wheel bolt torque FORD SIERRA 1991 2.G Suspension And Steering User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: SIERRA, Model: FORD SIERRA 1991 2.GPages: 20, PDF Size: 0.94 MB

Page 13 of 20

5Refitting is a reversal of removal, with

reference to the note at the beginning of this

Section. Refit any shims in their original noted

positions, and tighten all bolts to the specified

torque.

Removal

1Loosen the rear roadwheel nuts, chock the

front wheels, jack up the rear of the vehicle

and support on axle stands placed under the

side members.

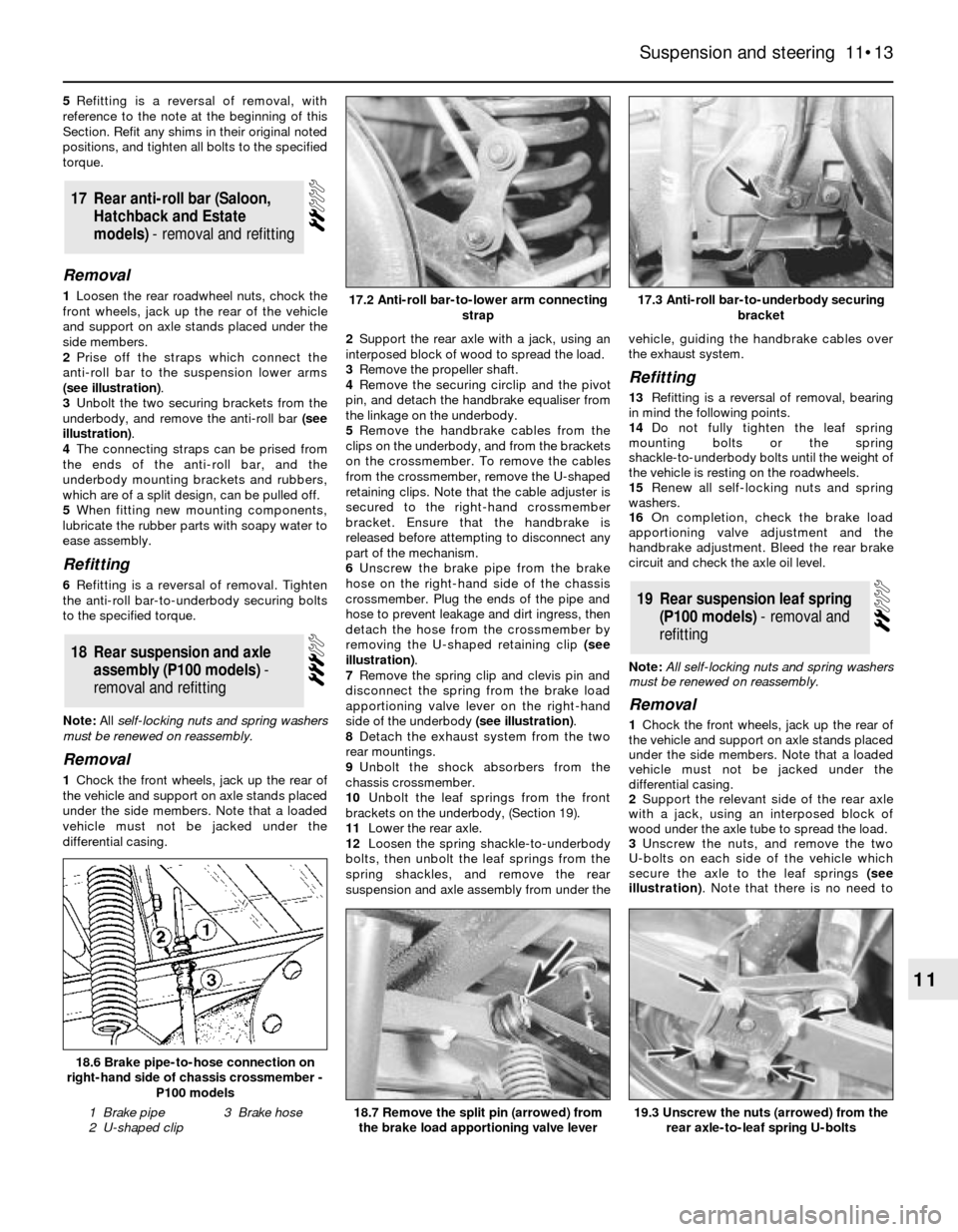

2Prise off the straps which connect the

anti-roll bar to the suspension lower arms

(see illustration).

