maintenance schedule FORD SIERRA 1992 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 0.93 MB

Page 17 of 24

Refitting

13Commence refitting by checking that No 1

cylinder is still at the firing point. The relevant

timing marks should be aligned. If the engine

has been turned whilst the distributor has

been removed, check that No 1 cylinder is on

its firing stroke by removing the No 1 cylinder

spark plug and placing a finger over the plug

hole. Turn the crankshaft until compression

can be felt, which indicates that No 1 piston is

rising on its firing stroke. Continue turning the

crankshaft until the relevant timing marks are

in alignment.

14Turn the rotor arm to the position noted in

paragraph 11. If a new distributor is being

fitted, and no alignment marks are present,

transfer the marks from the old distributor to

the new distributor.

15Hold the distributor directly over the

aperture in the cylinder block with the

previously made marks on the distributor

body and cylinder block aligned, then lower

the distributor into position. Again, if a new

distributor is being fitted, transfer the

alignment mark from the old distributor body

to the new distributor body. As the skew gear

drive meshes, the rotor arm will turn

anti-clockwise.

16With the distributor fitted and the marks

on the distributor body and cylinder block

aligned, check that the rotor arm is positioned

as described in paragraph 7 -if not, withdraw

the distributor, re-position the driveshaft and

try again.

17Refit the clamp, then insert and tighten

the bolt. Do not fully tighten the bolt at this

stage.

18Refit the distributor wiring plug, and

where applicable reconnect the vacuum pipe,

and refit the dust cover and/or rotor arm.

19Refit the distributor cap, and reconnect

the HT leads to the spark plugs and coil.

Ensure that the leads are refitted to their

correct cylinders.

20Where applicable, refit the screening can

to the top of the distributor and reconnect the

earth strap. On fuel injection models,

reconnect the air inlet hose, ensuring that the

clips are correctly aligned (refer to illustration,

Section 15, Chapter 4, PartB).21Reconnect the battery negative lead.

22Check and if necessary adjust the ignition

timing.

Early “Economy” models

Removal

23Removal of the distributor fitted to these

models is a similar process to that described

above.

Refitting

24Turn the crankshaft to bring No 1 cylinder

to the firing point, with the 16º BTDC mark on

the crankshaft pulley aligned with the pointer

on the crankshaft front oil seal housing, as

described above.

25Fit the new distributor to the engine as

described above, then proceed as follows.

26Cut the original distributor wiring plug

from the wiring loom. Make the cut close to

the connector.

27Strip back 10 mm of insulation from each

of the wires on the wiring loom, and on the

adapter loom supplied with the new

distributor.

28Solder the adapter loom wires to the

corresponding identically coloured wires in

the main loom.

29Carefully insulate each individual soldered

joint using insulating tape, then apply tape to

cover the join between the looms.

30Fit a new distributor cap (and screening

can, where applicable), and connect the HT

leads.31Connect the adapter loom to the

distributor.

32Start the engine, and adjust the ignition

timing to the value given in the Specifications

at the beginning of this Chapter. Work as

described above whilst noting that the

vacuum pipe must be left connected.

Note: During production the ignition timing is

accurately set using a microwave process,

and sealant is applied to the distributor clamp

bolt. Because the electronic components

require no maintenance, checking the ignition

timing does not constitute part of the routine

maintenance schedule, and the procedure is

therefore only necessary after removal and

refitting of the distributor. A timing light will be

required for this procedure. For details of

ignition timing adjustment in order to operate

vehicles on unleaded petrol refer to the

appropriate Section of this Chapter.

All models except 2.0 litre DOHC

1Before checking the ignition timing, the

following conditions must be met:

a)The engine must be at normal operating

temperature

b)Where applicable, the vacuum pipe to the

distributor vacuum unit or electronic

module (as applicable) must be

disconnected from the vacuum unit or

electronic module and plugged

c)The idle speed must be below 900 rpm

(isolate “idle speed adjustment” wire if

necessary)

