spark plugs replace FORD SIERRA 1989 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: SIERRA, Model: FORD SIERRA 1989 2.GPages: 24, PDF Size: 0.93 MB

Page 12 of 24

41Locate the brush box over the

commutator, position the brushes, then fit the

nylon cover over the brushes. Route the brush

wiring into the locating channel, then secure

the brushes in the channels with the locking

clips and springs.

42Refit the commutator end housing,

locating the rubber block in the cut-out in the

housing, then secure with the two screws.

43Refit the spacers and C-clip to the end of

the armature shaft, then fit the commutator end

housing cap and secure with the two screws.

44Reconnect the wiring to the solenoid

terminal and fit the washer and securing nut.

Nippondenso type

45With the starter motor removed from the

vehicle and cleaned, grip the unit in a vice

fitted with soft jaw protectors.

46Unscrew the retaining nut and washer and

disconnect the wiring from the terminal on the

solenoid.

47Remove the two screws securing the

commutator end housing cap and remove the

cap (see illustration).

48Remove the C-clip from the groove in the

armature shaft, and remove the spring.

49Unscrew the two bolts and washers, and

withdraw the commutator end housing.

50Withdraw the two field brushes from the

brush plate, then remove the brush plate.

51If the brushes have worn to less than the

specified minimum, renew them as a set. To

renew the brushes, cut the leads at their

midpoint and make a good soldered joint

when connecting the new brushes.

52The commutator face should be clean and

free from burnt spots. Where necessary

burnish with fine glass paper (not emery) and

wipe with a fuel-moistened cloth. 53Position the brush plate over the end of

the armature, aligning the cut-outs in the

brush plate with the loops in the field

windings. The brush plate will be positively

located when the commutator end housing

bolts are fitted.

54Fit the brushes to their locations in the

brush plate, and retain with the springs.

55Fit the commutator end housing and

secure with the two bolts and washers.

56Fit the spring and the C-clip to the end of

the armature shaft, then smear the end of the

shaft with a little lithium-based grease, and

refit the commutator end housing cap,

securing with the two screws.

57Reconnect the wiring to the solenoid

terminal and fit the washer and retaining nut.

Note: The correct functioning of the spark plugs

is vital for the correct running and efficiency of

the engine. It is essential that the plugs fitted are

appropriate for the engine, and the suitable type

is specified at the beginning of this Chapter. If

this type is used and the engine is in good

condition, the spark plugs should not need

attention between scheduled replacement

intervals. Spark plug cleaning is rarely necessary

and should not be attempted unless specialised

equipment is available as damage can easily be

caused to the firing ends.

Removal

1Where necessary, for improved access

remove the air cleaner and/or the inlet hose.

2If necessary, identify each HT lead for

position, so that the leads can be refitted to theircorrect cylinders, then disconnect the leads

from the plugs by pulling on the connectors, not

the leads. Note that the position of No 1 cylinder

HT lead in the distributor cap is marked with

either a pip, or a number “1 “.

3On 2.0 litre DOHC carburettor models, the

location of the spark plugs and the close

proximity of the carburettor makes spark plug

access difficult, particularly when removing

the plugs from cylinders 2 and 3. It is

suggested that a 3/8 inch ratchet drive spark

plug socket with rubber insert and long

extension bar is used, possibly in conjunction

with a universal joint adapter. It is also

advisable to disconnect No 3 cylinder HT lead

from the distributor first, to allow some slack

for disconnection at the spark plug.

4Clean the area around each spark plug

using a small brush, then using a plug

spanner (preferably with a rubber insert),

unscrew and remove the plugs. Cover the

spark plug holes with a clean rag to prevent

the ingress of any foreign matter.

Inspection

5The condition of the spark plugs will tell

much about the overall condition of the engine.

6If the insulator nose of the spark plug is clean

and white, with no deposits, this is indicative of

a weak air/fuel mixture, or too hot a plug. (A hot

plug transfers heat away from the electrode

slowly - a cold plug transfers it away quickly).

7If the tip and insulator nose is covered with

hard black-looking deposits, then this is

indicative that the mixture is too rich. Should

the plug be black and oily, then it is likely that

the engine is fairly worn, as well as the mixture

being too rich.

8If the insulator nose is covered with light tan

to greyish brown deposits, then the mixture is

correct and it is likely that the engine is in

good condition.

9The spark plug gap is of considerable

importance, as, if it is too large or too small,

the size of the spark and its efficiency will be

seriously impaired. The spark plug gap should

be set to the figure given in the Specifications

at the beginning of this Chapter. To set it,

measure the gap with a feeler blade, and then

bend open, or close the outer plug electrode

until the correct gap is achieved (see

illustrations). The centre electrode should

never be bent as this may crack the insulation

and cause plug failure, if nothing worse.

