Temperature FORD SIERRA 1989 2.G Body Electrical System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: SIERRA, Model: FORD SIERRA 1989 2.GPages: 25, PDF Size: 1.7 MB

Page 8 of 25

Speedometer

12Remove the panel lens (paras. 5 and 6).

13Remove the two screws securing the

speedometer to the rear of the instrument

panel, taking care not to lose the two brushes.

Withdraw the speedometer through the front

of the instrument panel.

14Refitting is a reversal of removal.

Tachometer

Models up to 1990

15Remove the four or five securing screws,

as applicable, and separate the two halves of

the instrument panel housing.

16Remove the three securing nuts and

washers from the rear of the instrument panel

housing, and withdraw the tachometer.

17Refitting is a reversal of removal, but ensure

that the tachometer engages with the locating

ribs in the housing around the dial edge.

Models from 1990

18The procedure is as described above but

before the tachometer can be withdrawn from

the instrument panel housing, the printed circuit

board must be carefully pulled from the

tachometer terminals. Ensure that the printed

circuit board is pushed fully home when refitting.

Fuel and temperature gauges

Models up to 1987

19Remove the four securing screws and

separate the two halves of the instrument

panel housing.

20Remove the four securing nuts and washers

from the rear of the instrument panel housing,

and withdraw the combined gauge assembly.

21Refitting is a reversal of removal.

Models from 1987

22Remove the five securing screws and

separate the two halves of the instrument

panel housing.

23Remove the printed circuit board as

described previously in this Section.

24On “low specification” models, remove the

two securing screws from the front of the

gauge assembly, then withdraw the combined

gauge assembly from the printed circuit board.25On “high specification” models, simply

withdraw the combined gauge assembly from

the printed circuit board.

26Refitting is a reversal of removal, but on

“high specification” models, ensure that the

gauge assembly engages with the locating

ribs in the housing around the gauge edge.

1Disconnect the battery negative lead

Computer module

2Remove the single screw from the top edge

of the facia panel in which the module is

housed, then withdraw the facia panel.

3Remove the four now exposed securing

screws, disconnect the wiring plug, and

carefully withdraw the module. On later

models a retaining lug must be depressed

before the wiring plug can be disconnected.

4Where applicable, the mounting brackets

can be removed from the module by

unscrewing the securing nuts.

5If necessary, the illumination bulb can be

removed from the module by twisting the

bulbholder anti-clockwise using a pair of long-

nosed pliers. The bulb is a push-fit in the holder.

6Refitting is a reversal of removal.

Speed sender unit

Models up to 1987

7The speed sender unit is located in the

engine compartment on the right-hand side of

the bulkhead.

8Disconnect the plug from the sender unit.

9Unscrew the two knurled nuts from the

sender unit and disconnect the two

speedometer cables.

10Remove the three securing screws and

remove the bracket and sender unit.

11Unscrew and remove the securing nut

and washer, and separate the sender unit

from the bracket.

12Refitting is a reversal of removal.

Models from 1987

13Detach the wiring, hose retainers andcover panel from the bulkhead to gain access

to the sender unit.

14Proceed as shown in paragraphs 7 to 9.

15Remove the retaining nut and washer and

withdraw the sender unit.

16Refitting is a reversal of removal.