d)Any earthed “octane adjustment” wires

must be temporarily isolated

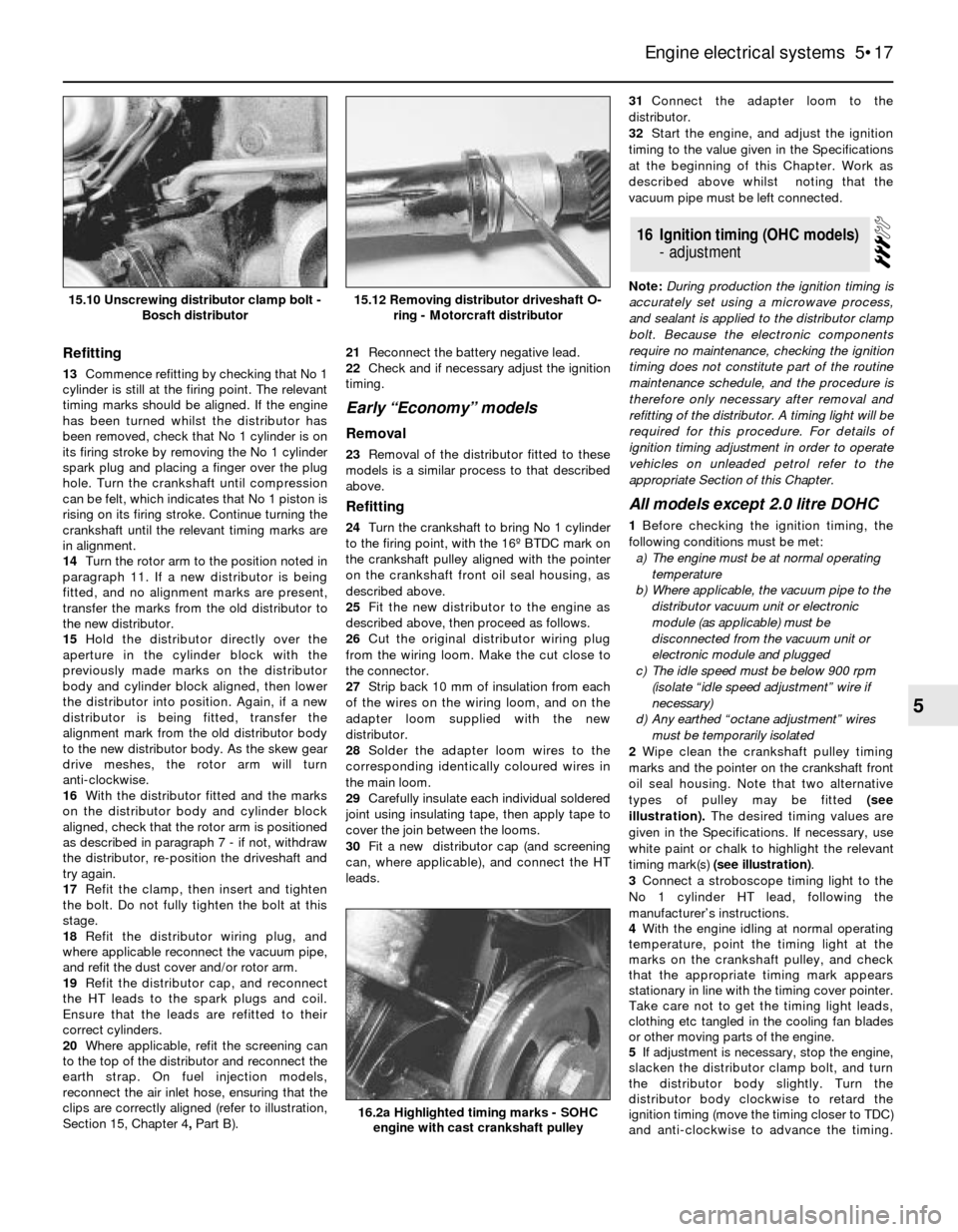

2Wipe clean the crankshaft pulley timing

marks and the pointer on the crankshaft front

oil seal housing. Note that two alternative

types of pulley may be fitted (see

illustration).The desired timing values are

given in the Specifications. If necessary, use

white paint or chalk to highlight the relevant

timing mark(s) (see illustration).

3Connect a stroboscope timing light to the

No 1 cylinder HT lead, following the

manufacturer’s instructions.

4With the engine idling at normal operating

temperature, point the timing light at the

marks on the crankshaft pulley, and check

that the appropriate timing mark appears

stationary in line with the timing cover pointer.

Take care not to get the timing light leads,

clothing etc tangled in the cooling fan blades

or other moving parts of the engine.

5If adjustment is necessary, stop the engine,

slacken the distributor clamp bolt, and turn

the distributor body slightly. Turn the

distributor body clockwise to retard the

ignition timing (move the timing closer to TDC)

and anti-clockwise to advance the timing.

16Ignition timing (OHC models)

- adjustment

Engine electrical systems 5•17

5

15.12 Removing distributor driveshaft O-

ring - Motorcraft distributor15.10 Unscrewing distributor clamp bolt -

Bosch distributor

16.2a Highlighted timing marks - SOHC

engine with cast crankshaft pulley