light FORD SIERRA 1992 2.G Braking System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 22, PDF Size: 1.11 MB

Page 4 of 22

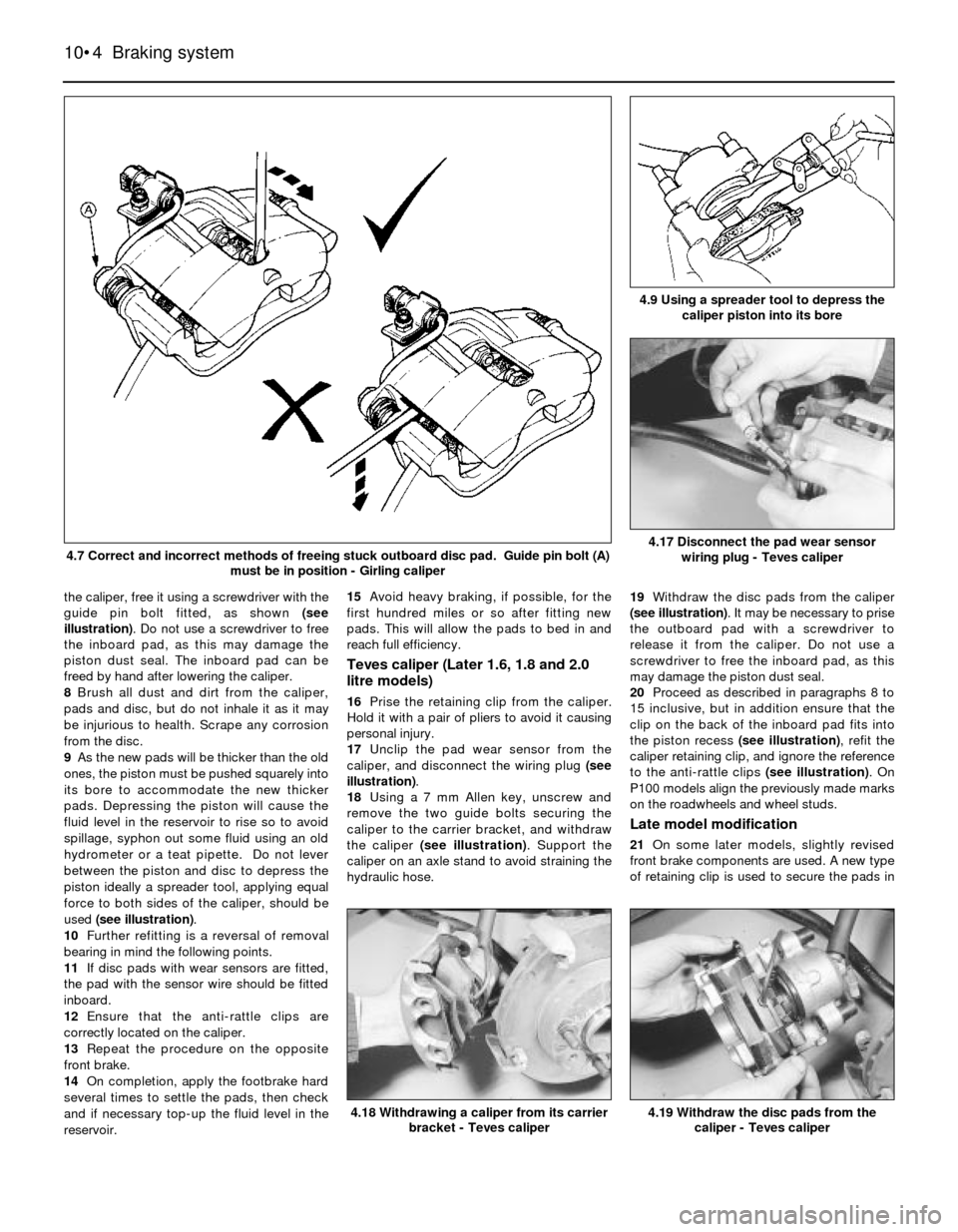

the caliper, free it using a screwdriver with the

guide pin bolt fitted, as shown (see

illustration). Do not use a screwdriver to free

the inboard pad, as this may damage the

piston dust seal. The inboard pad can be

freed by hand after lowering the caliper.

