low oil pressure FORD SIERRA 1991 2.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: SIERRA, Model: FORD SIERRA 1991 2.GPages: 26, PDF Size: 0.57 MB

Page 5 of 26

Introduction

A selection of good tools is a fundamental

requirement for anyone contemplating the

maintenance and repair of a motor vehicle.

For the owner who does not possess any,

their purchase will prove a considerable

expense, offsetting some of the savings made

by doing-it-yourself. However, provided that

the tools purchased meet the relevant national

safety standards and are of good quality, they

will last for many years and prove an

extremely worthwhile investment.

To help the average owner to decide which

tools are needed to carry out the various tasks

detailed in this manual, we have compiled

three lists of tools under the following

headings: Maintenance and minor repair,

Repair and overhaul, and Special. Newcomers

to practical mechanics should start off with

the Maintenance and minor repairtool kit, and

confine themselves to the simpler jobs around

the vehicle. Then, as confidence and

experience grow, more difficult tasks can be

undertaken, with extra tools being purchased

as, and when, they are needed. In this way, a

Maintenance and minor repairtool kit can be

built up into a Repair and overhaultool kit over

a considerable period of time, without any

major cash outlays. The experienced do-it-

yourselfer will have a tool kit good enough for

most repair and overhaul procedures, and will

add tools from the Specialcategory when it is

felt that the expense is justified by the amount

of use to which these tools will be put.

Maintenance and minor repair

tool kit

The tools given in this list should be

considered as a minimum requirement if

routine maintenance, servicing and minor

repair operations are to be undertaken. We

recommend the purchase of combination

spanners (ring one end, open-ended the

other); although more expensive than open-

ended ones, they do give the advantages of

both types of spanner.

MCombination spanners:

Metric - 8, 9, 10, 11, 12, 13, 14, 15, 17 &

19 mm

MAdjustable spanner - 35 mm jaw (approx.)

MSpark plug spanner (with rubber insert)

MSpark plug gap adjustment tool

MSet of feeler blades

MBrake bleed nipple spanner

MScrewdrivers:

Flat blade - 100 mm long x 6 mm dia

Cross blade - 100 mm long x 6 mm dia

MCombination pliers

MHacksaw (junior)

MTyre pump

MTyre pressure gauge

MOil can

MOil filter removal tool

MFine emery cloth

MWire brush (small)

MFunnel (medium size)

Repair and overhaul tool kit

These tools are virtually essential for

anyone undertaking any major repairs to amotor vehicle, and are additional to those

given in the Maintenance and minor repairlist.

Included in this list is a comprehensive set of

sockets. Although these are expensive, they

will be found invaluable as they are so

versatile - particularly if various drives are

included in the set. We recommend the half-

inch square-drive type, as this can be used

with most proprietary torque wrenches. If you

cannot afford a socket set, even bought

piecemeal, then inexpensive tubular box

spanners are a useful alternative.

The tools in this list will occasionally need to

be supplemented by tools from the Special

list.

MSockets (or box spanners) to cover range in

previous list (including Torx sockets)

MReversible ratchet drive (for use with

sockets)

MExtension piece, 250 mm (for use with

sockets)

MUniversal joint (for use with sockets)

MTorque wrench (for use with sockets)

MSelf-locking grips

MBall pein hammer

MSoft-faced mallet (plastic/aluminium or

rubber)

MScrewdrivers:

Flat blade - long & sturdy, short (chubby),

and narrow (electricians) types

Cross blade - Long & sturdy, and short

(chubby) types

MPliers:

Long-nosed

Side cutters (electricians)

Circlip (internal and external)

MCold chisel - 25 mm

MScriber

MScraper

MCentre punch

MPin punch

MHacksaw

MBrake hose clamp

MBrake/clutch bleeding kit

MSelection of twist drills

MSteel rule/straight-edge

MAllen keys (inc. splined/Torx type)

MSelection of files

MWire brush

MAxle-stands

MJack (strong trolley or hydraulic type)

