alternator belt FORD SIERRA 1991 2.G Cooling And Air Conditioning Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: SIERRA, Model: FORD SIERRA 1991 2.GPages: 12, PDF Size: 0.62 MB

Page 1 of 12

System type

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressurised, with belt-driven coolant pump, crossflow radiator,

thermo-viscous fan, thermostat, and expansion tank

CVH and DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressurised, with belt-driven coolant pump, crossflow radiator,

electric fan, thermostat, and expansion tank

Thermostat

Nominal temperature rating (fully open):

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88ºC (190º F)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100ºC (212ºF)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102ºC (216ºF)

Opening temperature:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88ºC (190ºF)

CVH (R6A type) models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 to 89ºC (185 to 192ºF)

Expansion tank cap opening pressure

SOHC models:

Up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.85 to 1.1 bar (12 to 16 lbf/in2)

From 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.25 bar (15 to 18 lbf/in2)

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.25 bar (15 to 18 lbf/in2)

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 to 1.4 bar (15 to 20 lbf/in2)

Coolant mixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

System capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 1 Specifications

Drivebelt tensions

Air conditioning system compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.4 in) deflection at the midpoint of the belt’s longest run

under firm thumb pressure

Coolant pump/alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.0 mm (0.4 in) deflection midway between coolant pump and

alternator (or power steering pump) pulleys under firm thumb pressure

Chapter 3

Cooling, heating and air conditioning systems

Air conditioning system - component renewal . . . . . . . . . . . . . . . . . .21

Coolant pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .9

Coolant pump/alternator drivebelt(s) - checking, renewal and

tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Coolant pump/alternator drivebelt tensioner (DOHC models with

power steering) - removal and refitting . . . . . . . . . . . . . . . . . . . . . .11

Cooling fan switch - removal and refitting . . . . . . . . . . . . . . . . . . . . .14

Cooling system - draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Cooling system - filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cooling system - flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electric cooling fan - removal and refitting . . . . . . . . . . . . . . . . . . . . .13

Expansion tank and coolant level sensor - removal and refitting . . . .15General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . . .1

Heater controls - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .17

Heater motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .20

Heater unit - overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Heater unit - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Radiator - inspection and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Radiator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Temperature gauge sender - removal and refitting . . . . . . . . . . . . . .16

Thermostat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Thermostat - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Thermo-viscous cooling fan (SOHC models) - removal and refitting .12

3•1

Specifications Contents3

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 2 of 12

Torque wrench settingsNmlbf ft

Radiator upper mounting nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2515 to 18

Radiator lower mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Coolant pump bolts:

SOHC models:

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

M10 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4226 to 31

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

CVH (R6A type) models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 21

Thermostat housing bolts:

SOHC/DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2013 to 15

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

CVH (R6A type) models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 126 to 9

Cooling fan shroud-to-radiator nuts/bolts . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Coolant pump pulley bolts:

SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 21

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Coolant pump/alternator drivebelt tensioner bolt:

CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 3017 to 22

DOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 9752 to 72

Cooling fan blades-to-fan hub bolts (SOHC models) . . . . . . . . . . . . . . .8 to 106 to 7

Air conditioning compressor-to-bracket bolts . . . . . . . . . . . . . . . . . . . .65 to 7548 to 55

Air conditioning compressor bracket-to-engine bolts:

M10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 to 9263 to 68

M12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110 to 12081 to 89

Air conditioning condenser fan assembly-to-condenser bolts:

Models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 to 31 to 2

Models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Air conditioning condenser securing bolts (models from 1987) . . . . . . .27 to 3320 to 24

General information

The cooling system is of pressurised type,

and consists of a front mounted radiator,

coolant pump, cooling fan, wax type

thermostat, and an expansion tank.

The radiator matrix is manufactured from

honeycombed metal, and the end tanks are

made of plastic. On automatic transmission

models, the right-hand end tank incorporates

the transmission fluid cooler.

The coolant pump is located on the front

face of the engine block, and is belt-driven.

The pump is of the impeller type.

The cooling fan draws cold air over the

radiator matrix to assist the cooling process

when the forward speed of the vehicle is too

low to provide sufficient cooling airflow, or the

ambient temperature is unusually high. SOHC

models have a thermo-viscous fan, whereas

CVH and DOHC models have an

electrically-operated fan.

The thermo-viscous fan is controlled by the

temperature of the air behind the radiator.

