boot FORD SIERRA 1992 2.G Body Electrical System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 25, PDF Size: 1.7 MB

Page 5 of 25

13Refitting is a reversal of removal, but note

that the wiring plug can only be fitted in one

position, and ensure that the joystick

assembly locating lug engages in the

corresponding hole in the facia panel.

1Disconnect the battery negative lead.

Models up to 1987

2Using a thin-bladed screwdriver, carefully

prise the switch from the door trim panel.

3Disconnect the wiring plug and withdraw

the switch (see illustration).

4Refitting is a reversal of removal.

Models from 1987

5Prise the securing screw cover from themirror control panel, then remove the screw

and withdraw the control panel.

6Depress the switch retaining tang, then

withdraw the switch from the control panel

and disconnect the wiring plug.

7Refitting is a reversal of removal.

1Disconnect the battery negative lead.

Switch

Models up to 1987

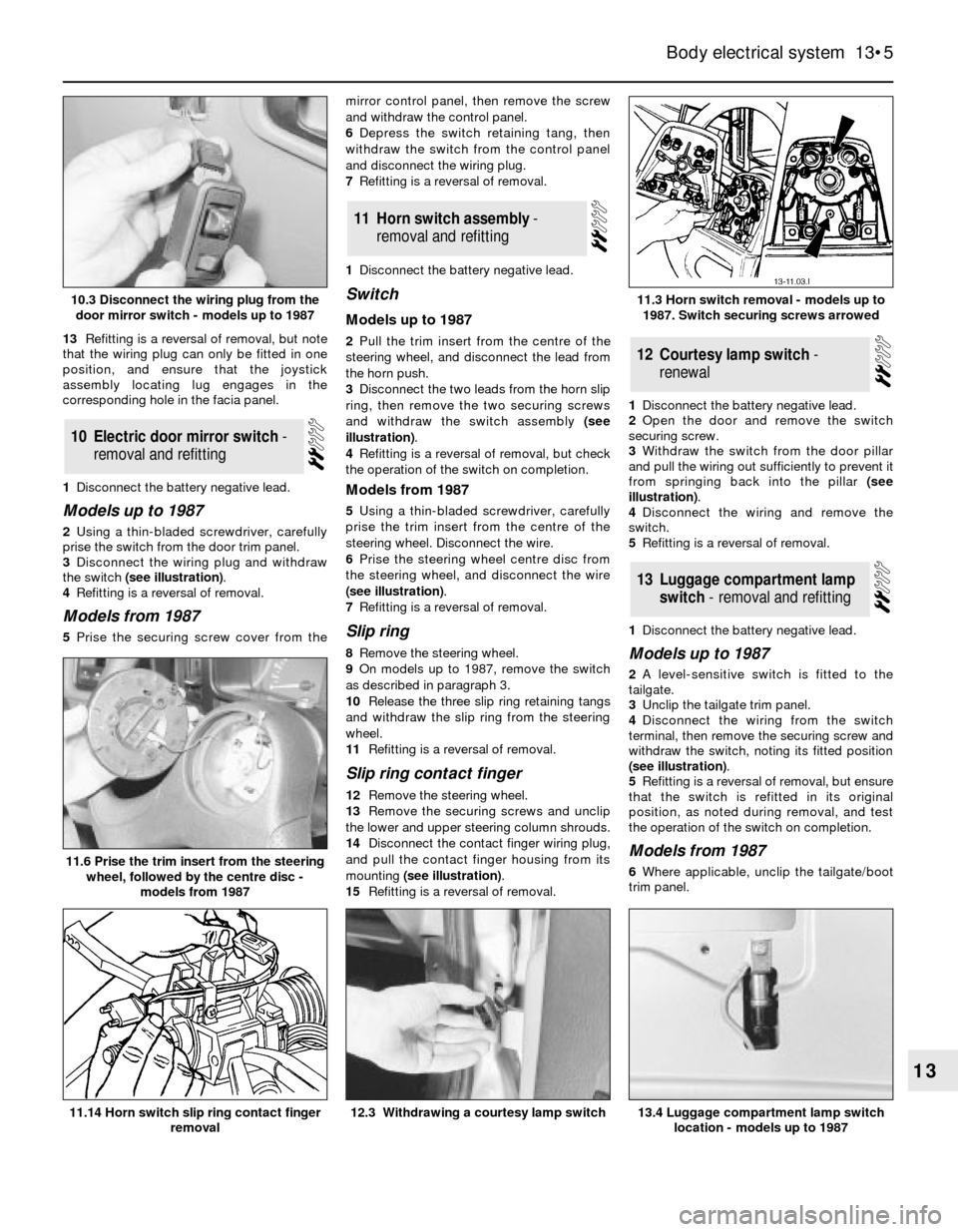

2Pull the trim insert from the centre of the

steering wheel, and disconnect the lead from

the horn push.

3Disconnect the two leads from the horn slip

ring, then remove the two securing screws

and withdraw the switch assembly (see

illustration).

4Refitting is a reversal of removal, but check

the operation of the switch on completion.

Models from 1987

5Using a thin-bladed screwdriver, carefully

prise the trim insert from the centre of the

steering wheel. Disconnect the wire.

6Prise the steering wheel centre disc from

the steering wheel, and disconnect the wire

(see illustration).

7Refitting is a reversal of removal.

Slip ring

8Remove the steering wheel.

9On models up to 1987, remove the switch

as described in paragraph 3.

10Release the three slip ring retaining tangs

and withdraw the slip ring from the steering

wheel.

11Refitting is a reversal of removal.

Slip ring contact finger

12Remove the steering wheel.

13Remove the securing screws and unclip

the lower and upper steering column shrouds.

14Disconnect the contact finger wiring plug,

and pull the contact finger housing from its

mounting (see illustration).

15Refitting is a reversal of removal.1Disconnect the battery negative lead.

2Open the door and remove the switch

securing screw.

3Withdraw the switch from the door pillar

