belt FORD SIERRA 1992 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 0.93 MB

Page 1 of 24

System type

1.3 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch inductive discharge system

1.6 litre models (except Economy) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch inductive discharge system

1.6 litre Economy models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ESC system with Lucas “Hall effect” distributor

1.6 litre CVH (R6A type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Distributorless controlled by EEC IV system

1.8 litre SOHC models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ESC II system with Bosch “Hall effect” distributor

1.8 litre CVH models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ESC Hybrid system

1.8 litre CVH (R6A type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Distributorless controlled by EEC IV system

2.0 litre SOHC carburettor models up to 1985 . . . . . . . . . . . . . . . . . . . . Bosch inductive discharge system

2.0 litre SOHC carburettor models from 1985 (except P100) . . . . . . . . . ESC II system with Bosch “Hall effect” distributor

2.0 litre DOHC carburettor models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ESC II system

P100 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bosch inductive discharge system

2.0 litre SOHC fuel injection models up to 1987 . . . . . . . . . . . . . . . . . . EEC IV system with Motorcraft “Hall effect” distributor

2.0 litre SOHC fuel injection models from 1987 . . . . . . . . . . . . . . . . . . . EEC IV system with Bosch “Hall effect” distributor

2.0 litre DOHC fuel injection models . . . . . . . . . . . . . . . . . . . . . . . . . . . EEC IV system

Coil

All models except CVH (R6A type) and 2.0 litre DOHC

Output (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 kilovolts

Primary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.72 to 0.88 ohm

Secondary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4500 to 7000 ohms

1.6 and 1.8 litre CVH (R6A type)

Output (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37.0 kilovolts

Primary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 ± 0.05 ohms

2.0 litre DOHC carburettor model

Output (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25.0 kilovolts

Primary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.72 to 0.88 ohms

Secondary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4500 to 8600 ohms

2.0 litre DOHC fuel injection model

Output (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.0 kilovolts

Primary winding resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.72 to 0.88 ohms

Secondary resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4500 to 8600 ohms

Distributor

Direction of rotor arm rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 3 - 4 - 2 (No 1 cylinder nearest timing cover)

Dwell angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatically controlled by electronic module (not adjustable)

Chapter 5

Engine electrical systems

Alternator - testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Alternator - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Alternator brushes - removal, inspection and refitting . . . . . . . . . . . . .7

Alternator drivebelt(s) - checking, renewal and tensioning . . . . . . . . . .5

Battery - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Battery - testing and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Coil - testing, removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .12

Distributor (OHC models) - removal and refitting . . . . . . . . . . . . . . . .15

Distributor cap and rotor arm (OHC models) - removal and refitting .13

Distributor components (CVH models) - removal and refitting . . . . . .14

EEC IV system components - removal and refitting . . . . . . . . . . . . . .21Electronic modules - removal and refitting . . . . . . . . . . . . . . . . . . . . .18

ESC Hybrid system components - removal and refitting . . . . . . . . . .20

ESC II system components - removal and refitting . . . . . . . . . . . . . .19

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . . .1

Ignition timing - adjustment for use with unleaded petrol . . . . . . . . .17

Ignition timing (OHC models) - adjustment . . . . . . . . . . . . . . . . . . . .16

Starter motor - brush renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Starter motor - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .8

Starter motor - testing in the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . .9

Spark control system components - removal and refitting . . . . . . . .22

Spark plugs and HT leads - removal, inspection and refitting . . . . . .11

5•1

Specifications Contents

5

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 3 of 24

General information

The electrical system is of the 12 volt

negative earth type, and consists of a 12 volt

battery, alternator with integral voltage

regulator, starter motor and related electrical

accessories, components and wiring. The

battery is of the low maintenance or

maintenance-free “sealed for life” type and is

charged by an alternator which is belt-driven

from the crankshaft pulley. The starter motor

is of the pre-engaged type, incorporating an

integral solenoid. On starting the solenoid

moves the drive pinion into engagement with

the flywheel ring gear before the starter motor

is energised. Once the engine has started, a

one-way clutch prevents the motor armature

being driven by the engine until the pinion

disengages from the flywheel.