MLight with extension lead

Tools and working facilities REF•5

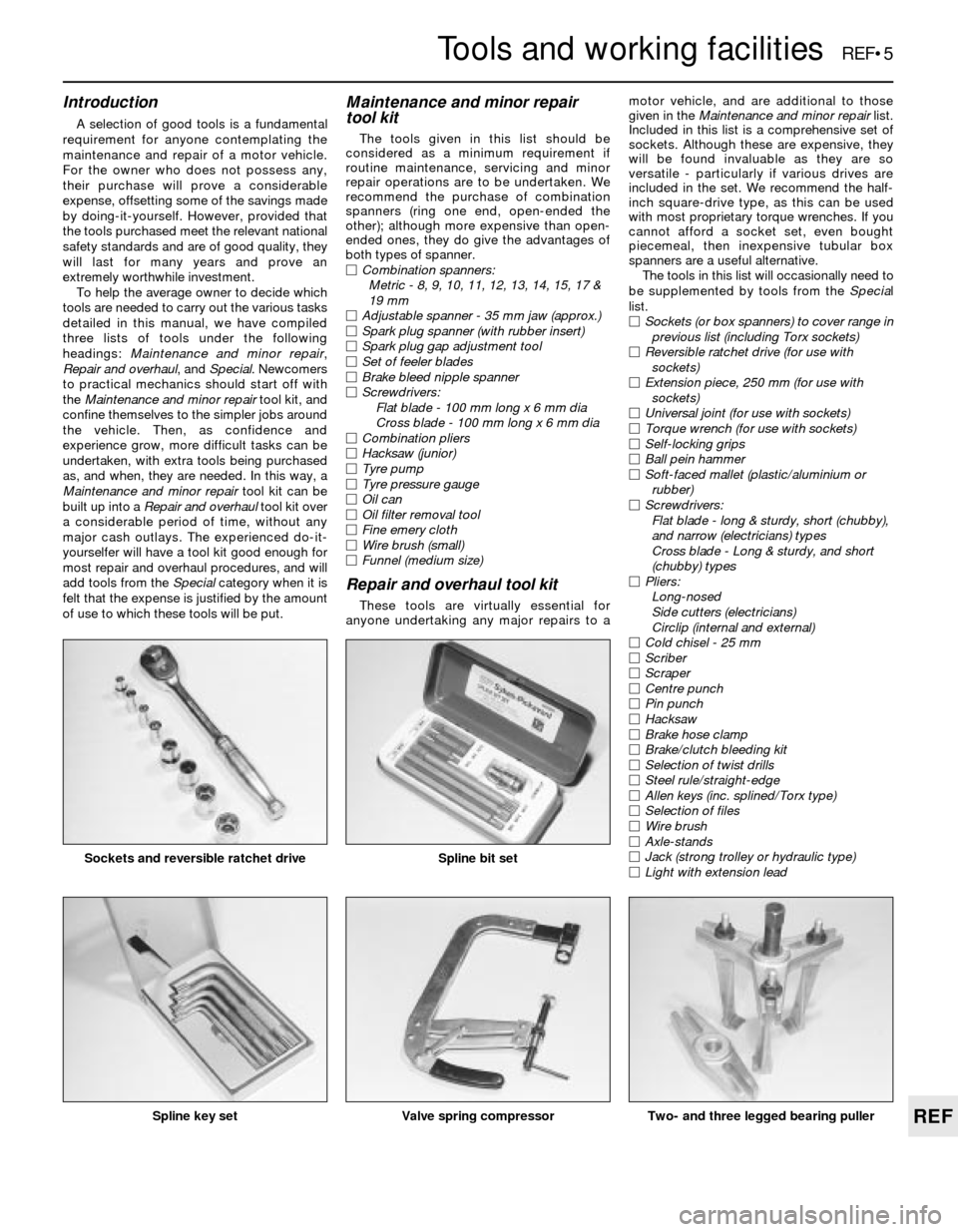

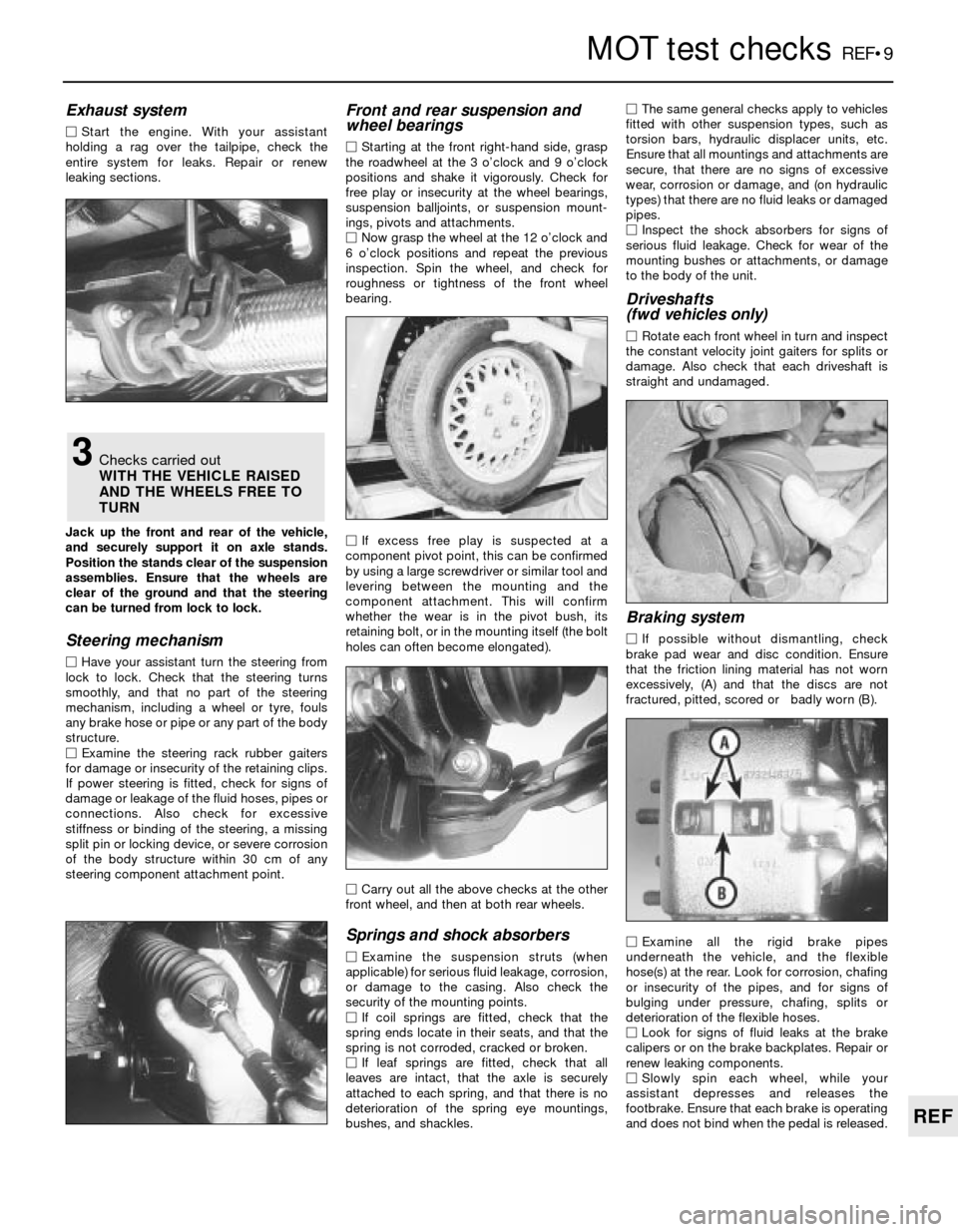

Sockets and reversible ratchet driveSpline bit set

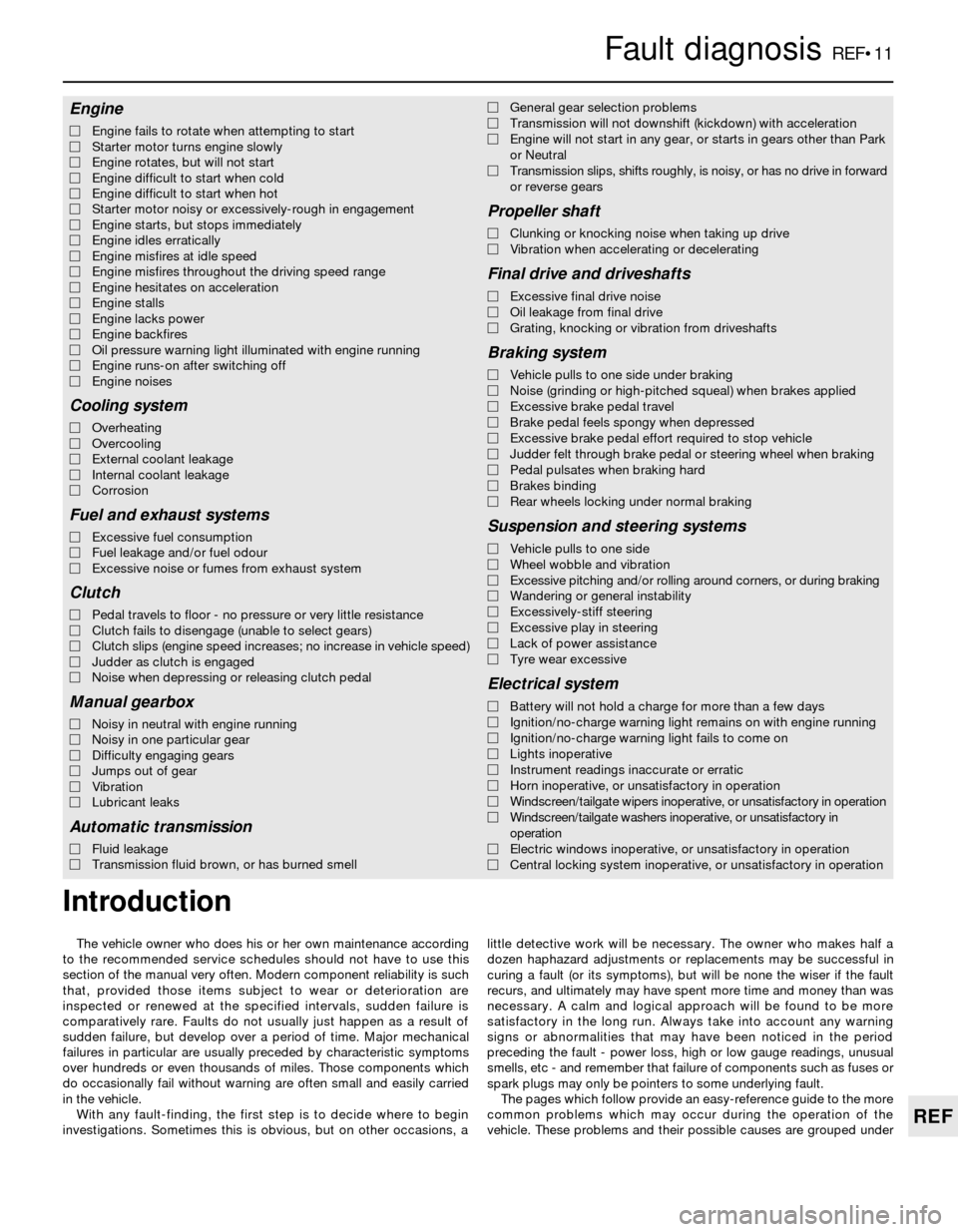

Spline key setValve spring compressorTwo- and three legged bearing pullerREF

Page 9 of 26

MOTtest checksREF•9

REF

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entire system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

MHave your assistant turn the steering from

lock to lock. Check that the steering turns

smoothly, and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

MExamine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stiffness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

MStarting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

free play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

MNow grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

roughness or tightness of the front wheel

bearing.

MIf excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

retaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

MCarry out all the above checks at the other

front wheel, and then at both rear wheels.

Springs and shock absorbers

MExamine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

MIf coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

MIf leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles.MThe same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensure that all mountings and attachments are

secure, that there are no signs of excessive

wear, corrosion or damage, and (on hydraulic

types) that there are no fluid leaks or damaged

pipes.

MInspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

MRotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

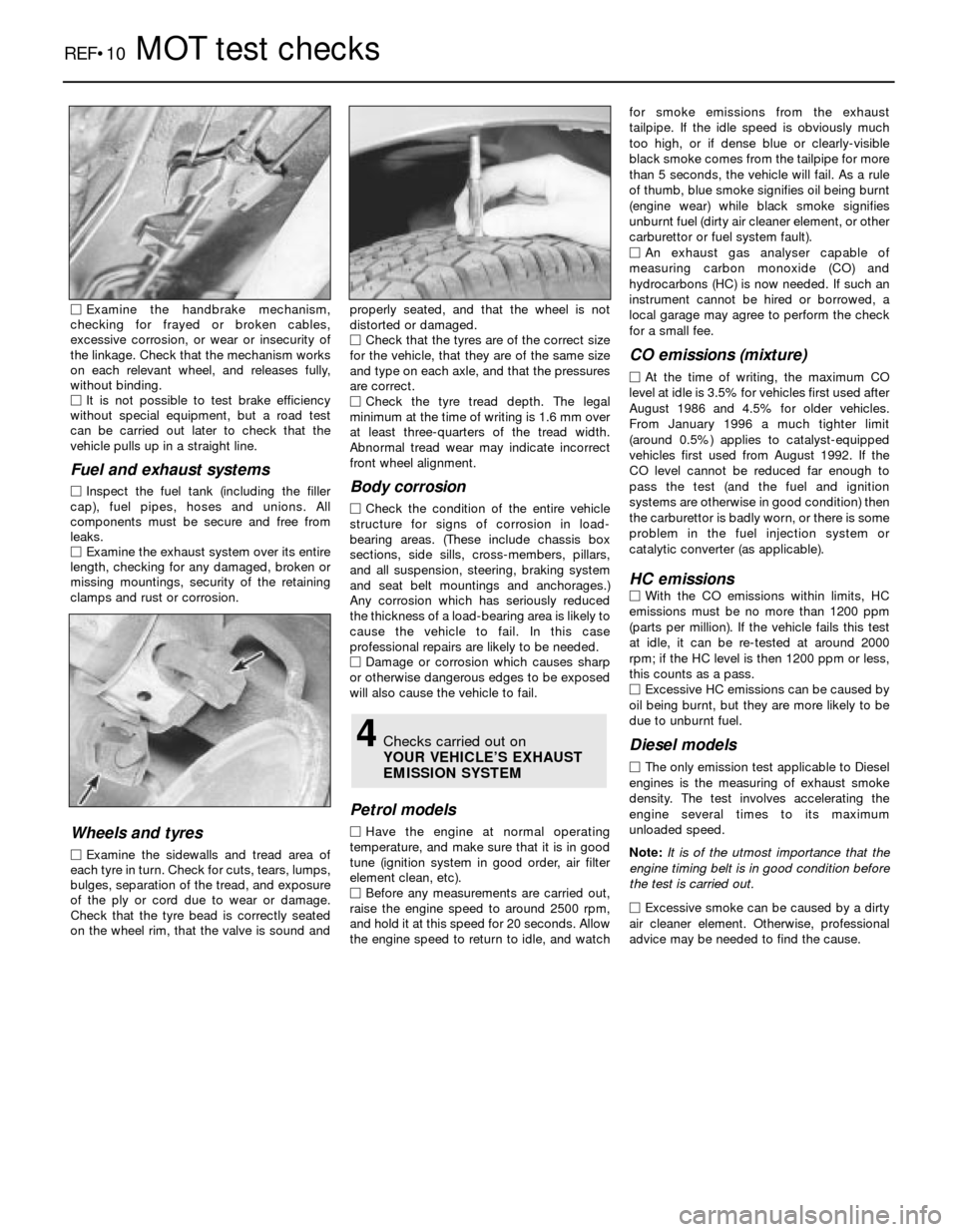

Braking system

MIf possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively, (A) and that the discs are not

fractured, pitted, scored or badly worn (B).

MExamine all the rigid brake pipes

underneath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

MLook for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

renew leaking components.

MSlowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

Page 10 of 26

REF•10MOTtest checks

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

MIt is not possible to test brake efficiency

without special equipment, but a road test

can be carried out later to check that the

vehicle pulls up in a straight line.

Fuel and exhaust systems

MInspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free from

leaks.

MExamine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

MExamine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound andproperly seated, and that the wheel is not

distorted or damaged.

MCheck that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressures

are correct.

MCheck the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

front wheel alignment.

Body corrosion

MCheck the condition of the entire vehicle

structure for signs of corrosion in load-

bearing areas. (These include chassis box

sections, side sills, cross-members, pillars,

and all suspension, steering, braking system

and seat belt mountings and anchorages.)

Any corrosion which has seriously reduced

the thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

professional repairs are likely to be needed.

