tow FORD SIERRA 1992 2.G Cooling And Air Conditioning Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 12, PDF Size: 0.62 MB

Page 5 of 12

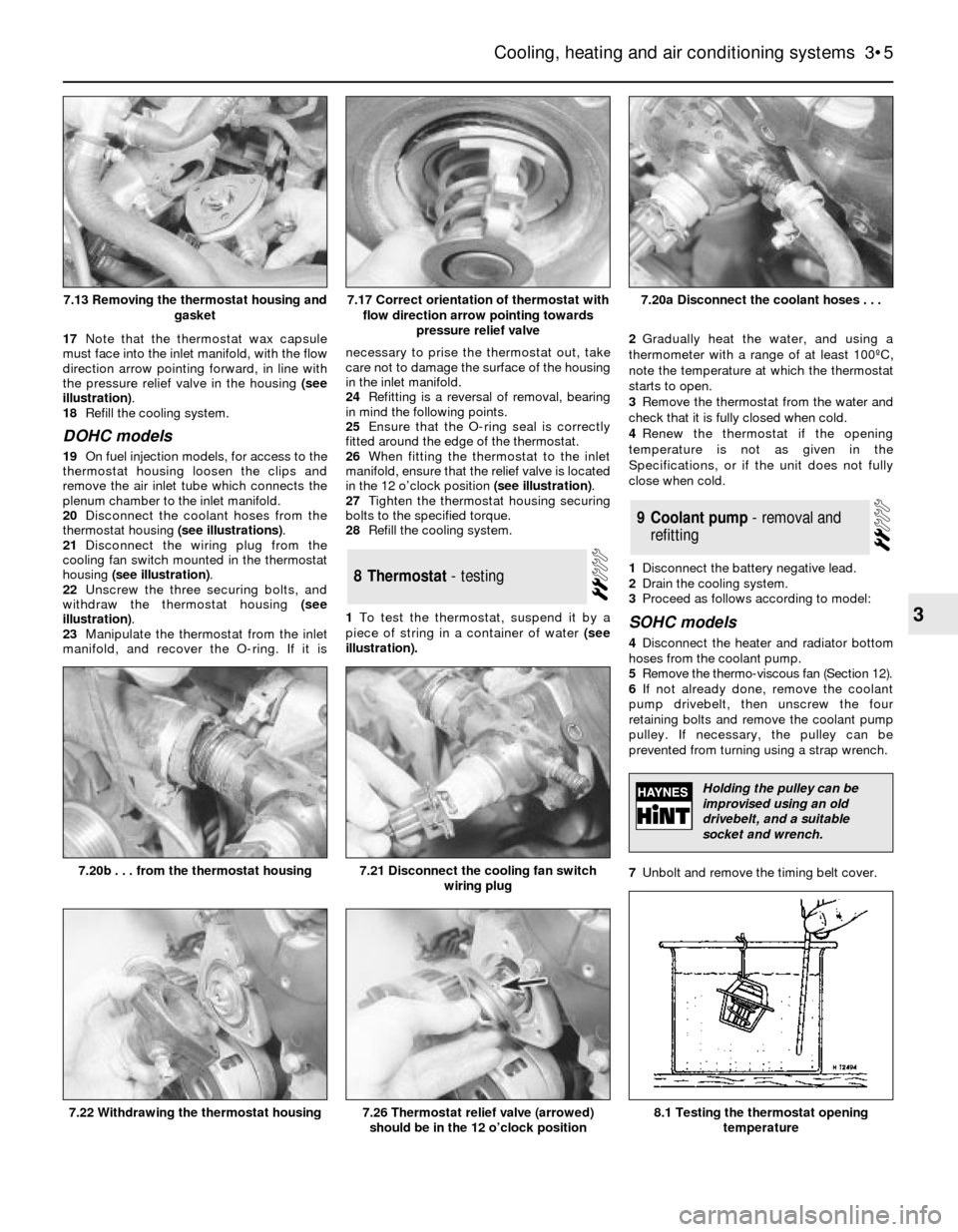

17Note that the thermostat wax capsule

must face into the inlet manifold, with the flow

direction arrow pointing forward, in line with

the pressure relief valve in the housing (see

illustration).

