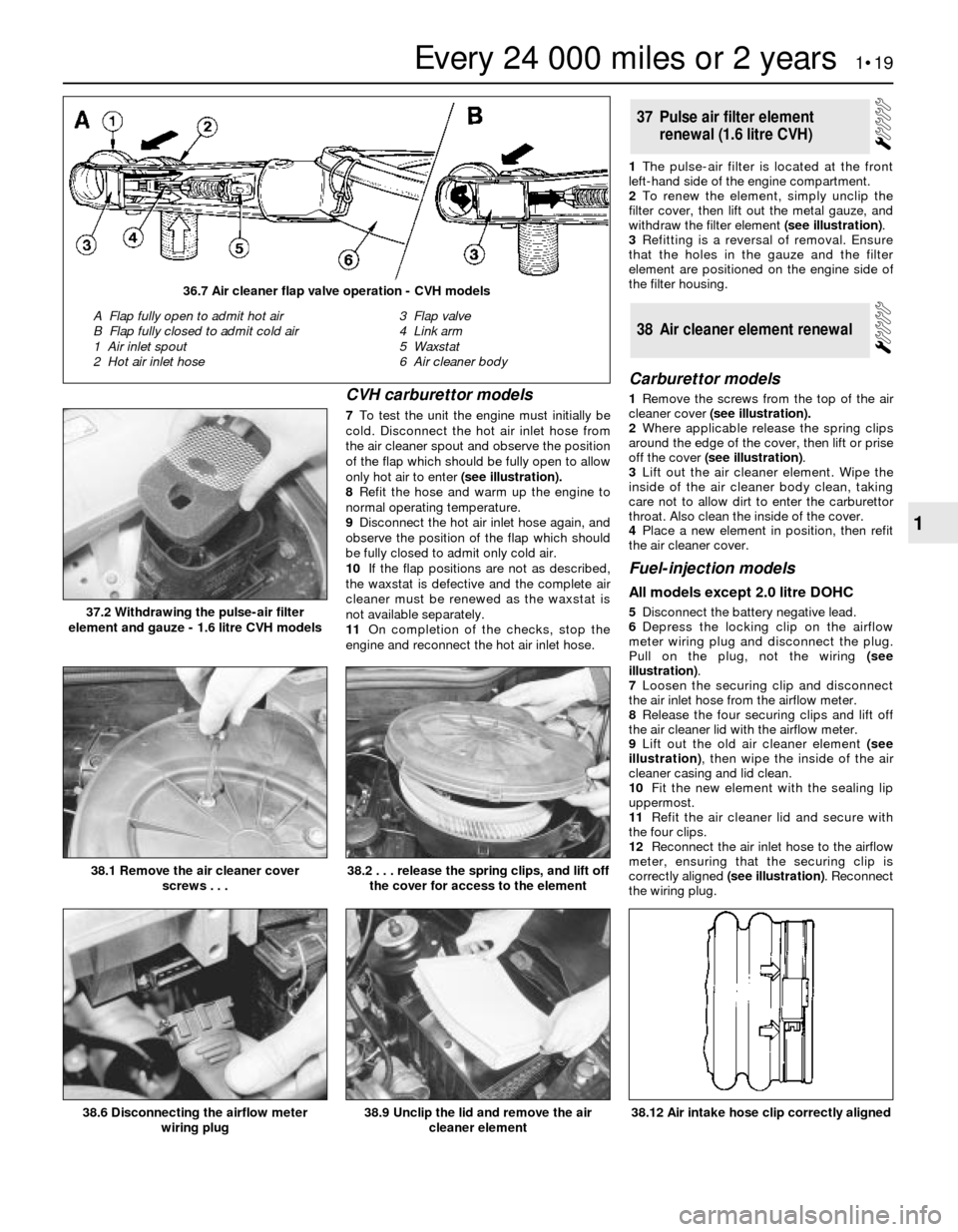

CVH carburettor models

7To test the unit the engine must initially be

cold. Disconnect the hot air inlet hose from

the air cleaner spout and observe the position

of the flap which should be fully open to allow

only hot air to enter (see illustration).

