fuel cap FORD SIERRA 1992 2.G DOHC Engine Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 18, PDF Size: 0.9 MB

Page 1 of 18

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder, in-line, double overhead camshaft

Engine code:

Carburettor engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N8A

Fuel injection engine without catalyst . . . . . . . . . . . . . . . . . . . . . . . . . N9A

Fuel injection engine with catalyst . . . . . . . . . . . . . . . . . . . . . . . . . . . N9C

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1998 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3 : 1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 11 to 13 bars

Maximum continuous engine speed:

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6050 rpm

All engines except N8A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5950 rpm

Maximum engine power (DIN):

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 kW at 5600 rpm

N9A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 kW at 5500 rpm

N9C engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 kW at 5500 rpm

Maximum engine torque:

N8A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 Nm at 3000 rpm

N9A engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 Nm at 2500 rpm

N9C engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 Nm at 2500 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.000 to 86.010 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.010 to 86.020 mm

Oversize 0.15 class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.150 to 86.160 mm

Oversize 0.15 class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.160 to 86.170 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.500 to 86.510 mm

Chapter 2 Part B:

DOHC engine

Camshafts and cam followers - removal, inspection and refitting . . .21

Crankcase ventilation system - inspection and maintenance . . . . . . .2

Crankshaft and bearings - examination and renovation . . . . . . . . . .31

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .30

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .19

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .20

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .17

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .18

Engine/automatic transmission assembly - removal and separation . .8

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine dismantling, examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Engine/manual gearbox assembly - removal and separation . . . . . . .7

Engine/manual gearbox assembly - reconnection and refitting . . . . .11Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . . .9

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .10

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .5

Engine - removal leaving automatic transmission in vehicle . . . . . . . .6

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .22

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .32

Major operations possible with the engine in the vehicle . . . . . . . . . . .3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .4

Oil pump drive chain and sprockets - examination and renovation . .28

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .27

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .29

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Timing chain and sprockets - removal and refitting . . . . . . . . . . . . . .15

Timing chain, sprockets and tensioner - examination and renovation .16

2B•1

Specifications Contents

2B

Unless otherwise stated, procedures are as described for the SOHC engines in Part A of this Chapter.

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 2 of 18

Crankshaft

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.090 to 0.300 mm (0.004 to 0.012 in)

Main bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.011 to 0.048 mm

Main bearing journal diameter:

Standard (yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.980 to 54.990 mm

Standard (red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.990 to 55.000 mm

Undersize 0.25 (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54.730 to 54.750 mm

Main bearing thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.301 to 2.351 mm (0.090 to 0.093 in)

Oversize 0.38 (yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.491 to 2.541 mm (0.098 to 0.100 in)

Big-end bearing running clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.006 to 0.060 mm

Big-end bearing journal diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50.890 to 50.910 mm

Undersize 0.25 (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50.640 to 50.660 mm

Pistons and piston rings

Piston diameter:

Standard 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.970 to 85.980 mm

Standard 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.980 to 85.990 mm

Standard service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85.980 to 85.990 mm

Oversize 0.15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.130 to 86.150 mm

Oversize 0.50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86.470 to 86.490 mm

Piston ring end gap:

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.300 to 0.600 mm (0.012 to 0.024 in)

Centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.500 to 0.800 mm (0.020 to 0.032 in)

Bottom (oil control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.400 to 1.500 mm (0.016 to 0.059 in)

Cylinder head

Valve guide bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.063 to 7.094 mm

Camshaft bearing parent bore diameter . . . . . . . . . . . . . . . . . . . . . . . .26.000 to 26.030 mm

Camshafts

Endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.020 to 0.260 mm (0.001 to 0.010 in)

Valves

Valve timing:

Carburettor engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13º BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39º ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43º BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13º ATDC

Fuel injection engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13º BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51º ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43º BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13º ATDC

Valve spring free length:

Inner spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48.200 mm (1.899 in)

Outer spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46.800 mm (1.844 in)

Inlet valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.025 to 7.043 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.225 to 7.243 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.425 to 7.443 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.625 to 7.643 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.825 to 7.843 mm

Exhaust valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.999 to 7.017 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.199 to 7.217 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.399 to 7.417 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.599 to 7.617 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.799 to 7.817 mm

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Multigrade engine oil, viscosity range SAE 10W/30 to 20W/50, to API

SG/CD or better

Oil capacity:

With filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.5 litres (7.9 pints)

Without filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.0 litres (7.0 pints)

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion C102

2B•2DOHC engine

Page 3 of 18

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10466 to 77

Connecting rod (big-end bearing cap) bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 1711 to 13

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 85º

Crankshaft pulley bolt:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5833 to 43

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 80º

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 to 6341 to 46

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82 to 9261 to 68

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 127 to 9

Oil pump sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 1912 to 14

Oil pump chain tensioner bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 137 to 10

Sump bolts and nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

Sump studs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 21

Sump front mounting plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 2817 to 21

Oil baffle nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Oil pick-up pipe-to-cylinder block bolts . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Oil pressure warning lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 to 2213 to 16

Cylinder head bolts:

M11 bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4030

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Angle-tighten a further 90º

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 to 3927 to 29

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Camshaft bearing cap nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 to 2616 to 19

Lower timing chain guide upper bolt . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 137 to 10

Lower timing chain guide lower bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 to 2818 to 21

Upper and lower timing chain cover bolts . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Engine-to-gearbox/transmission bolts . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

The 2.0 litre DOHC (Double OverHead

Camshaft) engine was introduced in August

1989 to replace the 2.0 litre SOHC engine

used previously in the Sierra range. The

engine is of four-cylinder, in-line type.

