jacking FORD SIERRA 1992 2.G Braking System User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 22, PDF Size: 1.11 MB

Page 19 of 22

Removal

1Chock the front wheels, jack up the rear of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

2The load apportioning valve is located on

the right-hand side of the vehicle underbody

above the axle.

3Remove the spring clip and clevis pin, and

detach the spring from the valve operating

lever (see illustration).

4Place a suitable container beneath the

valve to catch spilt fluid, then unscrew the

union nuts and disconnect the fluid pipes.

Plug the open ends of the pipes and valve to

prevent fluid leakage and dirt ingress.

5Unscrew the three securing nuts and bolts

from the valve mounting bracket, and remove

the valve assembly (see illustration).

Refitting

6Refitting is a reversal of removal, but note

that the fluid inlet pipe from the master cylindermust be connected to the lower valve port, and

the fluid outlet pipe to the rear brakes must be

connected to the upper valve port.

7On completion, bleed the rear hydraulic

circuit and check the valve adjustment.

Models before mid-April 1989

1The vehicle must be unladen, at normal

kerb weight (a full tank of petrol, but no driver

or load).

2With the vehicle standing on its roadwheels,

remove the spring clip and clevis pin, and

detach the spring from the valve operating

lever.

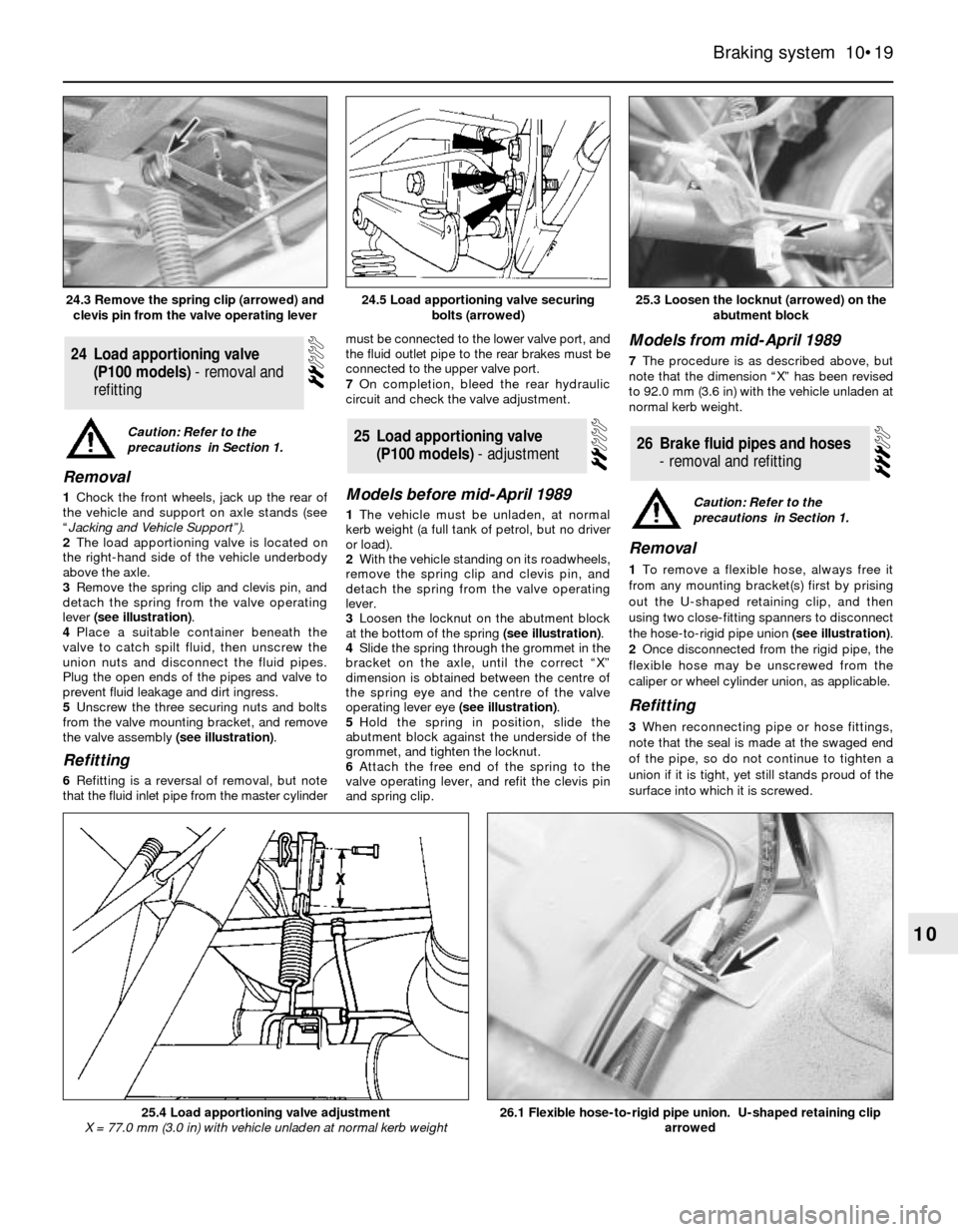

3Loosen the locknut on the abutment block

at the bottom of the spring (see illustration).