8Refit the hose and warm up the engine to

normal operating temperature.

9Disconnect the hot air inlet hose again, and

observe the position of the flap which should

be fully closed to admit only cold air.

10If the flap positions are not as described,

the waxstat is defective and the complete air

cleaner must be renewed as the waxstat is

not available separately.

11On completion of the checks, stop the

engine and reconnect the hot air inlet hose.1The pulse-air filter is located at the front

left-hand side of the engine compartment.

2To renew the element, simply unclip the

filter cover, then lift out the metal gauze, and

withdraw the filter element (see illustration).

3Refitting is a reversal of removal. Ensure

that the holes in the gauze and the filter

element are positioned on the engine side of

the filter housing.

Carburettor models

1Remove the screws from the top of the air

cleaner cover (see illustration).

2Where applicable release the spring clips

around the edge of the cover, then lift or prise

off the cover (see illustration).

3Lift out the air cleaner element. Wipe the

inside of the air cleaner body clean, taking

care not to allow dirt to enter the carburettor

throat. Also clean the inside of the cover.

4Place a new element in position, then refit

the air cleaner cover.

Fuel-injection models

All models except 2.0 litre DOHC

5Disconnect the battery negative lead.

6Depress the locking clip on the airflow

meter wiring plug and disconnect the plug.

Pull on the plug, not the wiring (see

illustration).

7Loosen the securing clip and disconnect

the air inlet hose from the airflow meter.

8Release the four securing clips and lift off

the air cleaner lid with the airflow meter.

9Lift out the old air cleaner element (see

illustration), then wipe the inside of the air

cleaner casing and lid clean.

10Fit the new element with the sealing lip

uppermost.

11Refit the air cleaner lid and secure with

the four clips.

12Reconnect the air inlet hose to the airflow

meter, ensuring that the securing clip is

correctly aligned (see illustration). Reconnect

the wiring plug.

38Air cleaner element renewal

37Pulse air filter element

renewal (1.6 litre CVH)

Every 24 000 miles or 2 years 1•19

1

37.2 Withdrawing the pulse-air filter

element and gauze - 1.6 litre CVH models

38.12 Air intake hose clip correctly aligned38.9 Unclip the lid and remove the air

cleaner element38.6 Disconnecting the airflow meter

wiring plug

38.2 . . . release the spring clips, and lift off

the cover for access to the element38.1 Remove the air cleaner cover

screws . . .

36.7 Air cleaner flap valve operation - CVH models

A Flap fully open to admit hot air

B Flap fully closed to admit cold air

1 Air inlet spout

2 Hot air inlet hose3 Flap valve

4 Link arm

5 Waxstat

6 Air cleaner body

Page 20 of 22

13Reconnect the battery negative lead.

2.0 litre DOHC models

14Disconnect the battery negative lead.

15Disconnect the wiring plug from the idle

speed control valve at the front of the plenum

chamber.

16Loosen the clamp, and detach the air inlet

hose from the air inlet tubing.

17Unscrew the securing nut, and release the

air inlet tube from the bracket on the engine

compartment front panel (see illustration).

18Release the air cleaner lid securing clips,

then lift away the air inlet tube, plenum

chamber and air cleaner lid as an assembly,

disconnecting the breather hose from the air

inlet tube.

19Lift out the air cleaner element (see

illustration), then wipe the inside of the air

cleaner lid and casing clean.

20Fit the new element with the sealing lip

uppermost.

21Further refitting is a reversal of removal.

1Before disturbing any part of the ignition

system, disconnect the battery negative lead.

2Identify and clearly mark all HT leads before

disconnecting them from the spark plugs.

3Refer to the appropriate Section in Chapter

5 and, where applicable, remove the

distributor cap and rotor arm.