18Refill the cooling system.

DOHC models

19On fuel injection models, for access to the

thermostat housing loosen the clips and

remove the air inlet tube which connects the

plenum chamber to the inlet manifold.

20Disconnect the coolant hoses from the

thermostat housing (see illustrations).

21Disconnect the wiring plug from the

cooling fan switch mounted in the thermostat

housing (see illustration).

22Unscrew the three securing bolts, and

withdraw the thermostat housing (see

illustration).

23Manipulate the thermostat from the inlet

manifold, and recover the O-ring. If it isnecessary to prise the thermostat out, take

care not to damage the surface of the housing

in the inlet manifold.

24Refitting is a reversal of removal, bearing

in mind the following points.

25Ensure that the O-ring seal is correctly

fitted around the edge of the thermostat.

26When fitting the thermostat to the inlet

manifold, ensure that the relief valve is located

in the 12 o’clock position (see illustration).

27Tighten the thermostat housing securing

bolts to the specified torque.

28Refill the cooling system.

1To test the thermostat, suspend it by a

piece of string in a container of water (see

illustration).2Gradually heat the water, and using a

thermometer with a range of at least 100ºC,

note the temperature at which the thermostat

starts to open.

3Remove the thermostat from the water and

check that it is fully closed when cold.

4Renew the thermostat if the opening

temperature is not as given in the

Specifications, or if the unit does not fully

close when cold.

1Disconnect the battery negative lead.

2Drain the cooling system.

3Proceed as follows according to model:

SOHC models

4Disconnect the heater and radiator bottom

hoses from the coolant pump.

5Remove the thermo-viscous fan (Section 12).

6If not already done, remove the coolant

pump drivebelt, then unscrew the four

retaining bolts and remove the coolant pump

pulley. If necessary, the pulley can be

prevented from turning using a strap wrench.

7Unbolt and remove the timing belt cover.

9Coolant pump - removal and

refitting

8Thermostat - testing

Cooling, heating and air conditioning systems 3•5

3

7.20a Disconnect the coolant hoses . . .

8.1 Testing the thermostat opening

temperature7.26 Thermostat relief valve (arrowed)

should be in the 12 o’clock position7.22 Withdrawing the thermostat housing

7.21 Disconnect the cooling fan switch

wiring plug7.20b . . . from the thermostat housing

7.17 Correct orientation of thermostat with

flow direction arrow pointing towards

pressure relief valve7.13 Removing the thermostat housing and

gasket

Holding the pulley can be

improvised using an old

drivebelt, and a suitable

socket and wrench.

Page 7 of 12

36Tighten the coolant pump securing bolts,

and where applicable the pump pulley

securing bolts, to the specified torque.

37On completion, refill the cooling system.

Refer to Chapter 1, Section 21.

Removal

1Remove the alternator drivebelt.

2Loosen the alternator lower mounting

through-bolt, then remove the alternator

upper mounting bolt and swing the alternator

away from the engine.