When the air temperature reaches a

predetermined level, a bi-metallic coil

commences to open a valve within the unit,

and silicon fluid is fed through a system of

vanes. Half the vanes are driven directly by

the coolant pump, and the remaining half are

connected to the fan blades. The vanes are

arranged so that drive is transmitted to the fan

blades in relation to the viscosity of the silicon

fluid, and this in turn depends on ambienttemperature and engine speed. The fan is

therefore only operating when required, and

compared with direct-drive type fans

represents a considerable improvement in fuel

economy, drivebelt wear and fan noise.

The electrically-operated fan is switched on

by a temperature sensor mounted in the

thermostat housing when the temperature

reaches a predetermined level. The fan is

therefore only operating when required, and like

the thermo-viscous fan, offers a considerable

advantage over direct-drive type fans.

A thermostat is fitted. Its purpose is to

ensure rapid engine warm-up by restricting

the flow of coolant to the engine when cold

and also to assist in regulating the normal

operating temperature of the engine.

The expansion tank incorporates a pressure

cap which effectively pressurises the cooling

system as the coolant temperature rises,

thereby increasing the boiling point of the

coolant. The tank also has a further degas

function. Any accumulation of air bubbles in the

coolant is returned to the tank and released in

the air space, thus maintaining the efficiency of

the coolant. The pressure cap also incorporates

a vacuum relief valve which prevents a vacuum

forming in the system as it cools.

The system functions as follows. Cold

coolant in the bottom of the radiator circulates

through the bottom hose to the coolant pump

where the pump impeller pushes the coolant

through the passages within the cylinder

block, cylinder head and inlet manifold. After

cooling the cylinder bores, combustion

chambers and valve seats, the coolant

reaches the underside of the thermostat

which is initially closed. A small proportion ofthe coolant passes from the thermostat

housing to the expansion tank, but the main

circulation is through the inlet manifold,

automatic choke (where applicable), and

heater matrix, finally returning to the coolant

pump. When the coolant reaches a

predetermined temperature, the thermostat

opens and hot water passes through the top

hose to the top of the radiator. As the coolant

circulates through the radiator, it is cooled by

the flow of air to the vehicle’s forward motion,

supplemented by the action of the cooling fan

where necessary. By the time it reaches the

bottom of the radiator the coolant is cooled,

and the cycle is repeated. Circulation of

coolant continues through the expansion

tank, inlet manifold, automatic choke (where

applicable) and heater at all times, the heater

temperature being controlled by an air flap.

An air conditioning system is available as

an optional extra on certain models. In

conjunction with the heater, the system

enables any reasonable air temperature to be

achieved inside the vehicle; it also reduces

the humidity of the incoming air, aiding

demisting even when cooling is not required.

