clock setting FORD SIERRA 1990 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1990, Model line: SIERRA, Model: FORD SIERRA 1990 2.GPages: 24, PDF Size: 0.93 MB

Page 23 of 24

25Remove the two securing screws and

detach the throttle damper and bracket

assembly from the carburettor (see

illustration).

26Commence refitting by securing the

throttle damper and bracket assembly to the

carburettor with the two screws. Ensure that

the throttle lever is correctly positioned in the

slot in the throttle damper actuating arm.

27Reconnect the vacuum pipe to the throttle

damper.

28Reconnect the air cleaner vacuum hose to

the inlet manifold, and reconnect the air

change temperature sensor wiring plug, then

place the air cleaner to one side to allow

access to the throttle damper.

29Reconnect the battery negative lead.

30Connect a tachometer to the engine in

accordance with the manufacturer’s

instructions.

31Start the engine, then check and if

necessary adjust the idle speed and mixture.

32Earth the “service adjustment” lead,

located in the battery negative wiring loom

(see illustration), for a minimum of 10

seconds. The throttle damper actuating arm

should move to the fully retracted position,

raising the engine speed.

33The engine speed should stabilise at 1700

±100 rpm. If adjustment is necessary, turn

the adjusting screw on the end of the throttle

damper actuating arm to give the correct

speed. Turn the screw clockwise to increase

the engine speed, or anti-clockwise to reduce

the engine speed.34On completion of adjustment, stop the

engine and disconnect the tachometer.

35Where necessary, ensure that any

tamperproof seals are refitted, then refit the

air cleaner, ensuring that the vacuum hose is

securely connected. Isolate the “service

adjustment” lead.

36Start the engine and check that normal

idle speed is resumed, then stop the engine.

Note:Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

Engine coolant temperature

sensor

2.0 litre SOHC fuel injection models

1For details of engine coolant temperature

sensor removal and refitting, refer to the

Section appertaining to the ESC II system.

1.6 and 1.8 litre (R6A type) CVH models

2The sensor is located in the side of the inlet

manifold.

3Disconnect the battery negative lead.

4Partially drain the cooling system.

5Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

6Unscrew the sensor from the inlet manifold

and remove it.

7Refitting is a reversal of removal. Refill the

cooling system.

2.0 litre DOHC fuel injection models

8The sensor is located in the side of the inlet

manifold, behind the throttle body. The

removal and refitting procedure is as

described for the 1.6 and 1.8 litre (R6A type)

CVH models above.