4Clean the HT leads and distributor cap with

a dry cloth. Scrape any corrosion or otherdeposits from the connectors and terminals.

Also clean the coil tower.

5Renew the HT leads if they are cracked,

burnt or otherwise damaged. If a multi-meter

is available, measure the resistance of the

leads. The desired value is given in the

Specifications of Chapter 5.

6Renew the distributor cap if it is cracked or

badly burnt inside, or if there is evidence of

“tracking” (black lines marking the path of HT

leakage). If there is a carbon brush at the

centre of the cap, make sure that it moves

freely, and is not excessively worn (see

illustration).

7Clean the metal track of the rotor arm with

fine abrasive paper. Renew the arm if it is

cracked or badly burnt.

8Refit the rotor arm and distributor cap.

9Reconnect the HT leads to the spark plugs

and coil.

10Reconnect the battery and run the engine.

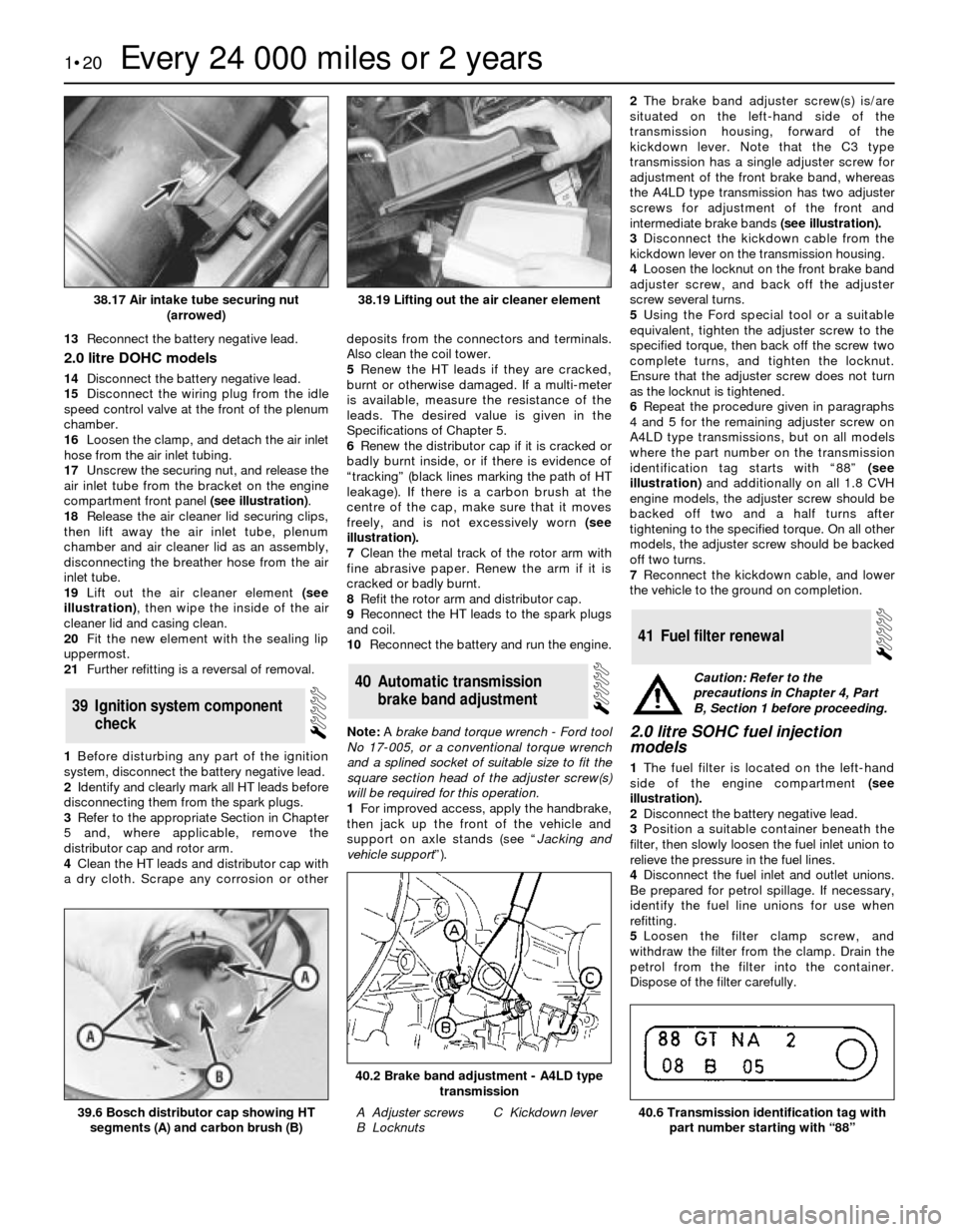

Note: A brake band torque wrench - Ford tool

No 17-005, or a conventional torque wrench

and a splined socket of suitable size to fit the

square section head of the adjuster screw(s)

will be required for this operation.

1For improved access, apply the handbrake,

then jack up the front of the vehicle and

support on axle stands (see “Jacking and

vehicle support”).2The brake band adjuster screw(s) is/are

situated on the left-hand side of the

transmission housing, forward of the

kickdown lever. Note that the C3 type

transmission has a single adjuster screw for

adjustment of the front brake band, whereas

the A4LD type transmission has two adjuster

screws for adjustment of the front and

intermediate brake bands(see illustration).

3Disconnect the kickdown cable from the

kickdown lever on the transmission housing.

4Loosen the locknut on the front brake band

adjuster screw, and back off the adjuster

screw several turns.

5Using the Ford special tool or a suitable

equivalent, tighten the adjuster screw to the

specified torque, then back off the screw two

complete turns, and tighten the locknut.

Ensure that the adjuster screw does not turn

as the locknut is tightened.

