ESP FORD SIERRA 1992 2.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.09 MB

Page 9 of 24

firmly in place in the transmission housing,

otherwise it could fall out resulting in fluid

spillage and possible damage. It may be

necessary to rock the units slightly to

separate them.

1.8 litre (R2A type)

1Reverse the procedure described in

Section 8, noting the following points.

2Before attempting to refit the engine, check

that the clutch friction disc is centralised. This

is necessary to ensure that the gearbox input

shaft splines will pass through the splines in

the centre of the friction disc.

3Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on its locating dowels.

5Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

6Fill the engine with the correct grade and

quantity of oil.

7Fill the cooling system.

8Check and if necessary adjust the tension

of the alternator drivebelt.

9Adjust the throttle cable.

1.6 and 1.8 litre (R6A type)

10Reverse the procedure described in

Section 8, noting the points made above.

1Reverse the procedure described in

Section 9, noting the following points.

2Check that the engine adapter plate is

correctly positioned on its locating dowels.

3As the torque converter is only loosely

engaged in the transmission, care must be

taken to prevent the torque converter from

falling out forwards. When the torque

converter hub is fully engaged with the fluid

pump drivegear in the transmission, distance

“A” in illustration 2.24 of Chapter 7B must be

as specified. Incorrect installation of the

torque converter will result in damage to the

transmission.

4As the engine is installed, guide the torque

converter studs through the holes in the

driveplate. When the engine is positioned

flush with the engine adapter plate and the

transmission housing, check that the torque

converter is free to move axially a small

amount before refitting and tightening the

engine-to-transmission bolts.

5Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

6Fill the engine with the correct grade and

quantity of oil. 7Fill the cooling system.

8Check and if necessary adjust the tension

of the alternator drivebelt.

9Adjust the throttle cable.

10If applicable, adjust the kickdown cable.

1.8 litre (R2A type)

1Reverse the procedure described in Section

10, noting the following points.

2Before attempting to reconnect the engine

to the gearbox, check that the clutch friction

disc is centralised. This is necessary to ensure

that the gearbox input shaft splines will pass

through the splines in the centre of the friction

disc.

3Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on its locating dowels.

5Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

6Fill the engine with the correct grade and

quantity of oil.

7Fill the cooling system.

8Check and if necessary top-up the gearbox

oil level.

9Check and if necessary adjust the tension

of the alternator drivebelt.

10Adjust the throttle cable.

1.6 and 1.8 litre (R6A type)

11Reverse the procedure described in

Section 10, noting the points made above.

Ensure that the vehicle speed sensor wiring

plug is reconnected.

1Reverse the procedure described in Section

11, noting the following points.

2Check that the engine adapter plate is

correctly positioned on its locating dowels.

3As the torque converter is only loosely

engaged in the transmission, care must be

taken to prevent the torque converter from

falling out forwards. When the torque

converter hub is fully engaged with the fluid

pump drivegear in the transmission, distance

“A” in illustration 2.24 of Chapter 7B must be

as specified. Incorrect installation of the

torque converter will result in damage to the

transmission.

4As the engine and transmission are

reconnected, guide the torque converter

studs through the holes in the driveplate.

When the engine is positioned flush with the

engine adapter plate and the transmission

housing, check that the torque converter is

free to move axially a small amount beforerefitting and tightening the engine-to-

transmission bolts.

5Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

6Reconnect and adjust the selector rod.

7Fill the engine with the correct grade and

quantity of oil.

8Fill the cooling system.

9Check and if necessary top-up the

transmission fluid level.

10Check and if necessary adjust the tension

of the alternator drivebelt.

11Adjust the throttle cable.

12Where applicable, adjust the kickdown

cable.

1The engine mountings incorporate

hydraulic dampers and must be renewed if

excessive engine movement is evident.

2Working in the engine compartment,

unscrew the central nuts securing the engine

mounting brackets to the tops of the

mountings. Recover the washers.

3Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

4Working underneath the vehicle, remove

the central nuts securing the mountings to the

crossmember. Recover the washers.

5Raise the engine using a suitable hoist and

lifting tackle attached to the engine lifting

brackets on the cylinder head, or a jack and

interposed block of wood under the sump,

until the mountings can be withdrawn.