3Unbolt the two securing brackets from the

underbody, and remove the anti-roll bar (see

illustration).

4The connecting straps can be prised from

the ends of the anti-roll bar, and the

underbody mounting brackets and rubbers,

which are of a split design, can be pulled off.

5When fitting new mounting components,

lubricate the rubber parts with soapy water to

ease assembly.

Refitting

6Refitting is a reversal of removal. Tighten

the anti-roll bar-to-underbody securing bolts

to the specified torque.

Note: All self-locking nuts and spring washers

must be renewed on reassembly.

Removal

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members. Note that a loaded

vehicle must not be jacked under the

differential casing.2Support the rear axle with a jack, using an

interposed block of wood to spread the load.

3Remove the propeller shaft.

4Remove the securing circlip and the pivot

pin, and detach the handbrake equaliser from

the linkage on the underbody.

5Remove the handbrake cables from the

clips on the underbody, and from the brackets

on the crossmember. To remove the cables

from the crossmember, remove the U-shaped

retaining clips. Note that the cable adjuster is

secured to the right-hand crossmember

bracket. Ensure that the handbrake is

released before attempting to disconnect any

part of the mechanism.

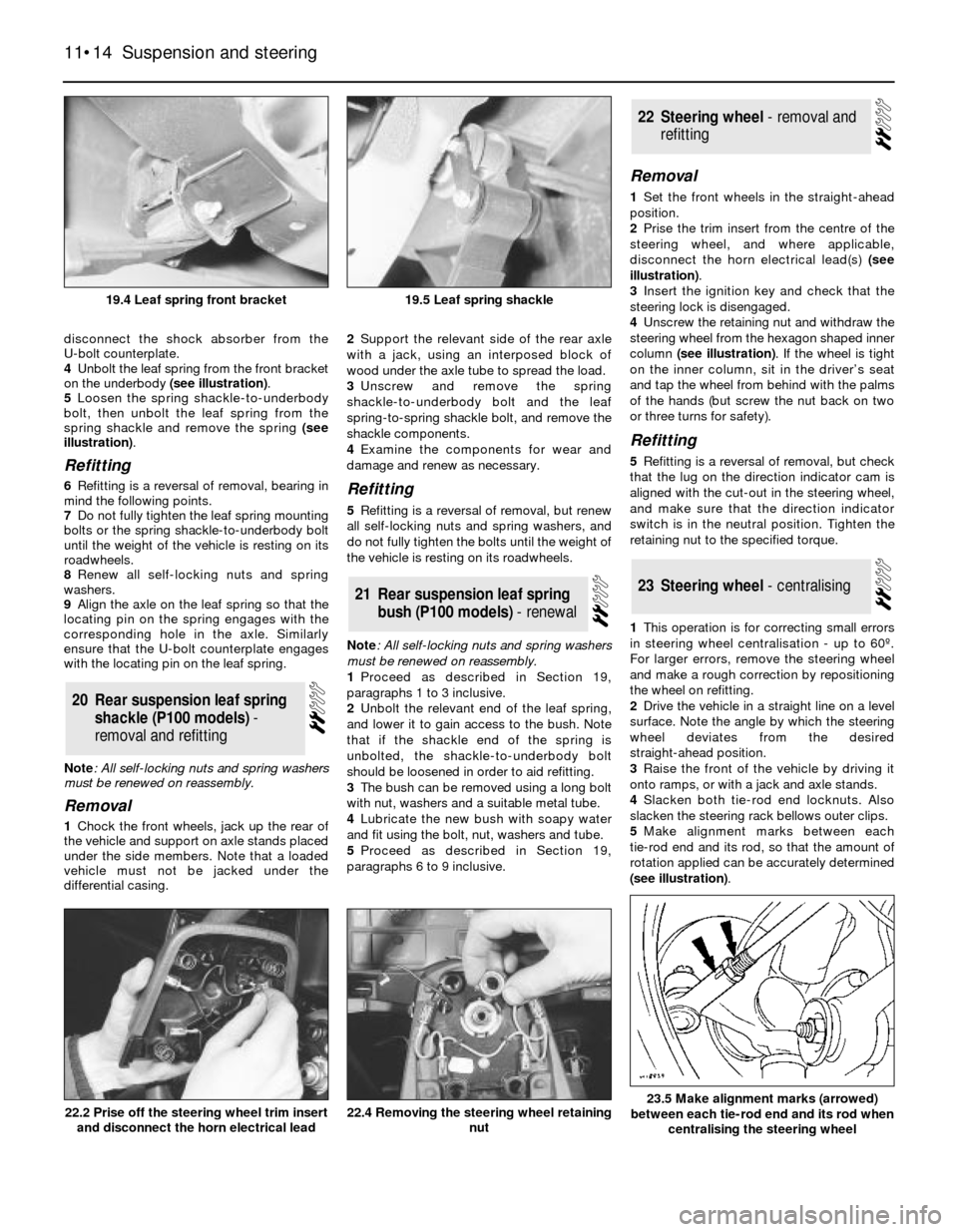

6Unscrew the brake pipe from the brake

hose on the right-hand side of the chassis

crossmember. Plug the ends of the pipe and

hose to prevent leakage and dirt ingress, then

detach the hose from the crossmember by

removing the U-shaped retaining clip (see

illustration).

7Remove the spring clip and clevis pin and

disconnect the spring from the brake load

apportioning valve lever on the right-hand

side of the underbody (see illustration).

8Detach the exhaust system from the two

rear mountings.

9Unbolt the shock absorbers from the

chassis crossmember.

10Unbolt the leaf springs from the front