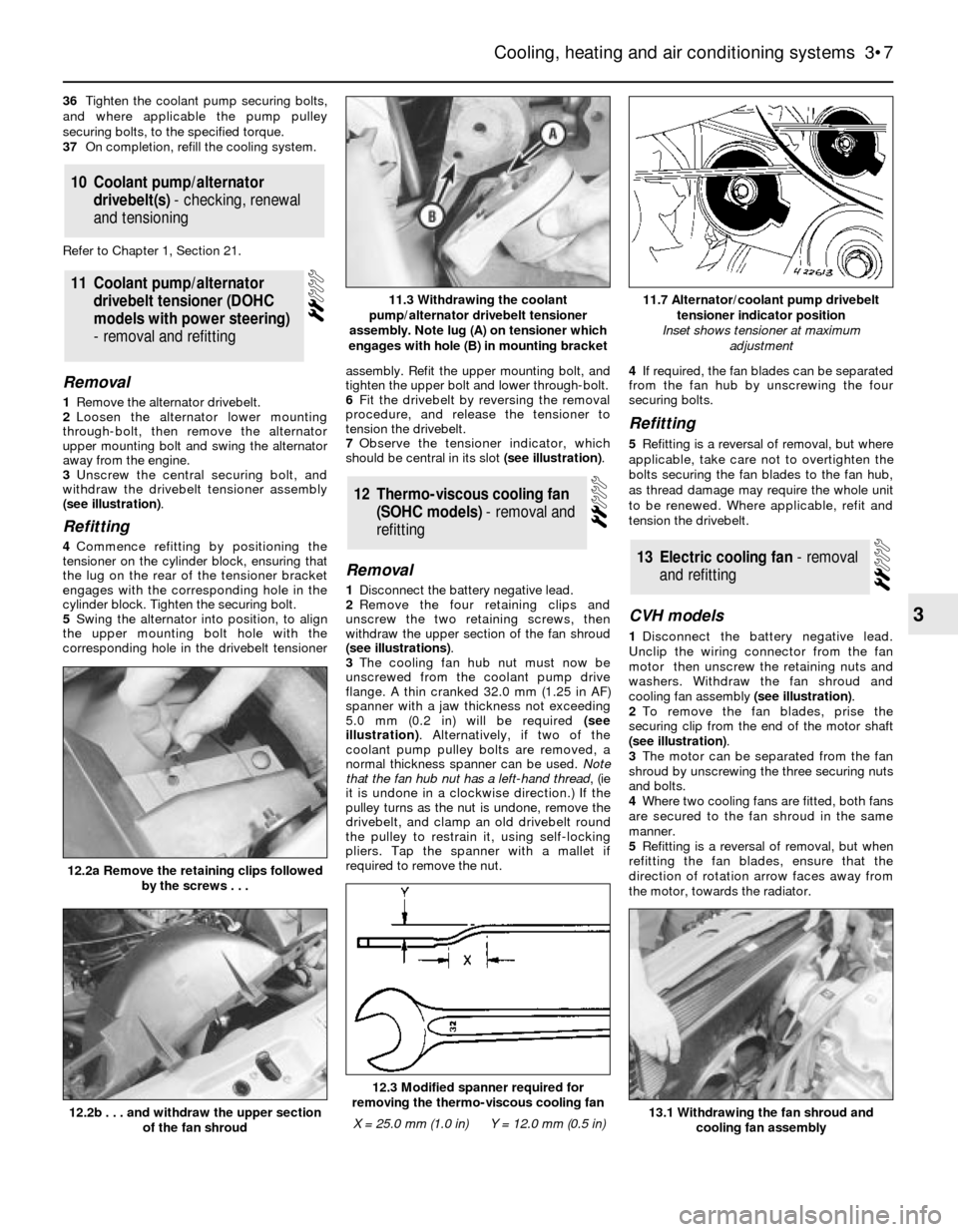

3Unscrew the central securing bolt, and

withdraw the drivebelt tensioner assembly

(see illustration).

Refitting

4Commence refitting by positioning the

tensioner on the cylinder block, ensuring that

the lug on the rear of the tensioner bracket

engages with the corresponding hole in the

cylinder block. Tighten the securing bolt.

5Swing the alternator into position, to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensionerassembly. Refit the upper mounting bolt, and

tighten the upper bolt and lower through-bolt.

6Fit the drivebelt by reversing the removal

procedure, and release the tensioner to

tension the drivebelt.

7Observe the tensioner indicator, which

should be central in its slot (see illustration).

Removal

1Disconnect the battery negative lead.

2Remove the four retaining clips and

unscrew the two retaining screws, then

withdraw the upper section of the fan shroud

(see illustrations).

3The cooling fan hub nut must now be

unscrewed from the coolant pump drive

flange. A thin cranked 32.0 mm (1.25 in AF)

spanner with a jaw thickness not exceeding

5.0 mm (0.2 in) will be required (see

illustration). Alternatively, if two of the

coolant pump pulley bolts are removed, a

normal thickness spanner can be used.Note

that the fan hub nut has a left-hand thread, (ie

it is undone in a clockwise direction.) If the

pulley turns as the nut is undone, remove the

drivebelt, and clamp an old drivebelt round

the pulley to restrain it, using self-locking

pliers. Tap the spanner with a mallet if

required to remove the nut.4If required, the fan blades can be separated

from the fan hub by unscrewing the four

securing bolts.

