low oil pressure FORD SIERRA 1989 2.G SOHC Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: SIERRA, Model: FORD SIERRA 1989 2.GPages: 24, PDF Size: 1.03 MB

Page 1 of 24

1.3 litre engine

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder, in-line, single overhead camshaft

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . JCT

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.02 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1294 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0:1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 11 to 13 bar

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5800 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 kW at 5700 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 Nm at 3100 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.000 to 79.010 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.010 to 79.020 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.020 to 79.030 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.030 to 79.040 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.510 to 79.520 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.520 to 79.530 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.530 to 79.540 mm

Standard service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.030 to 79.040 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.530 to 79.540 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.030 to 80.040 mm

Chapter 2 Part A:

SOHC engines

Auxiliary shaft - removal, inspection and refitting . . . . . . . . . . . . . . .25

Camshaft and cam followers - removal, inspection and refitting . . . .24

Compression test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Crankcase ventilation system - inspection and maintenance . . . . . . .4

Crankshaft and bearings - examination and renovation . . . . . . . . . .35

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .34

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Cylinder block and bores - examination and renovation . . . . . . . . . .36

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .22

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .23

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .20

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .21

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .14

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . .13

Engine - removal leaving automatic transmission in vehicle . . . . . . .10

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .9

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine/automatic transmission assembly - removal and separation .12Engine dismantling,examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Engine/manual gearbox - reconnection and refitting . . . . . . . . . . . . .15

Engine/manual gearbox assembly - removal and separation . . . . . .11

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .26

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .37

Major operations possible with the engine in the vehicle . . . . . . . . . . .6

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .7

Method of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .31

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Pistons and connecting rods - examination and renovation . . . . . . .33

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .32

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Timing belt and sprockets - removal and refitting . . . . . . . . . . . . . . .19

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . . . .3

2A¥1

Specifications Contents

2A

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 7 of 24

Piston ring end gap:

Top:

Up to 1985 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.038 to 0.048 mm

From 1985 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.400 to 0.600 mm

Centre:

Up to 1985 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.038 to 0.048 mm

From 1985 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.400 to 0.600 mm

Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.400 to 1.400 mm

Auxiliary shaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.050 to 0.204 mm (0.002 to 0.008 in)

Cylinder head

Specifications as for 1.3 litre engine

Valves

Specifications as for 1.3 litre engine except for the following:

Valve clearance (cold engine):

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.20 ±0.03 mm (0.008 ±0.001 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.25 ±0.003 mm (0.010 ±0.001 in)

Valve timing:All except code NAEEngine code NAE

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24¼ BTDC18¼ BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64¼ ABDC58¼ ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70¼ BBDC70¼ BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18¼ ATDC6¼ ATDC

Lubrication system

Specifications as for 1.3 litre engine

Torque wrench settingsNmlbf ft

Specifications as for 1.3 litre engine except for the following:

Crankshaft pulley bolt:

Fuel injection models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . .115 to 13085 to 96

Fuel injection models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 to 11574 to 85

SOHC engines 2A¥7

2A

The engine is of a four-cylinder, in-line,

single overhead camshaft type, mounted at

the front of the vehicle and available in 1.3,

1.6, 1.8 and 2.0 litre versions.

The crankshaft incorporates five main

bearings. Thrustwashers are fitted to the

centre main bearing in order to control

crankshaft endfloat.

The camshaft is driven by a toothed belt

and operates the slightly angled valves via

cam followers which pivot on ball-pins.

The auxiliary shaft which is also driven by

the toothed belt, drives the distributor, oil

pump and fuel pump.

The cylinder head is of crossflow design

with the inlet manifold mounted on the left-

hand side and the exhaust manifold mounted

on the right-hand side.

Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries where it

is distributed to the crankshaft, camshaft and

auxiliary shaft. The big-end bearings are

supplied with oil via internal drillings in the

crankshaft. The undersides of the pistons are

supplied with oil from drillings in the big-ends.

The distributor shaft is intermittently supplied

with oil from the drilled auxiliary shaft. The

camshaft followers are supplied with oil via adrilled spray tube from the centre camshaft

bearing.

A semi-closed crankcase ventilation system

is employed whereby piston blow-by gases

are drawn into the inlet manifold via an oil

separator and control valve.

Refer to Chapter 1, Section 8.

Refer to Chapter 1, Section 23.

Refer to Chapter 1, Section 35.

1When engine performance is poor, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.2The engine must be at operating

temperature, the battery must be fully

charged and the spark plugs must be

removed. The services of an assistant will also

be required.

3Disable the ignition system by

disconnecting the coil LT feed. Fit the

compression tester to No 1 spark plug hole.

(The type of tester which screws into the

spark plug hole is to be preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean

engine oil into the spark plug hole and repeat

the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore, piston or piston ring wear was

responsible for the pressure loss. No

improvement suggests that leaking or burnt

valves, or a blown head gasket, may be to

blame.

8A low reading from the two adjacent

cylinders is almost certainly due to the head

gasket between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

5Compression test

4Crankcase ventilation system -

inspection and maintenance

3Valve clearances - checking and

adjustment

2Engine oil and filter - renewal

1General information

Page 8 of 24

The following operations can be carried out

without removing the engine from the vehicle:

a)Removal and servicing of the cylinder

head

b)Removal of the camshaft after removal of

the cylinder head

c)Removal of the timing belt and sprockets

d)Removal of the sump

e)Removal of the oil pump

f)Removal of the pistons and connecting

rods

g)Removal of the big-end bearings

h)Removal of the engine mountings

i)Removal of the clutch and flywheel

j)Removal of crankshaft front and rear oil

seals

k)Removal of the auxiliary shaft

The following operations can only be carried

out after removing the engine from the

vehicle:

a)Removal of the crankshaft main bearings

b)Removal of the crankshaft

The engine may be lifted out either on its

own, or together with the manual

gearbox/automatic transmission. Unless work

is to be carried out on the manual

gearbox/automatic transmission, it is

recommended that the engine is removed on

its own. Where automatic transmission is

fitted, the engine should where possible be

removed on its own due to the additional

weight of the transmission. Note: The air conditioning system should

always be discharged by a Ford dealer or air

conditioning specialist.

Note: Refer to the warning in Section 8 before

proceeding. A suitable hoist and lifting tackle

will be required for this operation.

1Disconnect the battery negative lead.

2Remove the bonnet.

3On carburettor models remove the air cleaner.