and pull the wiring out sufficiently to prevent it

from springing back into the pillar (see

illustration).

4Disconnect the wiring and remove the

switch.

5Refitting is a reversal of removal.

1Disconnect the battery negative lead.

Models up to 1987

2A level-sensitive switch is fitted to the

tailgate.

3Unclip the tailgate trim panel.

4Disconnect the wiring from the switch

terminal, then remove the securing screw and

withdraw the switch, noting its fitted position

(see illustration).

5Refitting is a reversal of removal, but ensure

that the switch is refitted in its original

position, as noted during removal, and test

the operation of the switch on completion.

Models from 1987

6Where applicable, unclip the tailgate/boot

trim panel.

13Luggage compartment lamp

switch - removal and refitting

12Courtesy lamp switch -

renewal

11Horn switch assembly -

removal and refitting

10Electric door mirror switch -

removal and refitting

Body electrical system 13•5

13

11.6 Prise the trim insert from the steering

wheel, followed by the centre disc -

models from 1987

13.4 Luggage compartment lamp switch

location - models up to 198712.3 Withdrawing a courtesy lamp switch11.14 Horn switch slip ring contact finger

removal

11.3 Horn switch removal - models up to

1987. Switch securing screws arrowed10.3 Disconnect the wiring plug from the

door mirror switch - models up to 1987

Page 9 of 25

Location

1The AWS control unit, and (when fitted) the

bulb failure monitor, are located behind the

glovebox on models up to 1987.

2On models from 1987, the control and bulb

failure modules are located behind the driver’s

side footwell trim panel.

Testing

3Thorough testing and fault finding should

be left to a Ford dealer or other electrical

specialist, having test equipment. Unskilled or

uninformed testing may cause damage.

4Investigation of malfunctions should begin

by checking that all wiring is intact and

securely connected. If checking wires or

sensors for continuity, always disconnect the

control unit and/or bulb failure monitor before

so doing, otherwise damage may be caused.

5Note that false oil level readings can result if

the car is parked on a slope. False bulb failure

warnings may occur if incorrect wattage bulbs

are fitted.

Removal and refitting

6Disconnect the battery negative lead.

