light FORD SIERRA 1992 2.G CVH Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.09 MB

Page 5 of 24

1.8 litre (R6A type) engine

Note: Unless otherwise stated, the Specifications for this later version of the 1.8 litre CVH engine are as given for the earlier R2A type above.

General

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .R6A

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .5700 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64 kW at 5200 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145 Nm at 3000 rpm

Valve timing

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24º BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116º BTDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110º ATDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18º ATDC

1.6 litre engine

The 1.6 litre CVH engine was introduced in

September 1991, to replace the 1.6 litre

SOHC engine used previously in the Sierra

range. The engine is broadly similar to the 1.8

litre (R2A type) CVH engine described below.

The main differences are outlined in the

following paragraphs.

The centre main bearing is fitted with

thrustwashers to control crankshaft endfloat,

instead of a flanged bearing shell.

The hydraulic cam followers operate in a

similar manner to those described for the 1.8

litre (R2A) engine but no rollers are fitted, and

the base of each cam follower is in direct

contact with the cam profile.

A distributorless ignition system is used and

a blanking plate is therefore fitted to the cylinder

head in place of the distributor drive. The

electric fuel pump is mounted in the fuel tank.

A comprehensive emissions control system

is fitted, comprising Central Fuel Injection

(CFI), a sophisticated engine management

system, a crankcase ventilation system, a

catalytic converter, and a pulseair system (to

reduce exhaust gas emissions).

Unless otherwise stated, all procedures are

as described for the 1.8 litre (R2A) engine.

1.8 litre (R2A type) engine

The CVH (Compound Valve angle,

Hemispherical combustion chambers) engine

is of four-cylinder, in-line, single overhead

camshaft type. The engine was introduced to

replace the 1.8 SOHC engine previously used

in the range.

The crankshaft incorporates five main

bearings. The centre main bearing has a

flanged bearing shell (thrust bearing) fitted to

the cylinder block to control crankshaft endfloat

The camshaft is driven by a toothed belt and

operates the compound angled valves via roller

type hydraulic cam followers, which eliminates

the need for valve clearance adjustment. The

cam followers operate in the following way.

When the valve is closed, pressurised engine

oil passes through ports in the body of the cam

follower and the plunger into the cylinder feed

chamber. From this chamber, oil flows through

a ball type non-return valve into the pressurechamber. The tension of the coil spring causes

the plunger to press the rocker arm against the

valve and to eliminate any free play.

As the cam lifts the cam follower, the oil

pressure in the pressure chamber increases

and causes the non-return valve to close the

port to the feed chamber. As oil cannot be

compressed, it forms a rigid link between the

body of the cam follower, the cylinder and the

plunger which then rise as one component to

open the valve.

The clearance between the body of the cam

follower and the cylinder is accurately designed

to meter a specific quantity of oil as it escapes

from the pressure chamber. Oil will only pass

along the cylinder bore when pressure is high

during the moment of valve opening. Once the

valve has closed, the escape of oil will produce

a small amount of free play and no pressure will

exist in the pressure chamber. Oil from the feed

chamber can then flow through the non-return

valve into the pressure chamber so that the

cam follower cylinder can be raised by the

pressure of the coil spring, thus eliminating any

play in the arrangement until the valve is

operated again.

As wear occurs between rocker arm and

valve stem, the quantity of oil which flows into

the pressure chamber will be slightly more

than the quantity lost during the expansion

cycle of the cam follower. Conversely, when

the cam follower is compressed by the

expansion of the valve, a slightly smaller

quantity of oil will flow into the pressure

chamber than was lost.

To reduce valve clatter when the engine is

started, a small plastic stand pipe retains oil

inside the plunger. When the engine is started,

the reservoir in the plunger (and via the non-

return valve, the pressure chamber) are

immediately filled with oil. This reduces the

noise often associated with hydraulic cam

followers as they pressurise with oil after

engine start-up.

The cam follower rollers run in needle

bearings, which greatly reduces friction as the

rollers follow the cam profile.

The distributor and fuel pump are driven

directly from the camshaft and the oil pump is

driven directly from the front of the crankshaft.

The cylinder head is of crossflow design,

with the inlet manifold mounted on the right-

hand side and the exhaust manifold mounted

on the left-hand side.

Lubrication is by means of a bi-rotor pumpwhich draws oil through a strainer located

inside the sump and forces it through a full-

flow filter into the oil galleries where it is

distributed to the crankshaft and camshaft.

The big-end bearings are supplied with oil via

internal drillings in the crankshaft. The

undersides of the pistons are supplied with oil

from drillings in the big-ends. The hydraulic

cam followers are supplied with oil from the

camshaft bearings via short passages in the

cylinder head.

A semi-closed crankcase ventilation system

is employed whereby piston blow-by gases

are drawn from the crankcase, through the

camshaft cover via an external vent hose, out

to an oil separator built into the base of the air

cleaner.

1.8 litre (R6A type) engine

The 1.8 litre (R6A type) CVH engine,

introduced in March 1992, is a further

development of the earlier 1.8 litre (R2A type)

unit described above. Apart from minor

engineering modifications to provide

increased fuel economy, reliability and power

output, the engine is mechanically identical to

the earlier version.

In common with the 1.6 litre unit, a

distributorless ignition system is used,

together with a comprehensive emissions

control system comprising Central Fuel

Injection (CFI), a sophisticated engine

management system, a crankcase ventilation

system, a catalytic converter, and additionally,

an exhaust gas recirculation (EGR) system.

Unless otherwise stated, all procedures are

as described for the 1.8 litre (R2A type)

engine.

Refer to Section 2, Chapter 2, Part A.

Refer to Chapter 1, Section 35.

Refer to Section 5, Chapter 2, Part A.

4Compression test

3Crankcase ventilation system -

inspection and maintenance

2Engine oil and filter - renewal

1General information

CVH engines 2C•5

2C

Page 8 of 24

console. Where a full-length console is fitted,

it is only necessary to remove the front tray.

3Detach the outer gaiter from the retaining

frame and withdraw it over the gear lever.

4Release the clips and remove the gaiter

retaining frame and inner gaiter.