4On fuel injection models, disconnect the

crankcase ventilation hose from the air inlet

hose, then disconnect the air inlet hose from

the throttle body. Depress the locking clip on

the airflow meter wiring plug and disconnect

the plug (pulling on the plug, not the wiring)

then release the four securing clips and lift off

the air cleaner lid with the airflow meter and

air inlet hose.

5Remove the four retaining clips and

unscrew the two retaining screws, then

withdraw the upper section of the cooling fan

shroud from the radiator. Unclip and remove

the lower section of the shroud.

6Remove the thermo-viscous cooling fan as

described in Chapter 3.

7Drain the cooling system.

8Disconnect the upper radiator hose and

where applicable, the expansion tank hose

from the thermostat housing.

9Disconnect the coolant hoses from the

coolant pump, and where applicable from the

inlet manifold and automatic choke. Unclip

the coolant hose from the bracket on the

exhaust manifold hot air shroud/heat shield,

or the camshaft cover, as applicable.

10On carburettor models, where applicable

disconnect the vacuum pipe from the engine

management module.

11Disconnect the brake servo vacuum pipe

from the inlet manifold.

12On carburettor models, disconnect the fuel

hoses from the carburettor and where

applicable the mechanical fuel pump and plug

the ends of the hoses to minimise petrol

spillage. Remember to take adequate fire

precautions.

13On fuel injection models, disconnect the

fuel feed line from the fuel pressure regulator,

then disconnect the fuel supply hose from thefuel rail. Position a suitable container beneath

the pressure regulator, then slowly loosen the

fuel feed union to relieve the pressure in the

fuel lines before disconnecting the union.

Take adequate fire precautions. Plug the ends

of the hoses to minimise petrol spillage.

14Disconnect the throttle cable, and where

applicable remove its bracket.

15Disconnect the HT lead from the ignition

coil.

16Disconnect the wiring from the following

components as applicable depending on

model:

Alternator

Starter motor

Distributor

Oil pressure warning lamp switch

Temperature gauge sender

Engine coolant temperature sensor

Automatic choke

Automatic choke pull-down solenoid

Carburettor anti-dieselling valve

Inlet manifold heater

Carburettor stepper motor

Fuel injection harness

Dipstick

17Where applicable, detach the power

steering pump from the cylinder block and

move it to one side.

18Unscrew and remove the top engine-to-

gearbox bolts which are accessible from the

engine compartment. Note the location of the

earth strap on one of the bolts.

19Note the location of the earth strap on the

rear inlet manifold stud, then remove the nut

and disconnect the strap.

20Apply the handbrake (if not already done),

jack up the front of the vehicle and support on

axle stands (see ÒJacking and Vehicle SupportÓ).

21Drain the engine oil into a suitable

container.

22Remove the starter motor.

23Remove the exhaust downpipe.

24Unscrew the nuts or bolts, as applicable,

securing the engine mountings to the

crossmember. Recover the washers.

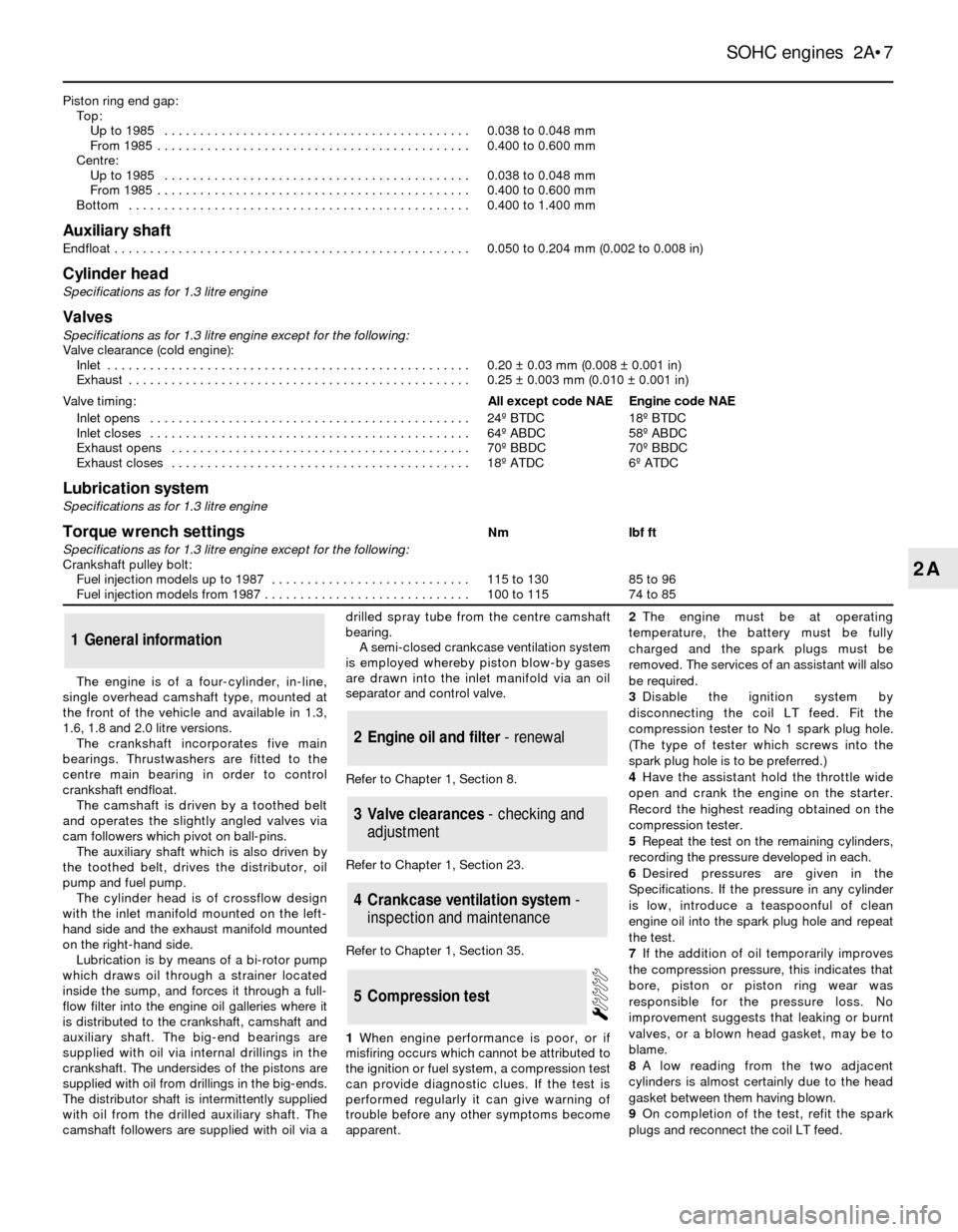

25Unscrew and remove the remaining

engine-to-gearbox bolts, and remove the bolt

from the engine adapter plate (see

illustration).