Warning lamp bulbs

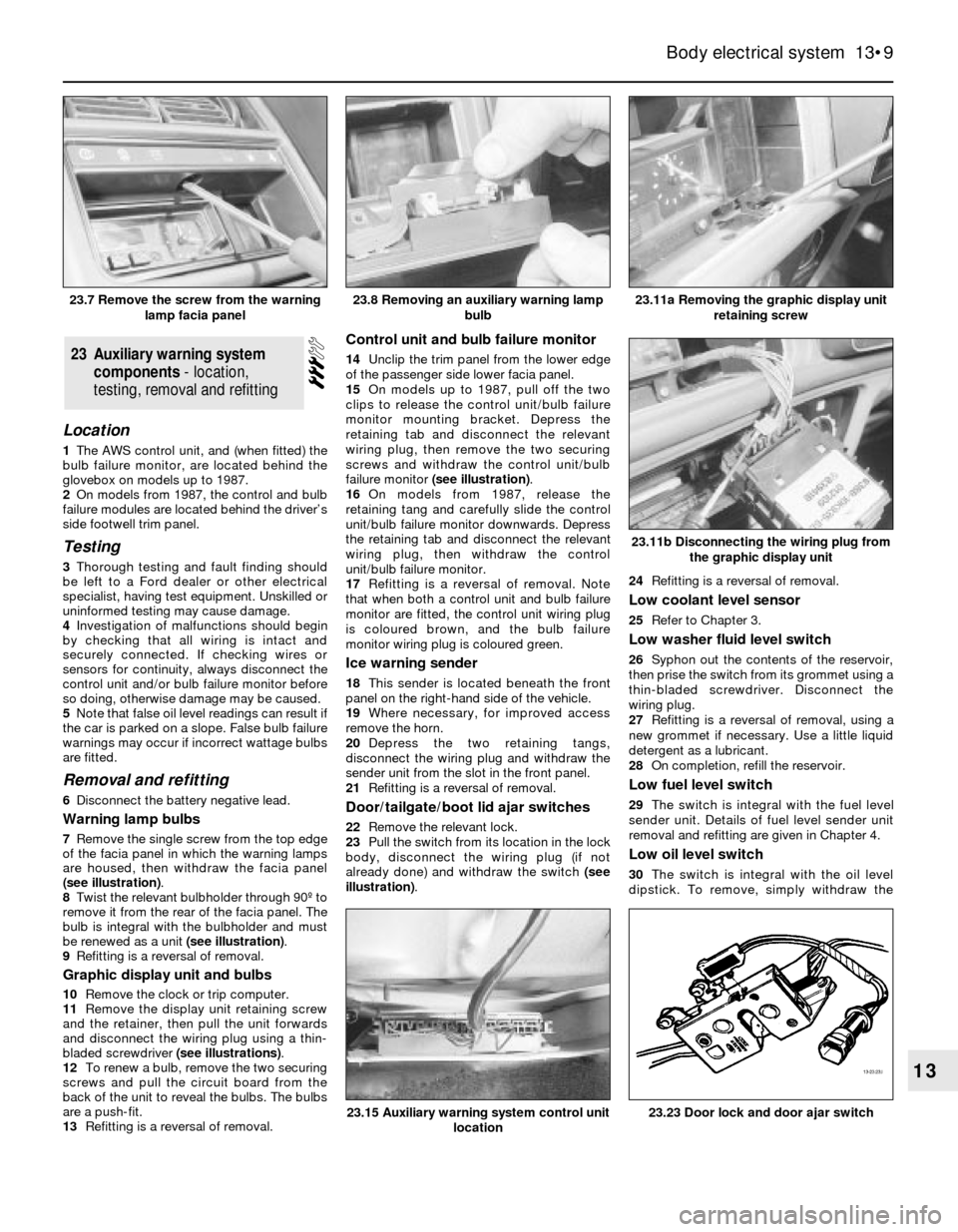

7Remove the single screw from the top edge

of the facia panel in which the warning lamps

are housed, then withdraw the facia panel

(see illustration).

