width FORD SIERRA 1992 2.G Braking System Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 22, PDF Size: 1.11 MB

Page 12 of 22

Specifications. To do this, fix the measuring

equipment, and rotate the disc, noting the

variation in measurement as the disc is

rotated. The difference between the minimum

and maximum measurements recorded is

known as disc run-out.

5Mark the position of the brake disc in

relation to the drive flange and on Saloon,

Hatchback and Estate models, remove the

retaining screw or spire washer(s), as

applicable, and remove the disc. On P100

models, also mark the position of the wheel

adapter plate in relation to the disc and drive

flange, then unscrew the five retaining nuts

and remove the wheel adapter plate and disc.

6Refitting is a reversal of removal, but when

refitting ensure that the mating faces of the

disc, drive flange and on P100 models the

wheel adapter plate, are clean. Align the

marks made on the disc, drive flange, and

where applicable the wheel adapter plate,

during removal. Refit the disc caliper and

carrier bracket.

Rear disc

7Chock the front wheels, loosen the relevant

roadwheel nuts, then jack up the rear of the

vehicle and support on axle stands.(see

“Jacking and Vehicle Support”).Remove the

roadwheel and release the handbrake.

8Detach the handbrake cable from the

retaining clip on the lower arm.

9Unscrew the two caliper carrier

bracket-to-hub carrier bolts and remove the

caliper assembly. Support the caliper on an

axle stand to avoid straining the flexible hose.

10Proceed as described in paragraphs 3

and 4.

11Mark the position of the brake disc in

relation to the drive flange, remove the

retaining spire washer(s), and withdraw the

disc.

12Refitting is a reversal of removal, but

ensure that the mating faces of the disc and

drive flanges are clean, and align the marks

made on the disc and drive flange during

removal.

1Whenever a brake drum is removed, brush

out the dust, taking care not to inhale any, as

it may be injurious to health.

2Examine the internal friction surface of the

drum. If deeply scored, or so worn that the

drum has become ridged to the width of the

shoes, then both drums must be renewed.

3Regrinding is not recommended as the

internal diameter of the drum will no longer be

compatible with the shoe friction material

contact diameter.

Saloon, Hatchback and Estate

models

1Chock the front wheels, loosen the relevant

roadwheel nuts, then jack up the rear of the

vehicle and support on axle stands (see

“Jacking and Vehicle Support”).Remove the

roadwheel and release the handbrake.

2Remove the retaining spire washer(s) from

the wheel stud(s) and pull off the brake drum.

If the drum will not pass over the shoes, it is

possible to release the automatic adjuster

mechanism by inserting a screwdriver through

the small hole in the drum and pressing down

on the ratchet.

3Remove the brake fluid reservoir cap and

secure a piece of polythene over the filler

neck with a rubber band, or by refitting the

cap. This will reduce the loss of fluid during

the following procedure.