Crankshaft speed/position sensor

1.6 and 1.8 litre (R6A type) CVH

models

1.6 litre

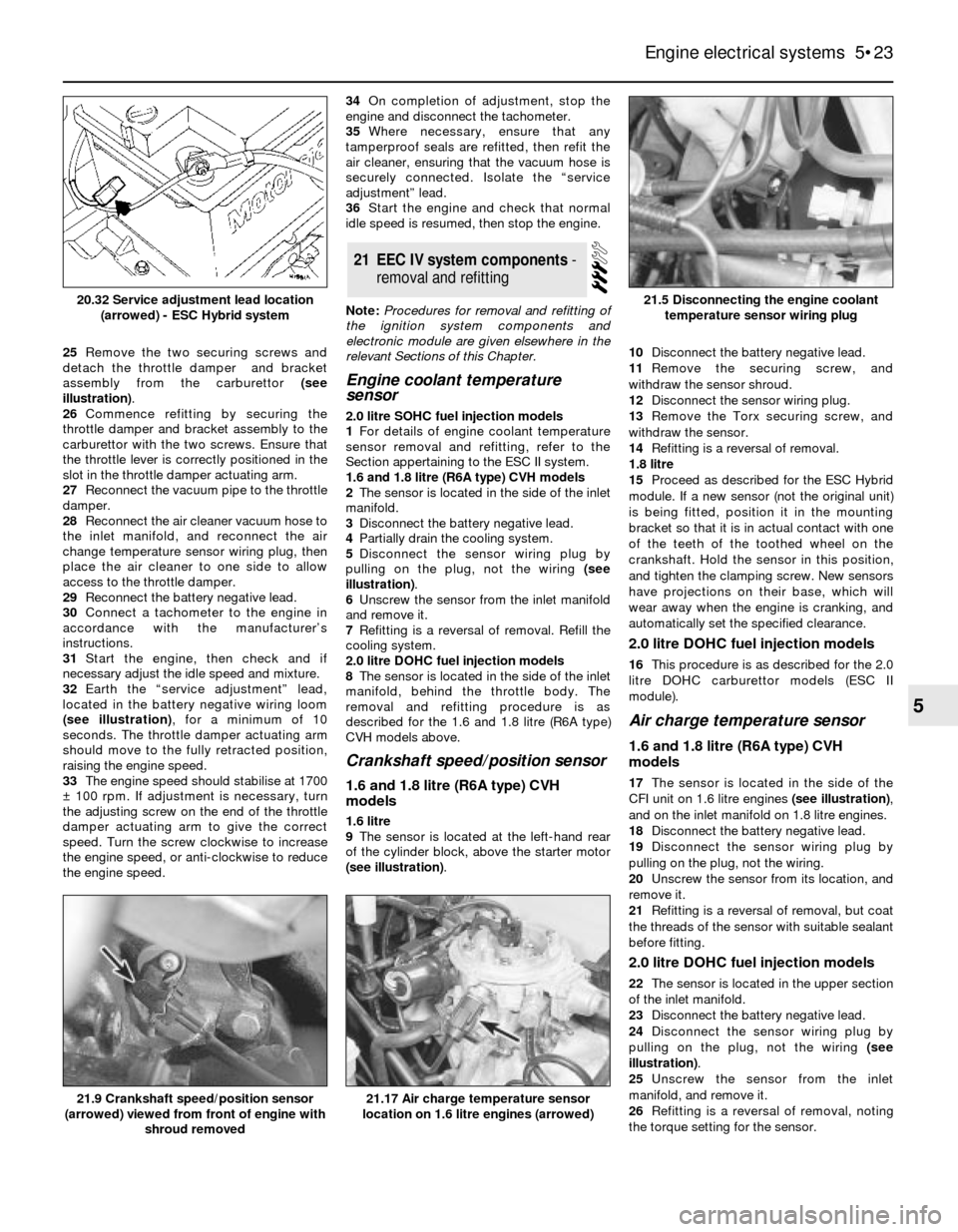

9The sensor is located at the left-hand rear

of the cylinder block, above the starter motor

(see illustration).10Disconnect the battery negative lead.

11Remove the securing screw, and

withdraw the sensor shroud.

12Disconnect the sensor wiring plug.

13Remove the Torx securing screw, and

withdraw the sensor.

14Refitting is a reversal of removal.

1.8 litre

15Proceed as described for the ESC Hybrid

module. If a new sensor (not the original unit)

is being fitted, position it in the mounting

bracket so that it is in actual contact with one

of the teeth of the toothed wheel on the

crankshaft. Hold the sensor in this position,

and tighten the clamping screw. New sensors

have projections on their base, which will

wear away when the engine is cranking, and

automatically set the specified clearance.

2.0 litre DOHC fuel injection models

16This procedure is as described for the 2.0

litre DOHC carburettor models (ESC II

module).

Air charge temperature sensor

1.6 and 1.8 litre (R6A type) CVH

models

17The sensor is located in the side of the

CFI unit on 1.6 litre engines (see illustration),

and on the inlet manifold on 1.8 litre engines.

18Disconnect the battery negative lead.

19Disconnect the sensor wiring plug by

pulling on the plug, not the wiring.

20Unscrew the sensor from its location, and

remove it.

21Refitting is a reversal of removal, but coat

the threads of the sensor with suitable sealant

before fitting.

2.0 litre DOHC fuel injection models

22The sensor is located in the upper section

of the inlet manifold.

23Disconnect the battery negative lead.

24Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

25Unscrew the sensor from the inlet

manifold, and remove it.

26Refitting is a reversal of removal, noting

the torque setting for the sensor.

21EEC IV system components -

removaland refitting

Engine electrical systems 5•23

5

21.9 Crankshaft speed/position sensor

(arrowed) viewed from front of engine with

shroud removed21.17 Air charge temperature sensor

location on 1.6 litre engines (arrowed)

21.5 Disconnecting the engine coolant

temperature sensor wiring plug20.32 Service adjustment lead location

(arrowed) - ESC Hybrid system