The crankshaft incorporates five main

bearings. Thrustwashers are fitted to the

centre main bearing in order to control

crankshaft endfloat.

The camshafts are driven by a chain from

the crankshaft, and operate the angled valves

via hydraulic cam followers. One camshaft

operates the inlet valves, and the other

operates the exhaust valves. The operation of

the cam followers is explained in Chapter 2,

Part C, but note that no rollers are fitted and

the base of each cam follower is in direct

contact with the cam profile.

The distributor is driven directly from the

front of the inlet camshaft, and the oil pump is

driven by a chain from the crankshaft. An

electric fuel pump is mounted in the fuel tank.Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries, from

where it is distributed to the crankshaft and

camshafts. The big-end bearings are supplied

with oil via internal drillings in the crankshaft.

The undersides of the pistons are supplied

with oil from drillings in the connecting rods.

The hydraulic cam followers are supplied with

oil from passages in the cylinder head. The

camshafts are lubricated by oil from spray

tubes mounted above the camshaft bearing

caps.

A closed crankcase ventilation system is

employed, whereby piston blow-by gases are

drawn from the crankcase, through a breather

pipe into the inlet manifold, where they are

burnt with fresh air/fuel mixture.

Refer to Chapter 1, Section 35.The following operations can be carried out

without removing the engine from the vehicle:

a)Removal of the camshafts.

b)Removal and servicing of the cylinder head

c)Removal of the timing chain and

sprockets.

d)Removal of the oil pump.

e)Removal of the sump.

f)Removal of the pistons and connecting

rods.

g)Removal of the big-end bearings.

h)Removal of the engine mountings

i)Removal of the clutch and flywheel.

j)Removal of the crankshaft front and rear

oil seals.

The following operation can only be carried out

after removing the engine from the vehicle:

a)Removal of the crankshaft and main

bearings.

4Major operations requiring

engine removal

3Major operations possible with

the engine in the vehicle

2Crankcase ventilation system -

inspection and maintenance

1General information

DOHC engine 2B•3

2B

Page 8 of 18

Dismantling

1Refer to Chapter 2, PartA, Section 18,

paragraphs 1 to 8 inclusive.

2A suitable selection of splined and Torx

sockets will be required to remove many of

the bolts when dismantling the engine.

3Before dismantling the main engine

components, the following externally-

mounted ancillary components can be

removed, with reference to the relevant

Chapters of this Manual and the relevant

Sections of this Chapter, where applicable.

Inlet manifold (and carburettor, if applicable)

Exhaust manifold

Alternator.

Coolant pump, and thermostat

Alternator/coolant pump drivebelt tensioner

Distributor cap, HT leads and spark plugs

Oil pressure warning lamp switch

Crankshaft speed/position sensor

Oil filter

Dipstick

Engine mounting brackets (if not already done)

Crankcase ventilation pipe and hoses

Clutch

Alternator mounting bracket.

Air conditioning compressor mounting

bracket (where applicable).

Engine lifting brackets.

Examination and renovation

4Refer to Chapter 2, PartA, Section 18, but

note that the connecting rod bolts should be

renewed on reassembly, and when renewing

the cylinder head bolts, the latest type bolts

with hexagonal heads should always be used.

Reassembly

5Proceed as described in Chapter 2, PartA,

Section 18, noting the following:

6If they have been removed, new cylinder

head bolts (both M11 and M8, of the latest

type with hexagonal heads), flywheel bolts,

and connecting rod bolts must be used.

Note: Refer to the warning at the beginning of

Section 5 before proceeding. A suitable puller

will be required to remove the crankshaft pulley.

A new crankshaft pulley bolt, a new timing chain

tensioner plunger assembly, new upper and

lower timing chain cover gaskets, and a new

camshaft cover gasket and reinforcing sleeve

sealing rings, must be used on refitting.

Removal

1If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.c)On carburettor models, remove the air

cleaner.

d)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

e)Disconnect the breather hose from the

camshaft cover.

f)Remove the distributor cap and HT leads,

and the rotor arm and housing.

2Proceed as described in paragraphs 2 to 11

inclusive of Section 18 (see illustration).

3Remove the alternator drivebelt.

4Slacken the crankshaft pulley bolt. Prevent

the crankshaft from turning by engaging top

gear (manual gearbox only) and having an

assistant press the brake pedal hard, or by

removing the starter motor and jamming the

ring gear teeth with a lever.

5Unscrew the bolt part-way, and use a puller

to remove the crankshaft pulley. The legs ofthe puller must be suitably shaped to enable

them to rest on the metal surfaces of the

pulley. Do not use a puller on the rubber

surface of the pulley (see illustrations).