8Twist the relevant bulbholder through 90º to

remove it from the rear of the facia panel. The

bulb is integral with the bulbholder and must

be renewed as a unit (see illustration).

9Refitting is a reversal of removal.

Graphic display unit and bulbs

10Remove the clock or trip computer.

11Remove the display unit retaining screw

and the retainer, then pull the unit forwards

and disconnect the wiring plug using a thin-

bladed screwdriver (see illustrations).

12To renew a bulb, remove the two securing

screws and pull the circuit board from the

back of the unit to reveal the bulbs. The bulbs

are a push-fit.

13Refitting is a reversal of removal.

Control unit and bulb failure monitor

14Unclip the trim panel from the lower edge

of the passenger side lower facia panel.

15On models up to 1987, pull off the two

clips to release the control unit/bulb failure

monitor mounting bracket. Depress the

retaining tab and disconnect the relevant

wiring plug, then remove the two securing

screws and withdraw the control unit/bulb

failure monitor (see illustration).

16On models from 1987, release the

retaining tang and carefully slide the control

unit/bulb failure monitor downwards. Depress

the retaining tab and disconnect the relevant

wiring plug, then withdraw the control

unit/bulb failure monitor.

17Refitting is a reversal of removal. Note

that when both a control unit and bulb failure

monitor are fitted, the control unit wiring plug

is coloured brown, and the bulb failure

monitor wiring plug is coloured green.

Ice warning sender

18This sender is located beneath the front

panel on the right-hand side of the vehicle.

19Where necessary, for improved access

remove the horn.

20Depress the two retaining tangs,

disconnect the wiring plug and withdraw the

sender unit from the slot in the front panel.

21Refitting is a reversal of removal.

Door/tailgate/boot lid ajar switches

22Remove the relevant lock.

23Pull the switch from its location in the lock

body, disconnect the wiring plug (if not

already done) and withdraw the switch (see

illustration).24Refitting is a reversal of removal.

Low coolant level sensor

25Refer to Chapter 3.

Low washer fluid level switch

26Syphon out the contents of the reservoir,

then prise the switch from its grommet using a

thin-bladed screwdriver. Disconnect the

wiring plug.

27Refitting is a reversal of removal, using a

new grommet if necessary. Use a little liquid

detergent as a lubricant.

28On completion, refill the reservoir.

Low fuel level switch

29The switch is integral with the fuel level

sender unit. Details of fuel level sender unit

removal and refitting are given in Chapter 4.

Low oil level switch

30The switch is integral with the oil level

dipstick. To remove, simply withdraw the

23Auxiliary warning system

components - location,

testing, removal and refitting

Body electrical system 13•9

13

23.11a Removing the graphic display unit

retaining screw

23.23 Door lock and door ajar switch23.15 Auxiliary warning system control unit

location

23.11b Disconnecting the wiring plug from

the graphic display unit

23.8 Removing an auxiliary warning lamp

bulb23.7 Remove the screw from the warning

lamp facia panel

Page 18 of 25

P100 models

43Pull the lamp cover from the rubber

housing to expose the bulb. The bulb is a

bayonet fitting in the bulbholder.

44Refitting is a reversal of removal.

1Disconnect the battery negative lead.

Switches

2Prise the switch from its location using a

thin-bladed screwdriver, and disconnect the

wiring plug (see illustration).

3Refitting is a reversal of removal.

Operating motors

4Remove the window regulator.

5Remove the three securing bolts, and

withdraw the motor from the regulator

assembly (see illustration).

6Refitting is a reversal of removal, but ensure

that the drive gear is correctly meshed with

the regulator.

Note:If a central locking solenoid or motor is

to be renewed due to jamming or overheating,

the central locking relay must be renewed atthe same time even if it is believed to be

working correctly. Before starting work on the

central locking system, unlock all the doors

and the tailgate/boot. Make sure that the keys

are outside the vehicle before reconnecting

the battery on completion of work.

Operation

Models up to 1987

1The central locking system is activated by

turning the key in the driver’s door lock, and

the locks are operated by solenoids.

Models from 1987

2The system is activated by turning the key

in either of the front door locks, and the locks

are operated by electric motors.