8Brush all dust and dirt from the caliper,

pads and disc, but do not inhale it as it may

be injurious to health. Scrape any corrosion

from the disc.

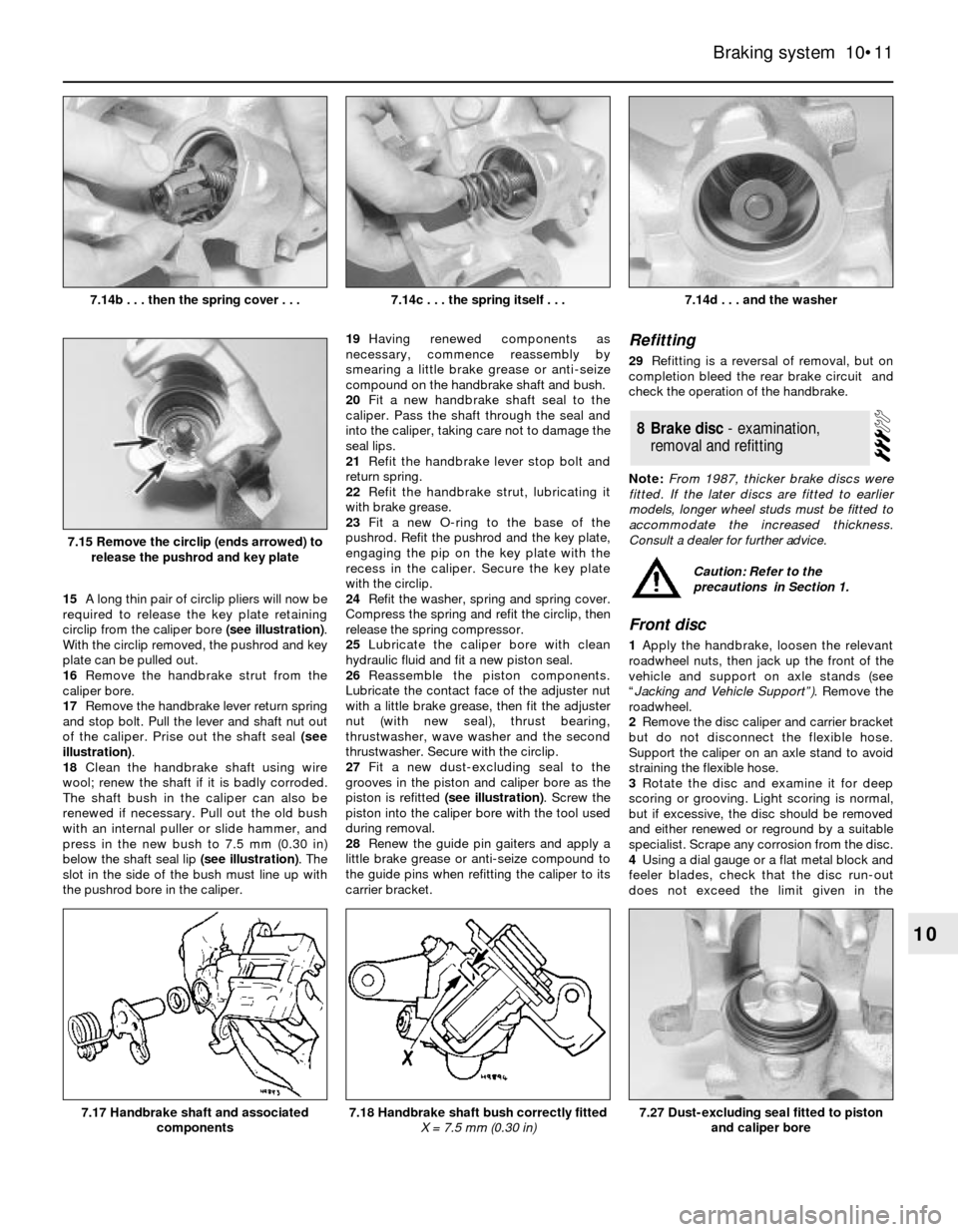

9As the new pads will be thicker than the old

ones, the piston must be pushed squarely into

its bore to accommodate the new thicker

pads. Depressing the piston will cause the

fluid level in the reservoir to rise so to avoid

spillage, syphon out some fluid using an old

hydrometer or a teat pipette. Do not lever

between the piston and disc to depress the

piston ideally a spreader tool, applying equal

force to both sides of the caliper, should be

used (see illustration).