15Timing chain and sprockets -

removal and refitting

14Engine dismantling,

examination, renovation and

reassembly - general information

2B•8DOHC engine

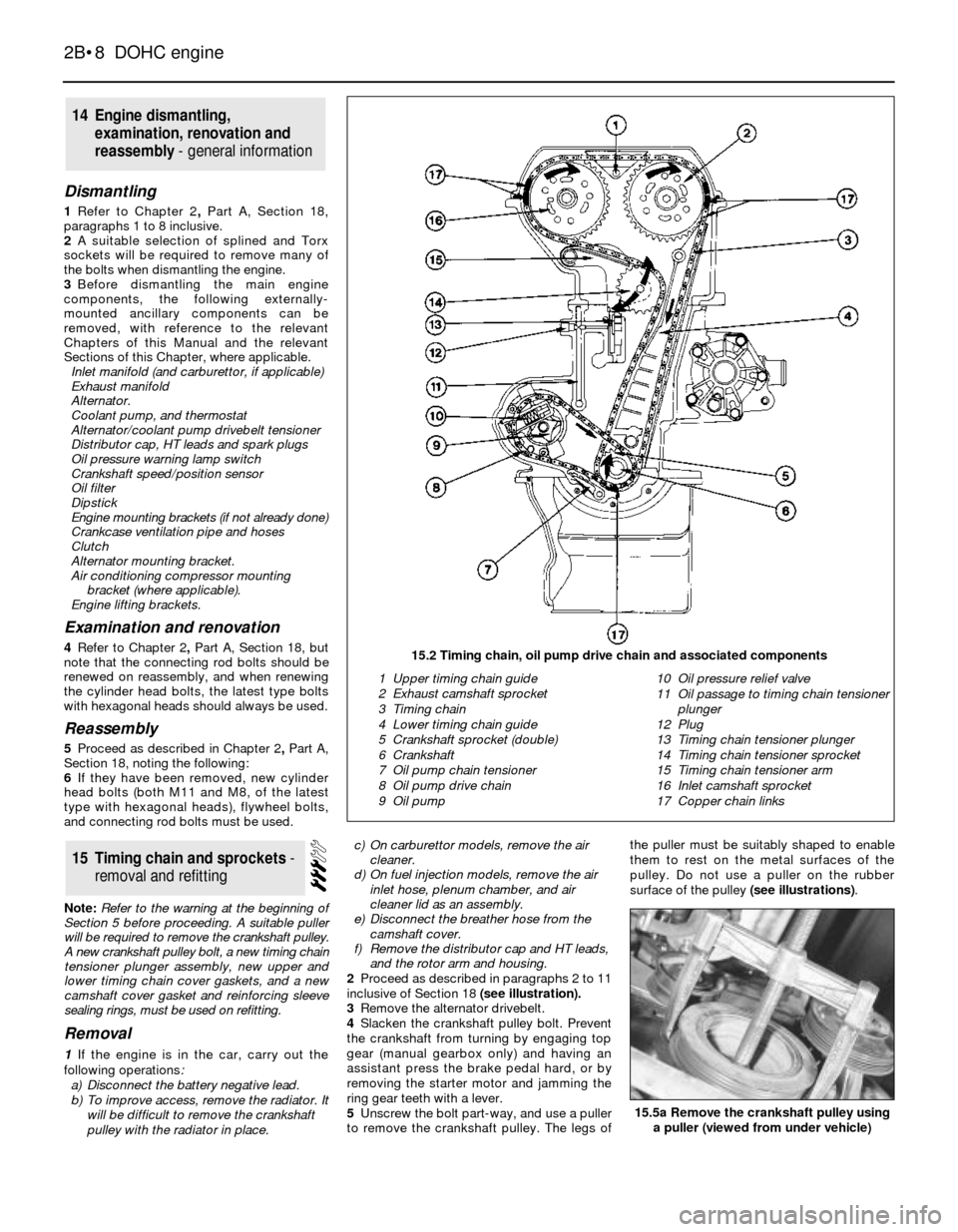

15.2 Timing chain, oil pump drive chain and associated components

1 Upper timing chain guide

2 Exhaust camshaft sprocket

3 Timing chain

4 Lower timing chain guide

5 Crankshaft sprocket (double)

6 Crankshaft

7 Oil pump chain tensioner

8 Oil pump drive chain

9 Oil pump10 Oil pressure relief valve

11 Oil passage to timing chain tensioner

plunger

12 Plug

13 Timing chain tensioner plunger

14 Timing chain tensioner sprocket

15 Timing chain tensioner arm

16 Inlet camshaft sprocket

17 Copper chain links

15.5a Remove the crankshaft pulley using

a puller (viewed from under vehicle)