5Using a suitable Torx key, remove the

screws securing the gear lever to the gearbox

extension housing, and withdraw the gear

lever. Note how the base of the gear lever

locates over the selector shaft.

6Jack up the vehicle and support on axle

stands (see “Jacking and Vehicle Support”).

Ensure that there is sufficient working room

beneath the vehicle.

7To improve access, disconnect the exhaust

downpipe from the manifold and remove the

exhaust system.

8Remove the propeller shaft.

9Where applicable bend back the locktabs,

then unscrew the two bolts securing each of

the two anti-roll bar U-clamps to the vehicle

underbody. Lower the anti-roll bar as far as

possible.

10Proceed as described in Section 8,

paragraphs 23 and 24.

11Drain the engine oil into a container.

12Unscrew the two nuts securing the engine

mountings to the crossmember. Recover the

washers.

13Disconnect the wiring from the reversing

lamp switch.

14Remove the retaining circlip, and

withdraw the speedometer cable from the

gearbox extension housing.

15Support the gearbox with a trolley jack,

using a block of wood between the jack and

the gearbox to spread the load.

16Unscrew the four bolts securing the

gearbox crossmember to the vehicle

underbody. Unscrew the central bolt securing

the crossmember to the gearbox and remove

the crossmember. Note the position of the

earth strap, where applicable. Recover the

mounting cup and where applicable the

exhaust mounting bracket and heat shield.

17Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

engine/gearbox assembly.

18Attach a hoist to the engine lifting

brackets located at the front and rear of the

cylinder head. Arrange the lifting tackle so that

the engine/gearbox assembly will assume a

steep angle of approximately 40º to 45º as it is

being removed.

19Raise the engine/gearbox so that the

engine mounting studs are clear of the

crossmember, then ease the assembly

forwards, at the same time lowering the trolley

jack which is supporting the gearbox. Lift the

assembly from the vehicle, taking care not to

damage the surrounding components.

20With the engine/gearbox assembly

removed, temporarily reconnect the anti-roll

bar to the underbody if the vehicle is to be

moved.

Separation

21To separate the engine from the gearbox,

proceed as follows. 22Remove the starter motor.

23Support the engine and gearbox

horizontally on blocks of wood.

24Unscrew and remove the engine-to-

gearbox bolts, noting the location of the earth

strap, and remove the two bolts from the

engine adapter plate.

25Pull the engine and gearbox apart, taking

care not to strain the gearbox input shaft. It

may be necessary to rock the units slightly to

separate them.

1.6 and 1.8 litre (R6A type)

26Proceed as described in paragraphs 30 to

40 inclusive of Section 8.

27Proceed as described in paragraphs 2 to

25 inclusive of Section 10, noting the

following points.

28Disconnect the wiring from the vehicle

speed sensor mounted on the gearbox before

removing the engine/gearbox assembly.

29Note that on 1.6 litre engines, the

crankshaft speed/position sensor shroud

(which is secured by a single bolt) must be

removed before separating the engine from

the gearbox.

Note: A suitable hoist and lifting tackle will be

required for this operation. Any suspected

faults in the automatic transmission should be

referred to a Ford dealer or automatic

transmission specialist before removal of the

unit, as the specialist fault diagnosis

equipment is designed to operate with the

transmission in the vehicle.

Removal

1Proceed as described in Section 8,

paragraphs 1 to 15 inclusive, but additionally,

where applicable disconnect the kickdown

cable from the carburettor.

2Jack up the vehicle and support on axle

stands (see “Jacking and Vehicle Support”).

Ensure that there is sufficient working room

beneath the vehicle.

3To improve access, disconnect the exhaust

downpipe from the manifold and remove the

exhaust system.

4Remove the propeller shaft.

5Where applicable bend back the locktabs,

then unscrew the two bolts securing each of

the two anti-roll bar U-clamps to the vehicle

underbody. Lower the anti-roll bar as far as

possible.

6Unscrew the unions and disconnect the

fluid cooler pipes from the transmission. Plug

the open ends of the pipes and the

transmission to prevent dirt ingress and fluid

leakage. Remove the fluid cooler pipe bracket

from the engine mounting bracket and place it

to one side.

7Remove the two clips securing the selector

rod, and detach the selector rod from the

manual selector lever, and the selector lever

on the transmission,

8If applicable, disconnect the kickdown cable

from the transmission and withdraw the cable.9Disconnect the wiring from the starter

inhibitor/reversing lamp switch, the lock-up

clutch and where applicable the kickdown

solenoid.

10Remove the securing screw, and

disconnect the speedometer cable from the

transmission extension housing. Plug the

opening in the transmission to prevent dirt

ingress.

11Disconnect the vacuum pipe from the

vacuum diaphragm unit, and unclip the pipe

from its securing bracket on the transmission

housing.

12Drain the engine oil into a container.

13Unscrew the two nuts securing the engine

mountings to the crossmember. Recover the

washers.

14Support the transmission with a trolley

jack using a block of wood between the jack

and the transmission to spread the load.

15Unscrew the four bolts securing the

transmission crossmember to the vehicle

underbody. Note the position of the earth

strap, where applicable. Unscrew the central

bolt securing the crossmember to the

transmission and remove the crossmember.

Recover the mounting cup and the exhaust

mounting bracket.

16Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

engine/transmission assembly.

17Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head. Arrange the lifting tackle so that

the engine/transmission assembly will assume

a steep angle of approximately 40º to 45º as it

is being removed.

18Raise the engine/transmission so that the

engine mounting studs are clear of the

crossmember, then ease the assembly

forwards, at the same time lowering the trolley

jack which is supporting the transmission. Lift

the assembly from the vehicle, taking care not

to damage surrounding components.

19With the engine/transmission assembly

removed, temporarily reconnect the anti-roll

bar to the underbody if the vehicle is to be

moved.

Separation

20To separate the engine from the

transmission, proceed as follows.

21Remove the starter motor.

22Support the engine and transmission

horizontally on blocks of wood.

23Working through the starter motor

aperture, unscrew the four torque converter-

to-driveplate nuts. It will be necessary to turn

the crankshaft using a suitable spanner on the

crankshaft pulley bolt in order to gain access

to each nut in turn through the aperture.