Removal and refitting

3Disconnect the battery negative lead.

Models up to 1987

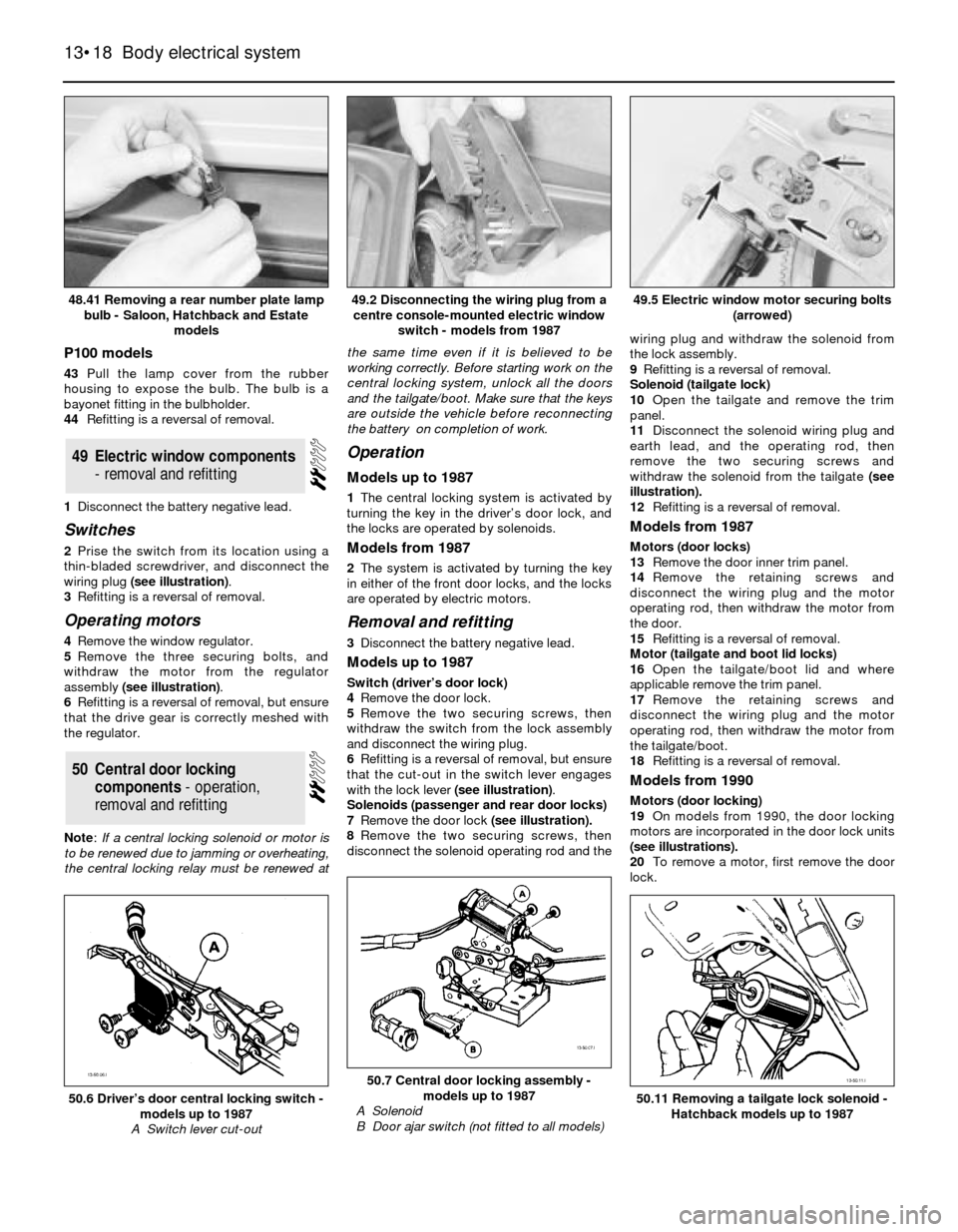

Switch (driver’s door lock)

4Remove the door lock.

5Remove the two securing screws, then

withdraw the switch from the lock assembly

and disconnect the wiring plug.