Page 10 of 18

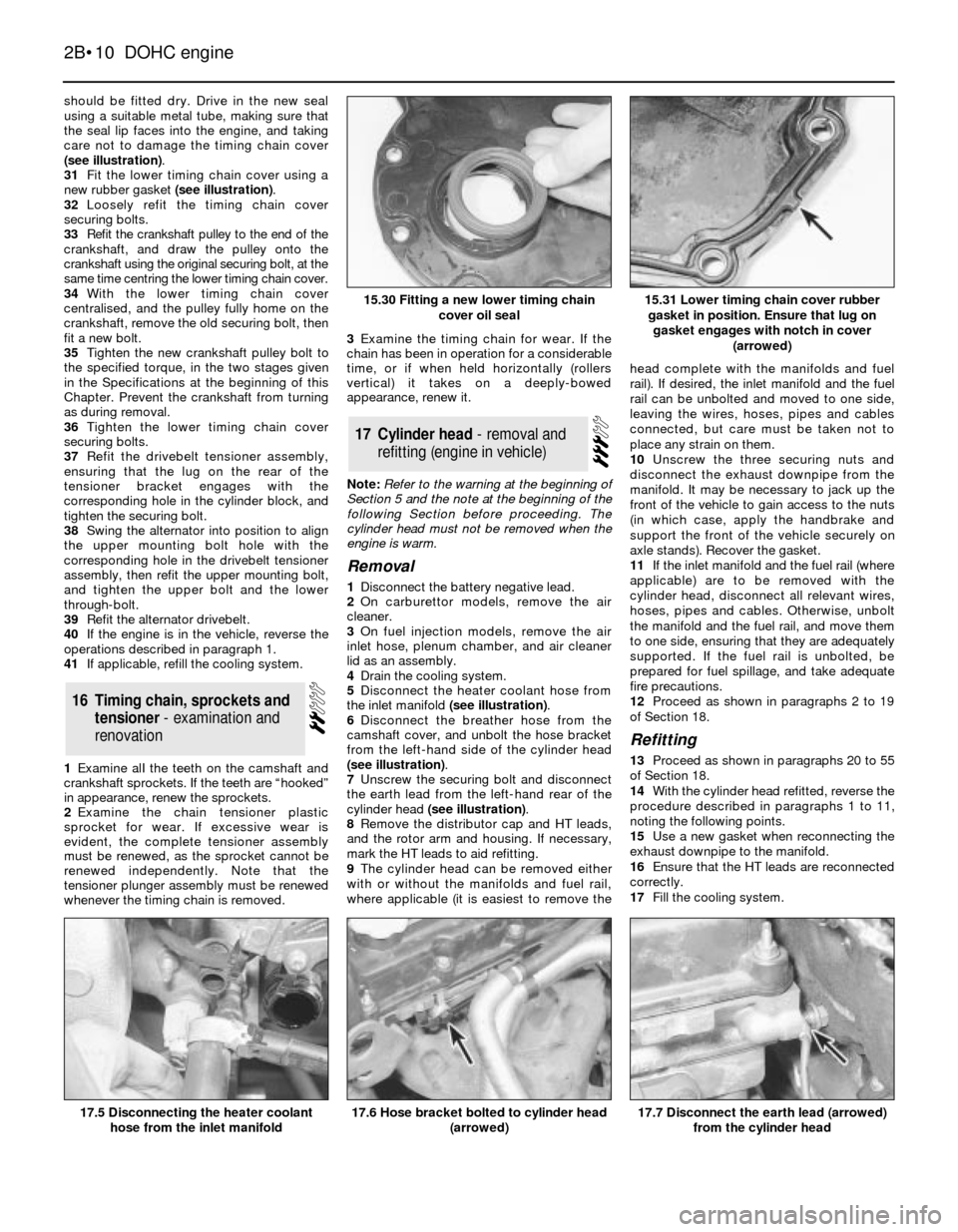

should be fitted dry. Drive in the new seal

using a suitable metal tube, making sure that

the seal lip faces into the engine, and taking

care not to damage the timing chain cover

(see illustration).

31Fit the lower timing chain cover using a

new rubber gasket (see illustration).

32Loosely refit the timing chain cover

securing bolts.

33Refit the crankshaft pulley to the end of the

crankshaft, and draw the pulley onto the

crankshaft using the original securing bolt, at the

same time centring the lower timing chain cover.

34With the lower timing chain cover

centralised, and the pulley fully home on the

crankshaft, remove the old securing bolt, then

fit a new bolt.

35Tighten the new crankshaft pulley bolt to

the specified torque, in the two stages given

in the Specifications at the beginning of this

Chapter. Prevent the crankshaft from turning

as during removal.

36Tighten the lower timing chain cover

securing bolts.

37Refit the drivebelt tensioner assembly,

ensuring that the lug on the rear of the

tensioner bracket engages with the

corresponding hole in the cylinder block, and

tighten the securing bolt.

38Swing the alternator into position to align

the upper mounting bolt hole with the

corresponding hole in the drivebelt tensioner

assembly, then refit the upper mounting bolt,

and tighten the upper bolt and the lower

through-bolt.

39Refit the alternator drivebelt.

40If the engine is in the vehicle, reverse the

operations described in paragraph 1.

41If applicable, refill the cooling system.

1Examine alI the teeth on the camshaft and

crankshaft sprockets. If the teeth are “hooked”

in appearance, renew the sprockets.