26Remove the two securing bolts and

disconnect the engine-to-gearbox brace from

the engine and gearbox.

27Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against its stop which will hold the

automatic adjuster pawl clear of the toothed

quadrant.

28Disconnect the clutch cable from the

clutch release arm, and pass the cable

through the bellhousing. Where applicable,

remove the clip securing the clutch cable to

the right-hand engine mounting bracket. Note

the cable routing for use when refitting.

29Lower the vehicle to the ground, and

support the gearbox with a trolley jack, using

a block of wood between the jack and the

gearbox to spread the load.

30Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate engine removal.

9Engine - removal leaving

manual gearbox in vehicle

8Method of engine removal

7Major operations requiring

engine removal

6Major operations possible with

the engine in the vehicle

2A¥8SOHC engines

9.25 Engine adapter plate bolt (A) and

engine-to-gearbox brace (B)

Warning: Vehicles equipped

with air conditioning:

Components of the air

conditioning system may

obstruct work being undertaken on the

engine, and it is not always possible to

unbolt and move them aside sufficiently,

within the limits of their flexible

connecting pipes. In such a case, the

system should be discharged by a Ford

dealer or air conditioning specialist. The

refrigerant is harmless under normal

conditions, but in the presence of a naked

flame (or a lighted cigarette) it forms a

highly toxic gas. Liquid refrigerant spilled

on the skin will cause frostbite. If

refrigerant enters the eyes, rinse them

with a diluted solution of boric acid and

seek medical advice immediately.

Page 11 of 24

4Check that the engine adapter plate is

correctly positioned on its locating dowels.

5Refit the propeller shaft.

6Refit the exhaust system.

7Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

8Fill the engine with the correct grade and

quantity of oil.

9Fill the cooling system.

10Check and if necessary top-up the

gearbox oil level.

11Check and if necessary adjust the tension

of the alternator and where applicable the

power steering pump drivebelt(s).

12Adjust the throttle cable.

1Reverse the removal procedure described

in Section 12, noting the following points.

2Check that the engine adapter plate is

correctly positioned on its locating dowels.

3As the torque converter is only loosely

engaged in the transmission, care must be

taken to prevent the torque converter from

falling out forwards. When the torque

converter hub is fully engaged with the fluid

pump drivegear in the transmission, distance

ÒAÓ in illustration 2.24 of Chapter 7B must be

as shown. Incorrect installation of the torque

converter will result in damage to the

transmission.

4As the engine and transmission are

reconnected, guide the torque converter studs

through the holes in the driveplate, noting that

on the C3 type transmission, the torque

converter fluid drain plug must line up with the

opening in the driveplate (see illustration 2.25

in Chapter 7B). When the engine is positioned

flush with the engine adapter plate and the

transmission housing, check that the torque

converter is free to move axially a small

amount before refitting and tightening the

engine-to-transmission bolts.

5Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

6Reconnect and adjust the selector rod.

7Refit the propeller shaft.8Refit the exhaust system.

9Fill the engine with the correct grade and

quantity of oil.

10Fill the cooling system.

11Check and if necessary top-up the

transmission fluid level.

12Check and if necessary adjust the tension

of the alternator and where applicable the

power steering pump drivebelt(s).

13Adjust the throttle cable.

14If applicable, adjust the kickdown cable.

1The engine mountings incorporate

hydraulic dampers and must be renewed if

excessive engine movement is evident.

2Working in the engine compartment,

unscrew the central nuts securing the engine

mounting brackets to the tops of the

mountings. Recover the washers where

applicable.

3Remove the two bolts or the central nut and

washer (as applicable) in each case securing

the mountings to the crossmember.