MDamage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

MHave the engine at normal operating

temperature, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

MBefore any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allow

the engine speed to return to idle, and watchfor smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unburnt fuel (dirty air cleaner element, or other

carburettor or fuel system fault).

MAn exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydrocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

MAt the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

From January 1996 a much tighter limit

(around 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

problem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsMWith the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000

rpm; if the HC level is then 1200 ppm or less,

this counts as a pass.

MExcessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

MThe only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density. The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

Page 11 of 26

The vehicle owner who does his or her own maintenance according

to the recommended service schedules should not have to use this

section of the manual very often. Modern component reliability is such

that, provided those items subject to wear or deterioration are

inspected or renewed at the specified intervals, sudden failure is

comparatively rare. Faults do not usually just happen as a result of

sudden failure, but develop over a period of time. Major mechanical

failures in particular are usually preceded by characteristic symptoms

over hundreds or even thousands of miles. Those components which

do occasionally fail without warning are often small and easily carried

in the vehicle.

With any fault-finding, the first step is to decide where to begin

investigations. Sometimes this is obvious, but on other occasions, alittle detective work will be necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in

curing a fault (or its symptoms), but will be none the wiser if the fault

recurs, and ultimately may have spent more time and money than was

necessary. A calm and logical approach will be found to be more

satisfactory in the long run. Always take into account any warning

signs or abnormalities that may have been noticed in the period

preceding the fault - power loss, high or low gauge readings, unusual

smells, etc - and remember that failure of components such as fuses or

spark plugs may only be pointers to some underlying fault.

The pages which follow provide an easy-reference guide to the more

common problems which may occur during the operation of the

vehicle. These problems and their possible causes are grouped under

Fault diagnosisREF•11

REF

Engine

MEngine fails to rotate when attempting to start

MStarter motor turns engine slowly

MEngine rotates, but will not start

MEngine difficult to start when cold

MEngine difficult to start when hot

MStarter motor noisy or excessively-rough in engagement

MEngine starts, but stops immediately

MEngine idles erratically

MEngine misfires at idle speed

MEngine misfires throughout the driving speed range

MEngine hesitates on acceleration

MEngine stalls

MEngine lacks power

MEngine backfires

MOil pressure warning light illuminated with engine running

MEngine runs-on after switching off

MEngine noises

Cooling system

MOverheating

MOvercooling

MExternal coolant leakage

MInternal coolant leakage

MCorrosion

Fuel and exhaust systems

MExcessive fuel consumption

MFuel leakage and/or fuel odour

MExcessive noise or fumes from exhaust system

Clutch

MPedal travels to floor - no pressure or very little resistance

MClutch fails to disengage (unable to select gears)

MClutch slips (engine speed increases; no increase in vehicle speed)

MJudder as clutch is engaged

MNoise when depressing or releasing clutch pedal

Manual gearbox

MNoisy in neutral with engine running

MNoisy in one particular gear

MDifficulty engaging gears

MJumps out of gear

MVibration

MLubricant leaks

Automatic transmission

MFluid leakage

MTransmission fluid brown, or has burned smellMGeneral gear selection problems

MTransmission will not downshift (kickdown) with acceleration

MEngine will not start in any gear, or starts in gears other than Park

or Neutral

MTransmission slips, shifts roughly, is noisy, or has no drive in forward

or reverse gears

Propeller shaft

MClunking or knocking noise when taking up drive

MVibration when accelerating or decelerating

Final drive and driveshafts

MExcessive final drive noise

MOil leakage from final drive

MGrating, knocking or vibration from driveshafts

Braking system

MVehicle pulls to one side under braking

MNoise (grinding or high-pitched squeal) when brakes applied

MExcessive brake pedal travel

MBrake pedal feels spongy when depressed

MExcessive brake pedal effort required to stop vehicle

MJudder felt through brake pedal or steering wheel when braking

MPedal pulsates when braking hard

MBrakes binding

MRear wheels locking under normal braking

Suspension and steering systems

MVehicle pulls to one side

MWheel wobble and vibration

MExcessive pitching and/or rolling around corners, or during braking

MWandering or general instability

MExcessively-stiff steering

MExcessive play in steering

MLack of power assistance

MTyre wear excessive

Electrical system

MBattery will not hold a charge for more than a few days

MIgnition/no-charge warning light remains on with engine running

MIgnition/no-charge warning light fails to come on

MLights inoperative

MInstrument readings inaccurate or erratic

MHorn inoperative, or unsatisfactory in operation

MWindscreen/tailgate wipers inoperative, or unsatisfactory in operation

MWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

MElectric windows inoperative, or unsatisfactory in operation

MCentral locking system inoperative, or unsatisfactory in operation

Introduction

Page 12 of 26

headings denoting various components or systems, such as Engine,

Cooling system, etc. The Chapter and/or Section which deals with the

problem is also shown in brackets. Whatever the fault, certain basic

principles apply. These are as follows:

Verify the fault. This is simply a matter of being sure that you know

what the symptoms are before starting work. This is particularly

important if you are investigating a fault for someone else, who may

not have described it very accurately.

Don’t overlook the obvious. For example, if the vehicle won’t start, is

there fuel in the tank? (Don’t take anyone else’s word on this particular

point, and don’t trust the fuel gauge either!) If an electrical fault is

indicated, look for loose or broken wires before digging out the test

gear.Cure the disease, not the symptom. Substituting a flat battery with a

fully-charged one will get you off the hard shoulder, but if the

underlying cause is not attended to, the new battery will go the same

way. Similarly, changing oil-fouled spark plugs for a new set will get

you moving again, but remember that the reason for the fouling (if it

wasn’t simply an incorrect grade of plug) will have to be established

and corrected.

Don’t take anything for granted. Particularly, don’t forget that a

“new” component may itself be defective (especially if it’s been rattling

around in the boot for months), and don’t leave components out of a

fault diagnosis sequence just because they are new or recently-fitted.

When you do finally diagnose a difficult fault, you’ll probably realise

that all the evidence was there from the start.

Engine fails to rotate when attempting to start

MBattery terminal connections loose or corroded (Chapter 1).

MBattery discharged or faulty (Chapter 5).

MBroken, loose or disconnected wiring in the starting circuit (Chapter 5).

MDefective starter solenoid or switch (Chapter 5).

MDefective starter motor (Chapter 5).

MStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

MEngine earth strap broken or disconnected.

Starter motor turns engine slowly

MPartially-discharged battery (recharge, use jump leads, or push start)

(Chapter 5).

MBattery terminals loose or corroded (Chapter 1).

MBattery earth to body defective (Chapter 5).

MEngine earth strap loose.

MStarter motor (or solenoid) wiring loose (Chapter 5).

MStarter motor internal fault (Chapter 5).

Engine rotates, but will not start

MFuel pump inertia switch tripped (electric pump) (Chapter 4).

MFuel tank empty.

MBattery discharged (engine rotates slowly) (Chapter 5).

MBattery terminal connections loose or corroded (Chapter 1).

MIgnition components damp or damaged (Chapters 1 and 5).

MBroken, loose or disconnected wiring in the ignition circuit (Chapters 1

and 5).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MFuel injection system fault (Chapter 4).