10Further refitting is a reversal of removal

bearing in mind the following points.

11If disc pads with wear sensors are fitted,

the pad with the sensor wire should be fitted

inboard.

12Ensure that the anti-rattle clips are

correctly located on the caliper.

13Repeat the procedure on the opposite

front brake.

14On completion, apply the footbrake hard

several times to settle the pads, then check

and if necessary top-up the fluid level in the

reservoir. 15Avoid heavy braking, if possible, for the

first hundred miles or so after fitting new

pads. This will allow the pads to bed in and

reach full efficiency.

Teves caliper (Later 1.6, 1.8 and 2.0

litre models)

16Prise the retaining clip from the caliper.

Hold it with a pair of pliers to avoid it causing

personal injury.

17Unclip the pad wear sensor from the

caliper, and disconnect the wiring plug (see

illustration).

18Using a 7 mm Allen key, unscrew and

remove the two guide bolts securing the

caliper to the carrier bracket, and withdraw

the caliper (see illustration). Support the

caliper on an axle stand to avoid straining the

hydraulic hose.19Withdraw the disc pads from the caliper

(see illustration). It may be necessary to prise

the outboard pad with a screwdriver to

release it from the caliper. Do not use a

screwdriver to free the inboard pad, as this

may damage the piston dust seal.

20Proceed as described in paragraphs 8 to

15 inclusive, but in addition ensure that the

clip on the back of the inboard pad fits into

the piston recess (see illustration), refit the

caliper retaining clip, and ignore the reference

to the anti-rattle clips (see illustration). On

P100 models align the previously made marks

on the roadwheels and wheel studs.