24Unscrew and remove the engine-to-

transmission bolts, noting the locations of the

earth strap, vacuum pipe bracket, and

transmission dipstick tube bracket. Remove

the two bolts from the engine adapter plate,

and where applicable pull the blanking plug

from the adapter plate.

25Pull the engine and transmission apart,

ensuring that the torque converter is held

11Engine/automatic

transmission assembly -

removal and separation

2C•8CVH engines

Page 9 of 24

firmly in place in the transmission housing,

otherwise it could fall out resulting in fluid

spillage and possible damage. It may be

necessary to rock the units slightly to

separate them.

1.8 litre (R2A type)

1Reverse the procedure described in

Section 8, noting the following points.

2Before attempting to refit the engine, check

that the clutch friction disc is centralised. This

is necessary to ensure that the gearbox input

shaft splines will pass through the splines in

the centre of the friction disc.

3Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on its locating dowels.

5Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

6Fill the engine with the correct grade and

quantity of oil.

7Fill the cooling system.

8Check and if necessary adjust the tension

of the alternator drivebelt.

9Adjust the throttle cable.

1.6 and 1.8 litre (R6A type)

10Reverse the procedure described in

Section 8, noting the points made above.

1Reverse the procedure described in

Section 9, noting the following points.

2Check that the engine adapter plate is

correctly positioned on its locating dowels.

3As the torque converter is only loosely

engaged in the transmission, care must be

taken to prevent the torque converter from

falling out forwards. When the torque

converter hub is fully engaged with the fluid

pump drivegear in the transmission, distance

“A” in illustration 2.24 of Chapter 7B must be

as specified. Incorrect installation of the

torque converter will result in damage to the

transmission.

4As the engine is installed, guide the torque

converter studs through the holes in the

driveplate. When the engine is positioned

flush with the engine adapter plate and the

transmission housing, check that the torque

converter is free to move axially a small

amount before refitting and tightening the

engine-to-transmission bolts.

5Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

6Fill the engine with the correct grade and

quantity of oil. 7Fill the cooling system.

8Check and if necessary adjust the tension

of the alternator drivebelt.

9Adjust the throttle cable.

10If applicable, adjust the kickdown cable.

1.8 litre (R2A type)

1Reverse the procedure described in Section

10, noting the following points.

2Before attempting to reconnect the engine

to the gearbox, check that the clutch friction

disc is centralised. This is necessary to ensure

that the gearbox input shaft splines will pass

through the splines in the centre of the friction

disc.

3Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

4Check that the engine adapter plate is

correctly positioned on its locating dowels.

5Reconnect the clutch cable to the release

arm, ensuring that it is routed as noted during

removal.

6Fill the engine with the correct grade and

quantity of oil.

7Fill the cooling system.

8Check and if necessary top-up the gearbox

oil level.

9Check and if necessary adjust the tension

of the alternator drivebelt.

10Adjust the throttle cable.

1.6 and 1.8 litre (R6A type)

11Reverse the procedure described in

Section 10, noting the points made above.

Ensure that the vehicle speed sensor wiring

plug is reconnected.

1Reverse the procedure described in Section

11, noting the following points.

2Check that the engine adapter plate is

correctly positioned on its locating dowels.

3As the torque converter is only loosely

engaged in the transmission, care must be

taken to prevent the torque converter from

falling out forwards. When the torque

converter hub is fully engaged with the fluid

pump drivegear in the transmission, distance

“A” in illustration 2.24 of Chapter 7B must be

as specified. Incorrect installation of the

torque converter will result in damage to the

transmission.

4As the engine and transmission are

reconnected, guide the torque converter

studs through the holes in the driveplate.

When the engine is positioned flush with the

engine adapter plate and the transmission

housing, check that the torque converter is

free to move axially a small amount beforerefitting and tightening the engine-to-

transmission bolts.

5Do not tighten the torque converter-to-

driveplate nuts until the lower engine-to-

transmission bolts have been fitted and

tightened.

6Reconnect and adjust the selector rod.

7Fill the engine with the correct grade and

quantity of oil.

8Fill the cooling system.

9Check and if necessary top-up the

transmission fluid level.

10Check and if necessary adjust the tension

of the alternator drivebelt.

11Adjust the throttle cable.

12Where applicable, adjust the kickdown

cable.

1The engine mountings incorporate

hydraulic dampers and must be renewed if

excessive engine movement is evident.

2Working in the engine compartment,

unscrew the central nuts securing the engine

mounting brackets to the tops of the

mountings. Recover the washers.

3Apply the handbrake, jack up the front of

the vehicle and support on axle stands (see

“Jacking and Vehicle Support”).

4Working underneath the vehicle, remove

the central nuts securing the mountings to the

crossmember. Recover the washers.

5Raise the engine using a suitable hoist and

lifting tackle attached to the engine lifting

brackets on the cylinder head, or a jack and

interposed block of wood under the sump,

until the mountings can be withdrawn.

