clock setting FORD SIERRA 1992 2.G Braking System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 22, PDF Size: 1.11 MB

Page 13 of 22

3Remove the wheel cylinder.

4Remove the driveshaft but do not refit the

securing bolts to the backplate.

5Remove the backplate.

6If required, prise out the handbrake stop

button.

7Refitting is a reversal of removal.

P 100 models

Note: When refitting the backplate, a new rear

hub nut and driveshaft O-ring must be used.

8Proceed as described in paragraphs 1 to 3

inclusive.

9Remove the driveshaft.

10Relieve the staking on the rear hub nut,

and using a 50 mm socket and a suitable

extension bar, unscrew the nut. Note that the

nut is extremely tight.

11Pull off the hub.

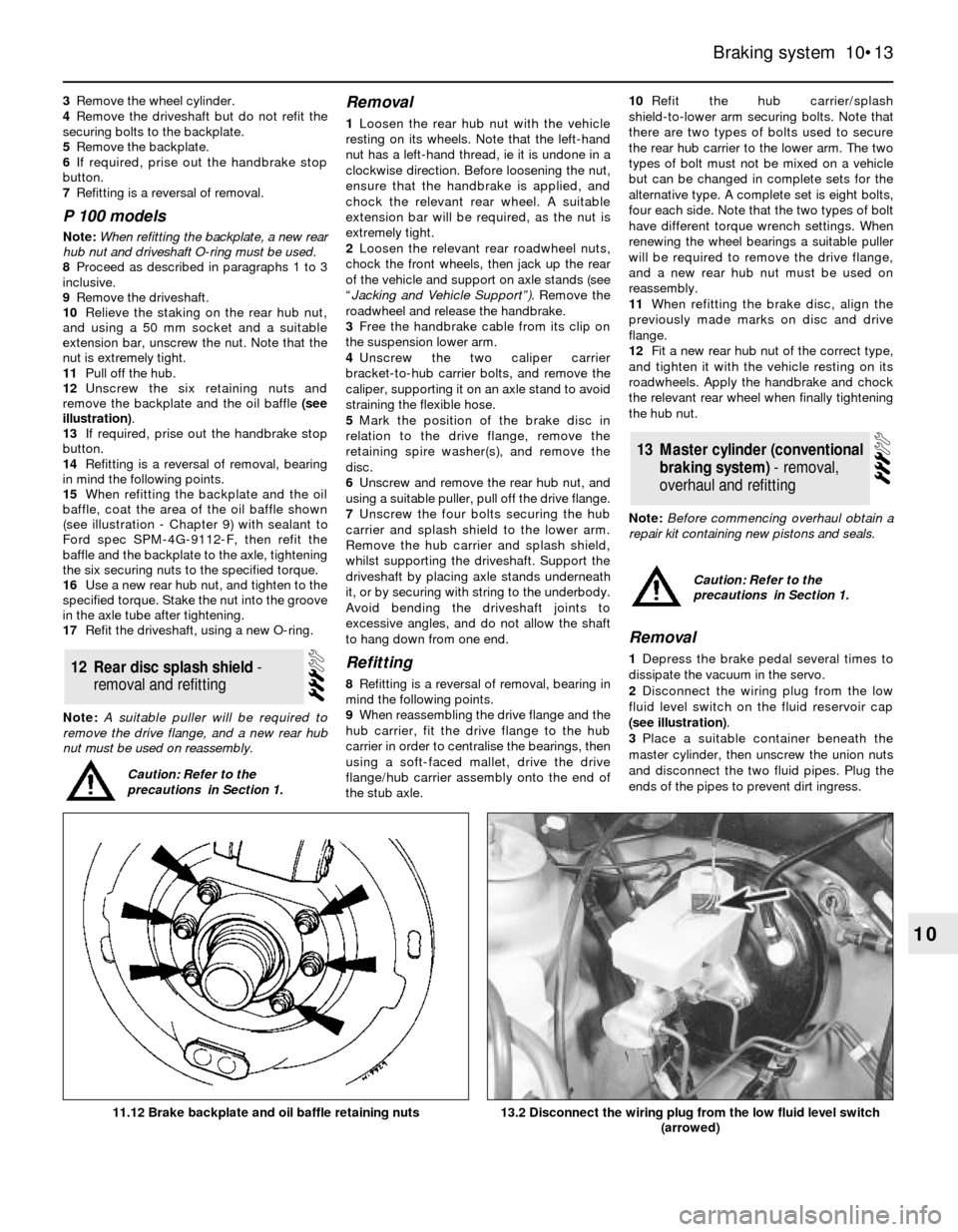

12Unscrew the six retaining nuts and

remove the backplate and the oil baffle (see

illustration).