6Refitting is a reversal of removal, but ensure

that the cut-out in the switch lever engages

with the lock lever (see illustration).

Solenoids (passenger and rear door locks)

7Remove the door lock (see illustration).

8Remove the two securing screws, then

disconnect the solenoid operating rod and thewiring plug and withdraw the solenoid from

the lock assembly.

9Refitting is a reversal of removal.

Solenoid (tailgate lock)

10Open the tailgate and remove the trim

panel.

11Disconnect the solenoid wiring plug and

earth lead, and the operating rod, then

remove the two securing screws and

withdraw the solenoid from the tailgate(see

illustration).

12Refitting is a reversal of removal.

Models from 1987

Motors (door locks)

13Remove the door inner trim panel.

14Remove the retaining screws and

disconnect the wiring plug and the motor

operating rod, then withdraw the motor from

the door.

15Refitting is a reversal of removal.

Motor (tailgate and boot lid locks)

16Open the tailgate/boot lid and where

applicable remove the trim panel.

17Remove the retaining screws and

disconnect the wiring plug and the motor

operating rod, then withdraw the motor from

the tailgate/boot.

18Refitting is a reversal of removal.

Models from 1990

Motors (door locking)

19On models from 1990, the door locking

motors are incorporated in the door lock units

(see illustrations).

20To remove a motor, first remove the door

lock.

50Central door locking

components - operation,

removal and refitting

49Electric window components

- removal and refitting

13•18Body electrical system

48.41 Removing a rear number plate lamp

bulb - Saloon, Hatchback and Estate

models49.5 Electric window motor securing bolts

(arrowed)

50.7 Central door locking assembly -

models up to 1987

A Solenoid

B Door ajar switch (not fitted to all models)

50.6 Driver’s door central locking switch -

models up to 1987

A Switch lever cut-out

49.2 Disconnecting the wiring plug from a

centre console-mounted electric window

switch - models from 1987

50.11 Removing a tailgate lock solenoid -

Hatchback models up to 1987

Page 19 of 25

21Remove the two securing screws, and

detach the motor from the lock assembly.

22Refitting is a reversal of removal, ensuring

that the motor operating rod engages with the

lock lever.