2Examine the chain tensioner plastic

sprocket for wear. If excessive wear is

evident, the complete tensioner assembly

must be renewed, as the sprocket cannot be

renewed independently. Note that the

tensioner plunger assembly must be renewed

whenever the timing chain is removed.3Examine the timing chain for wear. If the

chain has been in operation for a considerable

time, or if when held horizontally (rollers

vertical) it takes on a deeply-bowed

appearance, renew it.

Note: Refer to the warning at the beginning of

Section 5 and the note at the beginning of the

following Section before proceeding. The

cylinder head must not be removed when the

engine is warm.

Removal

1Disconnect the battery negative lead.

2On carburettor models, remove the air

cleaner.

3On fuel injection models, remove the air

inlet hose, plenum chamber, and air cleaner

lid as an assembly.

4Drain the cooling system.

5Disconnect the heater coolant hose from

the inlet manifold (see illustration).

6Disconnect the breather hose from the

camshaft cover, and unbolt the hose bracket

from the left-hand side of the cylinder head

(see illustration).

7Unscrew the securing bolt and disconnect

the earth lead from the left-hand rear of the

cylinder head (see illustration).

8Remove the distributor cap and HT leads,

and the rotor arm and housing. If necessary,

mark the HT leads to aid refitting.

9The cylinder head can be removed either

with or without the manifolds and fuel rail,

where applicable (it is easiest to remove thehead complete with the manifolds and fuel

rail). If desired, the inlet manifold and the fuel

rail can be unbolted and moved to one side,

leaving the wires, hoses, pipes and cables

connected, but care must be taken not to

place any strain on them.

10Unscrew the three securing nuts and

disconnect the exhaust downpipe from the

manifold. It may be necessary to jack up the

front of the vehicle to gain access to the nuts

(in which case, apply the handbrake and

support the front of the vehicle securely on

axle stands). Recover the gasket.

11If the inlet manifold and the fuel rail (where

applicable) are to be removed with the

cylinder head, disconnect all relevant wires,

hoses, pipes and cables. Otherwise, unbolt

the manifold and the fuel rail, and move them

to one side, ensuring that they are adequately

supported. If the fuel rail is unbolted, be

prepared for fuel spillage, and take adequate

fire precautions.

12Proceed as shown in paragraphs 2 to 19

of Section 18.

Refitting

13Proceed as shown in paragraphs 20 to 55

of Section 18.

14With the cylinder head refitted, reverse the

procedure described in paragraphs 1 to 11,

noting the following points.

15Use a new gasket when reconnecting the

exhaust downpipe to the manifold.

16Ensure that the HT leads are reconnected

correctly.

17Fill the cooling system.

17Cylinder head - removal and

refitting (engine in vehicle)

16Timing chain, sprockets and

tensioner - examination and

renovation

2B•10DOHC engine

15.30 Fitting a new lower timing chain

cover oil seal

17.5 Disconnecting the heater coolant

hose from the inlet manifold17.7 Disconnect the earth lead (arrowed)

from the cylinder head17.6 Hose bracket bolted to cylinder head

(arrowed)

15.31 Lower timing chain cover rubber

gasket in position. Ensure that lug on

gasket engages with notch in cover

(arrowed)

Page 14 of 18

42Fit a new upper timing chain guide to the

plate at the front of the cylinder head.

43Turn the crankshaft clockwise until the

inlet camshaft begins to turn.

44If the chain tensioner plunger piston

protrudes from the cylinder, unlatch the piston

by pressing the chain tensioner arm down by

hand.