13If required, prise out the handbrake stop

button.

14Refitting is a reversal of removal, bearing

in mind the following points.

15When refitting the backplate and the oil

baffle, coat the area of the oil baffle shown

(see illustration - Chapter 9) with sealant to

Ford spec SPM-4G-9112-F, then refit the

baffle and the backplate to the axle, tightening

the six securing nuts to the specified torque.

16Use a new rear hub nut, and tighten to the

specified torque. Stake the nut into the groove

in the axle tube after tightening.

17Refit the driveshaft, using a new O-ring.

Note: A suitable puller will be required to

remove the drive flange, and a new rear hub

nut must be used on reassembly.

Removal

1Loosen the rear hub nut with the vehicle

resting on its wheels. Note that the left-hand

nut has a left-hand thread, ie it is undone in a

clockwise direction. Before loosening the nut,

ensure that the handbrake is applied, and

chock the relevant rear wheel. A suitable

extension bar will be required, as the nut is

extremely tight.

2Loosen the relevant rear roadwheel nuts,

chock the front wheels, then jack up the rear

of the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Remove the

roadwheel and release the handbrake.

3Free the handbrake cable from its clip on

the suspension lower arm.

4Unscrew the two caliper carrier

bracket-to-hub carrier bolts, and remove the

caliper, supporting it on an axle stand to avoid

straining the flexible hose.

5Mark the position of the brake disc in

relation to the drive flange, remove the

retaining spire washer(s), and remove the

disc.

6Unscrew and remove the rear hub nut, and

using a suitable puller, pull off the drive flange.

7Unscrew the four bolts securing the hub

carrier and splash shield to the lower arm.

Remove the hub carrier and splash shield,

whilst supporting the driveshaft. Support the

driveshaft by placing axle stands underneath

it, or by securing with string to the underbody.

Avoid bending the driveshaft joints to

excessive angles, and do not allow the shaft

to hang down from one end.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9When reassembling the drive flange and the

hub carrier, fit the drive flange to the hub

carrier in order to centralise the bearings, then

using a soft-faced mallet, drive the drive

flange/hub carrier assembly onto the end of

the stub axle.10Refit the hub carrier/splash

shield-to-lower arm securing bolts. Note that

there are two types of bolts used to secure

the rear hub carrier to the lower arm. The two

types of bolt must not be mixed on a vehicle

but can be changed in complete sets for the

alternative type. A complete set is eight bolts,

four each side. Note that the two types of bolt

have different torque wrench settings. When

renewing the wheel bearings a suitable puller

will be required to remove the drive flange,

and a new rear hub nut must be used on

reassembly.

11When refitting the brake disc, align the

previously made marks on disc and drive

flange.

12Fit a new rear hub nut of the correct type,

and tighten it with the vehicle resting on its

roadwheels. Apply the handbrake and chock

the relevant rear wheel when finally tightening

the hub nut.

Note: Before commencing overhaul obtain a

repair kit containing new pistons and seals.

Removal

1Depress the brake pedal several times to

dissipate the vacuum in the servo.

2Disconnect the wiring plug from the low

fluid level switch on the fluid reservoir cap

(see illustration).

3Place a suitable container beneath the

master cylinder, then unscrew the union nuts

and disconnect the two fluid pipes. Plug the

ends of the pipes to prevent dirt ingress.

13Master cylinder (conventional

braking system) - removal,

overhaul and refitting

12Rear disc splash shield -

removal and refitting

Braking system 10•13

10

13.2 Disconnect the wiring plug from the low fluid level switch

(arrowed)11.12 Brake backplate and oil baffle retaining nuts

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.