Late model modification

21On some later models, slightly revised

front brake components are used. A new type

of retaining clip is used to secure the pads in

10•4Braking system

4.7 Correct and incorrect methods of freeing stuck outboard disc pad. Guide pin bolt (A)

must be in position - Girling caliper

4.9 Using a spreader tool to depress the

caliper piston into its bore

4.19 Withdraw the disc pads from the

caliper - Teves caliper4.18 Withdrawing a caliper from its carrier

bracket - Teves caliper

4.17 Disconnect the pad wear sensor

wiring plug - Teves caliper

Page 11 of 22

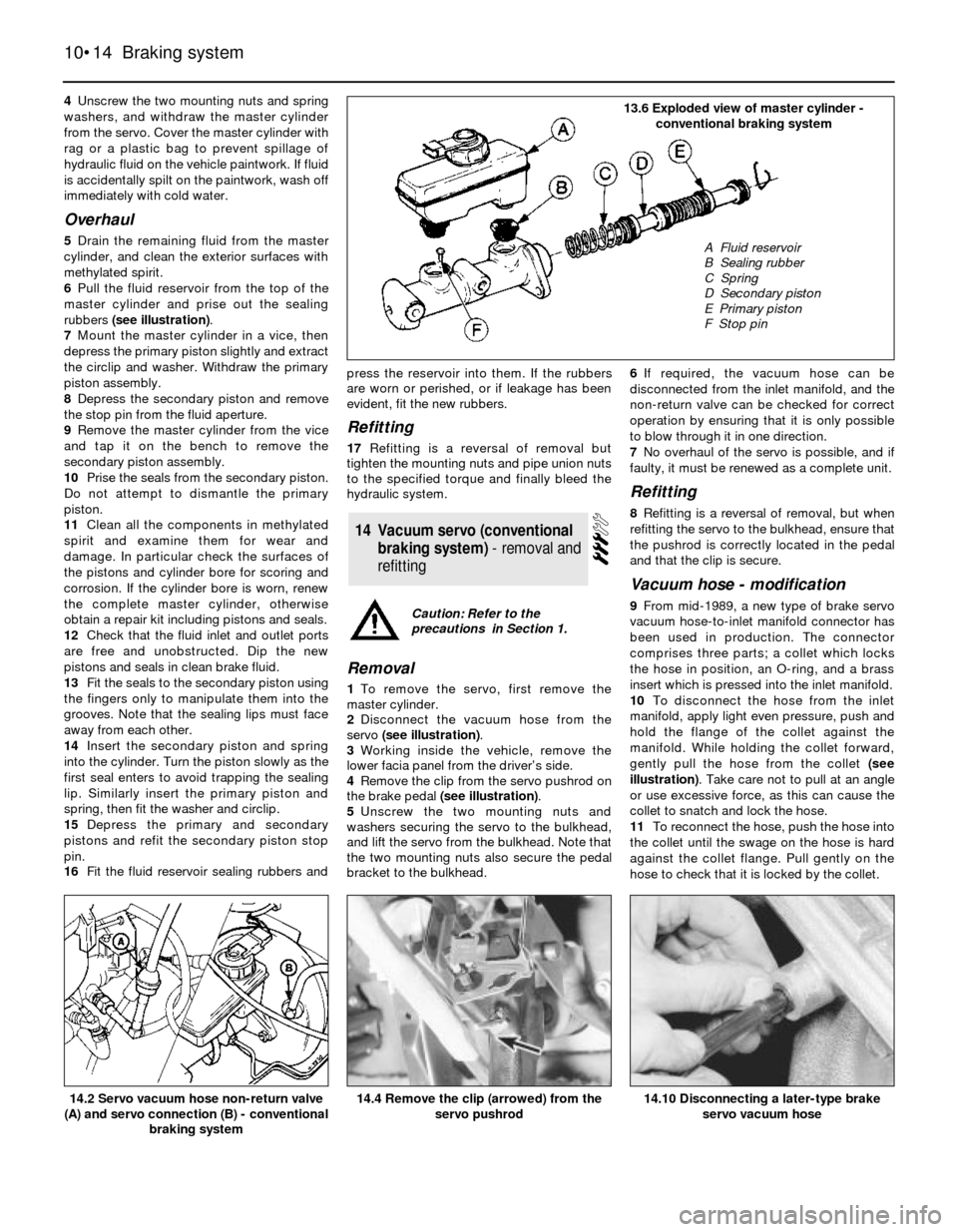

15A long thin pair of circlip pliers will now be

required to release the key plate retaining

circlip from the caliper bore (see illustration).

With the circlip removed, the pushrod and key

plate can be pulled out.

16Remove the handbrake strut from the

caliper bore.

17Remove the handbrake lever return spring

and stop bolt. Pull the lever and shaft nut out

of the caliper. Prise out the shaft seal (see

illustration).

18Clean the handbrake shaft using wire

wool; renew the shaft if it is badly corroded.

The shaft bush in the caliper can also be

renewed if necessary. Pull out the old bush

with an internal puller or slide hammer, and

press in the new bush to 7.5 mm (0.30 in)

below the shaft seal lip (see illustration). The

slot in the side of the bush must line up with

the pushrod bore in the caliper.19Having renewed components as

necessary, commence reassembly by

smearing a little brake grease or anti-seize

compound on the handbrake shaft and bush.

20Fit a new handbrake shaft seal to the

caliper. Pass the shaft through the seal and

into the caliper, taking care not to damage the

seal lips.

21Refit the handbrake lever stop bolt and

return spring.

22Refit the handbrake strut, lubricating it

with brake grease.

23Fit a new O-ring to the base of the

pushrod. Refit the pushrod and the key plate,

engaging the pip on the key plate with the

recess in the caliper. Secure the key plate

with the circlip.

24Refit the washer, spring and spring cover.

Compress the spring and refit the circlip, then

release the spring compressor.

25Lubricate the caliper bore with clean

hydraulic fluid and fit a new piston seal.