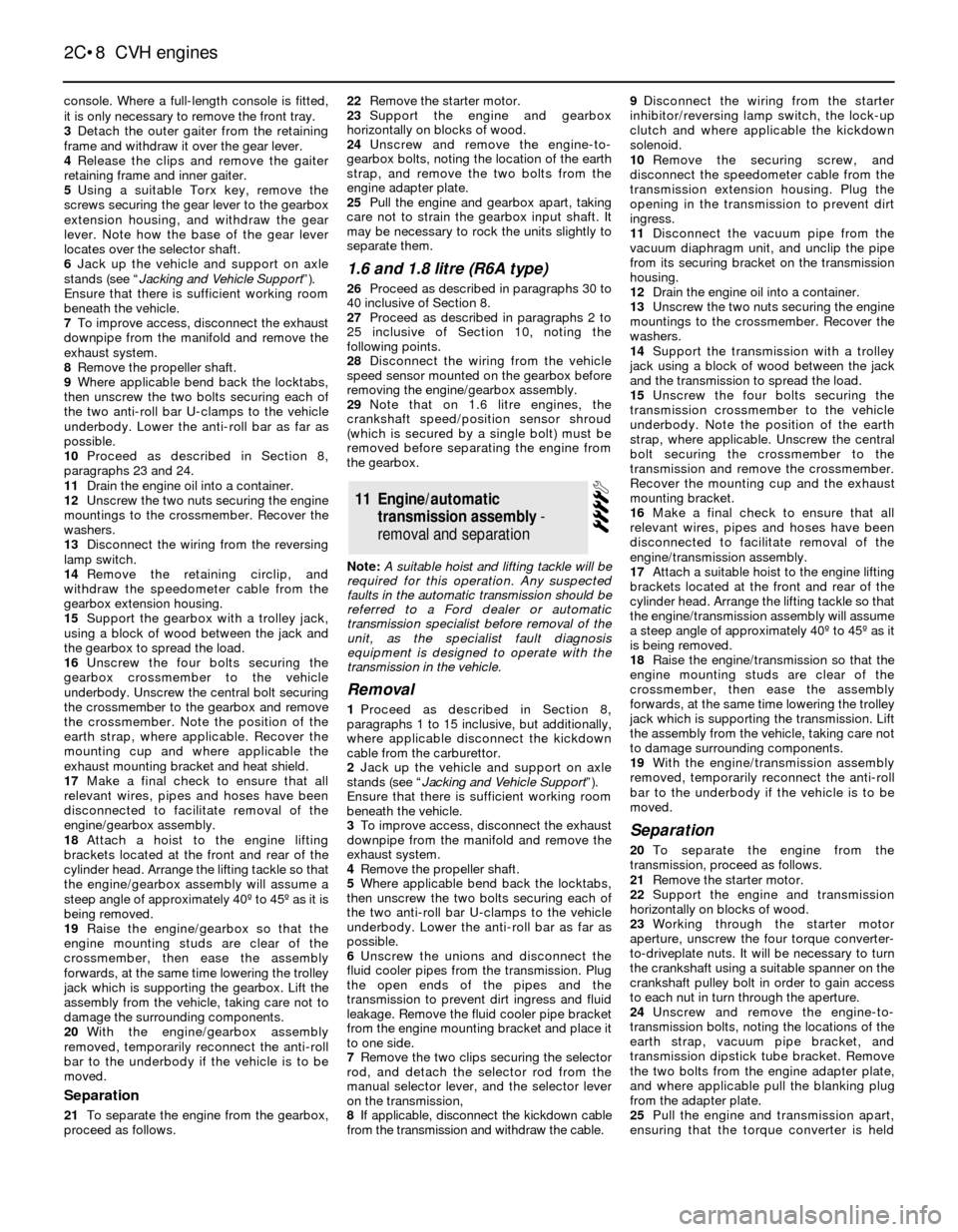

6Fit the new mountings, then lower the

engine onto them. Note that the locating pins

on the mountings must engage with the

corresponding holes in the engine mounting

brackets (see illustration).

7Fit the nuts and washers securing the

mountings to the crossmember and tighten

the nuts.

8Lower the vehicle to the ground and fit the

nuts and washers securing the engine

mounting brackets to the mountings. Tighten

the nuts.

16Engine mountings - renewal

15Engine/automatic

transmission assembly -

reconnection and refitting

14Engine/manual gearbox

assembly - reconnection and

refitting

13Engine - refitting (automatic

transmission in vehicle)

12Engine - refitting (manual

gearbox in vehicle)

CVH engines 2C•9

2C

16.6 Locating pin on mounting must

engage with hole (arrowed) in engine

mounting bracket

Page 19 of 24

Note: New flywheel securing bolts must be

used on refitting.

1.8 litre (R2A type)

1Refer to Section 26, Chapter 2, PartA but

also note the following points.