brackets on the underbody, (Section 19).

11Lower the rear axle.

12Loosen the spring shackle-to-underbody

bolts, then unbolt the leaf springs from the

spring shackles, and remove the rear

suspension and axle assembly from under thevehicle, guiding the handbrake cables over

the exhaust system.

Refitting

13Refitting is a reversal of removal, bearing

in mind the following points.

14Do not fully tighten the leaf spring

mounting bolts or the spring

shackle-to-underbody bolts until the weight of

the vehicle is resting on the roadwheels.

15Renew all self-locking nuts and spring

washers.

16On completion, check the brake load

apportioning valve adjustment and the

handbrake adjustment. Bleed the rear brake

circuit and check the axle oil level.

Note: All self-locking nuts and spring washers

must be renewed on reassembly.

Removal

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members. Note that a loaded

vehicle must not be jacked under the

differential casing.

2Support the relevant side of the rear axle

with a jack, using an interposed block of

wood under the axle tube to spread the load.

3Unscrew the nuts, and remove the two

U-bolts on each side of the vehicle which

secure the axle to the leaf springs (see

illustration). Note that there is no need to

19Rear suspension leaf spring

(P100 models) - removal and

refitting

18Rear suspension and axle

assembly (P100 models) -

removal and refitting

17Rear anti-roll bar (Saloon,

Hatchback and Estate

models) - removal and refitting

Suspension and steering 11•13

11

17.3 Anti-roll bar-to-underbody securing

bracket

18.7 Remove the split pin (arrowed) from

the brake load apportioning valve lever

18.6 Brake pipe-to-hose connection on

right-hand side of chassis crossmember -

P100 models

1 Brake pipe

2 U-shaped clip3 Brake hose

17.2 Anti-roll bar-to-lower arm connecting

strap

19.3 Unscrew the nuts (arrowed) from the

rear axle-to-leaf spring U-bolts

Page 14 of 20

disconnect the shock absorber from the

U-bolt counterplate.