6Repeat the procedure given in paragraphs

4 and 5 for the remaining adjuster screw on

A4LD type transmissions, but on all models

where the part number on the transmission

identification tag starts with “88”(see

illustration)and additionally on all 1.8 CVH

engine models, the adjuster screw should be

backed off two and a half turns after

tightening to the specified torque. On all other

models, the adjuster screw should be backed

off two turns.

7Reconnect the kickdown cable, and lower

the vehicle to the ground on completion.

2.0 litre SOHC fuel injection

models

1The fuel filter is located on the left-hand

side of the engine compartment(see

illustration).

2Disconnect the battery negative lead.

3Position a suitable container beneath the

filter, then slowly loosen the fuel inlet union to

relieve the pressure in the fuel lines.

4Disconnect the fuel inlet and outlet unions.

Be prepared for petrol spillage. If necessary,

identify the fuel line unions for use when

refitting.

5Loosen the filter clamp screw, and

withdraw the filter from the clamp. Drain the

petrol from the filter into the container.

Dispose of the filter carefully.

41Fuel filter renewal

40Automatic transmission

brake band adjustment

39Ignition system component

check

1•20Every 24 000 miles or 2 years

38.17 Air intake tube securing nut

(arrowed)

39.6 Bosch distributor cap showing HT

segments (A) and carbon brush (B)40.6 Transmission identification tag with

part number starting with “88”

40.2 Brake band adjustment - A4LD type

transmission

A Adjuster screws

B LocknutsC Kickdown lever

38.19 Lifting out the air cleaner element

Caution: Refer to the

precautions in Chapter 4, Part

B, Section 1 before proceeding.

Page 21 of 22

6Fit the new filter, ensuring that the arrows on

the filter body point in the direction of fuel flow.

7Tighten the clamp screw, and reconnect

the fuel inlet and outlet unions. Ensure that the

unions are correctly connected.

8Reconnect the battery negative lead, and

check the fuel line unions for leaks,

pressurising the system by switching the

ignition on and off several times.