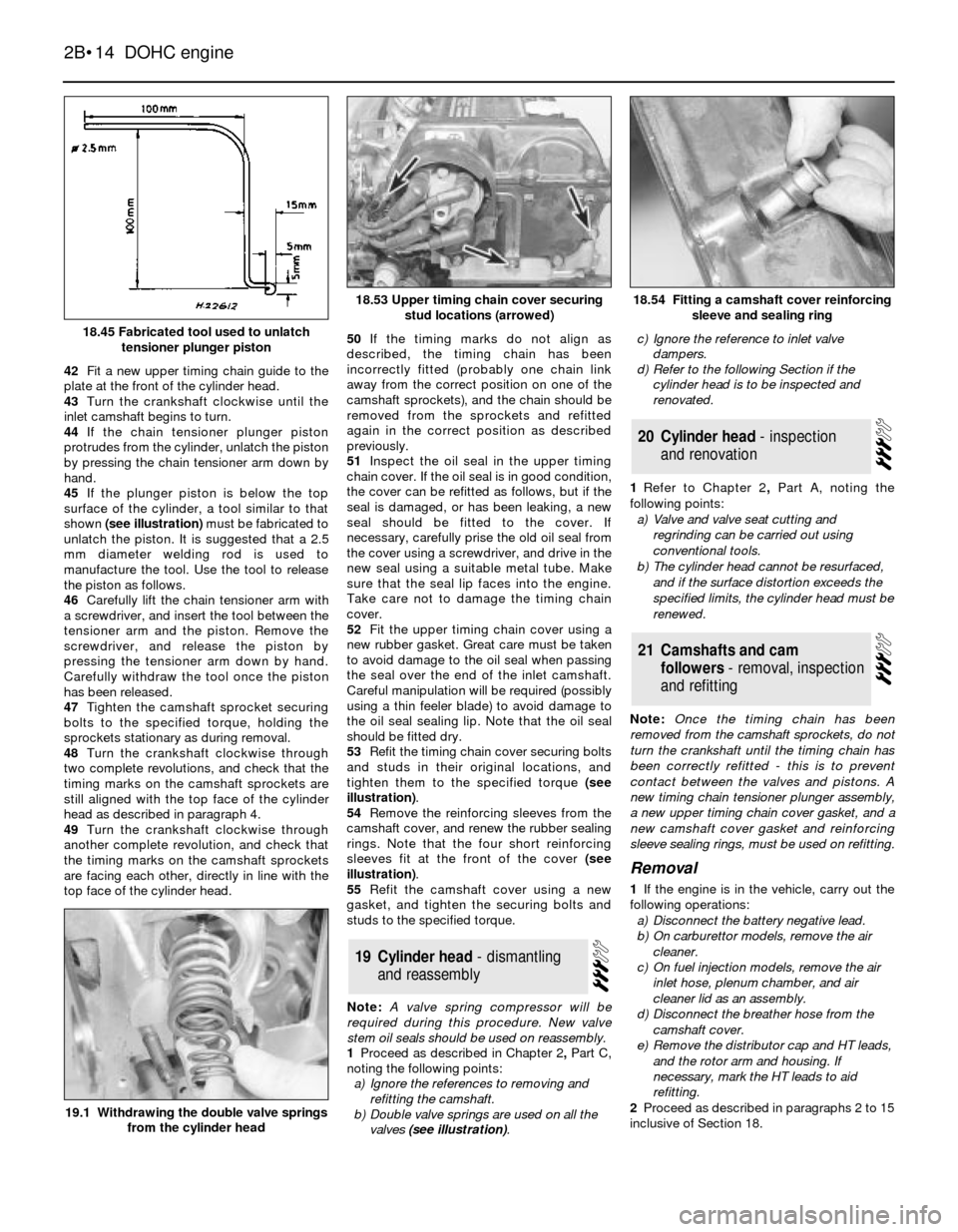

45If the plunger piston is below the top

surface of the cylinder, a tool similar to that

shown(see illustration)must be fabricated to

unlatch the piston. It is suggested that a 2.5

mm diameter welding rod is used to

manufacture the tool. Use the tool to release

the piston as follows.

46Carefully lift the chain tensioner arm with

a screwdriver, and insert the tool between the

tensioner arm and the piston. Remove the

screwdriver, and release the piston by

pressing the tensioner arm down by hand.

Carefully withdraw the tool once the piston

has been released.

47Tighten the camshaft sprocket securing

bolts to the specified torque, holding the

sprockets stationary as during removal.

48Turn the crankshaft clockwise through

two complete revolutions, and check that the

timing marks on the camshaft sprockets are

still aligned with the top face of the cylinder

head as described in paragraph 4.

49Turn the crankshaft clockwise through

another complete revolution, and check that

the timing marks on the camshaft sprockets

are facing each other, directly in line with the

top face of the cylinder head. 50If the timing marks do not align as

described, the timing chain has been

incorrectly fitted (probably one chain link

away from the correct position on one of the

camshaft sprockets), and the chain should be

removed from the sprockets and refitted

again in the correct position as described

previously.

51Inspect the oil seal in the upper timing

chain cover. If the oil seal is in good condition,

the cover can be refitted as follows, but if the

seal is damaged, or has been leaking, a new

seal should be fitted to the cover. If

necessary, carefully prise the old oil seal from

the cover using a screwdriver, and drive in the

new seal using a suitable metal tube. Make

sure that the seal lip faces into the engine.

Take care not to damage the timing chain

cover.

52Fit the upper timing chain cover using a

new rubber gasket. Great care must be taken

to avoid damage to the oil seal when passing

the seal over the end of the inlet camshaft.

Careful manipulation will be required (possibly

using a thin feeler blade) to avoid damage to

the oil seal sealing lip. Note that the oil seal

should be fitted dry.