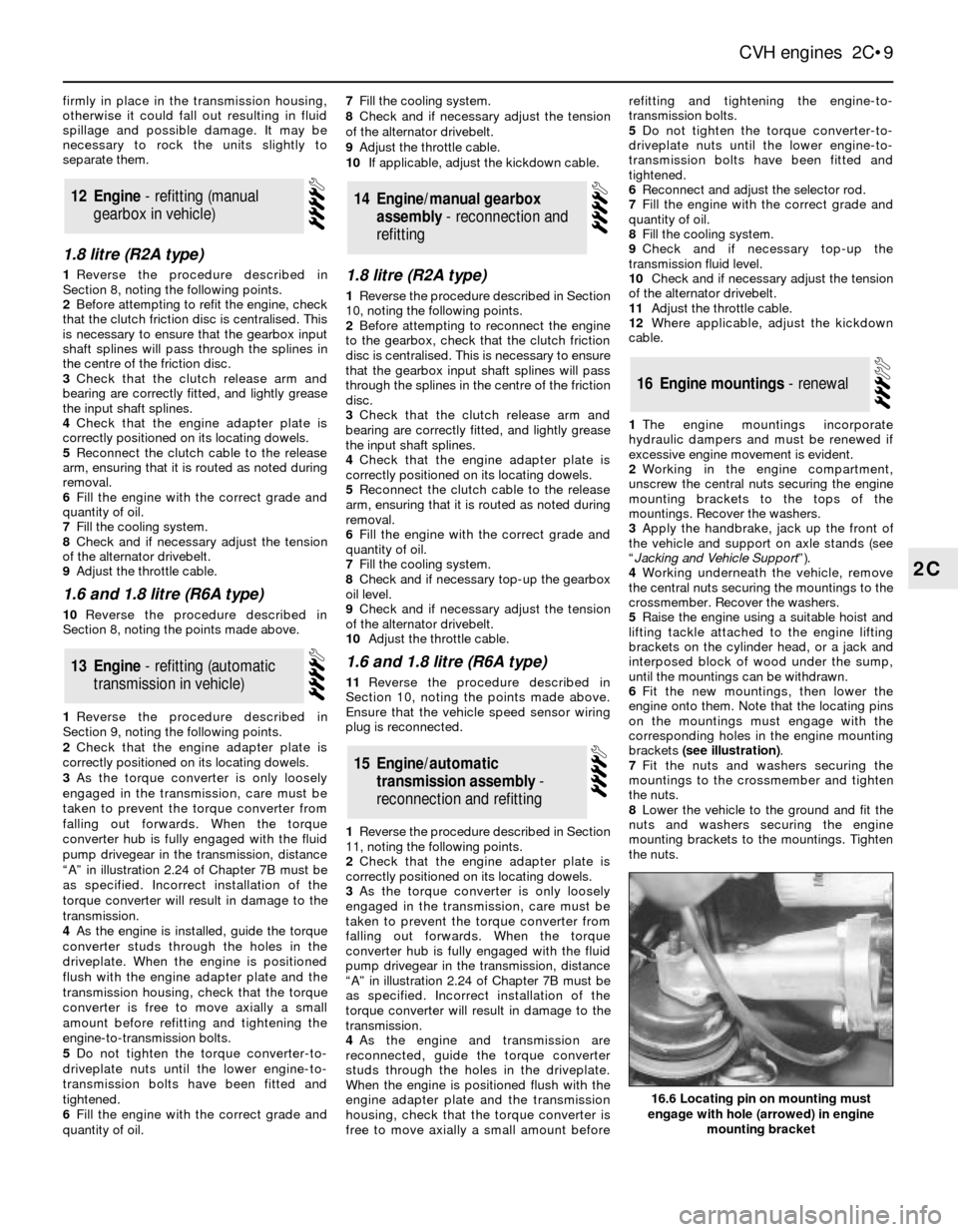

2The flywheel/driveplate securing bolts must

be renewed when refitting, and the new bolts

are supplied ready-coated with threadlocking

compound (see illustration).

3The ring gear cannot be renewed

independently of the flywheel/driveplate. If the

ring gear is badly worn or has missing teeth, a

new flywheel/driveplate must be fitted.

1.6 and 1.8 litre (R6A type)

4Refer to Section 26, Chapter 2, PartA,

noting the following points.

5If the engine is in the vehicle, refer to

Chapter 6 when removing the clutch.

6The flywheel securing bolts must be

renewed when refitting, and the new bolts are

supplied ready-coated with thread-locking

compound.

7The ring gear cannot be renewed

independently of the flywheel. If the ring gear

is badly worn or has missing teeth, a new

flywheel must be fitted. Similarly, the flywheel

must be renewed if the crankshaft

speed/position sensor toothed disc is

damaged.

1.8 litre (R2A type)

1Remove the timing belt and the crankshaft

sprocket and thrustwasher.

2Withdraw the oil seal using an oil seal

removal tool or by drilling the oil seal outer

face and using self-tapping screws and a pair

of grips.

3Clean the oil seal housing, then smear the

lip of a new oil seal with clean engine oil.

4Fit the oil seal using the crankshaft pulley

bolt and a suitable tool similar to that shown

(see illustration).5As the seal is drawn into position, the inner

edge of the seal may be damaged as it passes

over the end of the shaft. To prevent this, as

soon as the seal begins to locate in the

housing remove the tools being used to fit the

seal, and carefully work the inner edge of the

seal over the end of the crankshaft, using a

small screwdriver or similar blunt tool. The

seal can then be pushed home using the tools

described previously (see illustration).

6Refit the thrustwasher, crankshaft sprocket

and timing belt.

1.6 and 1.8 litre (R6A type)

7Remove the timing belt, and the crankshaft

sprocket and thrustwasher.

8Proceed as described in paragraphs 2 to 4

inclusive.

9Refit the thrustwasher, crankshaft sprocket

and timing belt.

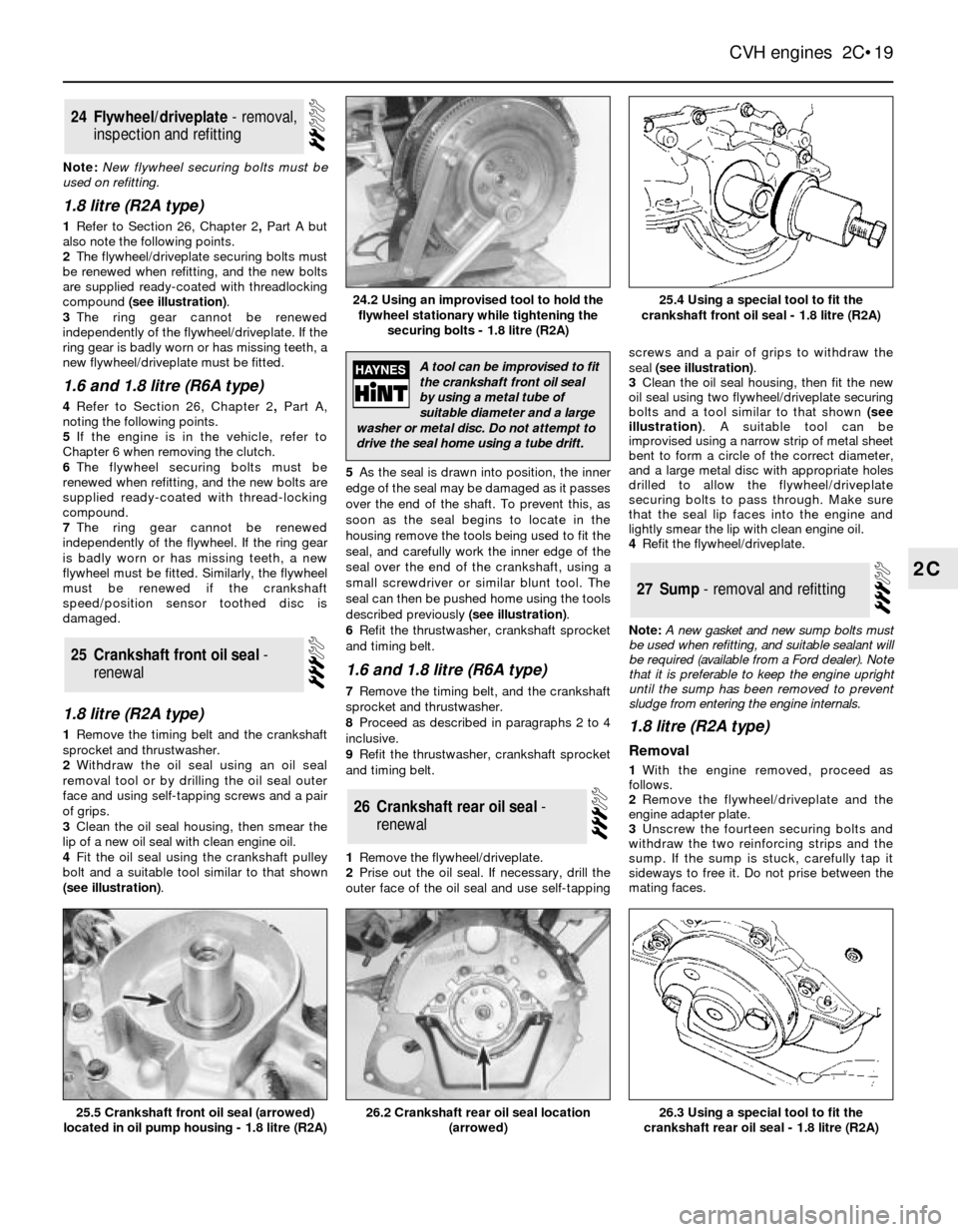

1Remove the flywheel/driveplate.