All models except 2.0 litre SOHC

9Proceed as described for the 2.0 litre SOHCmodels, noting the following points.

10The fuel filter is located under the rear of

the vehicle, above the driveshaft (see

illustration). For access to the filter, chock

the front wheels, then jack up the rear of the

vehicle and support it on axle stands.

11To remove the filter, the mounting bracket

must first be removed from the floor, after

unscrewing the securing bolt. The filter can

then be removed from the bracket after

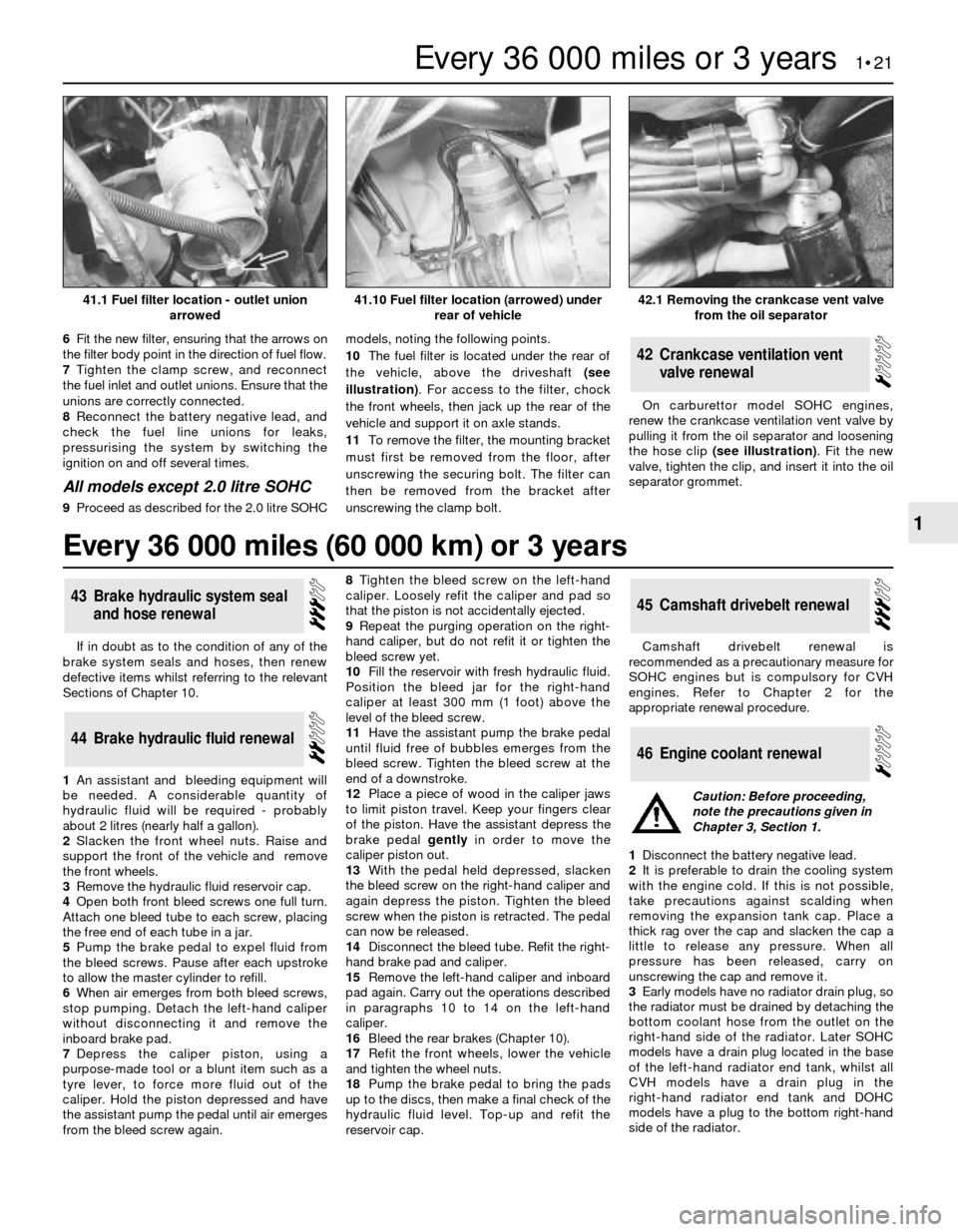

unscrewing the clamp bolt.On carburettor model SOHC engines,

renew the crankcase ventilation vent valve by

pulling it from the oil separator and loosening

the hose clip (see illustration). Fit the new

valve, tighten the clip, and insert it into the oil

separator grommet.

42Crankcase ventilation vent

valve renewal

If in doubt as to the condition of any of the

brake system seals and hoses, then renew

defective items whilst referring to the relevant

Sections of Chapter 10.

1An assistant and bleeding equipment will

be needed. A considerable quantity of

hydraulic fluid will be required - probably

about 2 litres (nearly half a gallon).

2Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheels.

3Remove the hydraulic fluid reservoir cap.

4Open both front bleed screws one full turn.

Attach one bleed tube to each screw, placing

the free end of each tube in a jar.

5Pump the brake pedal to expel fluid from

the bleed screws. Pause after each upstroke

to allow the master cylinder to refill.

6When air emerges from both bleed screws,

stop pumping. Detach the left-hand caliper

without disconnecting it and remove the

inboard brake pad.

7Depress the caliper piston, using a

purpose-made tool or a blunt item such as a

tyre lever, to force more fluid out of the

caliper. Hold the piston depressed and have

the assistant pump the pedal until air emerges

from the bleed screw again.8Tighten the bleed screw on the left-hand

caliper. Loosely refit the caliper and pad so

that the piston is not accidentally ejected.

9Repeat the purging operation on the right-

hand caliper, but do not refit it or tighten the