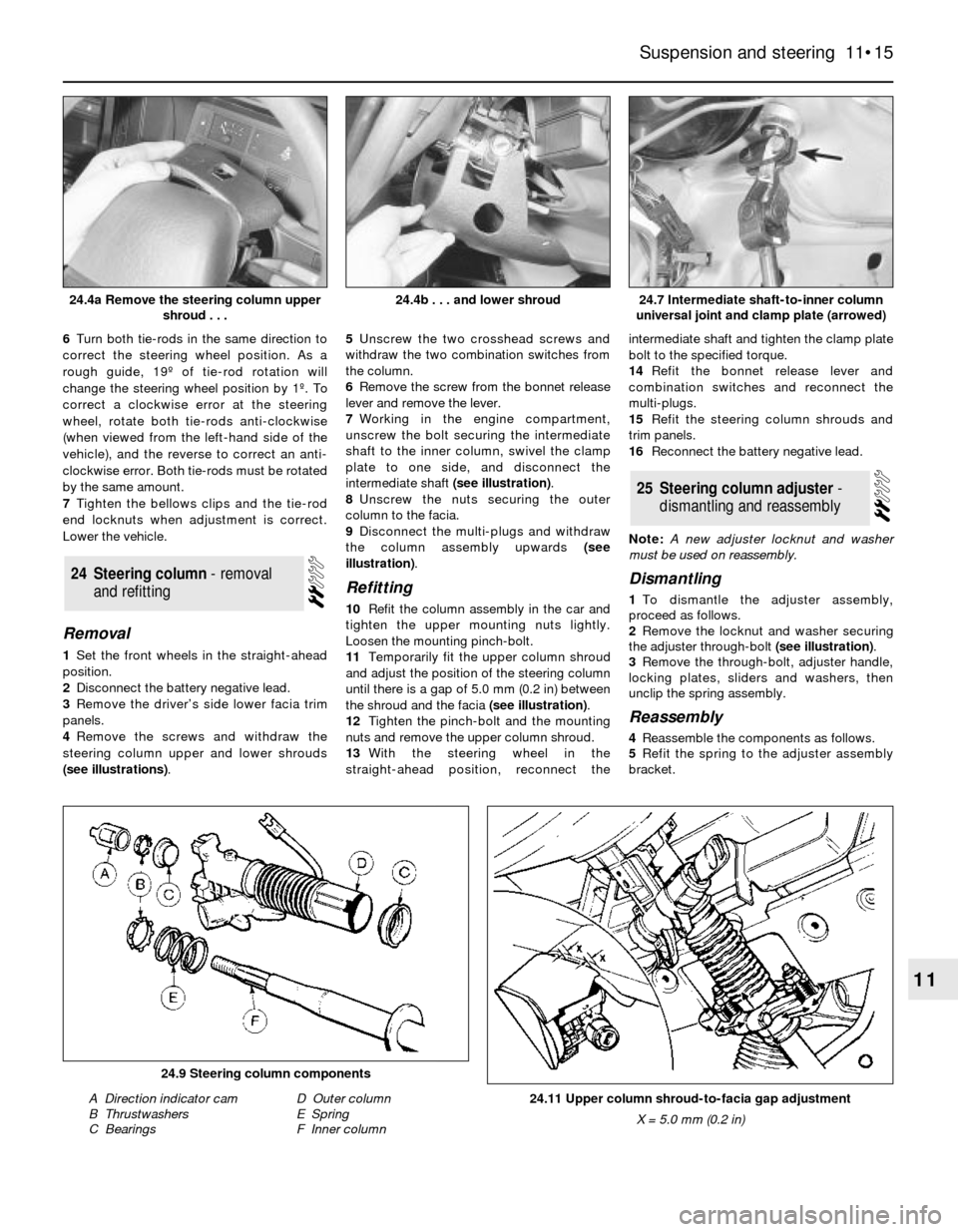

4Unbolt the leaf spring from the front bracket

on the underbody (see illustration).

5Loosen the spring shackle-to-underbody

bolt, then unbolt the leaf spring from the

spring shackle and remove the spring (see

illustration).

Refitting

6Refitting is a reversal of removal, bearing in

mind the following points.

7Do not fully tighten the leaf spring mounting

bolts or the spring shackle-to-underbody bolt

until the weight of the vehicle is resting on its

roadwheels.

8Renew all self-locking nuts and spring

washers.

9Align the axle on the leaf spring so that the

locating pin on the spring engages with the

corresponding hole in the axle. Similarly

ensure that the U-bolt counterplate engages

with the locating pin on the leaf spring.

Note: All self-locking nuts and spring washers

must be renewed on reassembly.

Removal

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands placed

under the side members. Note that a loaded

vehicle must not be jacked under the

differential casing.2Support the relevant side of the rear axle

with a jack, using an interposed block of

wood under the axle tube to spread the load.

3Unscrew and remove the spring

shackle-to-underbody bolt and the leaf

spring-to-spring shackle bolt, and remove the

shackle components.

4Examine the components for wear and

damage and renew as necessary.

Refitting

5Refitting is a reversal of removal, but renew

all self-locking nuts and spring washers, and

do not fully tighten the bolts until the weight of

the vehicle is resting on its roadwheels.

Note: All self-locking nuts and spring washers

must be renewed on reassembly.

1Proceed as described in Section 19,

paragraphs 1 to 3 inclusive.