The refrigeration side of the air conditioning

system functions in a similar way to a

domestic refrigerator. A compressor, belt-

driven from the crankshaft pulley, draws

refrigerant in its gaseous phase from an

evaporator. The compressed refrigerant

passes through a condenser where it loses

heat and enters its liquid phase. After passing

through the dehydrator, which acts as a

reservoir and filter to extract moisture from

the circuit, the refrigerant returns to the

evaporator where it absorbs heat from the air

1General information and

precautions

3•2Cooling, heating and air conditioning systems

Page 6 of 12

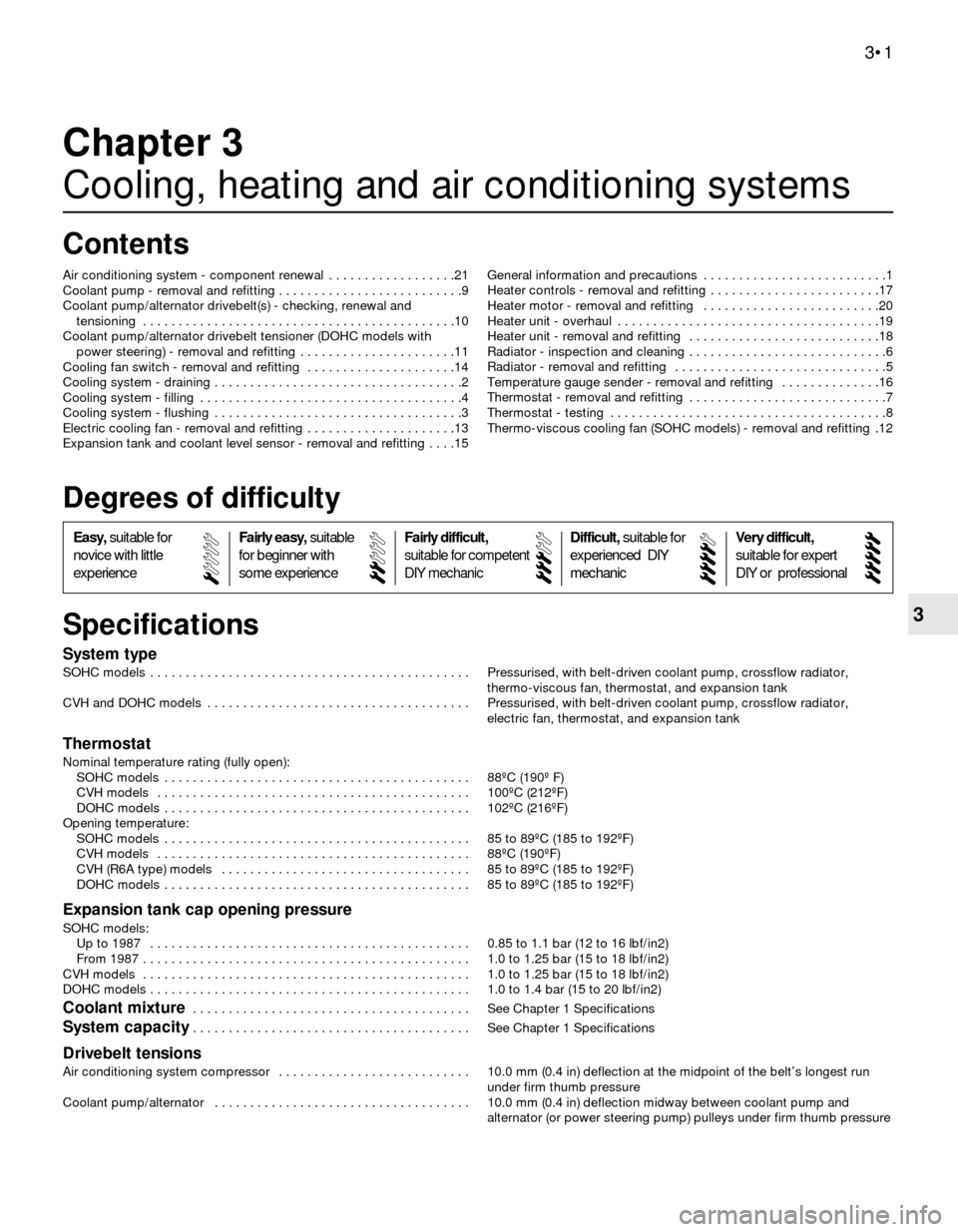

8Unscrew the three retaining bolts and

remove the coolant pump and gasket from the

front of the cylinder block. Note that on

certain models, the alternator adjusting link is

secured by the right-hand retaining bolt (see

illustration).

9If the coolant pump is faulty, it must be

renewed, as it is not possible to obtain

individual components.

10Before refitting, clean the mating faces of

the coolant pump and cylinder block.

11Refitting is a reversal of removal, bearing

in mind the following points.

12Use a new gasket, and tighten the

retaining bolts to the specified torque.

13Before fitting the coolant pump pulley,

ensure that the timing belt cover support bolt

is located in its hole in the pump.14Refill the cooling system.