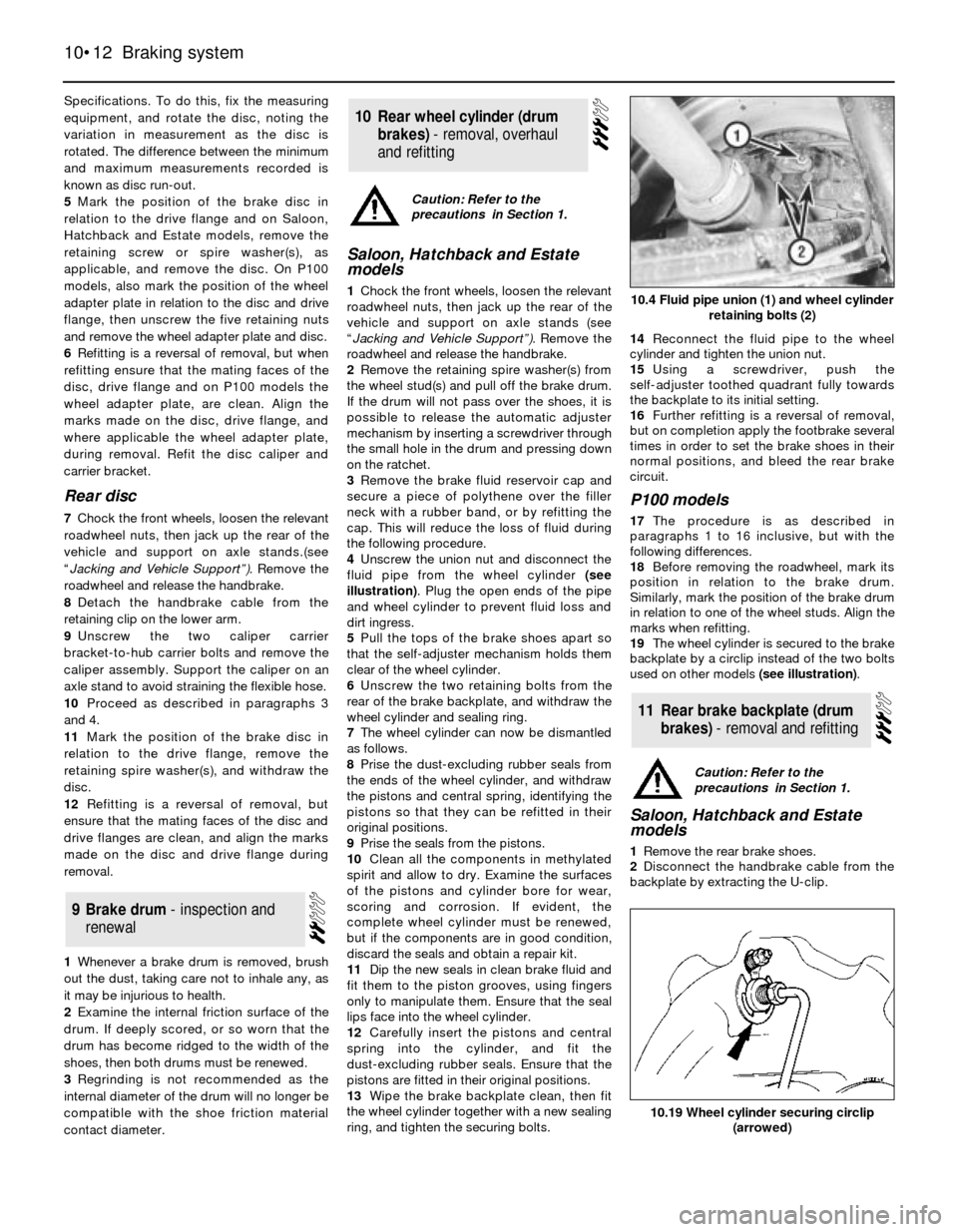

4Unscrew the union nut and disconnect the

fluid pipe from the wheel cylinder (see

illustration). Plug the open ends of the pipe

and wheel cylinder to prevent fluid loss and

dirt ingress.

5Pull the tops of the brake shoes apart so

that the self-adjuster mechanism holds them

clear of the wheel cylinder.

6Unscrew the two retaining bolts from the

rear of the brake backplate, and withdraw the

wheel cylinder and sealing ring.

7The wheel cylinder can now be dismantled

as follows.

8Prise the dust-excluding rubber seals from

the ends of the wheel cylinder, and withdraw

the pistons and central spring, identifying the

pistons so that they can be refitted in their

original positions.

9Prise the seals from the pistons.

10Clean all the components in methylated

spirit and allow to dry. Examine the surfaces

of the pistons and cylinder bore for wear,

scoring and corrosion. If evident, the

complete wheel cylinder must be renewed,

but if the components are in good condition,

discard the seals and obtain a repair kit.

11Dip the new seals in clean brake fluid and

fit them to the piston grooves, using fingers

only to manipulate them. Ensure that the seal

lips face into the wheel cylinder.

12Carefully insert the pistons and central

spring into the cylinder, and fit the

dust-excluding rubber seals. Ensure that the

pistons are fitted in their original positions.

13Wipe the brake backplate clean, then fit

the wheel cylinder together with a new sealing

ring, and tighten the securing bolts.14Reconnect the fluid pipe to the wheel

cylinder and tighten the union nut.

15Using a screwdriver, push the

self-adjuster toothed quadrant fully towards

the backplate to its initial setting.

16Further refitting is a reversal of removal,

but on completion apply the footbrake several

times in order to set the brake shoes in their

normal positions, and bleed the rear brake

circuit.

P100 models

17The procedure is as described in

paragraphs 1 to 16 inclusive, but with the

following differences.

18Before removing the roadwheel, mark its

position in relation to the brake drum.

Similarly, mark the position of the brake drum

in relation to one of the wheel studs. Align the

marks when refitting.

19The wheel cylinder is secured to the brake

backplate by a circlip instead of the two bolts

used on other models (see illustration).

Saloon, Hatchback and Estate

models

1Remove the rear brake shoes.

2Disconnect the handbrake cable from the

backplate by extracting the U-clip.

11Rear brake backplate (drum

brakes) - removal and refitting

10Rear wheel cylinder (drum

brakes) -removal,overhaul

andrefitting

9Brake drum -inspectionand

renewal

10•12Braking system

10.4 Fluid pipe union (1) and wheel cylinder

retaining bolts (2)

10.19 Wheel cylinder securing circlip

(arrowed)

Caution: Refer to the

precautions in Section 1.

Caution: Refer to the

precautions in Section 1.