bleed screw yet.

10Fill the reservoir with fresh hydraulic fluid.

Position the bleed jar for the right-hand

caliper at least 300 mm (1 foot) above the

level of the bleed screw.

11Have the assistant pump the brake pedal

until fluid free of bubbles emerges from the

bleed screw. Tighten the bleed screw at the

end of a downstroke.

12Place a piece of wood in the caliper jaws

to limit piston travel. Keep your fingers clear

of the piston. Have the assistant depress the

brake pedal gentlyin order to move the

caliper piston out.

13With the pedal held depressed, slacken

the bleed screw on the right-hand caliper and

again depress the piston. Tighten the bleed

screw when the piston is retracted. The pedal

can now be released.

14Disconnect the bleed tube. Refit the right-

hand brake pad and caliper.

15Remove the left-hand caliper and inboard

pad again. Carry out the operations described

in paragraphs 10 to 14 on the left-hand

caliper.

16Bleed the rear brakes (Chapter 10).

17Refit the front wheels, lower the vehicle

and tighten the wheel nuts.

18Pump the brake pedal to bring the pads

up to the discs, then make a final check of the

hydraulic fluid level. Top-up and refit the

reservoir cap.Camshaft drivebelt renewal is

recommended as a precautionary measure for

SOHC engines but is compulsory for CVH

engines. Refer to Chapter 2 for the

appropriate renewal procedure.

1Disconnect the battery negative lead.

2It is preferable to drain the cooling system

with the engine cold. If this is not possible,

take precautions against scalding when

removing the expansion tank cap. Place a

thick rag over the cap and slacken the cap a

little to release any pressure. When all

pressure has been released, carry on

unscrewing the cap and remove it.

3Early models have no radiator drain plug, so

the radiator must be drained by detaching the

bottom coolant hose from the outlet on the

right-hand side of the radiator. Later SOHC

models have a drain plug located in the base

of the left-hand radiator end tank, whilst all

CVH models have a drain plug in the

right-hand radiator end tank and DOHC

models have a plug to the bottom right-hand

side of the radiator.