4Slide the spring through the grommet in the

bracket on the axle, until the correct “X”

dimension is obtained between the centre of

the spring eye and the centre of the valve

operating lever eye (see illustration).

5Hold the spring in position, slide the

abutment block against the underside of the

grommet, and tighten the locknut.

6Attach the free end of the spring to the

valve operating lever, and refit the clevis pin

and spring clip.

Models from mid-April 1989

7The procedure is as described above, but

note that the dimension “X” has been revised

to 92.0 mm (3.6 in) with the vehicle unladen at

normal kerb weight.

Removal

1To remove a flexible hose, always free it

from any mounting bracket(s) first by prising

out the U-shaped retaining clip, and then

using two close-fitting spanners to disconnect

the hose-to-rigid pipe union (see illustration).

2Once disconnected from the rigid pipe, the

flexible hose may be unscrewed from the

caliper or wheel cylinder union, as applicable.

Refitting

3When reconnecting pipe or hose fittings,

note that the seal is made at the swaged end

of the pipe, so do not continue to tighten a

union if it is tight, yet still stands proud of the

surface into which it is screwed.

26Brake fluid pipes and hoses

- removal and refitting25Load apportioning valve

(P100 models) - adjustment

24Load apportioning valve

(P100 models) - removal and

refitting

Braking system 10•19

10

25.3 Loosen the locknut (arrowed) on the

abutment block

26.1 Flexible hose-to-rigid pipe union. U-shaped retaining clip

arrowed25.4 Load apportioning valve adjustment

X = 77.0 mm (3.0 in) with vehicle unladen at normal kerb weight

24.5 Load apportioning valve securing

bolts (arrowed)24.3 Remove the spring clip (arrowed) and

clevis pin from the valve operating lever

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.

Page 21 of 22

Note: Where fitted, the adjuster locking pin

must be renewed on completion of

adjustment.

Conventional braking system

(except P100 models)

1The handbrake cable is normally

self-adjusting in use, however adjustment

may be required to compensate for cable

stretch over a long period, and is also

necessary after fitting a new cable.

2Chock the front wheels, jack up the rear of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Release the

handbrake.