2Prise out the oil seal. If necessary, drill the

outer face of the oil seal and use self-tappingscrews and a pair of grips to withdraw the

seal (see illustration).

3Clean the oil seal housing, then fit the new

oil seal using two flywheel/driveplate securing

bolts and a tool similar to that shown (see

illustration). A suitable tool can be

improvised using a narrow strip of metal sheet

bent to form a circle of the correct diameter,

and a large metal disc with appropriate holes

drilled to allow the flywheel/driveplate

securing bolts to pass through. Make sure

that the seal lip faces into the engine and

lightly smear the lip with clean engine oil.

4Refit the flywheel/driveplate.

Note: A new gasket and new sump bolts must

be used when refitting, and suitable sealant will

be required (available from a Ford dealer). Note

that it is preferable to keep the engine upright

until the sump has been removed to prevent

sludge from entering the engine internals.

1.8 litre (R2A type)

Removal

1With the engine removed, proceed as

follows.

2Remove the flywheel/driveplate and the

engine adapter plate.

3Unscrew the fourteen securing bolts and

withdraw the two reinforcing strips and the

sump. If the sump is stuck, carefully tap it

sideways to free it. Do not prise between the

mating faces.

27Sump - removal and refitting

26Crankshaft rear oil seal -

renewal

25Crankshaft front oil seal -

renewal

24Flywheel/driveplate - removal,

inspection and refitting

CVH engines 2C•19

2C

25.5 Crankshaft front oil seal (arrowed)

located in oil pump housing - 1.8 litre (R2A)26.3 Using a special tool to fit the

crankshaft rear oil seal - 1.8 litre (R2A)26.2 Crankshaft rear oil seal location

(arrowed)

25.4 Using a special tool to fit the

crankshaft front oil seal - 1.8 litre (R2A)24.2 Using an improvised tool to hold the

flywheel stationary while tightening the

securing bolts - 1.8 litre (R2A)

A tool can be improvised to fit

the crankshaft front oil seal

by using a metal tube of

suitable diameter and a large

washer or metal disc. Do not attempt to

drive the seal home using a tube drift.

Page 20 of 24

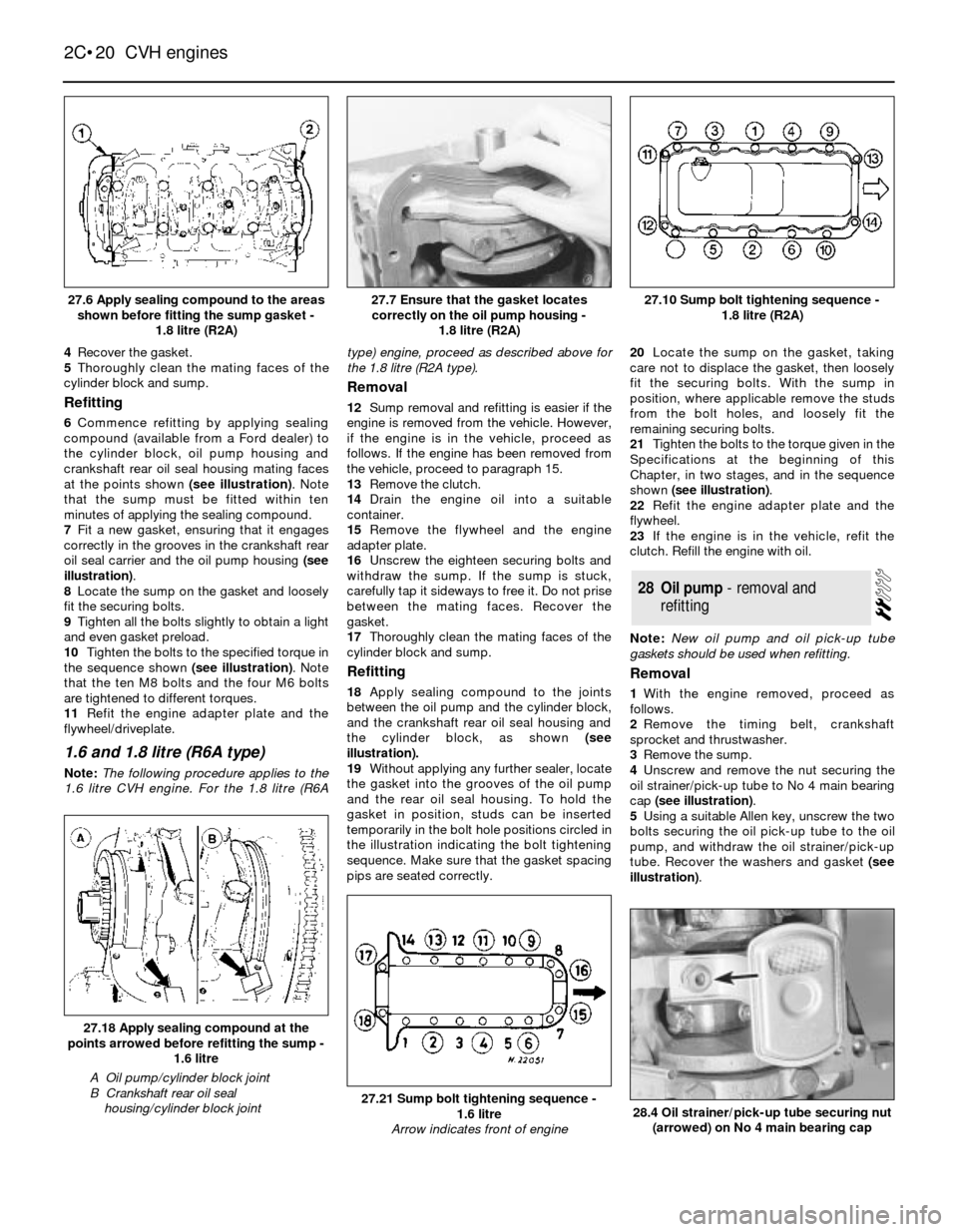

4Recover the gasket.

5Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

6Commence refitting by applying sealing

compound (available from a Ford dealer) to

the cylinder block, oil pump housing and

crankshaft rear oil seal housing mating faces

at the points shown (see illustration). Note

that the sump must be fitted within ten

minutes of applying the sealing compound.

7Fit a new gasket, ensuring that it engages

correctly in the grooves in the crankshaft rear

oil seal carrier and the oil pump housing (see

illustration).

8Locate the sump on the gasket and loosely

fit the securing bolts.

9Tighten all the bolts slightly to obtain a light

and even gasket preload.

10Tighten the bolts to the specified torque in

the sequence shown (see illustration). Note

that the ten M8 bolts and the four M6 bolts

are tightened to different torques.

11Refit the engine adapter plate and the

flywheel/driveplate.

1.6 and 1.8 litre (R6A type)

Note: The following procedure applies to the

1.6 litre CVH engine. For the 1.8 litre (R6Atype) engine, proceed as described above for

the 1.8 litre (R2A type).

Removal

12Sump removal and refitting is easier if the

engine is removed from the vehicle. However,

if the engine is in the vehicle, proceed as

follows. If the engine has been removed from

the vehicle, proceed to paragraph 15.

13Remove the clutch.

14Drain the engine oil into a suitable

container.

15Remove the flywheel and the engine

adapter plate.

16Unscrew the eighteen securing bolts and

withdraw the sump. If the sump is stuck,

carefully tap it sideways to free it. Do not prise

between the mating faces. Recover the

gasket.

17Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

18Apply sealing compound to the joints

between the oil pump and the cylinder block,

and the crankshaft rear oil seal housing and

the cylinder block, as shown (see

illustration).

19Without applying any further sealer, locate

the gasket into the grooves of the oil pump

and the rear oil seal housing. To hold the

gasket in position, studs can be inserted

temporarily in the bolt hole positions circled in

the illustration indicating the bolt tightening

sequence. Make sure that the gasket spacing

pips are seated correctly.20Locate the sump on the gasket, taking

care not to displace the gasket, then loosely

fit the securing bolts. With the sump in

position, where applicable remove the studs

from the bolt holes, and loosely fit the

remaining securing bolts.

21Tighten the bolts to the torque given in the

Specifications at the beginning of this

Chapter, in two stages, and in the sequence

shown (see illustration).

22Refit the engine adapter plate and the

flywheel.

23If the engine is in the vehicle, refit the

clutch. Refill the engine with oil.

Note: New oil pump and oil pick-up tube

gaskets should be used when refitting.

Removal

1With the engine removed, proceed as

follows.

2Remove the timing belt, crankshaft

sprocket and thrustwasher.

3Remove the sump.

4Unscrew and remove the nut securing the

oil strainer/pick-up tube to No 4 main bearing

cap (see illustration).

5Using a suitable Allen key, unscrew the two

bolts securing the oil pick-up tube to the oil

pump, and withdraw the oil strainer/pick-up

tube. Recover the washers and gasket (see

illustration).

28Oil pump - removal and

refitting

2C•20CVH engines

27.6 Apply sealing compound to the areas

shown before fitting the sump gasket -

1.8 litre (R2A)27.10 Sump bolt tightening sequence -

1.8 litre (R2A)

27.21 Sump bolt tightening sequence -

1.6 litre

Arrow indicates front of engine

27.18 Apply sealing compound at the

points arrowed before refitting the sump -

1.6 litre

A Oil pump/cylinder block joint

B Crankshaft rear oil seal

housing/cylinder block joint

27.7 Ensure that the gasket locates

correctly on the oil pump housing -

1.8 litre (R2A)

28.4 Oil strainer/pick-up tube securing nut

(arrowed) on No 4 main bearing cap

Page 23 of 24

the tapered lower compression ring with the

“TOP” mark towards the top of the piston and

the gap 150º from the spreader gap, then fit

the upper compression ring with the gap 150º

on the other side of the spreader gap. Note

that the compression rings are coated with a

molybdenum skin which must not be

damaged.

1.6 and 1.8 litre (R6A type)

6Proceed as described in paragraphs 1 to 5

inclusive, but note the following differences

for the 1.6 litre engine.

7Before fitting the new rings to the pistons,

insert them into the relevant cylinder bore and

use a feeler blade to check that the end gaps

are within the limits given in the Specifications

at the beginning of this Chapter. Check the

end gaps with the ring at the top and the

bottom of the cylinder bore.8Fit the oil control ring sections with the

spreader ends abutted opposite the front of

the piston, making sure that the ends do not

overlap. The side ring gaps should be offset

120º either side of the spreader gap. Fit the

tapered lower compression ring with the

“TOP” mark uppermost and the gap 120º

from the spreader gap, then fit the upper

compression ring with the gap 120º on the

other side of the spreader gap. Note that the

compression rings are coated with a

molybdenum disulphide skin, which must not

be damaged.

1.8 litre (R2A type)

Removal

1With the engine removed from the vehicle,

remove the timing belt, crankshaft sprocket

and thrustwasher.

2Remove the pistons and connecting rods. If

no work is to be done on the pistons and

connecting rods, there is no need to push the

pistons out of the cylinder bores.

3Remove the oil pump and pick-up tube.

4Unscrew the four securing bolts and

remove the crankshaft rear oil seal housing.

5Check the main bearing caps for

identification marks and if necessary use a

centre-punch to identify them.