CVH models

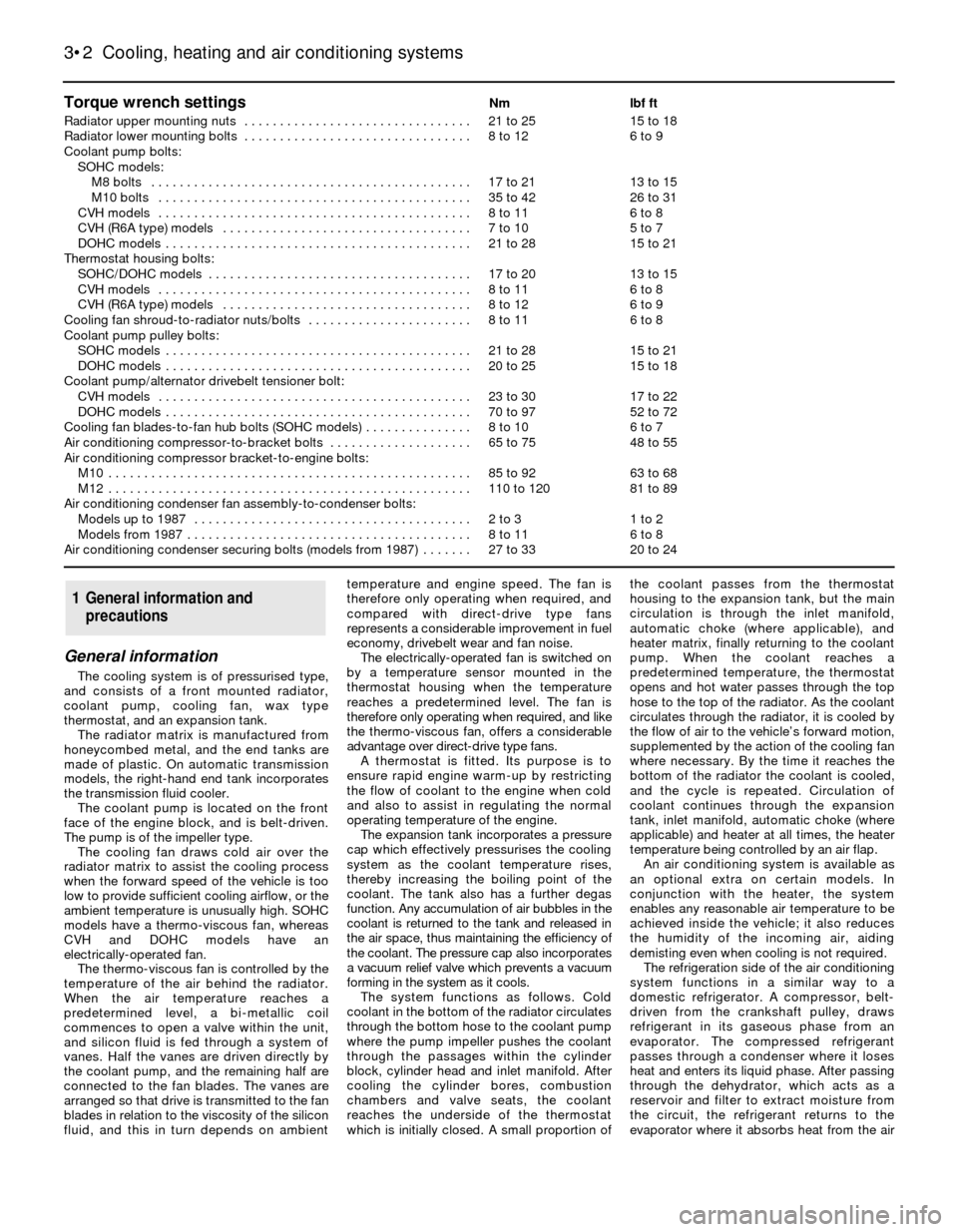

15Unscrew the two securing nuts, and

disconnect the coolant elbow from the

left-hand side of the coolant pump (see

illustration).

16Remove the timing belt.

17Unscrew the camshaft sprocket bolt and

withdraw the distributor drive sleeve.

18Screw the camshaft sprocket bolt part

way back into the end of the camshaft, and

using a suitable puller, pull the sprocket from

the camshaft.

19Remove the plastic rear timing belt cover.