The ignition system is responsible for

igniting the air/fuel mixture in each cylinder at

the correct moment in relation to engine

speed and load. A number of different ignition

systems are fitted to models within the

Sierra/P100 range, ranging from a basic

breakerless electronic system to a fully

integrated engine management system

controlling ignition and fuel injection systems.

The ignition system is based on feeding low

tension voltage from the battery to the coil

where it is converted to high tension voltage.

The high tension voltage is powerful enough

to jump the spark plug gap in the cylinders

many times a second under high compression

pressures, providing that the system is in

good condition. The low tension (or primary)

circuit consists of the battery, the lead to the

ignition switch, the lead from the ignition

switch to the low tension coil windings

(terminal + /15) and also to the supply terminal

on the electronic module, and the lead from

the low tension coil windings (terminal -/1) to

the control terminal on the electronic module.

The high tension (or secondary) circuit

consists of the high tension coil windings, the

HT (high tension) lead from the coil to the

distributor cap, the rotor arm, the HT leads to

the spark plugs, and the spark plugs.

The system functions in the following

manner. Current flowing through the low

tension coil windings produces a magnetic

field around the high tension windings. As the

engine rotates, a sensor produces an

electrical impulse which is amplified in the

electronic module and used to switch off the

low tension circuit.

The subsequent collapse of the magnetic

field over the high tension windings produces

high tension voltage which is then fed to the

relevant spark plug via the distributor cap and

rotor arm. The low tension circuit is

automatically switched on again by the

electronic module, to allow the magnetic field

to build up again before the firing of the next

spark plug. The ignition is advanced and

retarded automatically to ensure that thespark occurs at the correct instant in relation

to the engine speed and load.

To improve driveability during warm-up

conditions and to reduce exhaust emission

levels, a vacuum-operated,

temperature-sensitive spark control system is

fitted to certain vehicles.Inductive discharge system

This is the least sophisticated system fitted

to the Sierra/P100 range, and comprises a

breakerless distributor and an electronic

switching/amplifier module in addition to the

coil and spark plugs.

The electrical impulse which is required to

switch off the low tension circuit is generated

by a magnetic trigger coil in the distributor. A

trigger wheel rotates within a magnetic stator,

the magnetic field being provided by a

permanent magnet. The magnetic field across

the two poles (stator arm and trigger wheel) is

dependent on the air gap between the two

poles. When the air gap is at its minimum, the

trigger wheel arm is directly opposite the

stator arm, and this is the trigger point. As the

magnetic flux between the stator arm and

trigger wheel varies, a voltage is induced in

the trigger coil mounted below the trigger

wheel, and this voltage is sensed and then

amplified by the electronic module and used

to switch off the low tension circuit. There is

one trigger wheel arm and one stator arm for

each cylinder (4).

The ignition advance is a function of the

distributor and is controlled both mechanically

and by a vacuum operated system. The

mechanical governor mechanism consists of

two weights which move out from the

distributor shaft as the engine speed rises due

to centrifugal force. As they move outwards,

they rotate the trigger wheel relative to the

distributor shaft and so advance the spark.

The weights are held in position by two light

springs and it is the tension of the springs

which is largely responsible for correct spark

advancement.

The vacuum control consists of a

diaphragm, one side of which is connected

via a small bore hose to the carburettor or

inlet manifold and the other side to the

distributor. Depression in the inlet manifold

and/or carburettor, which varies with engine

speed and throttle position, causes the

diaphragm to move, so moving the baseplate

and advancing or retarding the spark. A fine

degree of control is achieved by a spring in

the diaphragm assembly.

ESC (Electronic Spark Control) system

This system is only fitted to early

“Economy” models, and comprises a “Hall

effect” distributor, and an ESC module, in

addition to the coil and spark plugs.

The electrical impulse which is required to

switch off the low tension circuit is generated

by a sensor in the distributor. A trigger vane

rotates in the gap between a permanent

magnet and the sensor. The trigger vane has

four cut-outs, one for each cylinder. When

one of the trigger vane cut-outs is in line with

the sensor, magnetic flux can pass betweenthe magnet and the sensor. When a trigger

vane segment is in line with the sensor, the

magnetic flux is diverted through the trigger

vane away from the sensor. The sensor

senses the change in magnetic flux and sends

an impulse to the ESC module, which

switches off the low tension circuit.