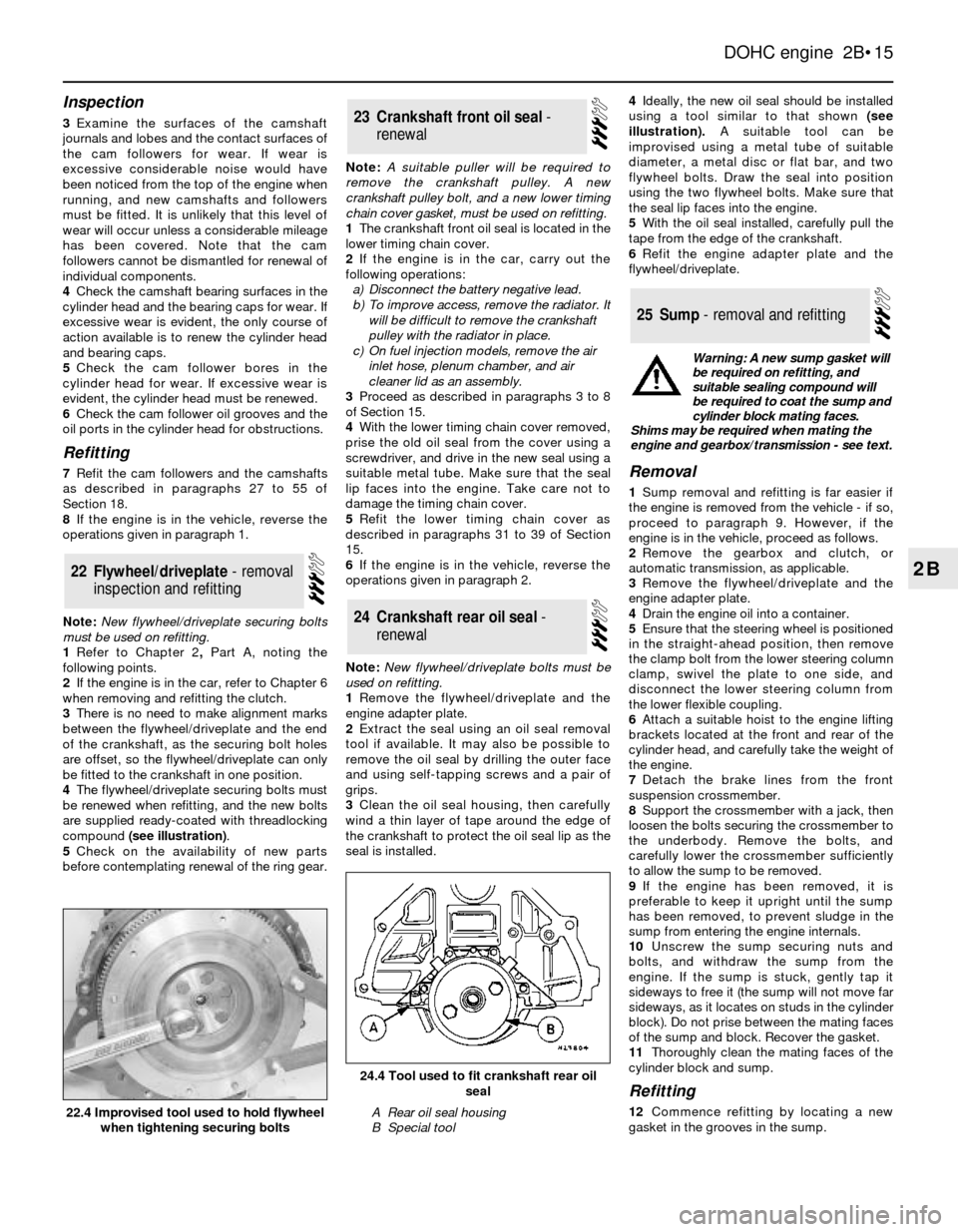

53Refit the timing chain cover securing bolts

and studs in their original locations, and

tighten them to the specified torque (see

illustration).

54Remove the reinforcing sleeves from the

camshaft cover, and renew the rubber sealing

rings. Note that the four short reinforcing

sleeves fit at the front of the cover (see

illustration).

55Refit the camshaft cover using a new

gasket, and tighten the securing bolts and

studs to the specified torque.

Note: A valve spring compressor will be

required during this procedure. New valve

stem oil seals should be used on reassembly.

1Proceed as described in Chapter 2, PartC,

noting the following points:

a)Ignore the references to removing and

refitting the camshaft.

b)Double valve springs are used on all the

valves (see illustration).c)Ignore the reference to inlet valve

dampers.

d)Refer to the following Section if the

cylinder head is to be inspected and

renovated.

1Refer to Chapter 2, PartA, noting the

following points:

a)Valve and valve seat cutting and

regrinding can be carried out using

conventional tools.

b)The cylinder head cannot be resurfaced,

and if the surface distortion exceeds the

specified limits, the cylinder head must be

renewed.

Note: Once the timing chain has been

removed from the camshaft sprockets, do not

turn the crankshaft until the timing chain has

been correctly refitted - this is to prevent

contact between the valves and pistons. A

new timing chain tensioner plunger assembly,

a new upper timing chain cover gasket, and a

new camshaft cover gasket and reinforcing

sleeve sealing rings, must be used on refitting.

Removal

1If the engine is in the vehicle, carry out the

following operations:

a)Disconnect the battery negative lead.

b)On carburettor models, remove the air

cleaner.

c)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

d)Disconnect the breather hose from the

camshaft cover.

e)Remove the distributor cap and HT leads,

and the rotor arm and housing. If

necessary, mark the HT leads to aid

refitting.

2Proceed as described in paragraphs 2 to 15

inclusive of Section 18.

21Camshafts and cam

followers - removal, inspection

and refitting

20Cylinder head - inspection

and renovation

19Cylinder head - dismantling

and reassembly

2B•14DOHC engine

18.45 Fabricated tool used to unlatch

tensioner plunger piston

18.54 Fitting a camshaft cover reinforcing

sleeve and sealing ring

19.1 Withdrawing the double valve springs

from the cylinder head

18.53 Upper timing chain cover securing

stud locations (arrowed)

Page 15 of 18

Inspection

3Examine the surfaces of the camshaft

journals and lobes and the contact surfaces of

the cam followers for wear. If wear is

excessive considerable noise would have

been noticed from the top of the engine when

running, and new camshafts and followers

must be fitted. It is unlikely that this level of

wear will occur unless a considerable mileage

has been covered. Note that the cam

followers cannot be dismantled for renewal of

individual components.