26Reassemble the piston components.

Lubricate the contact face of the adjuster nut

with a little brake grease, then fit the adjuster

nut (with new seal), thrust bearing,

thrustwasher, wave washer and the second

thrustwasher. Secure with the circlip.

27Fit a new dust-excluding seal to the

grooves in the piston and caliper bore as the

piston is refitted (see illustration). Screw the

piston into the caliper bore with the tool used

during removal.

28Renew the guide pin gaiters and apply a

little brake grease or anti-seize compound to

the guide pins when refitting the caliper to its

carrier bracket.

Refitting

29Refitting is a reversal of removal, but on

completion bleed the rear brake circuit and

check the operation of the handbrake.

Note: From 1987, thicker brake discs were

fitted. If the later discs are fitted to earlier

models, longer wheel studs must be fitted to

accommodate the increased thickness.

Consult a dealer for further advice.

Front disc

1Apply the handbrake, loosen the relevant

roadwheel nuts, then jack up the front of the

vehicle and support on axle stands (see

“Jacking and Vehicle Support”). Remove the

roadwheel.

2Remove the disc caliper and carrier bracket

but do not disconnect the flexible hose.

Support the caliper on an axle stand to avoid

straining the flexible hose.

3Rotate the disc and examine it for deep

scoring or grooving. Light scoring is normal,

but if excessive, the disc should be removed

and either renewed or reground by a suitable

specialist. Scrape any corrosion from the disc.

4Using a dial gauge or a flat metal block and

feeler blades, check that the disc run-out

does not exceed the limit given in the

8Brake disc - examination,

removal and refitting

Braking system 10•11

10

7.14d . . . and the washer

7.27 Dust-excluding seal fitted to piston

and caliper bore7.18 Handbrake shaft bush correctly fitted

X = 7.5 mm (0.30 in)7.17 Handbrake shaft and associated

components

7.15 Remove the circlip (ends arrowed) to

release the pushrod and key plate

7.14c . . . the spring itself . . .7.14b . . . then the spring cover . . .

Caution: Refer to the

precautions in Section 1.

Page 14 of 22

4Unscrew the two mounting nuts and spring

washers, and withdraw the master cylinder

from the servo. Cover the master cylinder with

rag or a plastic bag to prevent spillage of

hydraulic fluid on the vehicle paintwork. If fluid

is accidentally spilt on the paintwork, wash off

immediately with cold water.