The ignition advance is a function of the

ESC module and is controlled by vacuum. The

module is connected to the inlet manifold by a

vacuum pipe, and a transducer in the module

translates the vacuum signal into electrical

voltage. From the vacuum signal, the ESC

module determines engine load, and engine

speed is determined from the interval

between impulses supplied by the distributor

sensor. The module has a range of spark

advance settings stored in its memory, and a

suitable setting is selected for the relevant

engine speed and load. The degree of

advance can thus be constantly varied to suit

the prevailing engine speed and load

conditions.

ESC II (Electronic Spark Control II)

system

1.8 and 2.0 litre SOHC carburettor models

This system is a development of the ESC

system described previously in this Section,

but it enables more accurate control of engine

operation due to the inclusion of additional

monitoring features and control outputs.

Vehicles fitted with the ESC II system have an

electric inlet manifold heater which warms the

air/fuel mixture when the engine is cold, thus

reducing the amount of fuel enrichment

required, lowering fuel consumption and

improving driveability when the engine is cold.

The heater is operated by the ESC II module

receiving information on the engine temperature

from an engine coolant temperature sensor

mounted in the inlet manifold.

On 2.0 litre SOHC models, the ESC II

module operates a carburettor stepper motor

to control the engine idle speed. Using

information on engine speed, load,

temperature and throttle position (supplied by

a switch on the carburettor), the module

operates the stepper motor to maintain a

constant idle speed. On models equipped

with automatic transmission and/or air

conditioning, additional inputs are supplied to

the module to allow it to operate the stepper

motor to compensate for the additional engine

load imposed by the automatic

transmission/air conditioning. The ESC II

module also operates a “power hold” relay

which allows the stepper motor to function

briefly after the ignition has been switched off

in order to perform an anti-run-on and

manifold ventilation cycle.

2.0 litre DOHC carburettor models

A development of the ESC II system is used

to control the operation of the engine. The

module receives information from a

crankshaft speed/position sensor (similar to

that described for the ESC Hybrid system),

except that the sensor is activated by a

toothed disc on the rear of the crankshaft,

inside the cylinder block), and an engine

coolant temperature sensor.

