AUX FORD SIERRA 1992 2.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 18, PDF Size: 0.9 MB

Page 13 of 18

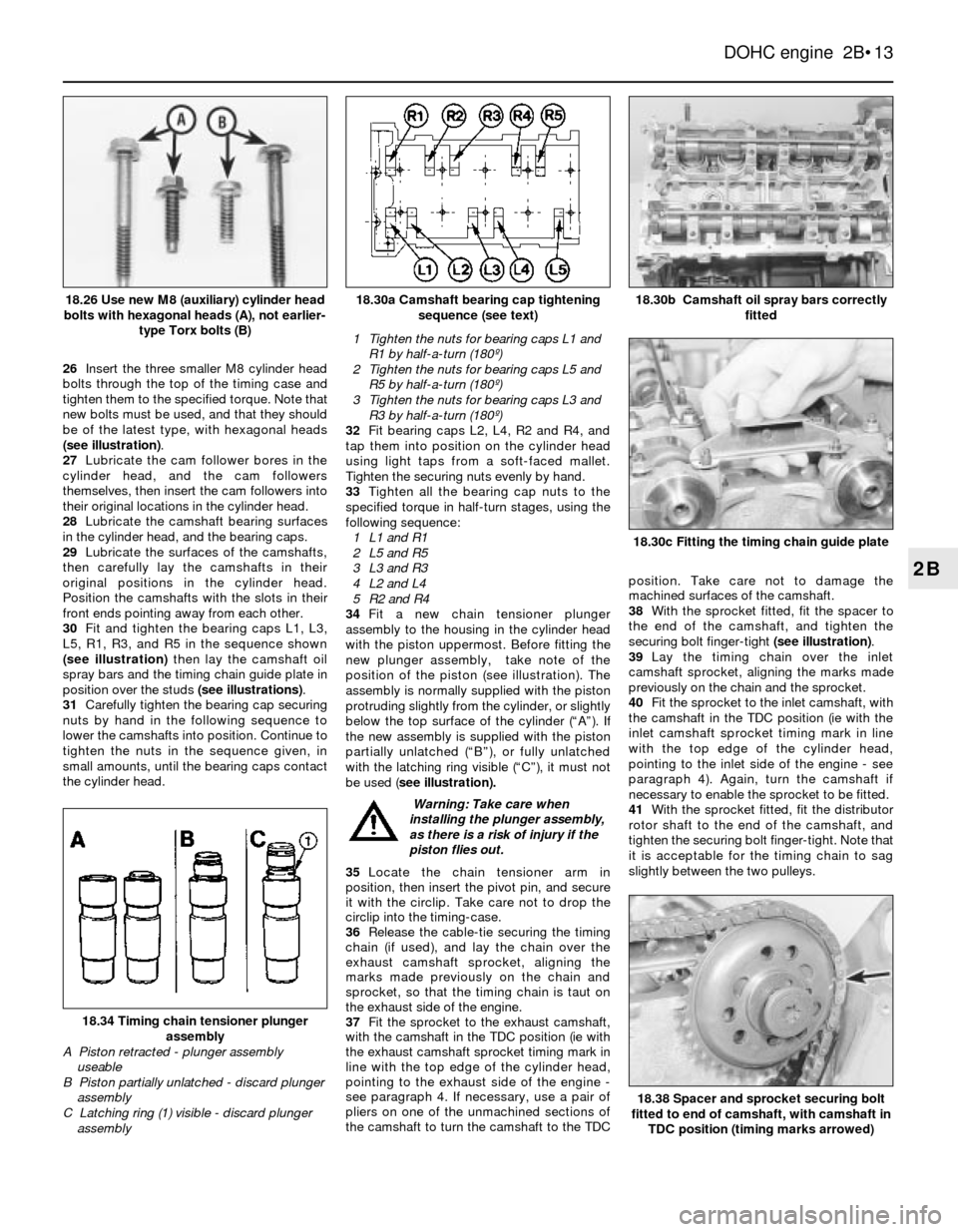

26Insert the three smaller M8 cylinder head

bolts through the top of the timing case and

tighten them to the specified torque. Note that

new bolts must be used, and that they should

be of the latest type, with hexagonal heads

(see illustration).