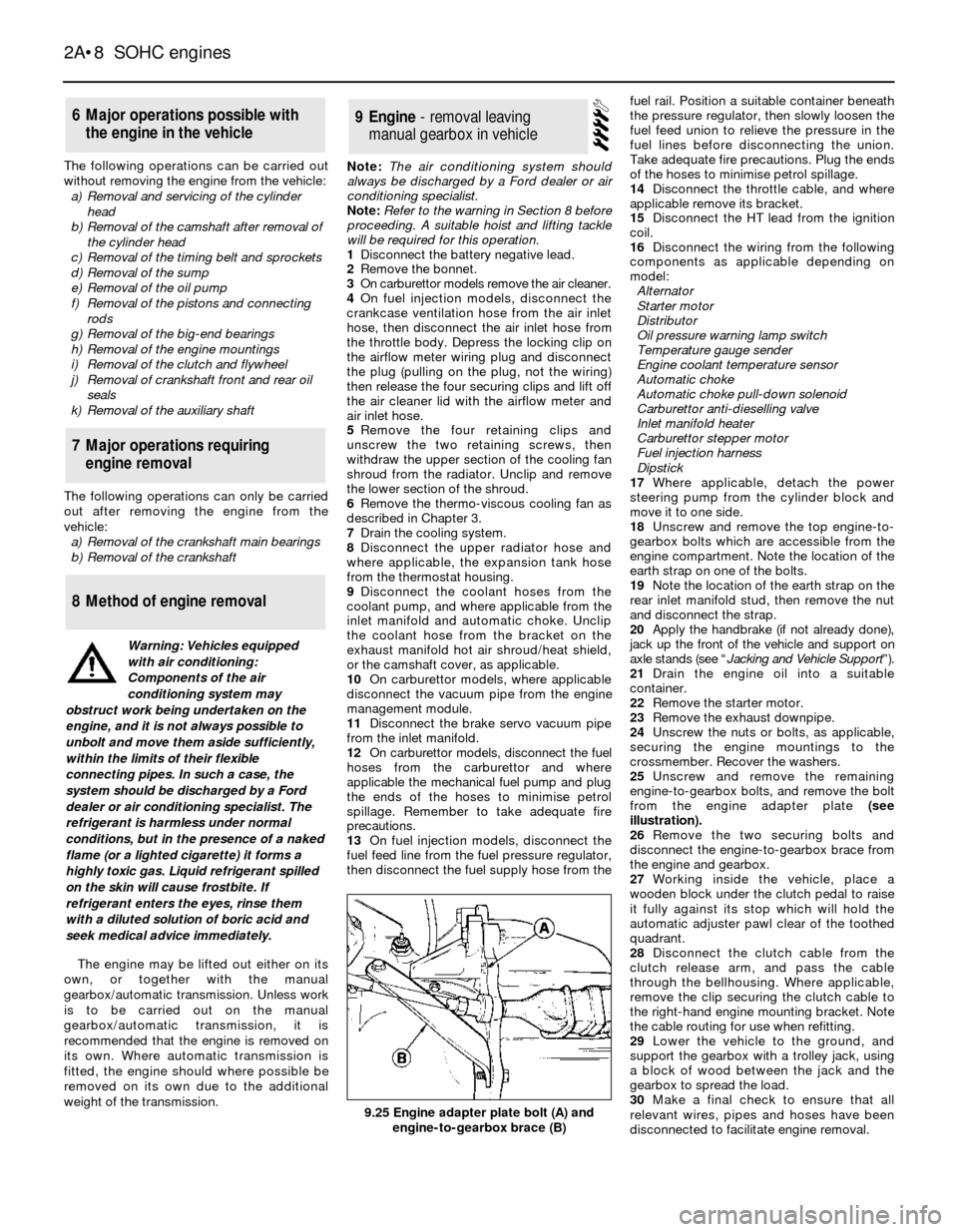

4Raise the engine using a hoist and lifting

tackle attached to the engine lifting brackets on

the cylinder head, or a jack with an interposed

block of wood under the sump, until the

mountings can be withdrawn (see illustration).

5Fit the new mountings, then lower the

engine onto them.

6Fit the bolts or the nuts and washers (as

applicable) securing the mountings to the

crossmember, and tighten them.

7Fit and tighten the central nuts, and washers

if applicable, securing the engine mounting

brackets to the tops of the mountings.

Dismantling

1It is best to mount the engine on a

dismantling stand but if this is not available,

stand the engine on a strong bench at a

comfortable working height. Failing this, it will

have to be stripped down on the floor.

2Cleanliness is most important, and if theengine is dirty, it should be cleaned with

paraffin while keeping it in an upright position.

3Avoid working with the engine directly on a

concrete floor, as grit presents a real source

of trouble.

4As parts are removed, clean them in a

paraffin bath. However, do not immerse parts

with internal oilways in paraffin as it is difficult

to remove, usually requiring a high pressure

hose. Clean oilways with nylon pipe cleaners.

5It is advisable to have suitable containers

available to hold small items according to

their use, as this will help when reassembling

the engine and also prevent possible losses.

6Always obtain a complete set of new

gaskets for use during engine reassembly, but

retain the old gaskets with a view to using

them as a pattern to make a replacement if a

new one is not available.

7Where possible, refit securing nuts, bolts and

washers to their locations after removing the

relevant components. This will help to protect

the threads and will also prevent losses.

8Retain unserviceable components in order

to compare them with the new parts supplied.

9Suitable splined sockets will be required for

removal of the oil pump bolts, the timing belt

tensioner bolts on early models (up to mid-

1985), and the cylinder head bolts on early

models (up to early 1984) and a size T55 Torx

socket will be required to remove the cylinder

head bolts on later models (from early 1984).

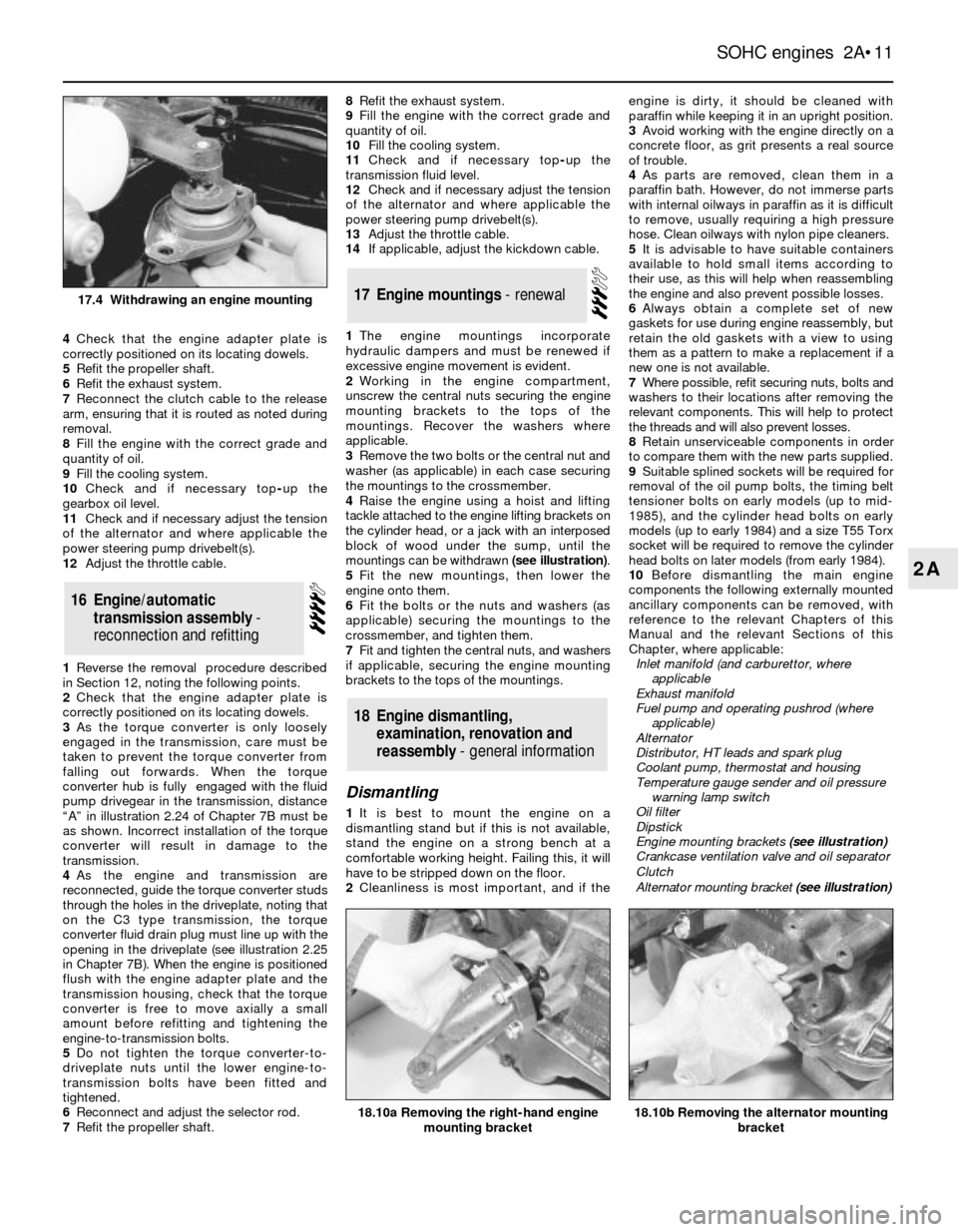

10Before dismantling the main engine

components the following externally mounted

ancillary components can be removed, with

reference to the relevant Chapters of this

Manual and the relevant Sections of this

Chapter, where applicable:

Inlet manifold (and carburettor, where

applicable

Exhaust manifold

Fuel pump and operating pushrod (where

applicable)

Alternator

Distributor, HT leads and spark plug

Coolant pump, thermostat and housing

Temperature gauge sender and oil pressure

warning lamp switch

Oil filter

Dipstick

Engine mounting brackets (see illustration)

Crankcase ventilation valve and oil separator

Clutch

Alternator mounting bracket (see illustration)

18Engine dismantling,

examination, renovation and

reassembly - general information

17Engine mountings - renewal

16Engine/automatic

transmission assembly -

reconnection and refitting

SOHC engines 2A¥11

2A

18.10b Removing the alternator mounting

bracket18.10a Removing the right-hand engine

mounting bracket

17.4 Withdrawing an engine mounting

Page 21 of 24

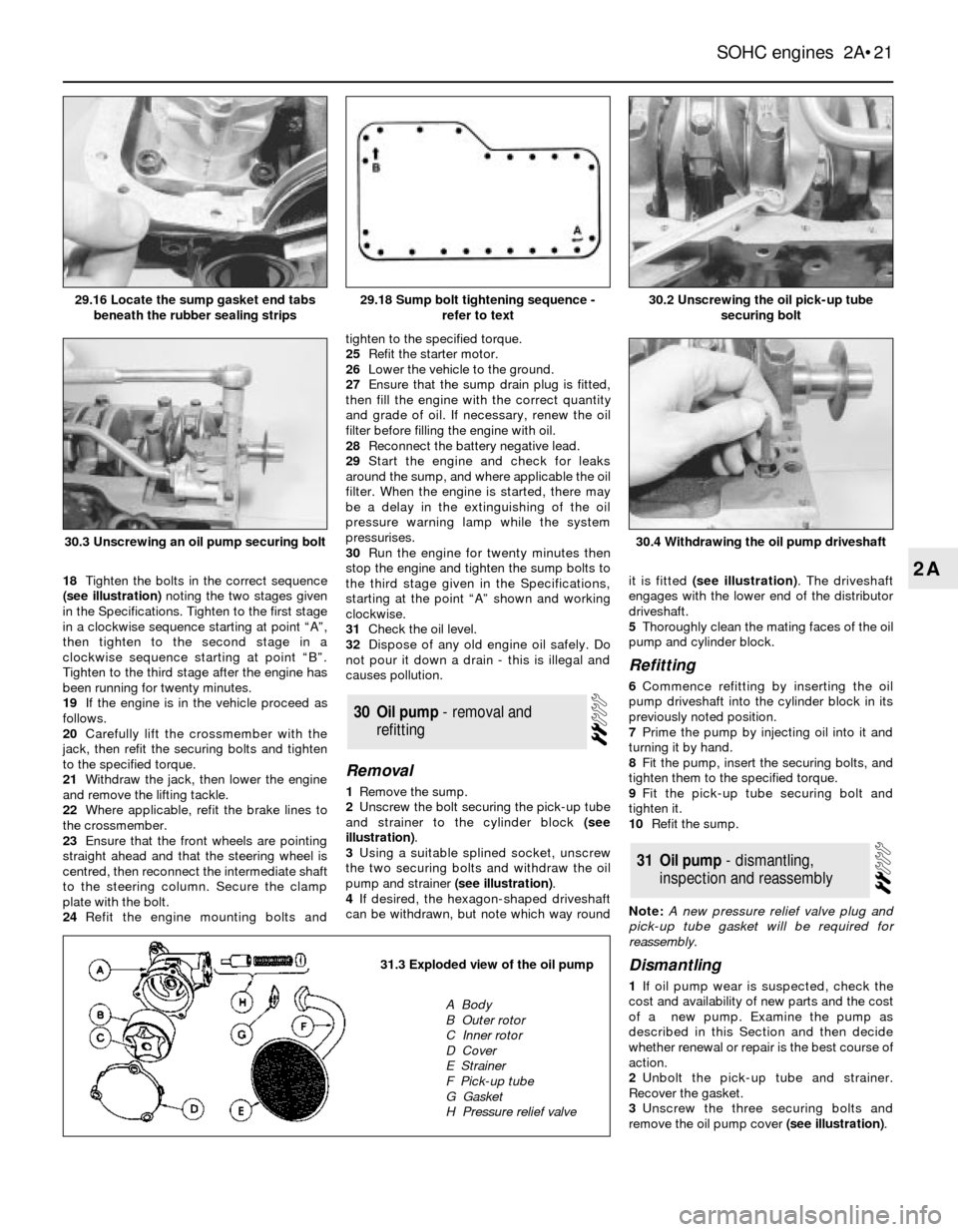

18Tighten the bolts in the correct sequence

(see illustration)noting the two stages given

in the Specifications. Tighten to the first stage

in a clockwise sequence starting at point ÒAÓ,

then tighten to the second stage in a

clockwise sequence starting at point ÒBÓ.

Tighten to the third stage after the engine has

been running for twenty minutes.

19If the engine is in the vehicle proceed as

follows.

20Carefully lift the crossmember with the

jack, then refit the securing bolts and tighten

to the specified torque.

21Withdraw the jack, then lower the engine

and remove the lifting tackle.

22Where applicable, refit the brake lines to

the crossmember.

23Ensure that the front wheels are pointing

straight ahead and that the steering wheel is

centred, then reconnect the intermediate shaft

to the steering column. Secure the clamp

plate with the bolt.

24Refit the engine mounting bolts andtighten to the specified torque.

25Refit the starter motor.

26Lower the vehicle to the ground.

27Ensure that the sump drain plug is fitted,

then fill the engine with the correct quantity

and grade of oil. If necessary, renew the oil

filter before filling the engine with oil.

28Reconnect the battery negative lead.

29Start the engine and check for leaks

around the sump, and where applicable the oil

filter. When the engine is started, there may

be a delay in the extinguishing of the oil

pressure warning lamp while the system

pressurises.