1General information and

precautions

Engine electrical systems 5•3

5

Page 6 of 24

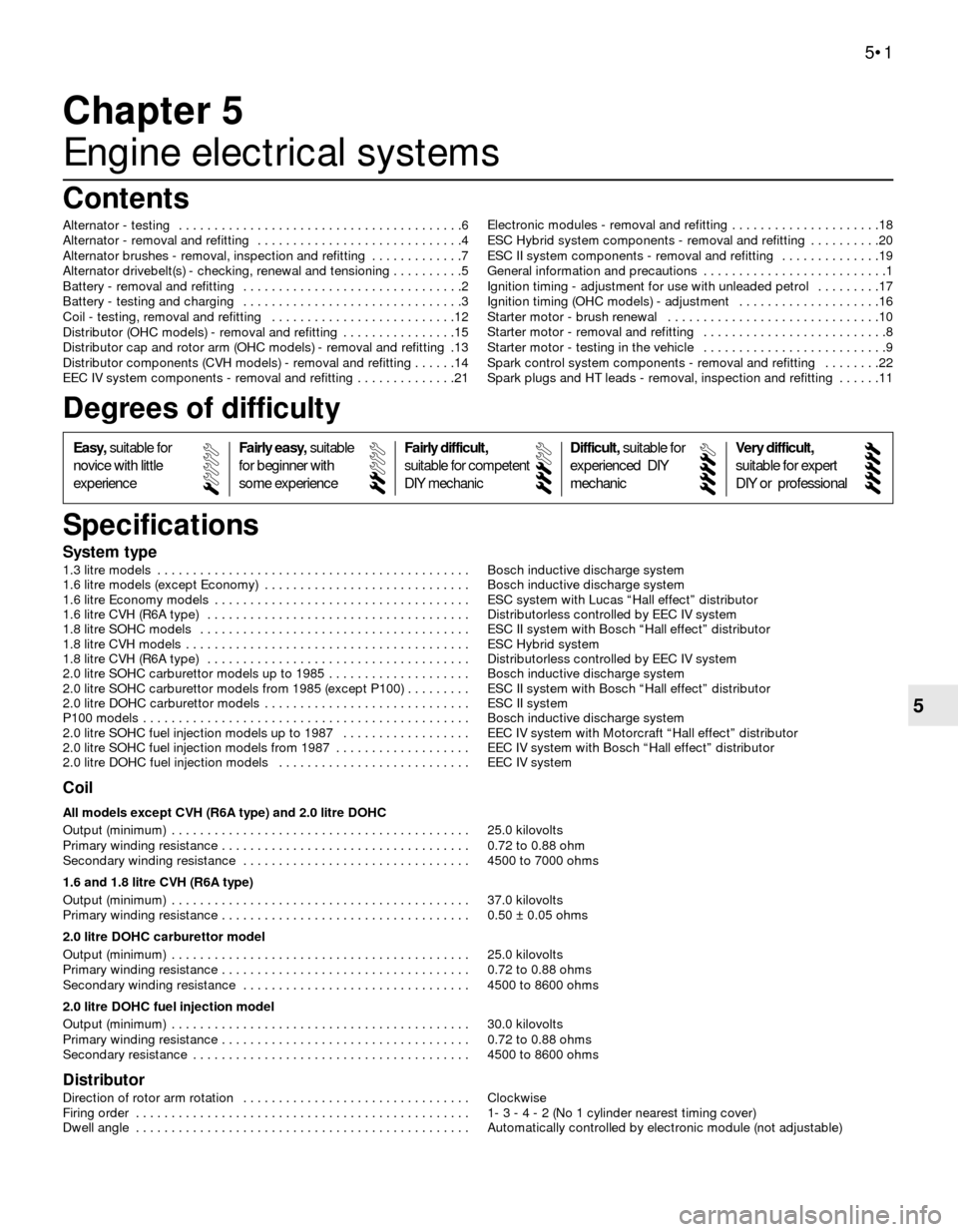

Removal

1Disconnect the battery leads.

2Disconnect the multi-plug, or disconnect

the wires from their terminals on the rear of

the alternator, noting their locations (as

applicable), then slacken the mounting and

adjustment bolts and tilt the alternator

towards the engine (see illustrations).

3Remove the drivebelt(s) from the alternator

pulley(s).

4Remove the mounting and adjustment nuts

and bolts, and withdraw the alternator from

the engine.