MMajor mechanical failure (eg broken timing chain) (Chapter 2).

Engine difficult to start when cold

MBattery discharged (Chapter 5).

MBattery terminal connections loose or corroded (Chapter 1).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MFuel injection system fault (Chapter 4).

MOther ignition system fault (Chapters 1 and 5).

MLow cylinder compressions (Chapter 2).

Engine difficult to start when hot

MAir filter element dirty or clogged (Chapter 1).

MFuel injection system fault (Chapter 4).

MLow cylinder compressions (Chapter 2).

Starter motor noisy or excessively-rough in

engagement

MStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

MStarter motor mounting bolts loose or missing (Chapter 5).

MStarter motor internal components worn or damaged (Chapter 5).

Engine starts, but stops immediately

MLoose or faulty electrical connections in the ignition circuit

(Chapters 1 and 5).

MVacuum leak at the throttle body or inlet manifold (Chapter 4).

MFuel injection system fault (Chapter 4).

Engine idles erratically

MIncorrectly-adjusted idle speed (Chapter 4).

MAir filter element clogged (Chapter 1).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MUneven or low cylinder compressions (Chapter 2).

MCamshaft lobes worn (Chapter 2).

MFuel injection system fault (Chapter 4).

Engine misfires at idle speed

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MFaulty spark plug HT leads (Chapter 5).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

MDistributor cap cracked or tracking internally, where applicable

(Chapter 5).

MUneven or low cylinder compressions (Chapter 2).

MDisconnected, leaking, or perished crankcase ventilation hoses

(Chapter 4).

Engine misfires throughout the driving speed range

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MFaulty spark plug HT leads (Chapter 5).

MDistributor cap cracked or tracking internally, where applicable

(Chapter 5).

MFaulty ignition coil (Chapter 5).

MUneven or low cylinder compressions (Chapter 2).

MFuel injection system fault (Chapter 4).

Engine hesitates on acceleration

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

Engine stalls

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

REF•12Fault diagnosis

Engine

Page 13 of 26

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

MFuel injection system fault (Chapter 4).

Engine lacks power

MFuel filter choked (Chapter 1).

MFuel pump faulty, or delivery pressure low (Chapter 4).

MUneven or low cylinder compressions (Chapter 2).

MWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

MBrakes binding (Chapters 1 and 10).

MClutch slipping (Chapter 6).

Engine backfires

MVacuum leak at the throttle body, inlet manifold or associated

hoses (Chapter 4).

MFuel injection system fault (Chapter 4).

Oil pressure warning light illuminated with engine

running

MLow oil level, or incorrect oil grade (Chapter 1).

MFaulty oil pressure sensor (Chapter 2).

MWorn engine bearings and/or oil pump (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

MOil pressure relief valve defective (Chapter 2).

MOil pick-up strainer clogged (Chapter 2).

Note:Low oil pressure in a high-mileage engine at tickover is not

necessarily a cause for concern. Sudden pressure loss at speed is far

more significant. In any event, check the gauge or warning light sender

before condemning the engine.

Engine runs-on after switching off

MExcessive carbon build-up in engine (Chapter 2).

MExcessively high engine operating temperature (Chapter 3).

Engine noises

Pre-ignition (pinking) or knocking during acceleration or

under load

MIgnition timing incorrect/ignition system fault (Chapters 1 and 5).

MIncorrect grade of spark plug (Chapter 1).

MIncorrect grade of fuel (Chapter 1).

MVacuum leak at throttle body, inlet manifold or associated hoses

(Chapter 4).

MExcessive carbon build-up in engine (Chapter 2).

MFuel injection system fault (Chapter 4).

Whistling or wheezing noises

MLeaking inlet manifold or throttle body gasket (Chapter 4).

MLeaking exhaust manifold gasket (Chapter 4).

MLeaking vacuum hose (Chapters 4 and 10).

MBlowing cylinder head gasket (Chapter 2).

Tapping or rattling noises

MWorn valve gear, timing chain, camshaft or hydraulic tappets

(Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Knocking or thumping noises

MWorn big-end bearings (regular heavy knocking, perhaps less

under load) (Chapter 2).

MWorn main bearings (rumbling and knocking, perhaps worsening

under load) (Chapter 2).

MPiston slap (most noticeable when cold) (Chapter 2).

MAncillary component fault (water pump, alternator, etc) (Chapters 3, 5)

Overheating

MAuxiliary drivebelt broken or incorrectly adjusted (Chapter 1).

MInsufficient coolant in system (Chapter 1).

MThermostat faulty (Chapter 3).

MRadiator core blocked, or grille restricted (Chapter 3).

MElectric cooling fan or thermostatic switch faulty (Chapter 3).

MViscous-coupled fan faulty (Chapter 3).

MIgnition timing incorrect, or ignition system fault (Chapters 1 and 5).

MInaccurate temperature gauge sender unit (Chapter 3).

MAirlock in cooling system (Chapter 3).

Overcooling

MThermostat faulty (Chapter 3).

MInaccurate temperature gauge sender unit (Chapter 3).

External coolant leakage

MDeteriorated or damaged hoses or hose clips (Chapter 1).

MRadiator core or heater matrix leaking (Chapter 3).

MPressure cap faulty (Chapter 3).

MWater pump internal seal leaking (Chapter 3).

MWater pump-to-block seal leaking (Chapter 3).

MBoiling due to overheating (Chapter 3).

MCore plug leaking (Chapter 2).

Internal coolant leakage

MLeaking cylinder head gasket (Chapter 2).

MCracked cylinder head or cylinder block (Chapter 2).

Corrosion

MInfrequent draining and flushing (Chapter 1).

MIncorrect coolant mixture or inappropriate coolant type (Chapter 1).

Fault diagnosisREF•13

REF

Cooling system

Excessive fuel consumption

MAir filter element dirty or clogged (Chapter 1).

MFuel injection system fault (Chapter 4).

MIgnition timing incorrect or ignition system fault (Chapters 1 and 5).

MBrakes binding (Chapter 10).

MTyres under-inflated (Chapter 1).

Fuel leakage and/or fuel odour

MDamaged fuel tank, pipes or connections (Chapters 1 and 4).

Excessive noise or fumes from exhaust system

MLeaking exhaust system or manifold joints (Chapters 1 and 4).

MLeaking, corroded or damaged silencers or pipe (Chapters 1 and 4).

MBroken mountings causing body or suspension contact (Chapter 4).

Fuel and exhaust systems

Page 14 of 26

Note:Due to the complexity of the automatic transmission, it is difficult

for the home mechanic to properly diagnose and service this unit. For

problems other than the following, the vehicle should be taken to a

dealer service department or automatic transmission specialist.

Fluid leakage

MAutomatic transmission fluid is usually deep red in colour. Fluid

leaks should not be confused with engine oil, which can easily be

blown onto the transmission by air flow.