Refitting

5Refitting is a reversal of removal, but where

applicable, take care not to overtighten the

bolts securing the fan blades to the fan hub,

as thread damage may require the whole unit

to be renewed. Where applicable, refit and

tension the drivebelt.

CVH models

1Disconnect the battery negative lead.

Unclip the wiring connector from the fan

motor then unscrew the retaining nuts and

washers. Withdraw the fan shroud and

cooling fan assembly (see illustration).

2To remove the fan blades, prise the

securing clip from the end of the motor shaft

(see illustration).

3The motor can be separated from the fan

shroud by unscrewing the three securing nuts

and bolts.

4Where two cooling fans are fitted, both fans

are secured to the fan shroud in the same

manner.

5Refitting is a reversal of removal, but when

refitting the fan blades, ensure that the

direction of rotation arrow faces away from

the motor, towards the radiator.

13Electric cooling fan -removal

andrefitting

12Thermo-viscous cooling fan

(SOHC models) - removal and

refitting

11Coolant pump/alternator

drivebelt tensioner (DOHC

models with power steering)

- removal and refitting

10Coolant pump/alternator

drivebelt(s) - checking, renewal

and tensioning

Cooling, heating and air conditioning systems 3•7

3

12.2a Remove the retaining clips followed

by the screws . . .

13.1 Withdrawing the fan shroud and

cooling fan assembly

12.3 Modified spanner required for

removing the thermo-viscous cooling fan

X = 25.0 mm (1.0 in)Y = 12.0 mm (0.5 in)12.2b . . . and withdraw the upper section

of the fan shroud

11.7 Alternator/coolant pump drivebelt

tensioner indicator position

Inset shows tensioner at maximum

adjustment11.3 Withdrawing the coolant

pump/alternator drivebelt tensioner

assembly. Note lug (A) on tensioner which

engages with hole (B) in mounting bracket

Page 9 of 12

2With the engine cold, slowly unscrew the

expansion tank cap to release any remaining

pressure from the cooling system, then refit

the cap.

3Disconnect the wiring from the sender

terminal (see illustrations).

4Unscrew and remove the sender, and

temporarily plug the aperture.

Refitting

5Refitting is a reversal of removal, but smear

a little sealing compound on the sender unit

threads before fitting.

6On completion, check and if necessary top-

up the coolant level.

Removal

1Disconnect the battery negative lead.

2Remove the securing screws and unclip the

lower and upper steering column shrouds.

3Remove the four securing screws and

withdraw the instrument panel surround. Note

that the bottom right-hand screw is covered

by a plastic panel which must be prised out.

4Remove the passenger side lower facia

panel.