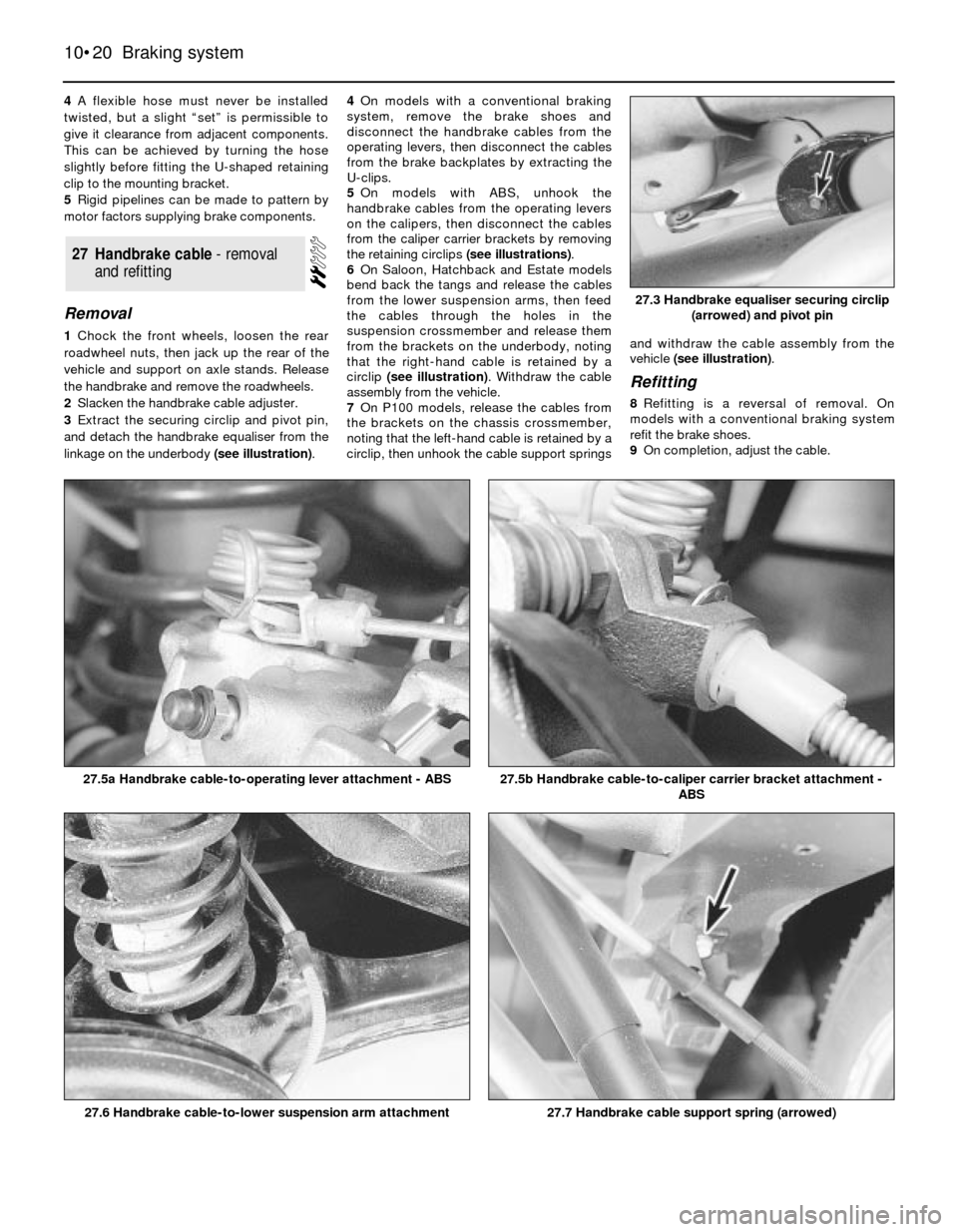

Overhaul

5Drain the remaining fluid from the master

cylinder, and clean the exterior surfaces with

methylated spirit.

6Pull the fluid reservoir from the top of the

master cylinder and prise out the sealing

rubbers (see illustration).

7Mount the master cylinder in a vice, then

depress the primary piston slightly and extract

the circlip and washer. Withdraw the primary

piston assembly.

8Depress the secondary piston and remove

the stop pin from the fluid aperture.

9Remove the master cylinder from the vice

and tap it on the bench to remove the

secondary piston assembly.

10Prise the seals from the secondary piston.

Do not attempt to dismantle the primary

piston.

11Clean all the components in methylated

spirit and examine them for wear and

damage. In particular check the surfaces of

the pistons and cylinder bore for scoring and

corrosion. If the cylinder bore is worn, renew

the complete master cylinder, otherwise

obtain a repair kit including pistons and seals.

12Check that the fluid inlet and outlet ports

are free and unobstructed. Dip the new

pistons and seals in clean brake fluid.

13Fit the seals to the secondary piston using

the fingers only to manipulate them into the

grooves. Note that the sealing lips must face

away from each other.

14Insert the secondary piston and spring

into the cylinder. Turn the piston slowly as the

first seal enters to avoid trapping the sealing

lip. Similarly insert the primary piston and

spring, then fit the washer and circlip.

15Depress the primary and secondary

pistons and refit the secondary piston stop

pin.

16Fit the fluid reservoir sealing rubbers andpress the reservoir into them. If the rubbers

are worn or perished, or if leakage has been

evident, fit the new rubbers.

Refitting

17Refitting is a reversal of removal but

tighten the mounting nuts and pipe union nuts

to the specified torque and finally bleed the

hydraulic system.

Removal

1To remove the servo, first remove the

master cylinder.

2Disconnect the vacuum hose from the

servo (see illustration).