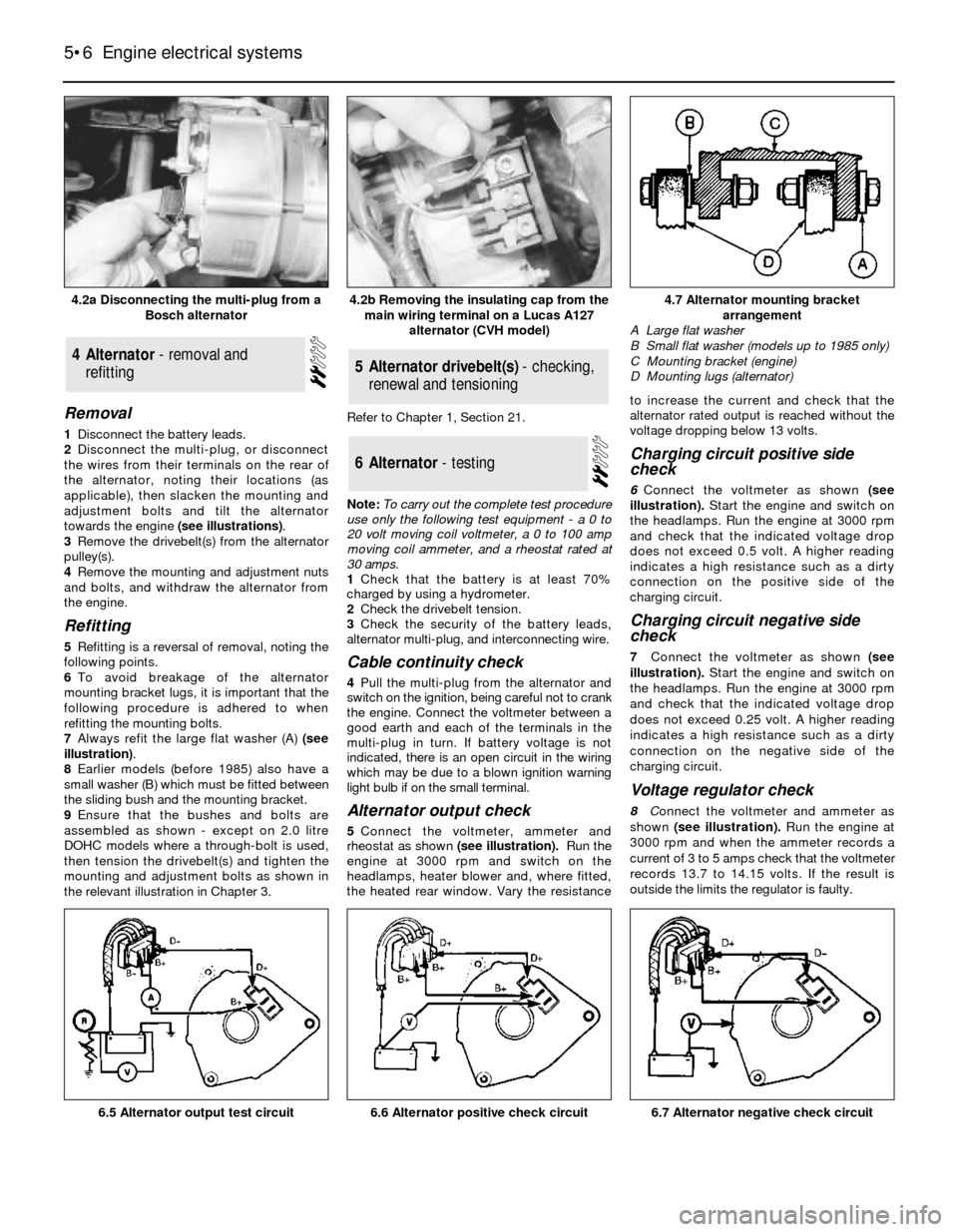

Refitting

5Refitting is a reversal of removal, noting the

following points.

6To avoid breakage of the alternator

mounting bracket lugs, it is important that the

following procedure is adhered to when

refitting the mounting bolts.

7Always refit the large flat washer (A) (see

illustration).

8Earlier models (before 1985) also have a

small washer (B) which must be fitted between

the sliding bush and the mounting bracket.

9Ensure that the bushes and bolts are

assembled as shown - except on 2.0 litre

DOHC models where a through-bolt is used,

then tension the drivebelt(s) and tighten the

mounting and adjustment bolts as shown in

the relevant illustration in Chapter 3.Refer to Chapter 1, Section 21.

Note: To carry out the complete test procedure

use only the following test equipment - a 0 to

20 volt moving coil voltmeter, a 0 to 100 amp

moving coil ammeter, and a rheostat rated at

30 amps.

1Check that the battery is at least 70%

charged by using a hydrometer.

2Check the drivebelt tension.

3Check the security of the battery leads,

alternator multi-plug, and interconnecting wire.

Cable continuity check

4Pull the multi-plug from the alternator and

switch on the ignition, being careful not to crank

the engine. Connect the voltmeter between a

good earth and each of the terminals in the

multi-plug in turn. If battery voltage is not

indicated, there is an open circuit in the wiring

which may be due to a blown ignition warning

light bulb if on the small terminal.

Alternator output check

5Connect the voltmeter, ammeter and

rheostat as shown (see illustration).Run the

engine at 3000 rpm and switch on the

headlamps, heater blower and, where fitted,

the heated rear window. Vary the resistanceto increase the current and check that the

alternator rated output is reached without the

voltage dropping below 13 volts.

Charging circuit positive side

check

6Connect the voltmeter as shown (see

illustration).Start the engine and switch on

the headlamps. Run the engine at 3000 rpm

and check that the indicated voltage drop

does not exceed 0.5 volt. A higher reading

indicates a high resistance such as a dirty

connection on the positive side of the

charging circuit.

Charging circuit negative side

check

7Connect the voltmeter as shown (see

illustration).Start the engine and switch on

the headlamps. Run the engine at 3000 rpm

and check that the indicated voltage drop

does not exceed 0.25 volt. A higher reading

indicates a high resistance such as a dirty

connection on the negative side of the

charging circuit.