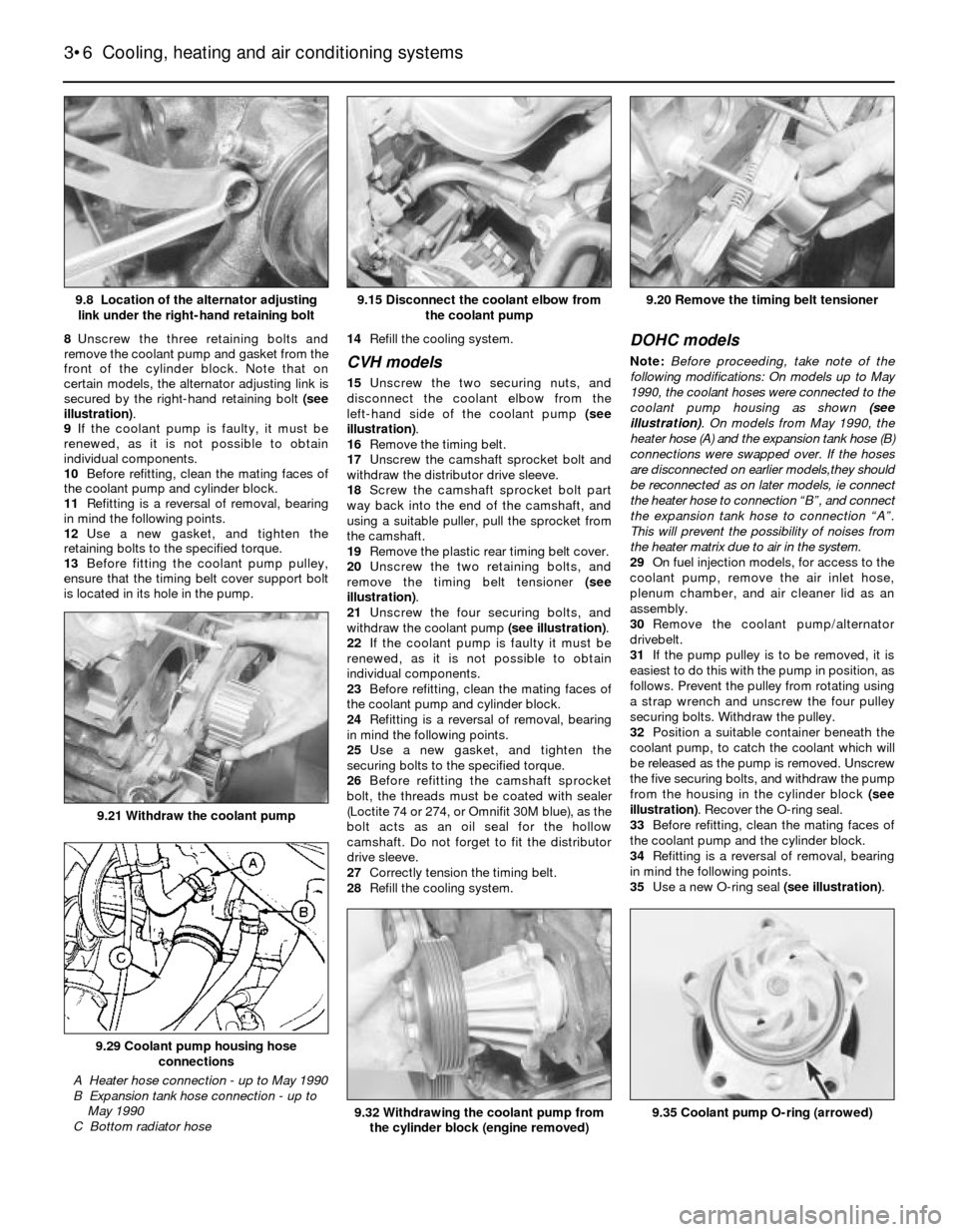

20Unscrew the two retaining bolts, and

remove the timing belt tensioner (see

illustration).

21Unscrew the four securing bolts, and

withdraw the coolant pump (see illustration).

22If the coolant pump is faulty it must be

renewed, as it is not possible to obtain

individual components.

23Before refitting, clean the mating faces of

the coolant pump and cylinder block.

24Refitting is a reversal of removal, bearing

in mind the following points.

25Use a new gasket, and tighten the

securing bolts to the specified torque.

26Before refitting the camshaft sprocket

bolt, the threads must be coated with sealer

(Loctite 74 or 274, or Omnifit 30M blue), as the

bolt acts as an oil seal for the hollow

camshaft. Do not forget to fit the distributor

drive sleeve.

27Correctly tension the timing belt.

28Refill the cooling system.