MTo determine the source of a leak, first remove all built-up dirt and

grime from the transmission housing and surrounding areas, using a

degreasing agent or by steam-cleaning. Drive the vehicle at low speed,

so that air flow will not blow the leak far from its source. Raise and

support the vehicle, and determine where the leak is coming from. The

following are common areas of leakage.

a)Fluid pan ( transmission “sump”).

b)Dipstick tube (Chapter 1).

c)Transmission-to-fluid cooler fluid pipes/unions (Chapter 7).

Transmission fluid brown, or has burned smell

MTransmission fluid level low, or fluid in need of renewal (Chapter 1).

General gear selection problems

MThe most likely cause of gear selection problems is a faulty or

poorly-adjusted gear selector mechanism. The following are common

problems associated with a faulty selector mechanism.

a)Engine starting in gears other than Park or Neutral.

b)Indicator on gear selector lever pointing to a gear other than the

one actually being used.

c)Vehicle moves when in Park or Neutral.

d)Poor gear shift quality, or erratic gear changes.

MRefer any problems to a Ford dealer, or transmission specialist.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

MLow transmission fluid level (Chapter 1).

MIncorrect selector adjustment (Chapter 7).

Noisy in neutral with engine running

MInput shaft bearings worn (noise apparent with clutch pedal

released, but not when depressed) (Chapter 7).*

MClutch release bearing worn (noise apparent with clutch pedal

depressed, possibly less when released) (Chapter 6).

Noisy in one particular gear

MWorn, damaged or chipped gear teeth (Chapter 7).*

Difficulty engaging gears

MClutch fault (Chapter 6).

MWorn or damaged gear linkage (Chapter 7).

MWorn synchroniser units (Chapter 7).*

Jumps out of gear

MWorn or damaged gear linkage (Chapter 7).MWorn synchroniser units (Chapter 7).*

MWorn selector forks (Chapter 7).*

Vibration

MLack of oil (Chapter 1).

MWorn bearings (Chapter 7).*

Lubricant leaks

MLeaking oil seal (Chapter 7).

MLeaking housing joint (Chapter 7).*

*Although the corrective action necessary to remedy the symptoms

described is beyond the scope of the home mechanic, the above

information should be helpful in isolating the cause of the condition, so

that the owner can communicate clearly with a professional mechanic.

Pedal travels to floor - no pressure or very little

resistance

MBadly stretched or broken cable (Chapter 6).

MStripped pawl on pedal (Chapter 6).

MBroken clutch release bearing or arm (Chapter 6).

MBroken diaphragm spring in clutch pressure plate (Chapter 6).

Clutch fails to disengage (unable to select gears)

MCable free play excessive (Chapter 6).

MClutch driven plate sticking on gearbox input shaft splines

(Chapter 6).

MClutch driven plate sticking to flywheel or pressure plate (Chapter 6).

MFaulty pressure plate assembly (Chapter 6).

MClutch release mechanism worn or incorrectly assembled (Chapter 6).

Clutch slips (engine speed increases, with no

increase in vehicle speed)

MClutch driven plate linings excessively worn (Chapter 6).MClutch driven plate linings contaminated with oil or grease (Chapter 6).

MFaulty pressure plate or weak diaphragm spring (Chapter 6).

Judder as clutch is engaged

MClutch driven plate linings contaminated with oil or grease (Chapter 6).

MClutch driven plate linings excessively worn (Chapter 6).

MFaulty or distorted pressure plate or diaphragm spring (Chapter 6).

MWorn or loose engine or gearbox mountings (Chapter 2).

MClutch driven plate hub or gearbox input shaft splines worn

(Chapter 6).

Noise when depressing or releasing clutch pedal

MWorn clutch release bearing (Chapter 6).

MWorn or dry clutch pedal pivot (Chapter 6).

MFaulty pressure plate assembly (Chapter 6).

MPressure plate diaphragm spring broken (Chapter 6).

MBroken clutch driven plate cushioning springs (Chapter 6).

REF•14Fault diagnosis

Clutch

Manual gearbox

Automatic transmission

Page 16 of 26

Brakes binding

MSeized brake caliper piston(s) (Chapter 10).

MIncorrectly-adjusted handbrake mechanism (Chapter 10).

MFaulty master cylinder (Chapter 10).

Rear wheels locking under normal braking

MSeized brake caliper piston(s) (Chapter 10).

MFaulty brake pressure regulator (Chapter 10).

Note:For problems associated with the starting system, refer to the

faults listed under “Engine” earlier in this Section.

Battery will not hold a charge for more than a few

days

MBattery defective internally (Chapter 5).

MBattery electrolyte level low - where applicable (Chapter 1).

MBattery terminal connections loose or corroded (Chapter 1).

MAuxiliary drivebelt worn - or incorrectly adjusted (Chapter 1).

MAlternator not charging at correct output (Chapter 5).MAlternator or voltage regulator faulty (Chapter 5).

MShort-circuit causing continual battery drain (Chapters 5 and 13).

Ignition/no-charge warning light remains illuminated

with engine running

MAuxiliary drivebelt broken, worn, or incorrectly adjusted (Chapter 1).

MAlternator brushes worn, sticking, or dirty (Chapter 5).

MAlternator brush springs weak or broken (Chapter 5).

MInternal fault in alternator or voltage regulator (Chapter 5).

MBroken, disconnected, or loose wiring in charging circuit (Chapter 5). Note:Before diagnosing suspension or steering faults, be sure that the

trouble is not due to incorrect tyre pressures, mixtures of tyre types, or

binding brakes.

Vehicle pulls to one side

MDefective tyre (Chapter 1).

MExcessive wear in suspension or steering components (Chapters 1

and 11).

MIncorrect front wheel alignment (Chapter 11).

MAccident damage to steering or suspension components (Chapters 1

and 11).

Wheel wobble and vibration

MFront roadwheels out of balance (vibration felt mainly through the

steering wheel) (Chapter 11).

MRear roadwheels out of balance (vibration felt throughout the

vehicle) (Chapter 11).

MRoadwheels damaged or distorted (Chapter 11).

MFaulty or damaged tyre (Chapter 1).

MWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

MWheel bolts loose (Chapter 11).

Excessive pitching and/or rolling around corners, or

during braking

MDefective shock absorbers (Chapters 1 and 11).

MBroken or weak coil spring and/or suspension component

(Chapters 1 and 11).

MWorn or damaged anti-roll bar or mountings (Chapter 11).

Wandering or general instability

MIncorrect front wheel alignment (Chapter 11).

MWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

MRoadwheels out of balance (Chapter 11).

MFaulty or damaged tyre (Chapter 1).

MWheel bolts loose (Chapter 11).

MDefective shock absorbers (Chapters 1 and 11).

Excessively-stiff steering

MLack of steering gear lubricant (Chapter 11).

MSeized track rod end balljoint or suspension balljoint (Chapters 1

and 11).MBroken or incorrectly adjusted auxiliary drivebelt (Chapter 1).

MIncorrect front wheel alignment (Chapter 11).

MSteering rack or column bent or damaged (Chapter 11).

Excessive play in steering

MWorn steering column universal joint(s) (Chapter 11).

MWorn steering track rod end balljoints (Chapters 1 and 11).