Voltage regulator check

8Connect the voltmeter and ammeter as

shown(see illustration).Run the engine at

3000 rpm and when the ammeter records a

current of 3 to 5 amps check that the voltmeter

records 13.7 to 14.15 volts. If the result is

outside the limits the regulator is faulty.

6Alternator - testing

5Alternator drivebelt(s) - checking,

renewal and tensioning4Alternator - removal and

refitting

5•6Engine electrical systems

4.2a Disconnecting the multi-plug from a

Bosch alternator4.7 Alternator mounting bracket

arrangement

A Large flat washer

B Small flat washer (models up to 1985 only)

C Mounting bracket (engine)

D Mounting lugs (alternator)

6.7 Alternator negative check circuit6.6 Alternator positive check circuit6.5 Alternator output test circuit

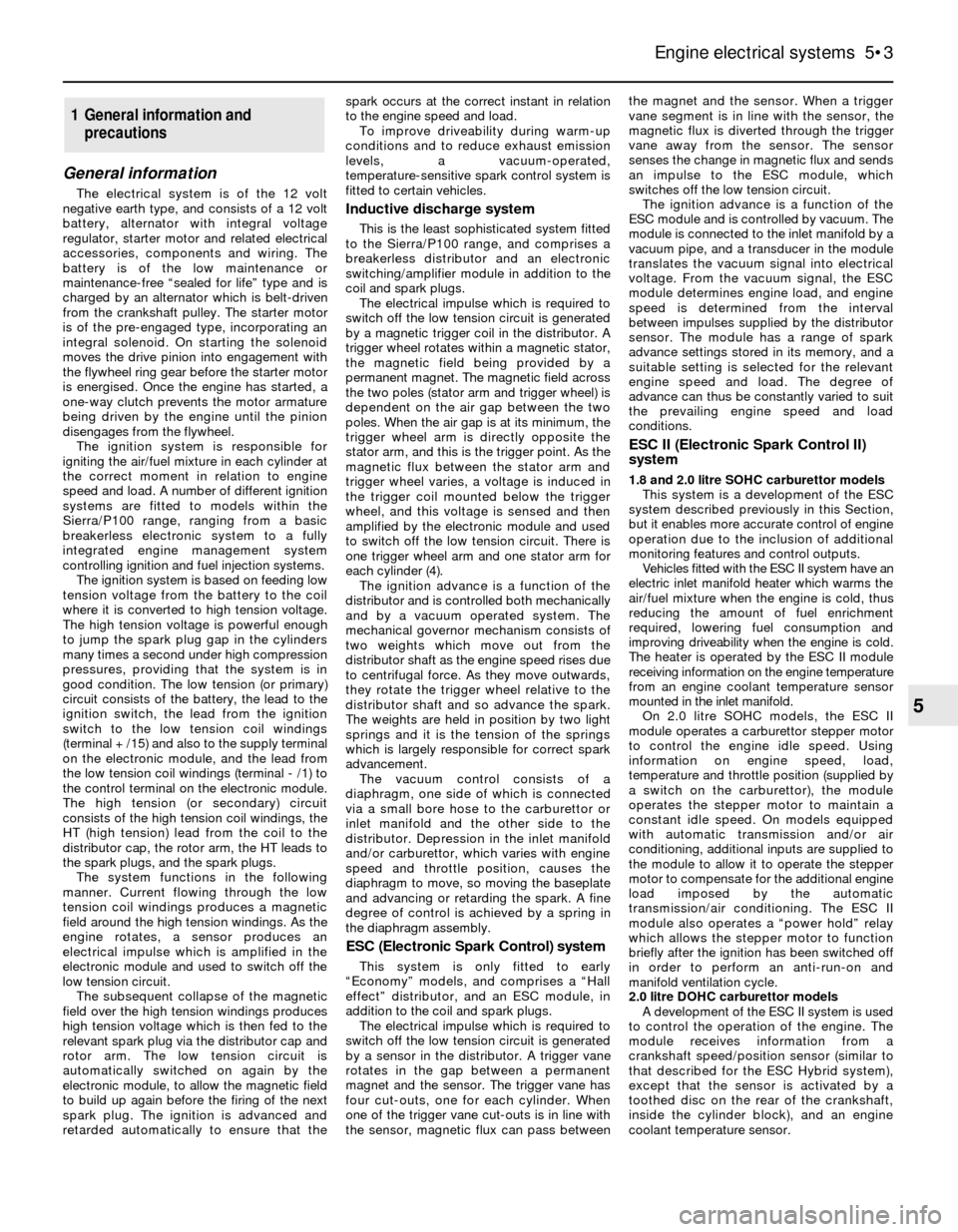

4.2b Removing the insulating cap from the

main wiring terminal on a Lucas A127

alternator (CVH model)

Page 16 of 24

sprocket bolt. Note that there is no need to

remove the timing belt or the sprockets.

Note: During production the engine ignition

timing is accurately set using a microwave

process, and sealant is applied to the

distributor clamp bolt. Removal of the

distributor should be avoided except where

excessive bearing wear has occurred due to

high mileage or during major engine overhaul.

A timing light will be required to check the

ignition timing after refitting the distributor.

All models except early

“Economy”

Removal

1Disconnect the battery negative lead.

2If necessary, identify each HT lead for

position, so that the leads can be refitted to

their correct cylinders, then disconnect the

leads from the spark plugs by pulling on the

connectors, not the leads.

3Where applicable, unclip the screening can

from the top of the distributor and disconnect

the earth strap. On fuel injection models,

disconnect the crankcase ventilation hose

from the air inlet hose, then disconnect the air

inlet hose from the inlet manifold and the

airflow meter for improved access.4Prise away the spring clips with a

screwdriver, or remove the two securing

screws, as applicable, and lift off the

distributor cap.

5Disconnect the HT lead from the coil by

pulling on the connector, not the lead, then

slide the HT lead holder from the clip on the

camshaft cover, and withdraw the distributor

cap.

6Where applicable, disconnect the vacuum

pipe from the vacuum advance unit on the

side of the distributor (see illustration).