3Working inside the vehicle, remove the

lower facia panel from the driver’s side.

4Remove the clip from the servo pushrod on

the brake pedal (see illustration).

5Unscrew the two mounting nuts and

washers securing the servo to the bulkhead,

and lift the servo from the bulkhead. Note that

the two mounting nuts also secure the pedal

bracket to the bulkhead.6If required, the vacuum hose can be

disconnected from the inlet manifold, and the

non-return valve can be checked for correct

operation by ensuring that it is only possible

to blow through it in one direction.

7No overhaul of the servo is possible, and if

faulty, it must be renewed as a complete unit.

Refitting

8Refitting is a reversal of removal, but when

refitting the servo to the bulkhead, ensure that

the pushrod is correctly located in the pedal

and that the clip is secure.

Vacuum hose - modification

9From mid-1989, a new type of brake servo

vacuum hose-to-inlet manifold connector has

been used in production. The connector

comprises three parts; a collet which locks

the hose in position, an O-ring, and a brass

insert which is pressed into the inlet manifold.

10To disconnect the hose from the inlet

manifold, apply light even pressure, push and

hold the flange of the collet against the

manifold. While holding the collet forward,

gently pull the hose from the collet (see

illustration). Take care not to pull at an angle

or use excessive force, as this can cause the

collet to snatch and lock the hose.

11To reconnect the hose, push the hose into

the collet until the swage on the hose is hard

against the collet flange. Pull gently on the

hose to check that it is locked by the collet.

14Vacuum servo (conventional

braking system) - removal and

refitting

10•14Braking system

14.10 Disconnecting a later-type brake

servo vacuum hose14.4 Remove the clip (arrowed) from the

servo pushrod14.2 Servo vacuum hose non-return valve

(A) and servo connection (B) - conventional

braking system

13.6 Exploded view of master cylinder -

conventional braking system

A Fluid reservoir

B Sealing rubber

C Spring

D Secondary piston

E Primary piston

F Stop pin

Caution: Refer to the

precautions in Section 1.

Page 20 of 22

4A flexible hose must never be installed

twisted, but a slight “set” is permissible to

give it clearance from adjacent components.

This can be achieved by turning the hose

slightly before fitting the U-shaped retaining

clip to the mounting bracket.

5Rigid pipelines can be made to pattern by

motor factors supplying brake components.

Removal

1Chock the front wheels, loosen the rear

roadwheel nuts, then jack up the rear of the

vehicle and support on axle stands. Release

the handbrake and remove the roadwheels.

2Slacken the handbrake cable adjuster.

3Extract the securing circlip and pivot pin,

and detach the handbrake equaliser from the

linkage on the underbody (see illustration).4On models with a conventional braking

system, remove the brake shoes and

disconnect the handbrake cables from the

operating levers, then disconnect the cables

from the brake backplates by extracting the

U-clips.

5On models with ABS, unhook the

handbrake cables from the operating levers

on the calipers, then disconnect the cables

from the caliper carrier brackets by removing

the retaining circlips (see illustrations).

6On Saloon, Hatchback and Estate models

bend back the tangs and release the cables

from the lower suspension arms, then feed

the cables through the holes in the

suspension crossmember and release them

from the brackets on the underbody, noting

that the right-hand cable is retained by a

circlip (see illustration). Withdraw the cable

assembly from the vehicle.

7On P100 models, release the cables from

the brackets on the chassis crossmember,

noting that the left-hand cable is retained by a

circlip, then unhook the cable support springsand withdraw the cable assembly from the

vehicle (see illustration).

Refitting

8Refitting is a reversal of removal. On

models with a conventional braking system

refit the brake shoes.

9On completion, adjust the cable.

27Handbrake cable -removal

andrefitting

10•20Braking system

27.3 Handbrake equaliser securing circlip

(arrowed) and pivot pin

27.5b Handbrake cable-to-caliper carrier bracket attachment -

ABS

27.7 Handbrake cable support spring (arrowed)27.6 Handbrake cable-to-lower suspension arm attachment

27.5a Handbrake cable-to-operating lever attachment - ABS