MWorn rack-and-pinion steering gear (Chapter 11).

MWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

Lack of power assistance

MBroken or incorrectly-adjusted auxiliary drivebelt (Chapter 1).

MIncorrect power steering fluid level (Chapter 1).

MRestriction in power steering fluid hoses (Chapter 11).

MFaulty power steering pump (Chapter 11).

MFaulty rack-and-pinion steering gear (Chapter 11).

Tyre wear excessive

Tyres worn on inside or outside edges

MTyres under-inflated (wear on both edges) (Chapter 1).

MIncorrect camber or castor angles (wear on one edge only)

(Chapter 11).

MWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

MExcessively-hard cornering.

MAccident damage.

Tyre treads exhibit feathered edges

MIncorrect toe setting (Chapter 11).

Tyres worn in centre of tread

MTyres over-inflated (Chapter 1).

Tyres worn on inside and outside edges

MTyres under-inflated (Chapter 1).

MWorn shock absorbers (Chapters 1 and 11).

Tyres worn unevenly

MTyres out of balance (Chapter 1).

MExcessive wheel or tyre run-out (Chapter 1).

MWorn shock absorbers (Chapters 1 and 11).

MFaulty tyre (Chapter 1).

REF•16Fault diagnosis

Steering and suspension

Electrical system

Page 19 of 26

Glossary of Technical termsREF•19

REF

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

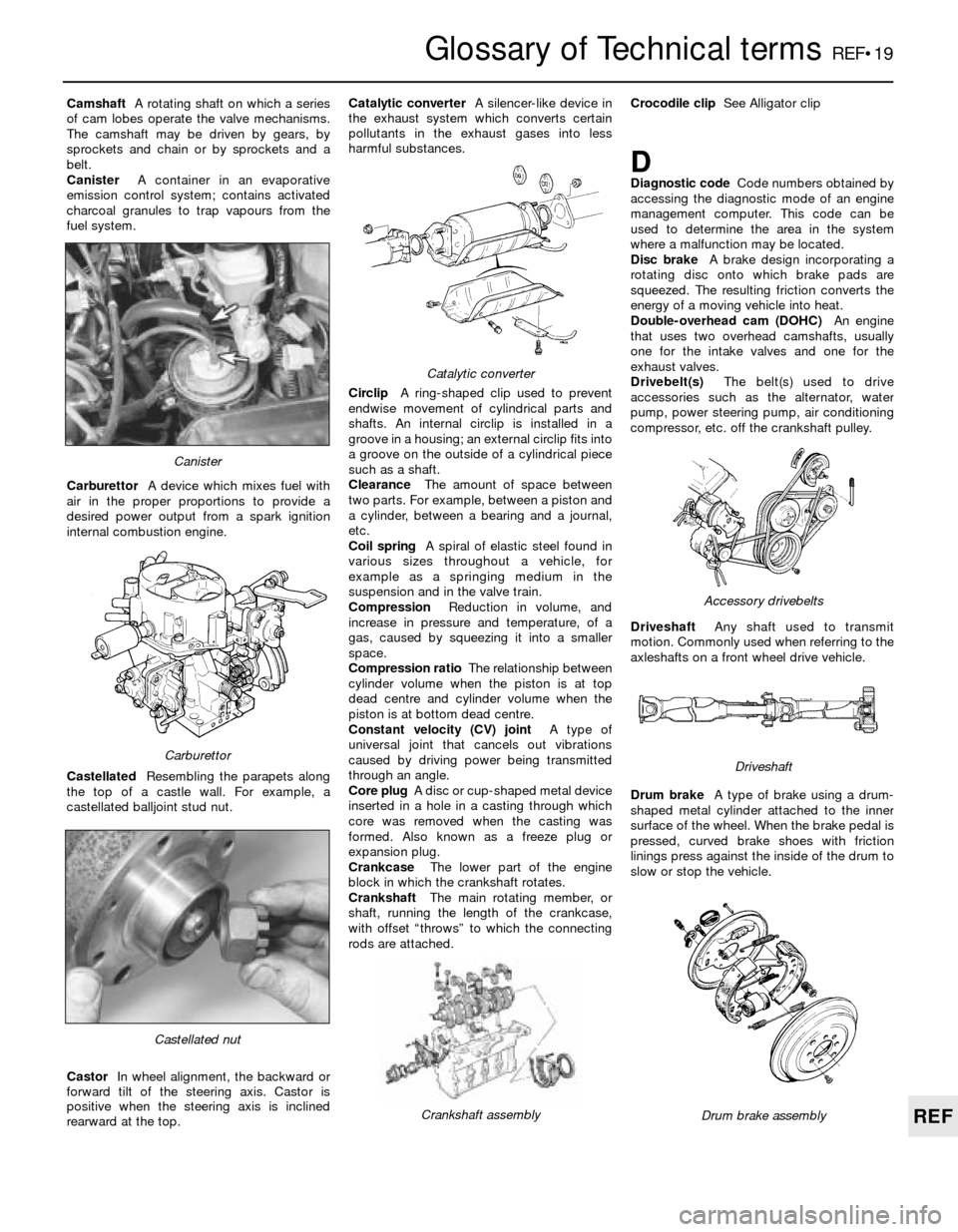

rearward at the top.Catalytic converterA silencer-like device in

the exhaust system which converts certain

pollutants in the exhaust gases into less

harmful substances.

CirclipA ring-shaped clip used to prevent

endwise movement of cylindrical parts and

shafts. An internal circlip is installed in a

groove in a housing; an external circlip fits into

a groove on the outside of a cylindrical piece

such as a shaft.

ClearanceThe amount of space between

two parts. For example, between a piston and

a cylinder, between a bearing and a journal,

etc.

Coil springA spiral of elastic steel found in

various sizes throughout a vehicle, for

example as a springing medium in the

suspension and in the valve train.

CompressionReduction in volume, and

increase in pressure and temperature, of a

gas, caused by squeezing it into a smaller

space.

Compression ratioThe relationship between

cylinder volume when the piston is at top

dead centre and cylinder volume when the

piston is at bottom dead centre.

Constant velocity (CV) jointA type of

universal joint that cancels out vibrations

caused by driving power being transmitted

through an angle.

Core plugA disc or cup-shaped metal device

inserted in a hole in a casting through which

core was removed when the casting was

formed. Also known as a freeze plug or

expansion plug.

CrankcaseThe lower part of the engine

block in which the crankshaft rotates.

CrankshaftThe main rotating member, or

shaft, running the length of the crankcase,

with offset “throws” to which the connecting

rods are attached.Crocodile clipSee Alligator clip

DDiagnostic codeCode numbers obtained by

accessing the diagnostic mode of an engine

management computer. This code can be

used to determine the area in the system

where a malfunction may be located.

Disc brakeA brake design incorporating a

rotating disc onto which brake pads are

squeezed. The resulting friction converts the

energy of a moving vehicle into heat.

Double-overhead cam (DOHC)An engine

that uses two overhead camshafts, usually

one for the intake valves and one for the

exhaust valves.