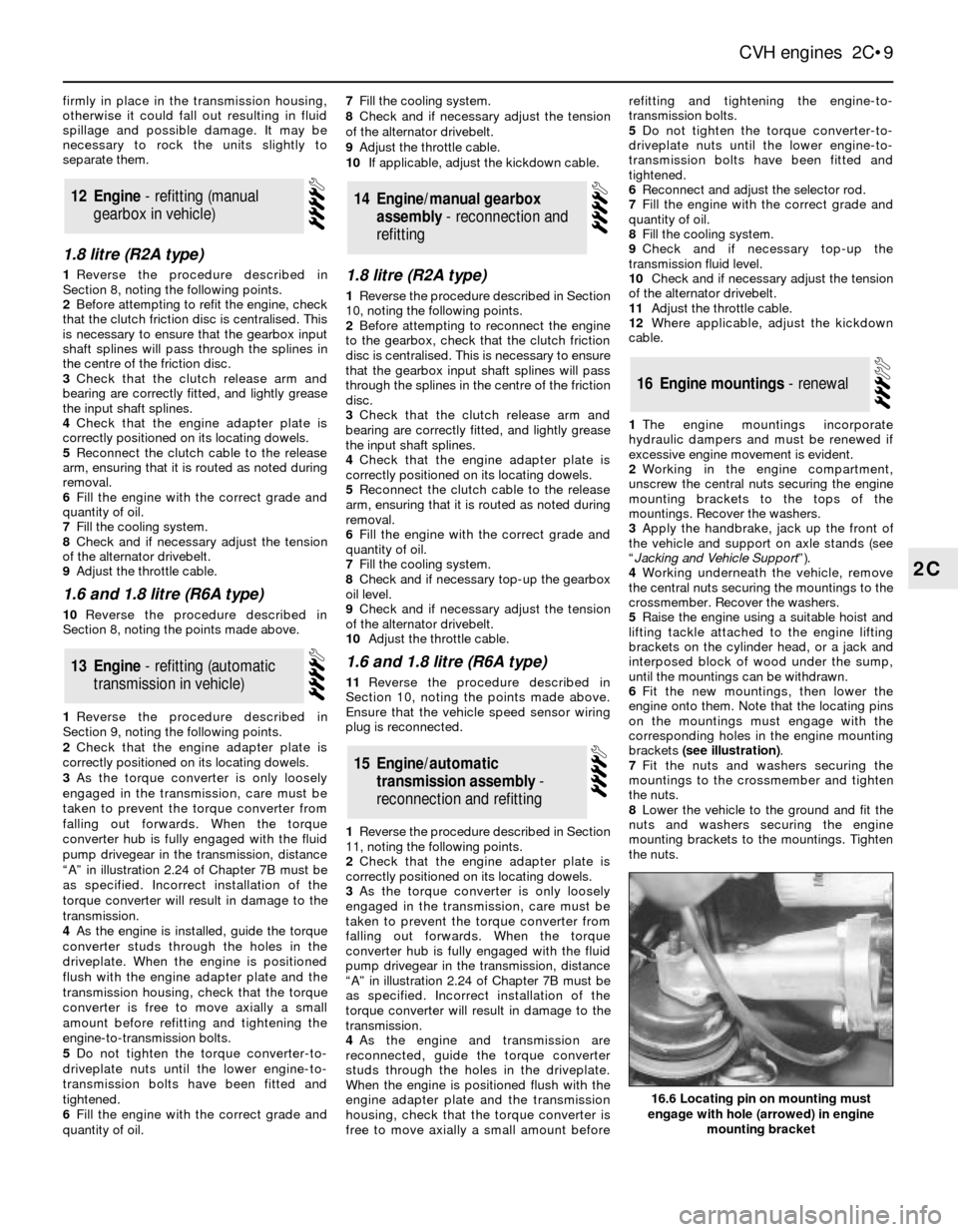

6Fit the new mountings, then lower the

engine onto them. Note that the locating pins

on the mountings must engage with the

corresponding holes in the engine mounting

brackets (see illustration).

7Fit the nuts and washers securing the

mountings to the crossmember and tighten

the nuts.

8Lower the vehicle to the ground and fit the

nuts and washers securing the engine

mounting brackets to the mountings. Tighten

the nuts.

16Engine mountings - renewal

15Engine/automatic

transmission assembly -

reconnection and refitting

14Engine/manual gearbox

assembly - reconnection and

refitting

13Engine - refitting (automatic

transmission in vehicle)

12Engine - refitting (manual

gearbox in vehicle)

CVH engines 2C•9

2C

16.6 Locating pin on mounting must

engage with hole (arrowed) in engine

mounting bracket