Fuel flow sensor unit

Carburettor models

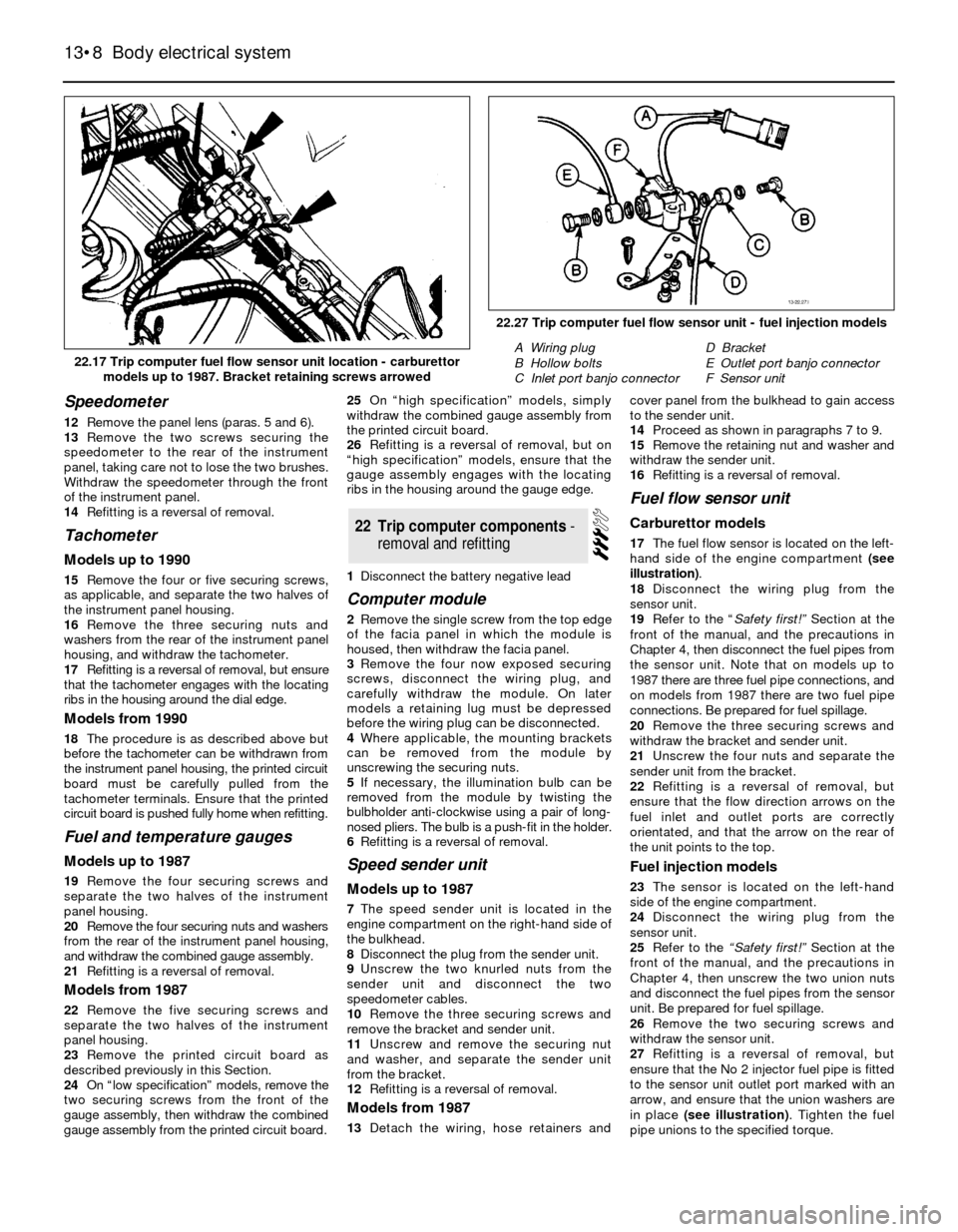

17The fuel flow sensor is located on the left-

hand side of the engine compartment (see

illustration).

18Disconnect the wiring plug from the

sensor unit.

19Refer to the “Safety first!” Section at the

front of the manual, and the precautions in

Chapter 4, then disconnect the fuel pipes from

the sensor unit. Note that on models up to

1987 there are three fuel pipe connections, and

on models from 1987 there are two fuel pipe

connections. Be prepared for fuel spillage.

20Remove the three securing screws and

withdraw the bracket and sender unit.

21Unscrew the four nuts and separate the

sender unit from the bracket.

22Refitting is a reversal of removal, but

ensure that the flow direction arrows on the

fuel inlet and outlet ports are correctly

orientated, and that the arrow on the rear of

the unit points to the top.

Fuel injection models

23The sensor is located on the left-hand

side of the engine compartment.

24Disconnect the wiring plug from the

sensor unit.

25Refer to the “Safety first!” Section at the

front of the manual, and the precautions in

Chapter 4, then unscrew the two union nuts

and disconnect the fuel pipes from the sensor

unit. Be prepared for fuel spillage.

26Remove the two securing screws and

withdraw the sensor unit.

27Refitting is a reversal of removal, but

ensure that the No 2 injector fuel pipe is fitted

to the sensor unit outlet port marked with an

arrow, and ensure that the union washers are

in place (see illustration). Tighten the fuel

pipe unions to the specified torque.

22Trip computer components -

removal and refitting

13•8Body electrical system

22.17 Trip computer fuel flow sensor unit location - carburettor

models up to 1987. Bracket retaining screws arrowed

22.27 Trip computer fuel flow sensor unit - fuel injection models

A Wiring plug

B Hollow bolts

C Inlet port banjo connectorD Bracket

E Outlet port banjo connector

F Sensor unit