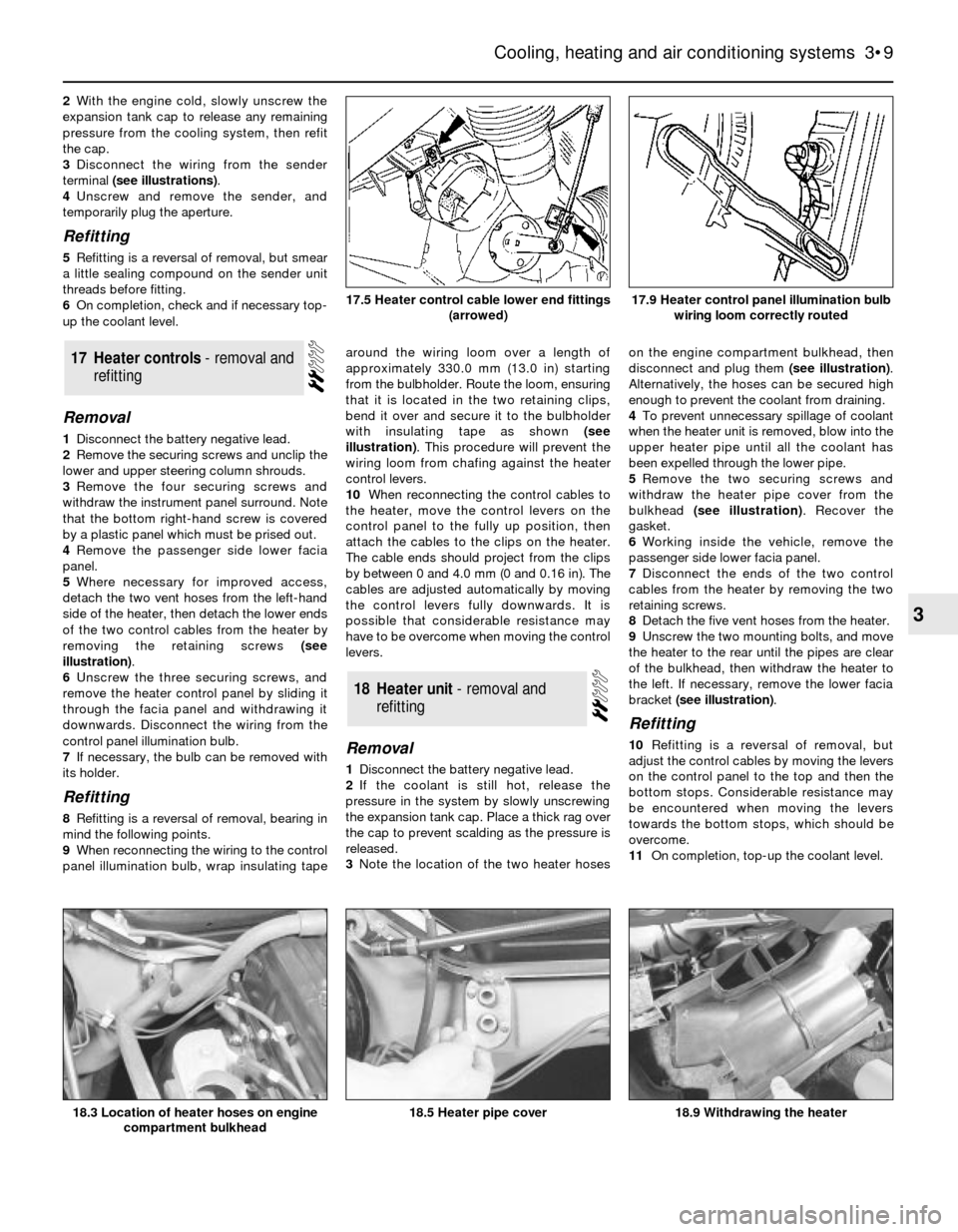

5Where necessary for improved access,

detach the two vent hoses from the left-hand

side of the heater, then detach the lower ends

of the two control cables from the heater by

removing the retaining screws (see

illustration).

6Unscrew the three securing screws, and

remove the heater control panel by sliding it

through the facia panel and withdrawing it

downwards. Disconnect the wiring from the

control panel illumination bulb.

7If necessary, the bulb can be removed with

its holder.

Refitting

8Refitting is a reversal of removal, bearing in

mind the following points.

9When reconnecting the wiring to the control

panel illumination bulb, wrap insulating tapearound the wiring loom over a length of

approximately 330.0 mm (13.0 in) starting

from the bulbholder. Route the loom, ensuring

that it is located in the two retaining clips,

bend it over and secure it to the bulbholder

with insulating tape as shown (see

illustration). This procedure will prevent the

wiring loom from chafing against the heater

control levers.

10When reconnecting the control cables to

the heater, move the control levers on the

control panel to the fully up position, then

attach the cables to the clips on the heater.

The cable ends should project from the clips

by between 0 and 4.0 mm (0 and 0.16 in). The

cables are adjusted automatically by moving

the control levers fully downwards. It is

possible that considerable resistance may

have to be overcome when moving the control

levers.

Removal

1Disconnect the battery negative lead.