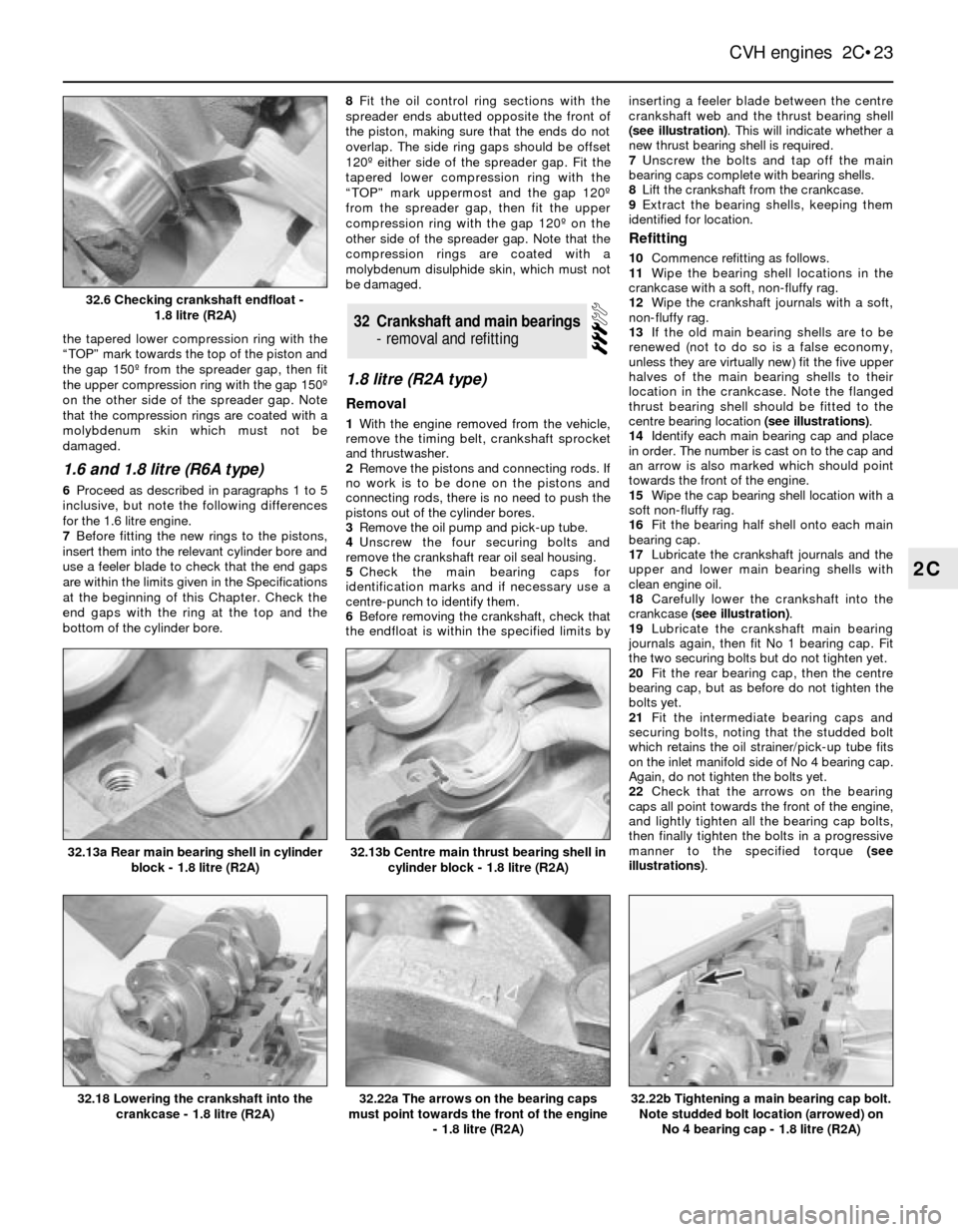

6Before removing the crankshaft, check that

the endfloat is within the specified limits byinserting a feeler blade between the centre

crankshaft web and the thrust bearing shell

(see illustration). This will indicate whether a

new thrust bearing shell is required.

7Unscrew the bolts and tap off the main

bearing caps complete with bearing shells.

8Lift the crankshaft from the crankcase.

9Extract the bearing shells, keeping them

identified for location.

Refitting

10Commence refitting as follows.

11Wipe the bearing shell locations in the

crankcase with a soft, non-fluffy rag.

12Wipe the crankshaft journals with a soft,

non-fluffy rag.

13If the old main bearing shells are to be

renewed (not to do so is a false economy,

unless they are virtually new) fit the five upper

halves of the main bearing shells to their

location in the crankcase. Note the flanged

thrust bearing shell should be fitted to the

centre bearing location (see illustrations).

14Identify each main bearing cap and place

in order. The number is cast on to the cap and

an arrow is also marked which should point

towards the front of the engine.

15Wipe the cap bearing shell location with a

soft non-fluffy rag.

16Fit the bearing half shell onto each main

bearing cap.

17Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil.

18Carefully lower the crankshaft into the

crankcase (see illustration).

19Lubricate the crankshaft main bearing

journals again, then fit No 1 bearing cap. Fit

the two securing bolts but do not tighten yet.

20Fit the rear bearing cap, then the centre

bearing cap, but as before do not tighten the

bolts yet.

21Fit the intermediate bearing caps and

securing bolts, noting that the studded bolt

which retains the oil strainer/pick-up tube fits

on the inlet manifold side of No 4 bearing cap.

Again, do not tighten the bolts yet.

22Check that the arrows on the bearing

caps all point towards the front of the engine,

and lightly tighten all the bearing cap bolts,

then finally tighten the bolts in a progressive

manner to the specified torque (see

illustrations).

32Crankshaft and main bearings

- removal and refitting

CVH engines 2C•23

2C

32.13b Centre main thrust bearing shell in

cylinder block - 1.8 litre (R2A)

32.22b Tightening a main bearing cap bolt.

Note studded bolt location (arrowed) on

No 4 bearing cap - 1.8 litre (R2A)32.22a The arrows on the bearing caps

must point towards the front of the engine

- 1.8 litre (R2A)32.18 Lowering the crankshaft into the

crankcase - 1.8 litre (R2A)

32.13a Rear main bearing shell in cylinder

block - 1.8 litre (R2A)

32.6 Checking crankshaft endfloat -

1.8 litre (R2A)