2Unbolt the relevant end of the leaf spring,

and lower it to gain access to the bush. Note

that if the shackle end of the spring is

unbolted, the shackle-to-underbody bolt

should be loosened in order to aid refitting.

3The bush can be removed using a long bolt

with nut, washers and a suitable metal tube.

4Lubricate the new bush with soapy water

and fit using the bolt, nut, washers and tube.

5Proceed as described in Section 19,

paragraphs 6 to 9 inclusive.

Removal

1Set the front wheels in the straight-ahead

position.

2Prise the trim insert from the centre of the

steering wheel, and where applicable,

disconnect the horn electrical lead(s) (see

illustration).

3Insert the ignition key and check that the

steering lock is disengaged.

4Unscrew the retaining nut and withdraw the

steering wheel from the hexagon shaped inner

column (see illustration). If the wheel is tight

on the inner column, sit in the driver’s seat

and tap the wheel from behind with the palms

of the hands (but screw the nut back on two

or three turns for safety).

Refitting

5Refitting is a reversal of removal, but check

that the lug on the direction indicator cam is

aligned with the cut-out in the steering wheel,

and make sure that the direction indicator

switch is in the neutral position. Tighten the

retaining nut to the specified torque.

1This operation is for correcting small errors

in steering wheel centralisation - up to 60º.

For larger errors, remove the steering wheel

and make a rough correction by repositioning

the wheel on refitting.

2Drive the vehicle in a straight line on a level

surface. Note the angle by which the steering

wheel deviates from the desired

straight-ahead position.

3Raise the front of the vehicle by driving it

onto ramps, or with a jack and axle stands.

4Slacken both tie-rod end locknuts. Also

slacken the steering rack bellows outer clips.