2If the coolant is still hot, release the

pressure in the system by slowly unscrewing

the expansion tank cap. Place a thick rag over

the cap to prevent scalding as the pressure is

released.

3Note the location of the two heater hoseson the engine compartment bulkhead, then

disconnect and plug them (see illustration).

Alternatively, the hoses can be secured high

enough to prevent the coolant from draining.

4To prevent unnecessary spillage of coolant

when the heater unit is removed, blow into the

upper heater pipe until all the coolant has

been expelled through the lower pipe.

5Remove the two securing screws and

withdraw the heater pipe cover from the

bulkhead (see illustration). Recover the

gasket.

6Working inside the vehicle, remove the

passenger side lower facia panel.

7Disconnect the ends of the two control

cables from the heater by removing the two

retaining screws.

8Detach the five vent hoses from the heater.

9Unscrew the two mounting bolts, and move

the heater to the rear until the pipes are clear

of the bulkhead, then withdraw the heater to

the left. If necessary, remove the lower facia

bracket (see illustration).

Refitting

10Refitting is a reversal of removal, but

adjust the control cables by moving the levers

on the control panel to the top and then the

bottom stops. Considerable resistance may

be encountered when moving the levers

towards the bottom stops, which should be

overcome.

11On completion, top-up the coolant level.

18Heater unit - removal and

refitting

17Heater controls - removal and

refitting

Cooling, heating and air conditioning systems 3•9

3

18.3 Location of heater hoses on engine

compartment bulkhead18.9 Withdrawing the heater18.5 Heater pipe cover

17.9 Heater control panel illumination bulb

wiring loom correctly routed17.5 Heater control cable lower end fittings

(arrowed)