30Run the engine for twenty minutes then

stop the engine and tighten the sump bolts to

the third stage given in the Specifications,

starting at the point ÒAÓ shown and working

clockwise.

31Check the oil level.

32Dispose of any old engine oil safely. Do

not pour it down a drain - this is illegal and

causes pollution.

Removal

1Remove the sump.

2Unscrew the bolt securing the pick-up tube

and strainer to the cylinder block (see

illustration).

3Using a suitable splined socket, unscrew

the two securing bolts and withdraw the oil

pump and strainer (see illustration).

4If desired, the hexagon-shaped driveshaft

can be withdrawn, but note which way roundit is fitted (see illustration). The driveshaft

engages with the lower end of the distributor

driveshaft.

5Thoroughly clean the mating faces of the oil

pump and cylinder block.

Refitting

6Commence refitting by inserting the oil

pump driveshaft into the cylinder block in its

previously noted position.

7Prime the pump by injecting oil into it and

turning it by hand.

8Fit the pump, insert the securing bolts, and

tighten them to the specified torque.

9Fit the pick-up tube securing bolt and

tighten it.

10Refit the sump.

Note: A new pressure relief valve plug and

pick-up tube gasket will be required for

reassembly.

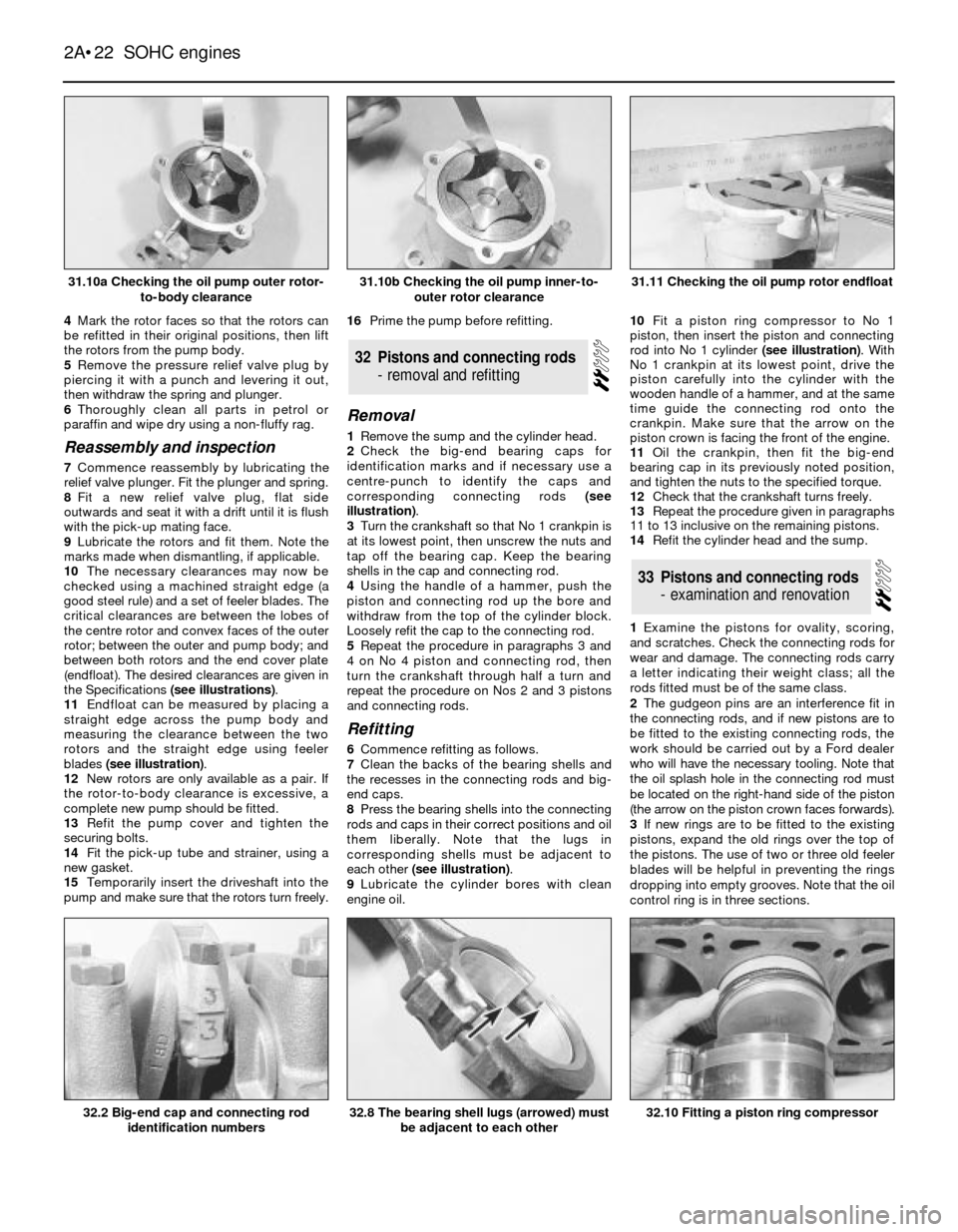

Dismantling

1If oil pump wear is suspected, check the

cost and availability of new parts and the cost

of a new pump. Examine the pump as

described in this Section and then decide

whether renewal or repair is the best course of

action.

2Unbolt the pick-up tube and strainer.

Recover the gasket.

3Unscrew the three securing bolts and

remove the oil pump cover (see illustration).

31Oil pump - dismantling,

inspection and reassembly

30Oil pump - removal and

refitting

SOHC engines 2A¥21

2A

30.2 Unscrewing the oil pick-up tube

securing bolt

30.4 Withdrawing the oil pump driveshaft30.3 Unscrewing an oil pump securing bolt

29.18 Sump bolt tightening sequence -

refer to text29.16 Locate the sump gasket end tabs

beneath the rubber sealing strips

31.3 Exploded view of the oil pump

A Body

B Outer rotor

C Inner rotor

D Cover

E Strainer

F Pick-up tube

G Gasket

H Pressure relief valve

Page 22 of 24

4Mark the rotor faces so that the rotors can

be refitted in their original positions, then lift

the rotors from the pump body.

5Remove the pressure relief valve plug by

piercing it with a punch and levering it out,

then withdraw the spring and plunger.

6Thoroughly clean all parts in petrol or

paraffin and wipe dry using a non-fluffy rag.

Reassembly and inspection

7Commence reassembly by lubricating the

relief valve plunger. Fit the plunger and spring.