46Engine coolant renewal

45Camshaft drivebelt renewal

44Brake hydraulic fluid renewal

43Brake hydraulic system seal

and hose renewal

Every 36 000 miles or 3 years 1•21

1

42.1 Removing the crankcase vent valve

from the oil separator41.10 Fuel filter location (arrowed) under

rear of vehicle41.1 Fuel filter location - outlet union

arrowed

Caution: Before proceeding,

note the precautions given in

Chapter 3, Section 1.

Every 36 000 miles (60 000 km) or 3 years

Page 22 of 22

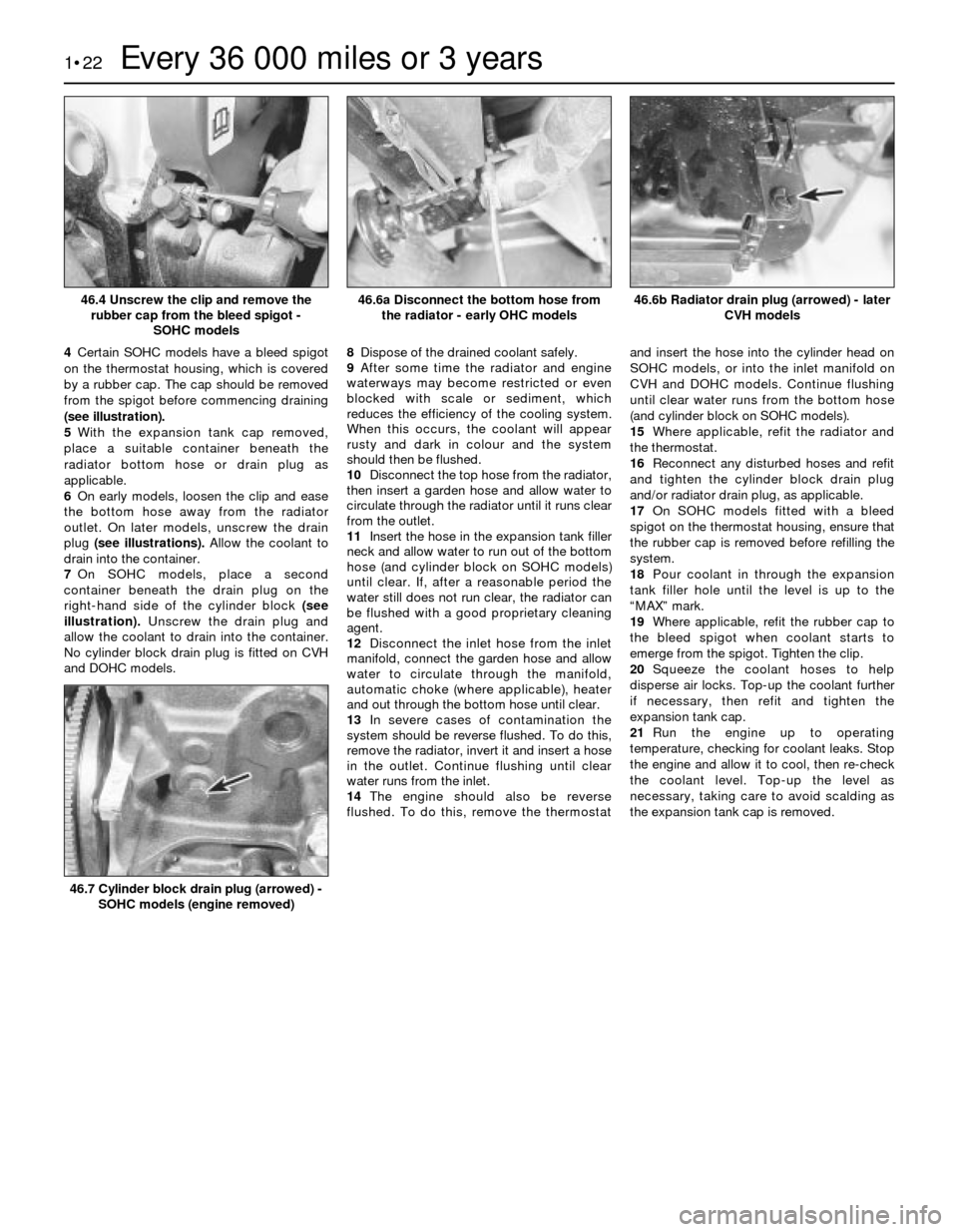

4Certain SOHC models have a bleed spigot

on the thermostat housing, which is covered

by a rubber cap. The cap should be removed

from the spigot before commencing draining

(see illustration).

5With the expansion tank cap removed,

place a suitable container beneath the

radiator bottom hose or drain plug as

applicable.

6On early models, loosen the clip and ease

the bottom hose away from the radiator

outlet. On later models, unscrew the drain

plug (see illustrations).Allow the coolant to

drain into the container.

7On SOHC models, place a second

container beneath the drain plug on the

right-hand side of the cylinder block (see

illustration).Unscrew the drain plug and

allow the coolant to drain into the container.

No cylinder block drain plug is fitted on CVH

and DOHC models.8Dispose of the drained coolant safely.

9After some time the radiator and engine

waterways may become restricted or even

blocked with scale or sediment, which

reduces the efficiency of the cooling system.

When this occurs, the coolant will appear

rusty and dark in colour and the system

should then be flushed.

10Disconnect the top hose from the radiator,

then insert a garden hose and allow water to

circulate through the radiator until it runs clear

from the outlet.

11Insert the hose in the expansion tank filler

neck and allow water to run out of the bottom

hose (and cylinder block on SOHC models)

until clear. If, after a reasonable period the

water still does not run clear, the radiator can