4Check the camshaft bearing surfaces in the

cylinder head and the bearing caps for wear. If

excessive wear is evident, the only course of

action available is to renew the cylinder head

and bearing caps.

5Check the cam follower bores in the

cylinder head for wear. If excessive wear is

evident, the cylinder head must be renewed.

6Check the cam follower oil grooves and the

oil ports in the cylinder head for obstructions.

Refitting

7Refit the cam followers and the camshafts

as described in paragraphs 27 to 55 of

Section 18.

8If the engine is in the vehicle, reverse the

operations given in paragraph 1.

Note: New flywheel/driveplate securing bolts

must be used on refitting.

1Refer to Chapter 2, PartA, noting the

following points.

2If the engine is in the car, refer to Chapter 6

when removing and refitting the clutch.

3There is no need to make alignment marks

between the flywheel/driveplate and the end

of the crankshaft, as the securing bolt holes

are offset, so the flywheel/driveplate can only

be fitted to the crankshaft in one position.

4The flywheel/driveplate securing bolts must

be renewed when refitting, and the new bolts

are supplied ready-coated with threadlocking

compound (see illustration).

5Check on the availability of new parts

before contemplating renewal of the ring gear.Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, and a new lower timing

chain cover gasket, must be used on refitting.

1The crankshaft front oil seal is located in the

lower timing chain cover.

2If the engine is in the car, carry out the

following operations:

a)Disconnect the battery negative lead.

b)To improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel injection models, remove the air

inlet hose, plenum chamber, and air

cleaner lid as an assembly.

3Proceed as described in paragraphs 3 to 8

of Section 15.

4With the lower timing chain cover removed,

prise the old oil seal from the cover using a

screwdriver, and drive in the new seal using a

suitable metal tube. Make sure that the seal

lip faces into the engine. Take care not to

damage the timing chain cover.

5Refit the lower timing chain cover as

described in paragraphs 31 to 39 of Section

15.

6If the engine is in the vehicle, reverse the

operations given in paragraph 2.

Note: New flywheel/driveplate bolts must be

used on refitting.

1Remove the flywheel/driveplate and the

engine adapter plate.

2Extract the seal using an oil seal removal

tool if available. It may also be possible to

remove the oil seal by drilling the outer face

and using self-tapping screws and a pair of

grips.

3Clean the oil seal housing, then carefully

wind a thin layer of tape around the edge of

the crankshaft to protect the oil seal lip as the

seal is installed.4Ideally, the new oil seal should be installed

using a tool similar to that shown (see

illustration).A suitable tool can be

improvised using a metal tube of suitable

diameter, a metal disc or flat bar, and two

flywheel bolts. Draw the seal into position

using the two flywheel bolts. Make sure that

the seal lip faces into the engine.

5With the oil seal installed, carefully pull the

tape from the edge of the crankshaft.

6Refit the engine adapter plate and the

flywheel/driveplate.Removal

1Sump removal and refitting is far easier if

the engine is removed from the vehicle - if so,

proceed to paragraph 9. However, if the

engine is in the vehicle, proceed as follows.

2Remove the gearbox and clutch, or

automatic transmission, as applicable.

3Remove the flywheel/driveplate and the

engine adapter plate.

4Drain the engine oil into a container.

5Ensure that the steering wheel is positioned

in the straight-ahead position, then remove

the clamp bolt from the lower steering column

clamp, swivel the plate to one side, and

disconnect the lower steering column from

the lower flexible coupling.

6Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

7Detach the brake lines from the front

suspension crossmember.

8Support the crossmember with a jack, then

loosen the bolts securing the crossmember to

the underbody. Remove the bolts, and

carefully lower the crossmember sufficiently

to allow the sump to be removed.

9If the engine has been removed, it is

preferable to keep it upright until the sump

has been removed, to prevent sludge in the

sump from entering the engine internals.

10Unscrew the sump securing nuts and

bolts, and withdraw the sump from the

engine. If the sump is stuck, gently tap it

sideways to free it (the sump will not move far

sideways, as it locates on studs in the cylinder

block). Do not prise between the mating faces

of the sump and block. Recover the gasket.

11Thoroughly clean the mating faces of the

cylinder block and sump.

Refitting

12Commence refitting by locating a new

gasket in the grooves in the sump.

25Sump - removal and refitting

24Crankshaft rear oil seal -

renewal

23Crankshaft front oil seal -

renewal

22Flywheel/driveplate - removal

inspection and refitting

DOHC engine 2B•15

2B

24.4 Tool used to fit crankshaft rear oil

seal

A Rear oil seal housing

B Special tool22.4 Improvised tool used to hold flywheel

when tightening securing bolts

Warning: A new sump gasket will

be required on refitting, and

suitable sealing compound will

be required to coat the sump and

cylinder block mating faces.

Shims may be required when mating the

engine and gearbox/transmission - see text.