DOHC models

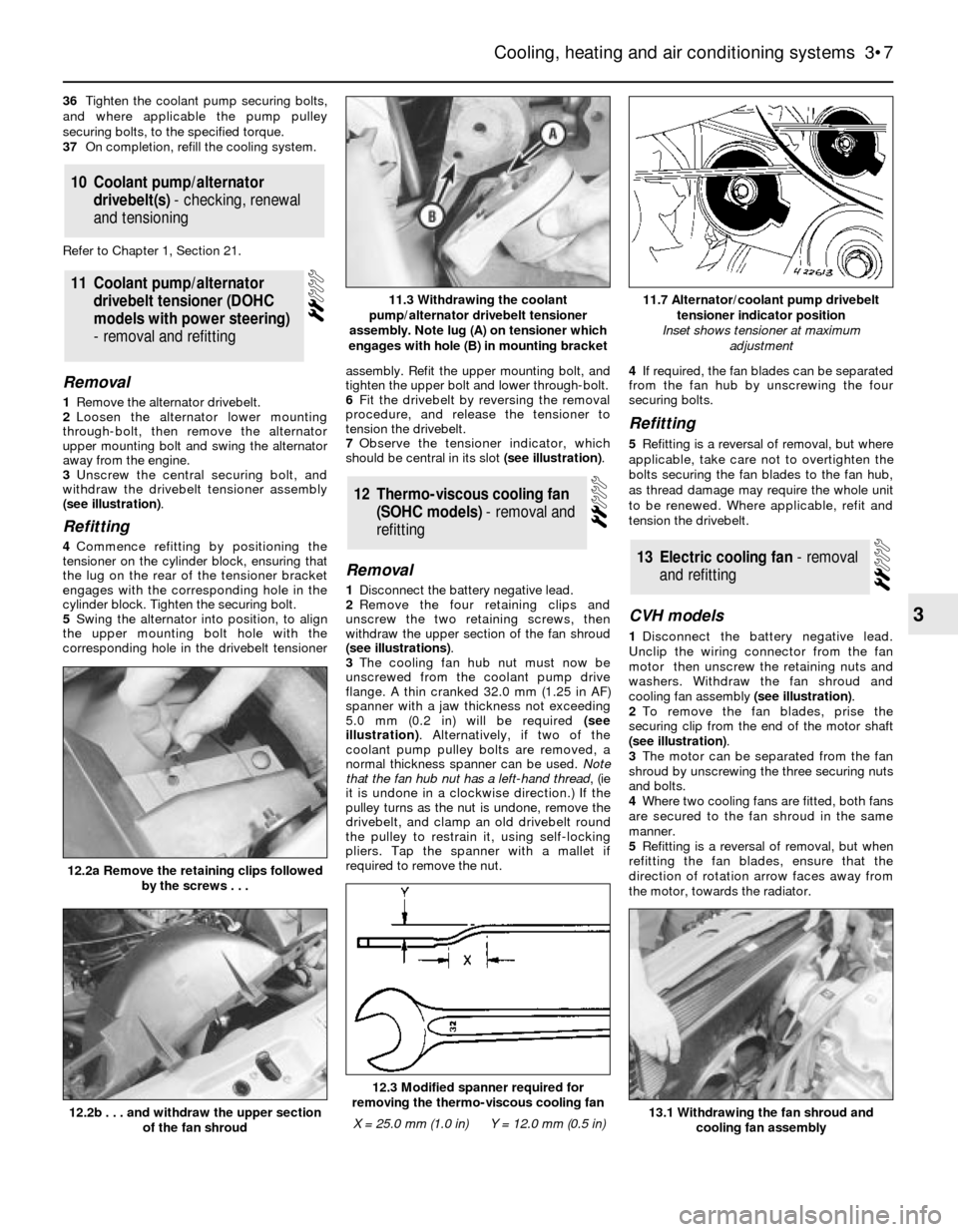

Note:Before proceeding, take note of the

following modifications: On models up to May

1990, the coolant hoses were connected to the

coolant pump housing as shown (see

illustration). On models from May 1990, the

heater hose (A) and the expansion tank hose (B)

connections were swapped over. If the hoses

are disconnected on earlier models,they should

be reconnected as on later models, ie connect

the heater hose to connection “B”, and connect

the expansion tank hose to connection “A”.

This will prevent the possibility of noises from

the heater matrix due to air in the system.

29On fuel injection models, for access to the

coolant pump, remove the air inlet hose,

plenum chamber, and air cleaner lid as an

assembly.

30Remove the coolant pump/alternator

drivebelt.

31If the pump pulley is to be removed, it is

easiest to do this with the pump in position, as

follows. Prevent the pulley from rotating using

a strap wrench and unscrew the four pulley

securing bolts. Withdraw the pulley.

32Position a suitable container beneath the

coolant pump, to catch the coolant which will

be released as the pump is removed. Unscrew

the five securing bolts, and withdraw the pump

from the housing in the cylinder block (see

illustration). Recover the O-ring seal.

33Before refitting, clean the mating faces of

the coolant pump and the cylinder block.

34Refitting is a reversal of removal, bearing

in mind the following points.