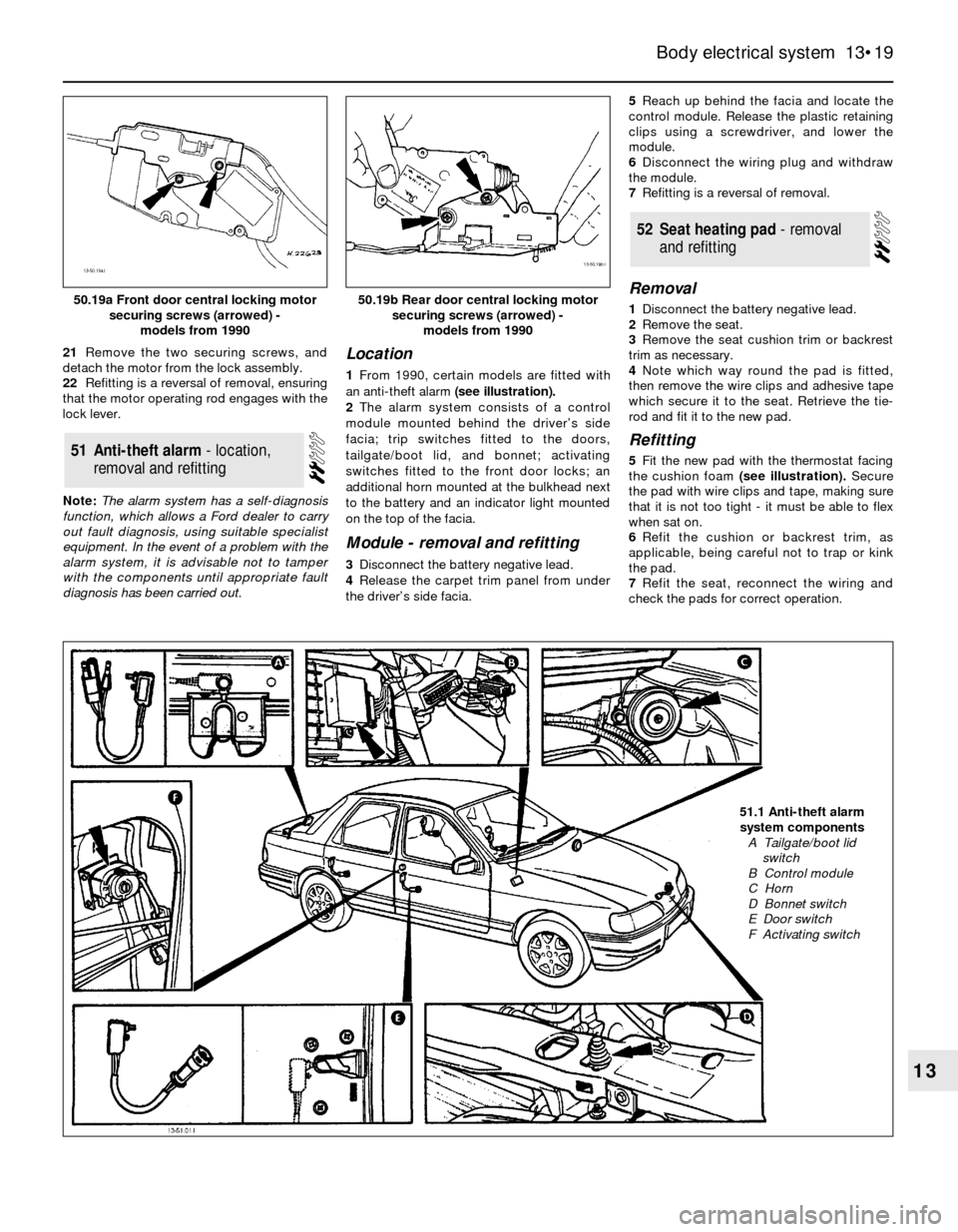

Note: The alarm system has a self-diagnosis

function, which allows a Ford dealer to carry

out fault diagnosis, using suitable specialist

equipment. In the event of a problem with the

alarm system, it is advisable not to tamper

with the components until appropriate fault

diagnosis has been carried out.Location

1From 1990, certain models are fitted with

an anti-theft alarm(see illustration).

2The alarm system consists of a control

module mounted behind the driver’s side

facia; trip switches fitted to the doors,

tailgate/boot lid, and bonnet; activating

switches fitted to the front door locks; an

additional horn mounted at the bulkhead next

to the battery and an indicator light mounted

on the top of the facia.

Module - removal and refitting

3Disconnect the battery negative lead.

4Release the carpet trim panel from under

the driver’s side facia. 5Reach up behind the facia and locate the

control module. Release the plastic retaining

clips using a screwdriver, and lower the

module.

6Disconnect the wiring plug and withdraw

the module.

7Refitting is a reversal of removal.

Removal

1Disconnect the battery negative lead.

2Remove the seat.

3Remove the seat cushion trim or backrest

trim as necessary.

4Note which way round the pad is fitted,

then remove the wire clips and adhesive tape

which secure it to the seat. Retrieve the tie-

rod and fit it to the new pad.

Refitting

5Fit the new pad with the thermostat facing

the cushion foam(see illustration).Secure

the pad with wire clips and tape, making sure

that it is not too tight - it must be able to flex

when sat on.

6Refit the cushion or backrest trim, as

applicable, being careful not to trap or kink

the pad.

7Refit the seat, reconnect the wiring and

check the pads for correct operation.

52Seat heating pad - removal

and refitting

51Anti-theft alarm - location,

removal and refitting

Body electrical system 13•19

13

50.19b Rear door central locking motor

securing screws (arrowed) -

models from 199050.19a Front door central locking motor

securing screws (arrowed) -

models from 1990

51.1 Anti-theft alarm

system components

A Tailgate/boot lid

switch

B Control module

C Horn

D Bonnet switch

E Door switch

F Activating switch