11Spark plugs and HT leads -

removal, inspection and

refitting

5•12Engine electrical systems

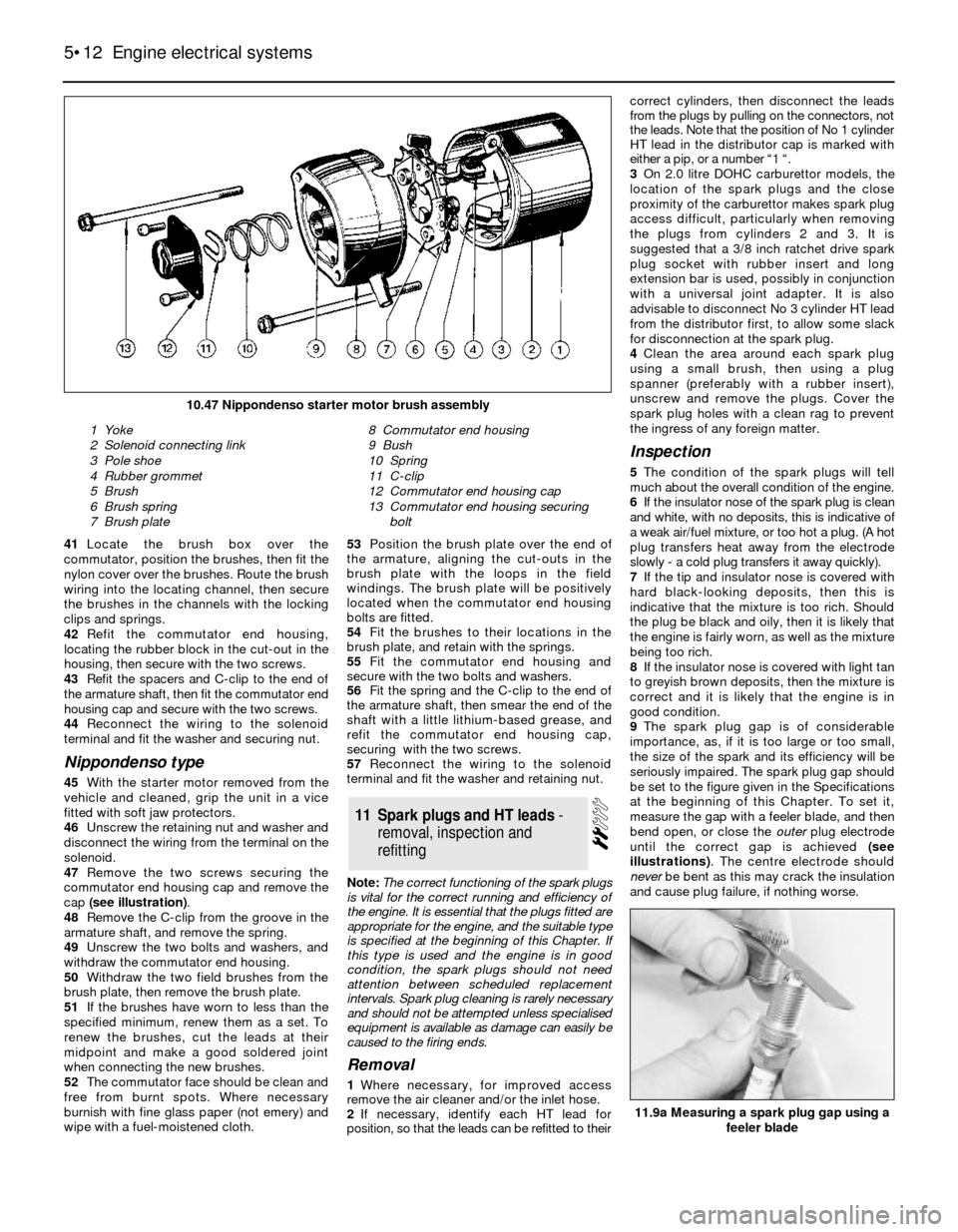

10.47 Nippondenso starter motor brush assembly

1 Yoke

2 Solenoid connecting link

3 Pole shoe

4 Rubber grommet

5 Brush

6 Brush spring

7 Brush plate8 Commutator end housing

9 Bush

10 Spring

11 C-clip

12 Commutator end housing cap

13 Commutator end housing securing

bolt

11.9a Measuring a spark plug gap using a

feeler blade