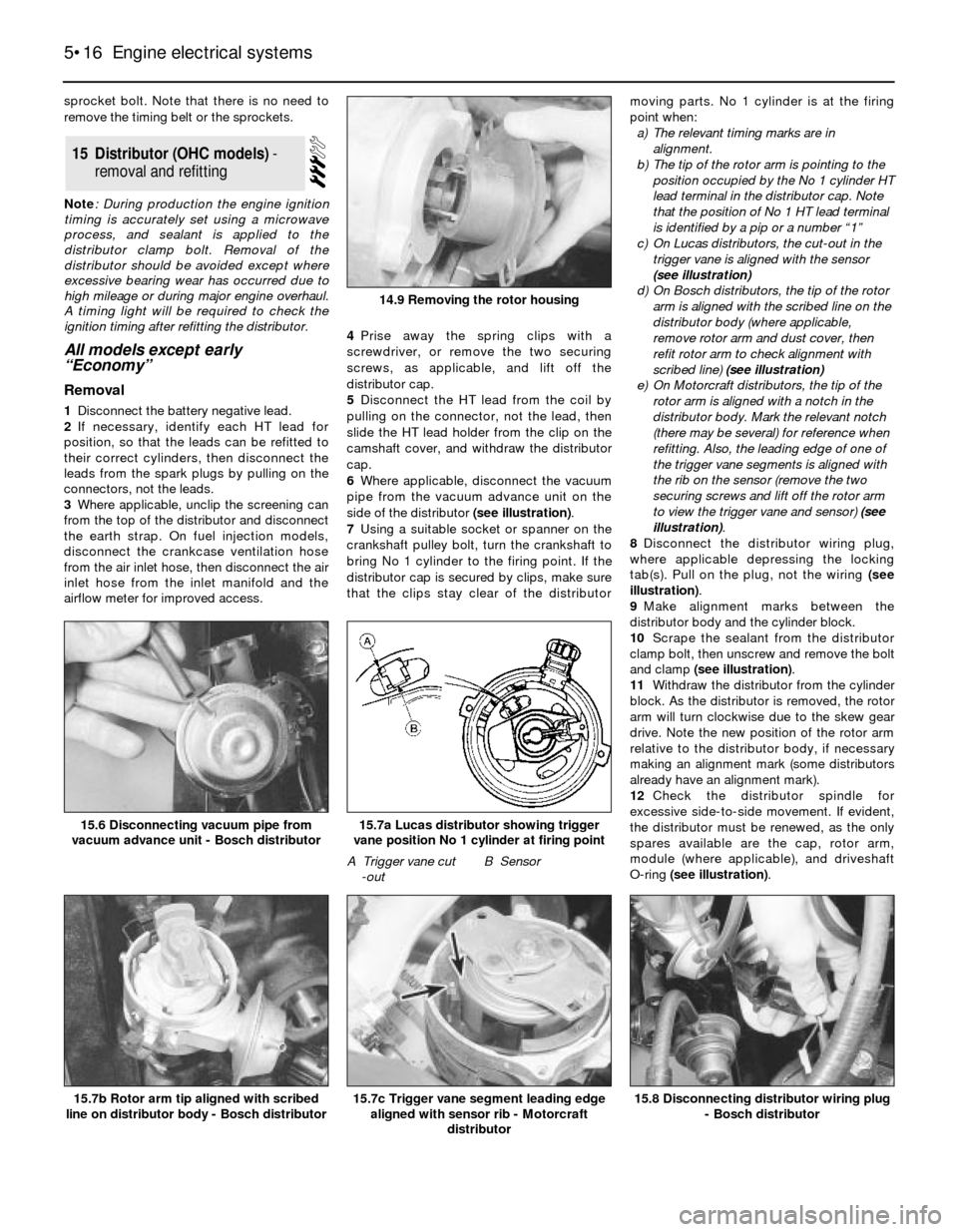

7Using a suitable socket or spanner on the

crankshaft pulley bolt, turn the crankshaft to

bring No 1 cylinder to the firing point. If the

distributor cap is secured by clips, make sure

that the clips stay clear of the distributormoving parts. No 1 cylinder is at the firing

point when:

a)The relevant timing marks are in

alignment.

b)The tip of the rotor arm is pointing to the

position occupied by the No 1 cylinder HT

lead terminal in the distributor cap. Note

that the position of No 1 HT lead terminal

is identified by a pip or a number “1”

c)On Lucas distributors, the cut-out in the

trigger vane is aligned with the sensor

(see illustration)

d)On Bosch distributors, the tip of the rotor

arm is aligned with the scribed line on the

distributor body (where applicable,

remove rotor arm and dust cover, then

refit rotor arm to check alignment with

scribed line) (see illustration)

e)On Motorcraft distributors, the tip of the

rotor arm is aligned with a notch in the

distributor body. Mark the relevant notch

(there may be several) for reference when

refitting. Also, the leading edge of one of

the trigger vane segments is aligned with

the rib on the sensor (remove the two

securing screws and lift off the rotor arm

to view the trigger vane and sensor) (see

illustration).

8Disconnect the distributor wiring plug,