8Fit a new relief valve plug, flat side

outwards and seat it with a drift until it is flush

with the pick-up mating face.

9Lubricate the rotors and fit them. Note the

marks made when dismantling, if applicable.

10The necessary clearances may now be

checked using a machined straight edge (a

good steel rule) and a set of feelerblades. The

critical clearances are between the lobes of

the centre rotor and convex faces of the outer

rotor; between the outer and pump body; and

between both rotors and the end cover plate

(endfloat). The desired clearances are given in

the Specifications (see illustrations).

11Endfloat can be measured by placing a

straight edge across the pump body and

measuring the clearance between the two

rotors and the straight edge using feeler

blades (see illustration).

12New rotors are only available as a pair. If

the rotor-to-body clearance is excessive, a

complete new pump should be fitted.

13Refit the pump cover and tighten the

securing bolts.

14Fit the pick-up tube and strainer, using a

new gasket.

15Temporarily insert the driveshaft into the

pump and make sure that the rotors turn freely.16Prime the pump before refitting.

Removal

1Remove the sump and the cylinder head.

2Check the big-end bearing caps for

identification marks and if necessary use a

centre-punch to identify the caps and

corresponding connecting rods (see

illustration).

3Turn the crankshaft so that No 1 crankpin is

at its lowest point, then unscrew the nuts and

tap off the bearing cap. Keep the bearing

shells in the cap and connecting rod.

4Using the handle of a hammer, push the

piston and connecting rod up the bore and

withdraw from the top of the cylinder block.

Loosely refit the cap to the connecting rod.

5Repeat the procedure in paragraphs 3 and

4 on No 4 piston and connecting rod, then

turn the crankshaft through half a turn and

repeat the procedure on Nos 2 and 3 pistons

and connecting rods.

Refitting

6Commence refitting as follows.

7Clean the backs of the bearing shells and

the recesses in the connecting rods and big-

end caps.

8Press the bearing shells into the connecting

rods and caps in their correct positions and oil

them liberally. Note that the lugs in

corresponding shells must be adjacent to

each other (see illustration).

9Lubricate the cylinder bores with clean

engine oil.10Fit a piston ring compressor to No 1

piston, then insert the piston and connecting

rod into No 1 cylinder (see illustration). With

No 1 crankpin at its lowest point, drive the

piston carefully into the cylinder with the

wooden handle of a hammer, and at the same

time guide the connecting rod onto the

crankpin. Make sure that the arrow on the

piston crown is facing the front of the engine.

11Oil the crankpin, then fit the big-end

bearing cap in its previously noted position,

and tighten the nuts to the specified torque.

12Check that the crankshaft turns freely.

13Repeat the procedure given in paragraphs

11 to 13 inclusive on the remaining pistons.

14Refit the cylinder head and the sump.

1Examine the pistons for ovality, scoring,

and scratches. Check the connecting rods for

wear and damage. The connecting rods carry

a letter indicating their weight class; all the

rods fitted must be of the same class.

2The gudgeon pins are an interference fit in

the connecting rods, and if new pistons are to

be fitted to the existing connecting rods, the

work should be carried out by a Ford dealer

who will have the necessary tooling. Note that

the oil splash hole in the connecting rod must

be located on the right-hand side of the piston

(the arrow on the piston crown faces forwards).

3If new rings are to be fitted to the existing

pistons, expand the old rings over the top of

the pistons. The use of two or three old feeler

blades will be helpful in preventing the rings

dropping into empty grooves. Note that the oil

control ring is in three sections.

33Pistons and connecting rods

- examination and renovation

32Pistons and connecting rods

- removal and refitting

2A¥22SOHC engines

31.10a Checking the oil pump outer rotor-

to-body clearance31.11 Checking the oil pump rotor endfloat

32.10 Fitting a piston ring compressor32.8 The bearing shell lugs (arrowed) must

be adjacent to each other32.2 Big-end cap and connecting rod

identification numbers

31.10b Checking the oil pump inner-to-

outer rotor clearance

Page 24 of 24

components, but there must be no tight spots

or binding.

28Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

29Make sure that the rear oil seal is fully

located onto its seating. Coat the rear main

bearing cap sealing wedges with sealing

compound, then press them into position

using a blunt screwdriver with the rounded

red face towards the cap (see illustration).

30Refit the oil pump and pick-up tube.

31Refit the crankshaft front oil seal housing

and the auxiliary shaft front cover using a new

gasket, and tighten the securing bolts. Smear

the lip of the oil seal with clean engine oil

before fitting; and using a straight edge, ensure

that the bottom face of the oil seal housing is

aligned with the bottom face of the cylinder

block before finally tightening the bolts.

32Refit the pistons and connecting rods.

33Refit the flywheel/driveplate and the

auxiliary shaft sprocket, crankshaft sprocket,

and timing belt.