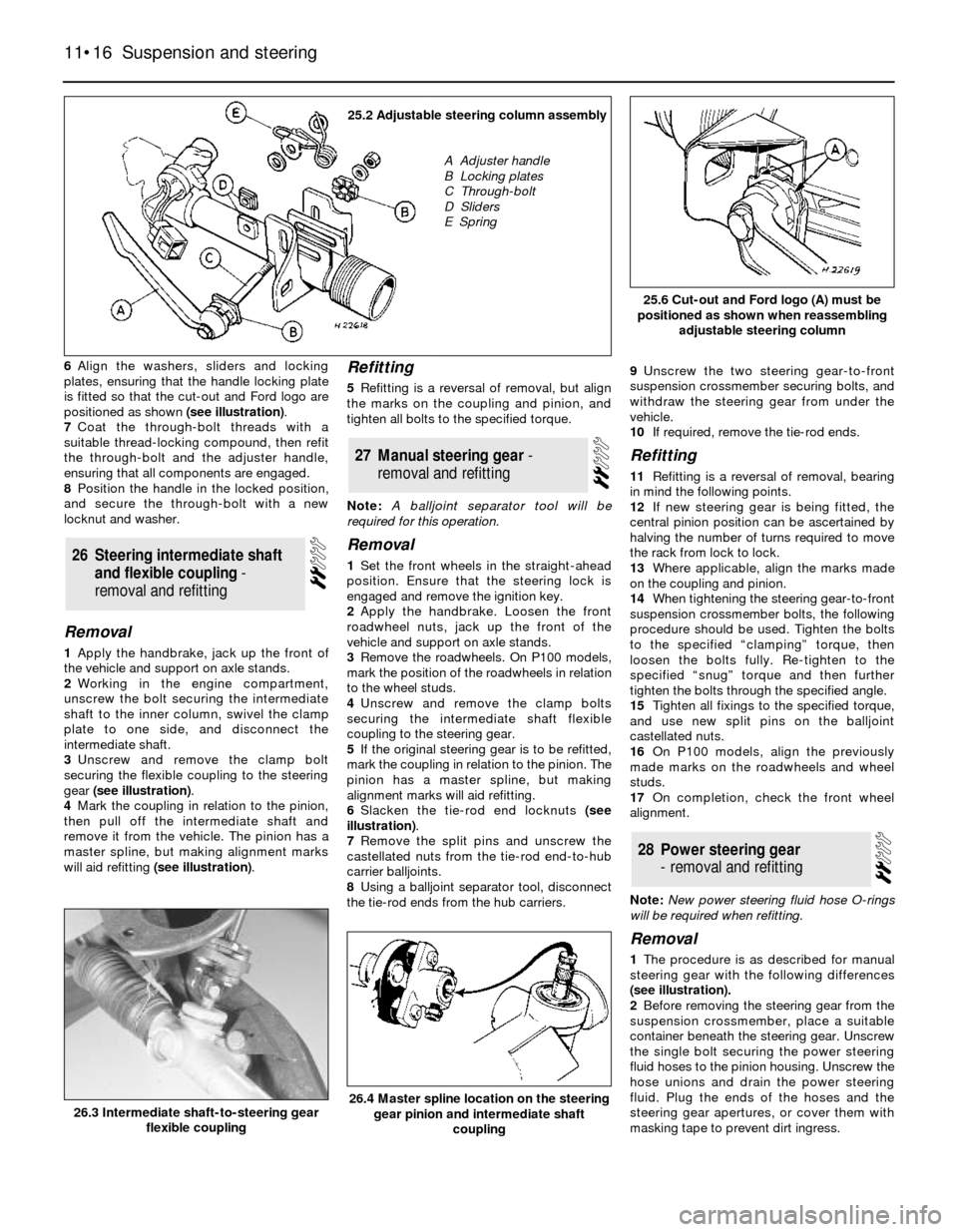

5Make alignment marks between each

tie-rod end and its rod, so that the amount of

rotation applied can be accurately determined

(see illustration).

23Steering wheel - centralising

22Steering wheel - removal and

refitting

21Rear suspension leaf spring

bush (P100 models) - renewal

20Rear suspension leaf spring

shackle (P100 models) -

removal and refitting

11•14Suspension and steering

19.5 Leaf spring shackle

22.4 Removing the steering wheel retaining

nut22.2 Prise off the steering wheel trim insert

and disconnect the horn electrical lead

19.4 Leaf spring front bracket

23.5 Make alignment marks (arrowed)

between each tie-rod end and its rod when

centralising the steering wheel

Page 15 of 20

6Turn both tie-rods in the same direction to

correct the steering wheel position. As a

rough guide, 19º of tie-rod rotation will

change the steering wheel position by 1º. To

correct a clockwise error at the steering

wheel, rotate both tie-rods anti-clockwise

(when viewed from the left-hand side of the

vehicle), and the reverse to correct an anti-

clockwise error. Both tie-rods must be rotated

by the same amount.

7Tighten the bellows clips and the tie-rod

end locknuts when adjustment is correct.

Lower the vehicle.

Removal

1Set the front wheels in the straight-ahead

position.

2Disconnect the battery negative lead.

3Remove the driver’s side lower facia trim

panels.

4Remove the screws and withdraw the

steering column upper and lower shrouds

(see illustrations). 5Unscrew the two crosshead screws and

withdraw the two combination switches from

the column.

6Remove the screw from the bonnet release

lever and remove the lever.

7Working in the engine compartment,

unscrew the bolt securing the intermediate

shaft to the inner column, swivel the clamp

plate to one side, and disconnect the

intermediate shaft (see illustration).

8Unscrew the nuts securing the outer

column to the facia.

9Disconnect the multi-plugs and withdraw

the column assembly upwards (see

illustration).

Refitting

10Refit the column assembly in the car and

tighten the upper mounting nuts lightly.

Loosen the mounting pinch-bolt.

11Temporarily fit the upper column shroud

and adjust the position of the steering column

until there is a gap of 5.0 mm (0.2 in) between

the shroud and the facia (see illustration).

12Tighten the pinch-bolt and the mounting

nuts and remove the upper column shroud.

13With the steering wheel in the

straight-ahead position, reconnect theintermediate shaft and tighten the clamp plate

bolt to the specified torque.

14Refit the bonnet release lever and

combination switches and reconnect the

multi-plugs.

15Refit the steering column shrouds and

trim panels.

16Reconnect the battery negative lead.

Note: A new adjuster locknut and washer

must be used on reassembly.

Dismantling

1To dismantle the adjuster assembly,

proceed as follows.

2Remove the locknut and washer securing

the adjuster through-bolt (see illustration).

3Remove the through-bolt, adjuster handle,

locking plates, sliders and washers, then

unclip the spring assembly.

Reassembly

4Reassemble the components as follows.

5Refit the spring to the adjuster assembly

bracket.