27Lubricate the cam follower bores in the

cylinder head, and the cam followers

themselves, then insert the cam followers into

their original locations in the cylinder head.

28Lubricate the camshaft bearing surfaces

in the cylinder head, and the bearing caps.

29Lubricate the surfaces of the camshafts,

then carefully lay the camshafts in their

original positions in the cylinder head.

Position the camshafts with the slots in their

front ends pointing away from each other.

30Fit and tighten the bearing caps L1, L3,

L5, R1, R3, and R5 in the sequence shown

(see illustration)then lay the camshaft oil

spray bars and the timing chain guide plate in

position over the studs (see illustrations).

31Carefully tighten the bearing cap securing

nuts by hand in the following sequence to

lower the camshafts into position. Continue to

tighten the nuts in the sequence given, in

small amounts, until the bearing caps contact

the cylinder head.1Tighten the nuts for bearing caps L1 and

R1 by half-a-turn (180º)

2Tighten the nuts for bearing caps L5 and

R5 by half-a-turn (180º)

3Tighten the nuts for bearing caps L3 and

R3 by half-a-turn (180º)

32Fit bearing caps L2, L4, R2 and R4, and

tap them into position on the cylinder head

using light taps from a soft-faced mallet.

Tighten the securing nuts evenly by hand.

33Tighten all the bearing cap nuts to the

specified torque in half-turn stages, using the

following sequence:

1L1 and R1

2L5 and R5

3L3 and R3

4L2 and L4

5R2 and R4

34Fit a newchain tensioner plunger

assembly to the housing in the cylinder head

with the piston uppermost. Before fitting the

new plunger assembly, take note of the

position of the piston(see illustration). The

assembly is normally supplied with the piston

protruding slightly from the cylinder, or slightly

below the top surface of the cylinder (“A”). If

the new assembly is supplied with the piston

partially unlatched (“B”), or fully unlatched

with the latching ring visible (“C”), it must not

be used (see illustration).

35Locate the chain tensioner arm in

position, then insert the pivot pin, and secure

it with the circlip. Take care not to drop the

circlip into the timing-case.

36Release the cable-tie securing the timing

chain (if used), and lay the chain over the

exhaust camshaft sprocket, aligning the

marks made previously on the chain and

sprocket, so that the timing chain is taut on

the exhaust side of the engine.

37Fit the sprocket to the exhaust camshaft,

with the camshaft in the TDC position (ie with

the exhaust camshaft sprocket timing mark in

line with the top edge of the cylinder head,

pointing to the exhaust side of the engine -

see paragraph 4. If necessary, use a pair of

pliers on one of the unmachined sections of

the camshaft to turn the camshaft to the TDCposition. Take care not to damage the

machined surfaces of the camshaft.

38With the sprocket fitted, fit the spacer to

the end of the camshaft, and tighten the

securing bolt finger-tight (see illustration).

39Lay the timing chain over the inlet

camshaft sprocket, aligning the marks made

previously on the chain and the sprocket.

40Fit the sprocket to the inlet camshaft, with

the camshaft in the TDC position (ie with the

inlet camshaft sprocket timing mark in line

with the top edge of the cylinder head,

pointing to the inlet side of the engine - see

paragraph 4). Again, turn the camshaft if

necessary to enable the sprocket to be fitted.

41With the sprocket fitted, fit the distributor

rotor shaft to the end of the camshaft, and

tighten the securing bolt finger-tight. Note that

it is acceptable for the timing chain to sag

slightly between the two pulleys.

DOHC engine 2B•13

2B

18.30b Camshaft oil spray bars correctly

fitted

18.38 Spacer and sprocket securing bolt

fitted to end of camshaft, with camshaft in

TDC position (timing marks arrowed)

18.34 Timing chain tensioner plunger

assembly

A Piston retracted - plunger assembly

useable

B Piston partially unlatched - discard plunger

assembly

C Latching ring (1) visible - discard plunger

assembly

18.30c Fitting the timing chain guide plate

18.30a Camshaft bearing cap tightening

sequence (see text)18.26 Use new M8 (auxiliary) cylinder head

bolts with hexagonal heads (A), not earlier-

type Torx bolts (B)

Warning: Take care when

installing the plunger assembly,

as there is a risk of injury if the

piston flies out.