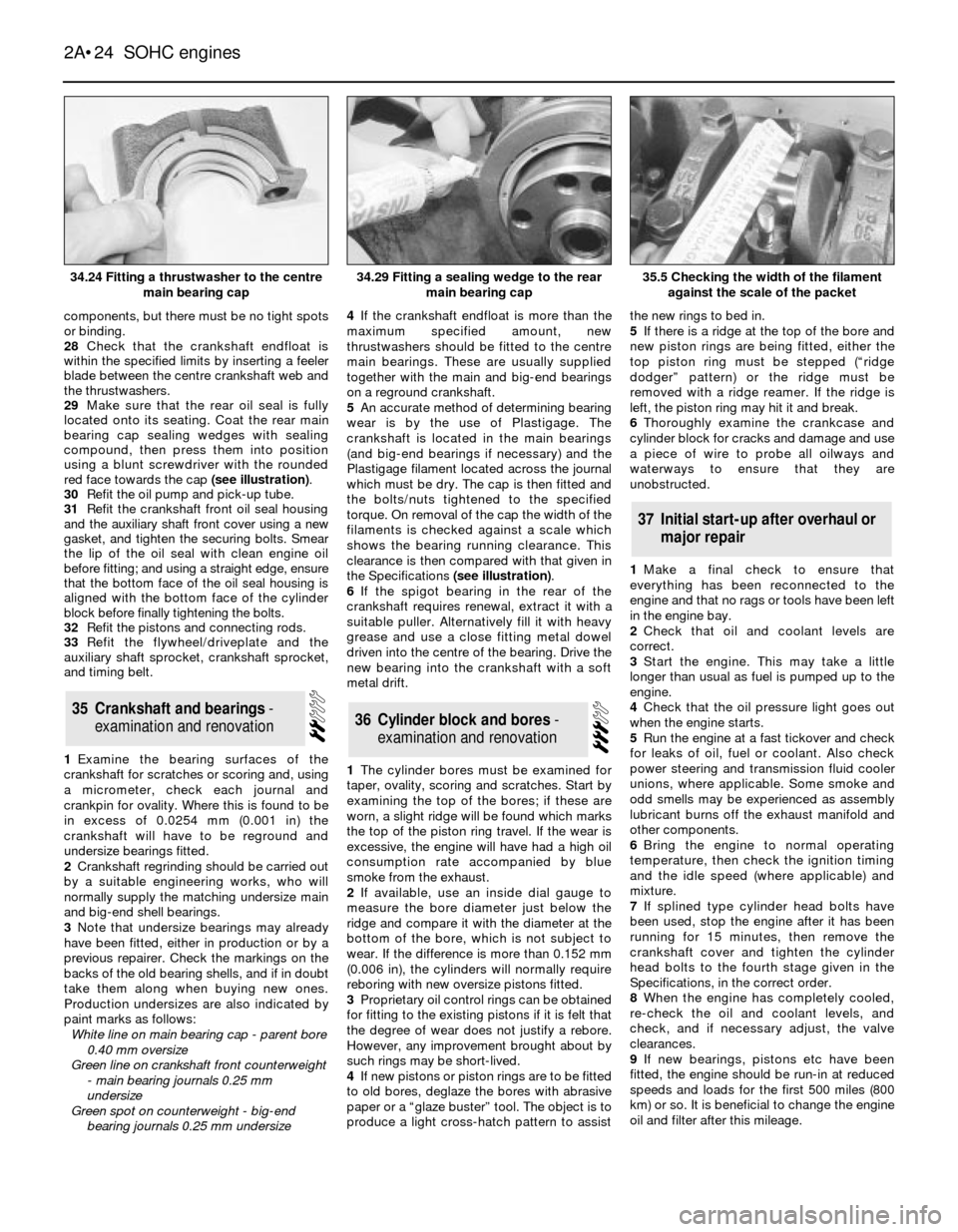

1Examine the bearing surfaces of the

crankshaft for scratches or scoring and, using

a micrometer, check each journal and

crankpin for ovality. Where this is found to be

in excess of 0.0254 mm (0.001 in) the

crankshaft will have to be reground and

undersize bearings fitted.

2Crankshaft regrinding should be carried out

by a suitable engineering works, who will

normally supply the matching undersize main

and big-end shell bearings.

3Note that undersize bearings may already

have been fitted, either in production or by a

previous repairer. Check the markings on the

backs of the old bearing shells, and if in doubt

take them along when buying new ones.

Production undersizes are also indicated by

paint marks as follows:

White line on main bearing cap - parent bore

0.40 mm oversize

Green line on crankshaft front counterweight

- main bearing journals 0.25 mm

undersize

Green spot on counterweight - big-end

bearing journals 0.25 mm undersize4If the crankshaft endfloat is more than the

maximum specified amount, new

thrustwashers should be fitted to the centre

main bearings. These are usually supplied

together with the main and big-end bearings

on a reground crankshaft.

5An accurate method of determining bearing

wear is by the use of Plastigage. The

crankshaft is located in the main bearings

(and big-end bearings if necessary) and the

Plastigage filament located across the journal

which must be dry. The cap is then fitted and

the bolts/nuts tightened to the specified

torque. On removal of the cap the width of the

filaments is checked against a scale which

shows the bearing running clearance. This

clearance is then compared with that given in

the Specifications (see illustration).

6If the spigot bearing in the rear of the

crankshaft requires renewal, extract it with a

suitable puller. Alternatively fill it with heavy

grease and use a close fitting metal dowel

driven into the centre of the bearing. Drive the

new bearing into the crankshaft with a soft

metal drift.

1The cylinder bores must be examined for

taper, ovality, scoring and scratches. Start by

examining the top of the bores; if these are

worn, a slight ridge will be found which marks

the top of the piston ring travel. If the wear is

excessive, the engine will have had a high oil

consumption rate accompanied by blue

smoke from the exhaust.

2If available, use an inside dial gauge to

measure the bore diameter just below the

ridge and compare it with the diameter at the

bottom of the bore, which is not subject to

wear. If the difference is more than 0.152 mm

(0.006 in), the cylinders will normally require

reboring with new oversize pistons fitted.

3Proprietary oil control rings can be obtained

for fitting to the existing pistons if it is felt that

the degree of wear does not justify a rebore.

However, any improvement brought about by

such rings may be short-lived.

4If new pistons or piston rings are to be fitted

to old bores, deglaze the bores with abrasive

paper or a Òglaze busterÓ tool. The object is to

produce a light cross-hatch pattern to assistthe new rings to bed in.

5If there is a ridge at the top of the bore and

new piston rings are being fitted, either the

top piston ring must be stepped (Òridge

dodgerÓ pattern) or the ridge must be

removed with a ridge reamer. If the ridge is

left, the piston ring may hit it and break.

6Thoroughly examine the crankcase and

cylinder block for cracks and damage and use

a piece of wire to probe all oilways and

waterways to ensurethatthey are

unobstructed.

1Make a final check to ensure that

everything has been reconnected to the

engine and that no rags or tools have been left

in the engine bay.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little

longer than usual as fuel is pumped up to the

engine.

4Check that the oil pressure light goes out

when the engine starts.

5Run the engine at a fast tickover and check

for leaks of oil, fuel or coolant. Also check

power steering and transmission fluid cooler

unions, where applicable. Some smoke and

odd smells may be experienced as assembly

lubricant burns off the exhaust manifold and

other components.

6Bring the engine to normal operating

temperature, then check the ignition timing

and the idle speed (where applicable) and

mixture.

7If splined type cylinder head bolts have

been used, stop the engine after it has been

running for 15 minutes, then remove the

crankshaft cover and tighten the cylinder

head bolts to the fourth stage given in the

Specifications, in the correct order.

8When the engine has completely cooled,

re-check the oil and coolant levels, and

check, and if necessary adjust, the valve

clearances.

9If new bearings, pistons etc have been

fitted, the engine should be run-in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

37Initial start-up after overhaul or

major repair

36Cylinder block and bores -

examination and renovation35Crankshaft and bearings -

examination and renovation

2A¥24SOHC engines

34.24 Fitting a thrustwasher to the centre

main bearing cap35.5 Checking the width of the filament

against the scale of the packet34.29 Fitting a sealing wedge to the rear

main bearing cap