25Steering column adjuster -

dismantling and reassembly

24Steering column - removal

and refitting

Suspension and steering 11•15

11

24.4b . . . and lower shroud

24.11 Upper column shroud-to-facia gap adjustment

X = 5.0 mm (0.2 in)

24.9 Steering column components

A Direction indicator cam

B Thrustwashers

C BearingsD Outer column

E Spring

F Inner column

24.7 Intermediate shaft-to-inner column

universal joint and clamp plate (arrowed)24.4a Remove the steering column upper

shroud . . .

Page 16 of 20

6Align the washers, sliders and locking

plates, ensuring that the handle locking plate

is fitted so that the cut-out and Ford logo are

positioned as shown (see illustration).

7Coat the through-bolt threads with a

suitable thread-locking compound, then refit

the through-bolt and the adjuster handle,

ensuring that all components are engaged.

8Position the handle in the locked position,

and secure the through-bolt with a new

locknut and washer.

Removal

1Apply the handbrake, jack up the front of

the vehicle and support on axle stands.

2Working in the engine compartment,

unscrew the bolt securing the intermediate

shaft to the inner column, swivel the clamp

plate to one side, and disconnect the

intermediate shaft.

3Unscrew and remove the clamp bolt

securing the flexible coupling to the steering

gear (see illustration).

4Mark the coupling in relation to the pinion,

then pull off the intermediate shaft and

remove it from the vehicle. The pinion has a

master spline, but making alignment marks

will aid refitting (see illustration).

Refitting

5Refitting is a reversal of removal, but align

the marks on the coupling and pinion, and

tighten all bolts to the specified torque.

Note: A balljoint separator tool will be

required for this operation.

Removal

1Set the front wheels in the straight-ahead

position. Ensure that the steering lock is

engaged and remove the ignition key.

2Apply the handbrake. Loosen the front

roadwheel nuts, jack up the front of the

vehicle and support on axle stands.

3Remove the roadwheels. On P100 models,

mark the position of the roadwheels in relation

to the wheel studs.

4Unscrew and remove the clamp bolts

securing the intermediate shaft flexible

coupling to the steering gear.

5If the original steering gear is to be refitted,

mark the coupling in relation to the pinion. The

pinion has a master spline, but making

alignment marks will aid refitting.

6Slacken the tie-rod end locknuts (see

illustration).

7Remove the split pins and unscrew the

castellated nuts from the tie-rod end-to-hub

carrier balljoints.

8Using a balljoint separator tool, disconnect

the tie-rod ends from the hub carriers.9Unscrew the two steering gear-to-front

suspension crossmember securing bolts, and

withdraw the steering gear from under the

vehicle.

10If required, remove the tie-rod ends.

Refitting

11Refitting is a reversal of removal, bearing

in mind the following points.

12If new steering gear is being fitted, the

central pinion position can be ascertained by

halving the number of turns required to move

the rack from lock to lock.

13Where applicable, align the marks made

on the coupling and pinion.

14When tightening the steering gear-to-front

suspension crossmember bolts, the following

procedure should be used. Tighten the bolts

to the specified “clamping” torque, then

loosen the bolts fully. Re-tighten to the

specified “snug” torque and then further

tighten the bolts through the specified angle.

15Tighten all fixings to the specified torque,

and use new split pins on the balljoint

castellated nuts.

16On P100 models, align the previously

made marks on the roadwheels and wheel

studs.

17On completion, check the front wheel

alignment.

Note: New power steering fluid hose O-rings

will be required when refitting.

Removal

1The procedure is as described for manual

steering gear with the following differences

(see illustration).

2Before removing the steering gear from the

suspension crossmember, place a suitable

container beneath the steering gear. Unscrew

the single bolt securing the power steering

fluid hoses to the pinion housing. Unscrew the

hose unions and drain the power steering

fluid. Plug the ends of the hoses and the

steering gear apertures, or cover them with

masking tape to prevent dirt ingress.

28Power steering gear

- removal and refitting

27Manual steering gear -

removaland refitting

26Steering intermediate shaft

and flexible coupling -

removal and refitting

11•16Suspension and steering

25.6 Cut-out and Ford logo (A) must be

positioned as shown when reassembling

adjustable steering column

26.4 Master spline location on the steering

gear pinion and intermediate shaft

coupling26.3 Intermediate shaft-to-steering gear

flexible coupling

25.2 Adjustable steering column assembly

A Adjuster handle

B Locking plates

C Through-bolt

D Sliders

E Spring