Drivebelt(s)The belt(s) used to drive

accessories such as the alternator, water

pump, power steering pump, air conditioning

compressor, etc. off the crankshaft pulley.

DriveshaftAny shaft used to transmit

motion. Commonly used when referring to the

axleshafts on a front wheel drive vehicle.

Drum brakeA type of brake using a drum-

shaped metal cylinder attached to the inner

surface of the wheel. When the brake pedal is

pressed, curved brake shoes with friction

linings press against the inside of the drum to

slow or stop the vehicle.

Castellated nut

Catalytic converter

Crankshaft assembly

Carburettor

Canister

Drum brake assembly

Accessory drivebelts

Driveshaft

Page 20 of 26

REF•20Glossary of Technical terms

EEGR valveA valve used to introduce exhaust

gases into the intake air stream.

Electronic control unit (ECU)A computer

which controls (for instance) ignition and fuel

injection systems, or an anti-lock braking

system. For more information refer to the

Haynes Automotive Electrical and Electronic

Systems Manual.

Electronic Fuel Injection (EFI)A computer

controlled fuel system that distributes fuel

through an injector located in each intake port

of the engine.

Emergency brakeA braking system,

independent of the main hydraulic system,

that can be used to slow or stop the vehicle if

the primary brakes fail, or to hold the vehicle

stationary even though the brake pedal isn’t

depressed. It usually consists of a hand lever

that actuates either front or rear brakes

mechanically through a series of cables and

linkages. Also known as a handbrake or

parking brake.

EndfloatThe amount of lengthwise

movement between two parts. As applied to a

crankshaft, the distance that the crankshaft

can move forward and back in the cylinder

block.

Engine management system (EMS)A

computer controlled system which manages

the fuel injection and the ignition systems in

an integrated fashion.

Exhaust manifoldA part with several

passages through which exhaust gases leave

the engine combustion chambers and enter

the exhaust pipe.

FFan clutchA viscous (fluid) drive coupling

device which permits variable engine fan

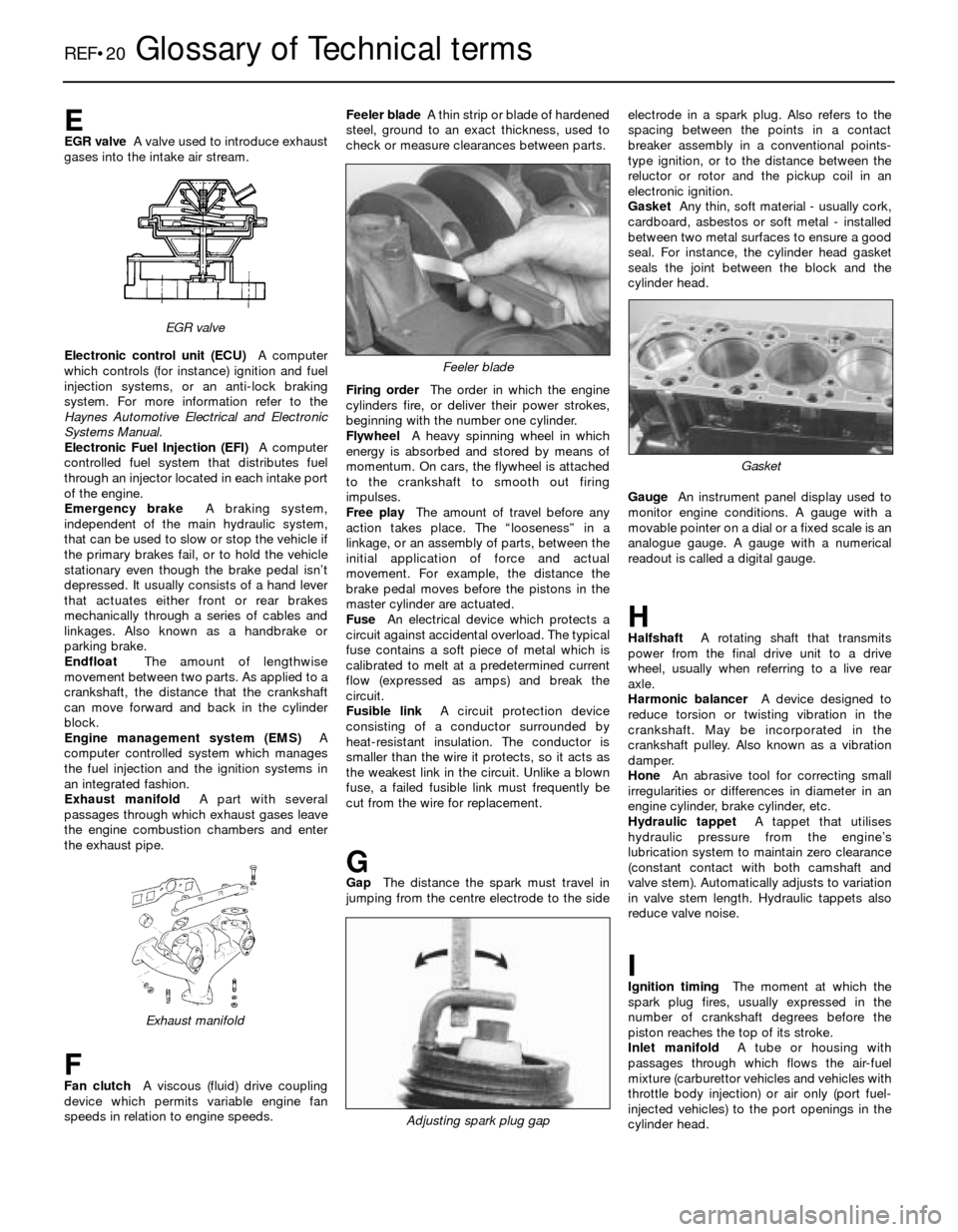

speeds in relation to engine speeds.Feeler bladeA thin strip or blade of hardened

steel, ground to an exact thickness, used to

check or measure clearances between parts.

Firing orderThe order in which the engine

cylinders fire, or deliver their power strokes,

beginning with the number one cylinder.

Flywheel A heavy spinning wheel in which

energy is absorbed and stored by means of

momentum. On cars, the flywheel is attached

to the crankshaft to smooth out firing

impulses.

Free playThe amount of travel before any

action takes place. The “looseness” in a

linkage, or an assembly of parts, between the

initial application of force and actual

movement. For example, the distance the

brake pedal moves before the pistons in the

master cylinder are actuated.

FuseAn electrical device which protects a

circuit against accidental overload. The typical

fuse contains a soft piece of metal which is

calibrated to melt at a predetermined current

flow (expressed as amps) and break the

circuit.

Fusible linkA circuit protection device

consisting of a conductor surrounded by

heat-resistant insulation. The conductor is

smaller than the wire it protects, so it acts as

the weakest link in the circuit. Unlike a blown

fuse, a failed fusible link must frequently be

cut from the wire for replacement.

GGapThe distance the spark must travel in

jumping from the centre electrode to the sideelectrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

Exhaust manifold

Feeler blade

Adjusting spark plug gap

Gasket

EGR valve