be flushed with a good proprietary cleaning

agent.

12Disconnect the inlet hose from the inlet

manifold, connect the garden hose and allow

water to circulate through the manifold,

automatic choke (where applicable), heater

and out through the bottom hose until clear.

13In severe cases of contamination the

system should be reverse flushed. To do this,

remove the radiator, invert it and insert a hose

in the outlet. Continue flushing until clear

water runs from the inlet.

14The engine should also be reverse

flushed. To do this, remove the thermostatand insert the hose into the cylinder head on

SOHC models, or into the inlet manifold on

CVH and DOHC models. Continue flushing

until clear water runs from the bottom hose

(and cylinder block on SOHC models).

15Where applicable, refit the radiator and

the thermostat.

16Reconnect any disturbed hoses and refit

and tighten the cylinder block drain plug

and/or radiator drain plug, as applicable.

17On SOHC models fitted with a bleed

spigot on the thermostat housing, ensure that

the rubber cap is removed before refilling the

system.

18Pour coolant in through the expansion

tank filler hole until the level is up to the

“MAX” mark.

19Where applicable, refit the rubber cap to

the bleed spigot when coolant starts to

emerge from the spigot. Tighten the clip.

20Squeeze the coolant hoses to help

disperse air locks. Top-up the coolant further

if necessary, then refit and tighten the

expansion tank cap.

21Run the engine up to operating

temperature, checking for coolant leaks. Stop

the engine and allow it to cool, then re-check

the coolant level. Top-up the level as

necessary, taking care to avoid scalding as

the expansion tank cap is removed.

1•22Every 36 000 miles or 3 years

46.4 Unscrew the clip and remove the

rubber cap from the bleed spigot -

SOHC models46.6b Radiator drain plug (arrowed) - later

CVH models

46.7 Cylinder block drain plug (arrowed) -

SOHC models (engine removed)

46.6a Disconnect the bottom hose from

the radiator - early OHC models