where applicable depressing the locking

tab(s). Pull on the plug, not the wiring (see

illustration).

9Make alignment marks between the

distributor body and the cylinder block.

10Scrape the sealant from the distributor

clamp bolt, then unscrew and remove the bolt

and clamp (see illustration).

11Withdraw the distributor from the cylinder

block. As the distributor is removed, the rotor

arm will turn clockwise due to the skew gear

drive. Note the new position of the rotor arm

relative to the distributor body, if necessary

making an alignment mark (some distributors

already have an alignment mark).

12Check the distributor spindle for

excessive side-to-side movement. If evident,

the distributor must be renewed, as the only

spares available are the cap, rotor arm,

module (where applicable), and driveshaft

O-ring (see illustration).

15Distributor (OHC models) -

removal and refitting

5•16Engine electrical systems

14.9 Removing the rotor housing

15.7a Lucas distributor showing trigger

vane position No 1 cylinder at firing point

A Trigger vane cut

-outB Sensor

15.8 Disconnecting distributor wiring plug

- Bosch distributor15.7c Trigger vane segment leading edge

aligned with sensor rib - Motorcraft

distributor15.7b Rotor arm tip aligned with scribed

line on distributor body - Bosch distributor

15.6 Disconnecting vacuum pipe from

vacuum advance unit - Bosch distributor