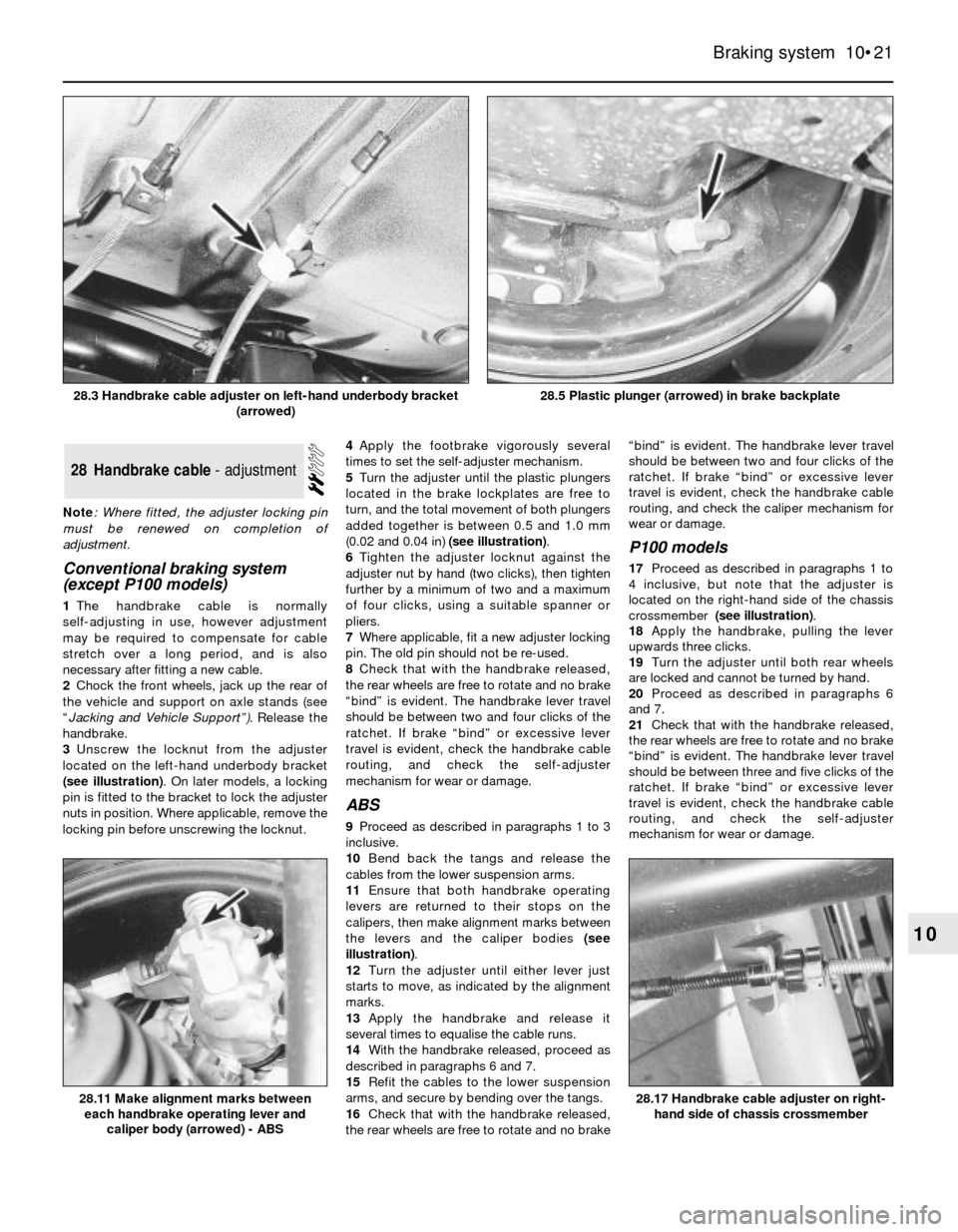

3Unscrew the locknut from the adjuster

located on the left-hand underbody bracket

(see illustration). On later models, a locking

pin is fitted to the bracket to lock the adjuster

nuts in position. Where applicable, remove the

locking pin before unscrewing the locknut.4Apply the footbrake vigorously several

times to set the self-adjuster mechanism.

5Turn the adjuster until the plastic plungers

located in the brake lockplates are free to

turn, and the total movement of both plungers

added together is between 0.5 and 1.0 mm

(0.02 and 0.04 in) (see illustration).

6Tighten the adjuster locknut against the

adjuster nut by hand (two clicks), then tighten

further by a minimum of two and a maximum

of four clicks, using a suitable spanner or

pliers.

7Where applicable, fit a new adjuster locking

pin. The old pin should not be re-used.

8Check that with the handbrake released,

the rear wheels are free to rotate and no brake

“bind” is evident. The handbrake lever travel

should be between two and four clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the self-adjuster

mechanism for wear or damage.

ABS

9Proceed as described in paragraphs 1 to 3

inclusive.

10Bend back the tangs and release the

cables from the lower suspension arms.

11Ensure that both handbrake operating

levers are returned to their stops on the

calipers, then make alignment marks between

the levers and the caliper bodies (see

illustration).

12Turn the adjuster until either lever just

starts to move, as indicated by the alignment

marks.

13Apply the handbrake and release it

several times to equalise the cable runs.

14With the handbrake released, proceed as

described in paragraphs 6 and 7.

15Refit the cables to the lower suspension

arms, and secure by bending over the tangs.

16Check that with the handbrake released,

the rear wheels are free to rotate and no brake“bind” is evident. The handbrake lever travel

should be between two and four clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the caliper mechanism for

wear or damage.

P100 models

17Proceed as described in paragraphs 1 to

4 inclusive, but note that the adjuster is

located on the right-hand side of the chassis

crossmember (see illustration).

18Apply the handbrake, pulling the lever

upwards three clicks.

19Turn the adjuster until both rear wheels

are locked and cannot be turned by hand.

20Proceed as described in paragraphs 6

and 7.

21Check that with the handbrake released,

the rear wheels are free to rotate and no brake

“bind” is evident. The handbrake lever travel

should be between three and five clicks of the

ratchet. If brake “bind” or excessive lever

travel is evident, check the handbrake cable

routing, and check the self-adjuster

mechanism for wear or damage.

28Handbrake cable - adjustment

Braking system 10•21

10

28.5 Plastic plunger (arrowed) in brake backplate

28.17 Handbrake cable adjuster on right-

hand side of chassis crossmember28.11 Make alignment marks between

each handbrake operating lever and

caliper body (arrowed) - ABS

28.3 Handbrake cable adjuster on left-hand underbody bracket

(arrowed)