35Use a new O-ring seal (see illustration).

3•6Cooling, heating and air conditioning systems

9.8 Location of the alternator adjusting

link under the right-hand retaining bolt9.20 Remove the timing belt tensioner

9.35 Coolant pump O-ring (arrowed)9.32 Withdrawing the coolant pump from

the cylinder block (engine removed)

9.29 Coolant pump housing hose

connections

A Heater hose connection - up to May 1990

B Expansion tank hose connection - up to

May 1990

C Bottom radiator hose

9.21 Withdraw the coolant pump

9.15 Disconnect the coolant elbow from

the coolant pump

Page 7 of 12

36Tighten the coolant pump securing bolts,

and where applicable the pump pulley

securing bolts, to the specified torque.

37On completion, refill the cooling system.

Refer to Chapter 1, Section 21.

Removal

1Remove the alternator drivebelt.

2Loosen the alternator lower mounting

through-bolt, then remove the alternator

upper mounting bolt and swing the alternator

away from the engine.

3Unscrew the central securing bolt, and

withdraw the drivebelt tensioner assembly

(see illustration).

Refitting

4Commence refitting by positioning the

tensioner on the cylinder block, ensuring that

the lug on the rear of the tensioner bracket

engages with the corresponding hole in the

cylinder block. Tighten the securing bolt.

5Swing the alternator into position, to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensionerassembly. Refit the upper mounting bolt, and

tighten the upper bolt and lower through-bolt.

6Fit the drivebelt by reversing the removal

procedure, and release the tensioner to

tension the drivebelt.

7Observe the tensioner indicator, which

should be central in its slot (see illustration).

Removal

1Disconnect the battery negative lead.

2Remove the four retaining clips and

unscrew the two retaining screws, then

withdraw the upper section of the fan shroud

(see illustrations).

3The cooling fan hub nut must now be

unscrewed from the coolant pump drive

flange. A thin cranked 32.0 mm (1.25 in AF)

spanner with a jaw thickness not exceeding

5.0 mm (0.2 in) will be required (see

illustration). Alternatively, if two of the

coolant pump pulley bolts are removed, a

normal thickness spanner can be used.Note

that the fan hub nut has a left-hand thread, (ie

it is undone in a clockwise direction.) If the

pulley turns as the nut is undone, remove the

drivebelt, and clamp an old drivebelt round

the pulley to restrain it, using self-locking

pliers. Tap the spanner with a mallet if

required to remove the nut.4If required, the fan blades can be separated

from the fan hub by unscrewing the four

securing bolts.

Refitting

5Refitting is a reversal of removal, but where

applicable, take care not to overtighten the

bolts securing the fan blades to the fan hub,

as thread damage may require the whole unit

to be renewed. Where applicable, refit and

tension the drivebelt.

CVH models

1Disconnect the battery negative lead.

Unclip the wiring connector from the fan

motor then unscrew the retaining nuts and

washers. Withdraw the fan shroud and

cooling fan assembly (see illustration).

2To remove the fan blades, prise the

securing clip from the end of the motor shaft

(see illustration).

3The motor can be separated from the fan

shroud by unscrewing the three securing nuts

and bolts.

4Where two cooling fans are fitted, both fans

are secured to the fan shroud in the same

manner.

5Refitting is a reversal of removal, but when

refitting the fan blades, ensure that the

direction of rotation arrow faces away from

the motor, towards the radiator.

13Electric cooling fan -removal

andrefitting

12Thermo-viscous cooling fan

(SOHC models) - removal and

refitting

11Coolant pump/alternator

drivebelt tensioner (DOHC

models with power steering)

- removal and refitting

10Coolant pump/alternator

drivebelt(s) - checking, renewal

and tensioning

Cooling, heating and air conditioning systems 3•7

3

12.2a Remove the retaining clips followed

by the screws . . .

13.1 Withdrawing the fan shroud and

cooling fan assembly

12.3 Modified spanner required for

removing the thermo-viscous cooling fan

X = 25.0 mm (1.0 in)Y = 12.0 mm (0.5 in)12.2b . . . and withdraw the upper section

of the fan shroud

11.7 Alternator/coolant pump drivebelt

tensioner indicator position

Inset shows tensioner at maximum

adjustment11.3 Withdrawing the coolant

pump/alternator drivebelt tensioner

assembly. Note lug (A) on tensioner which

engages with hole (B) in mounting bracket