Page 11 of 12

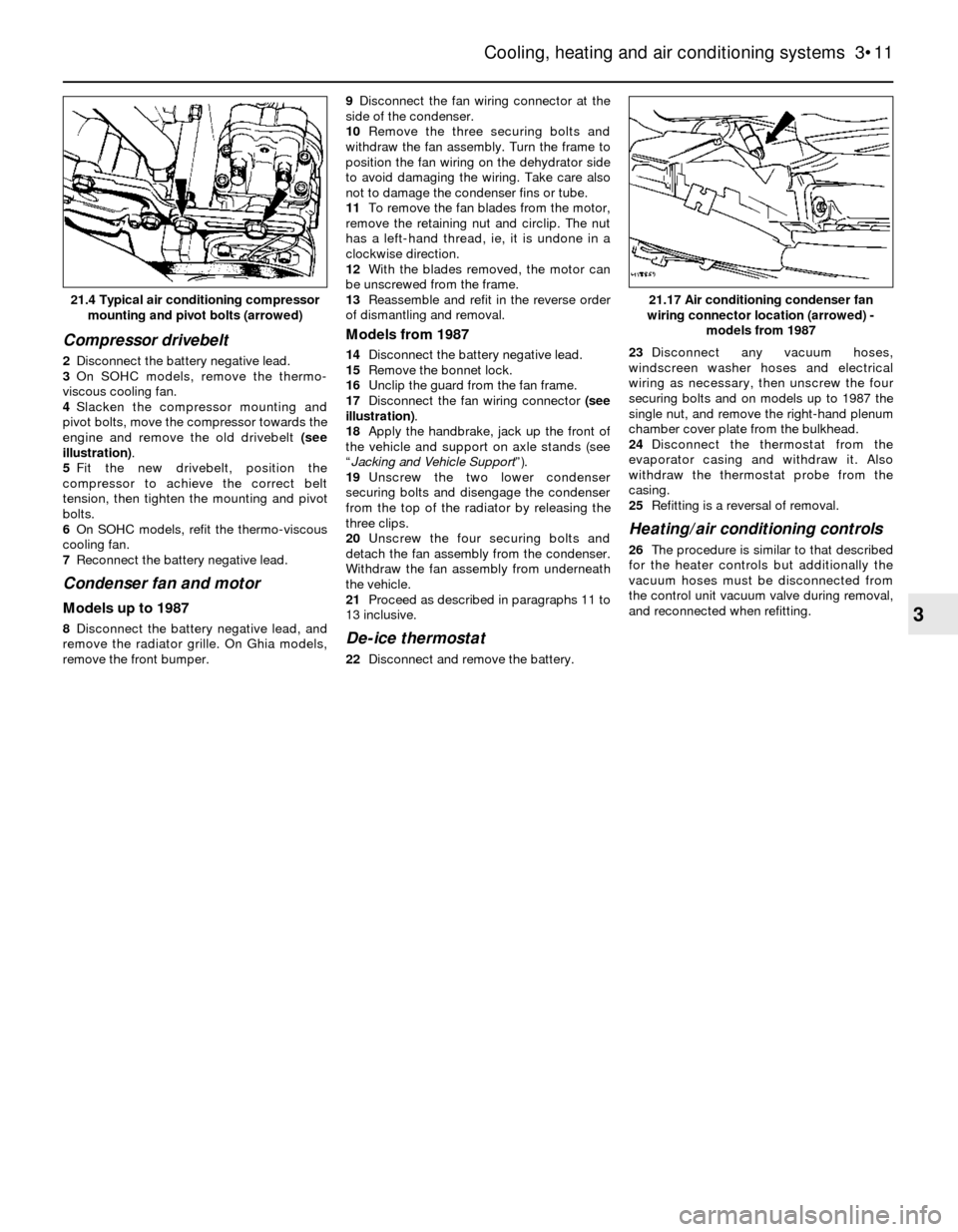

Compressor drivebelt

2Disconnect the battery negative lead.

3On SOHC models, remove the thermo-

viscous cooling fan.

4Slacken the compressor mounting and

pivot bolts, move the compressor towards the

engine and remove the old drivebelt (see

illustration).

5Fit the new drivebelt, position the

compressor to achieve the correct belt

tension, then tighten the mounting and pivot

bolts.

6On SOHC models, refit the thermo-viscous

cooling fan.

7Reconnect the battery negative lead.

Condenser fan and motor

Models up to 1987

8Disconnect the battery negative lead, and

remove the radiator grille. On Ghia models,

remove the front bumper.9Disconnect the fan wiring connector at the

side of the condenser.

10Remove the three securing bolts and

withdraw the fan assembly. Turn the frame to

position the fan wiring on the dehydrator side

to avoid damaging the wiring. Take care also

not to damage the condenser fins or tube.

11To remove the fan blades from the motor,

remove the retaining nut and circlip. The nut

has a left-hand thread, ie, it is undone in a

clockwise direction.

12With the blades removed, the motor can

be unscrewed from the frame.

13Reassemble and refit in the reverse order

of dismantling and removal.

Models from 1987

14Disconnect the battery negative lead.

15Remove the bonnet lock.

16Unclip the guard from the fan frame.

17Disconnect the fan wiring connector (see

illustration).

18Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

19Unscrew the two lower condenser

securing bolts and disengage the condenser

from the top of the radiator by releasing the

three clips.

20Unscrew the four securing bolts and

detach the fan assembly from the condenser.

Withdraw the fan assembly from underneath

the vehicle.

21Proceed as described in paragraphs 11 to

13 inclusive.

De-ice thermostat

22Disconnect and remove the battery.23Disconnect any vacuum hoses,

windscreen washer hoses and electrical

wiring as necessary, then unscrew the four

securing bolts and on models up to 1987 the

single nut, and remove the right-hand plenum

chamber cover plate from the bulkhead.

24Disconnect the thermostat from the

evaporator casing and withdraw it. Also

withdraw the thermostat probe from the

casing.

25Refitting is a reversal of removal.

Heating/air conditioning controls

26The procedure is similar to that described

for the heater controls but additionally the

vacuum hoses must be disconnected from

the control unit vacuum valve during removal,

and reconnected when refitting.

Cooling, heating and air conditioning systems 3•11

3

21.17 Air conditioning condenser fan

wiring connector location (arrowed) -

models from 198721.4 Typical air conditioning compressor

mounting and pivot bolts (arrowed)