radio FORD SIERRA 1992 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 0.93 MB

Page 14 of 24

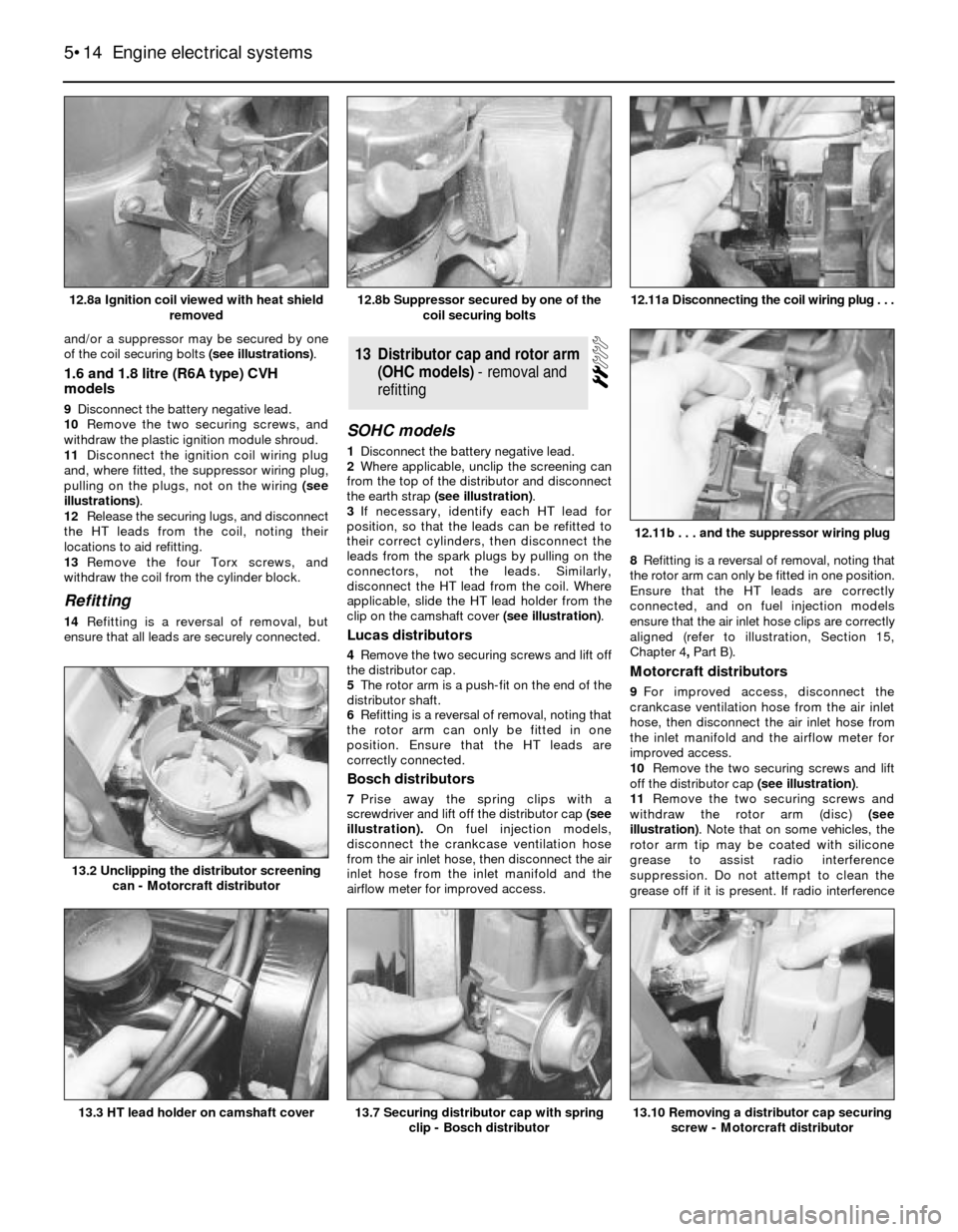

and/or a suppressor may be secured by one

of the coil securing bolts (see illustrations).

1.6 and 1.8 litre (R6A type) CVH

models

9Disconnect the battery negative lead.

10Remove the two securing screws, and

withdraw the plastic ignition module shroud.

11Disconnect the ignition coil wiring plug

and, where fitted, the suppressor wiring plug,

pulling on the plugs, not on the wiring (see

illustrations).

12Release the securing lugs, and disconnect

the HT leads from the coil, noting their

locations to aid refitting.

13Remove the four Torx screws, and

withdraw the coil from the cylinder block.

Refitting

14Refitting is a reversal of removal, but

ensure that all leads are securely connected.

SOHC models

1Disconnect the battery negative lead.

2Where applicable, unclip the screening can

from the top of the distributor and disconnect

the earth strap (see illustration).

3If necessary, identify each HT lead for

position, so that the leads can be refitted to

their correct cylinders, then disconnect the

leads from the spark plugs by pulling on the

connectors, not the leads. Similarly,

disconnect the HT lead from the coil. Where

applicable, slide the HT lead holder from the

clip on the camshaft cover (see illustration).

Lucas distributors

4Remove the two securing screws and lift off

the distributor cap.

5The rotor arm is a push-fit on the end of the

distributor shaft.

6Refitting is a reversal of removal, noting that

the rotor arm can only be fitted in one

position. Ensure that the HT leads are

correctly connected.

Bosch distributors

7Prise away the spring clips with a

screwdriver and lift off the distributor cap(see

illustration).On fuel injection models,

disconnect the crankcase ventilation hose

from the air inlet hose, then disconnect the air

inlet hose from the inlet manifold and the

airflow meter for improved access. 8Refitting is a reversal of removal, noting that

the rotor arm can only be fitted in one position.

Ensure that the HT leads are correctly

connected, and on fuel injection models

ensure that the air inlet hose clips are correctly

aligned (refer to illustration, Section 15,

Chapter 4, PartB).

Motorcraft distributors

9For improved access, disconnect the

crankcase ventilation hose from the air inlet

hose, then disconnect the air inlet hose from

the inlet manifold and the airflow meter for

improved access.

10Remove the two securing screws and lift

off the distributor cap (see illustration).

11Remove the two securing screws and

withdraw the rotor arm (disc) (see

illustration). Note that on some vehicles, the

rotor arm tip may be coated with silicone

grease to assist radio interference

suppression. Do not attempt to clean the

grease off if it is present. If radio interference

13Distributor cap and rotor arm

(OHC models) - removal and

refitting

5•14Engine electrical systems

12.8a Ignition coil viewed with heat shield

removed12.11a Disconnecting the coil wiring plug . . .

13.10 Removing a distributor cap securing

screw - Motorcraft distributor13.7 Securing distributor cap with spring

clip - Bosch distributor13.3 HT lead holder on camshaft cover

13.2 Unclipping the distributor screening

can - Motorcraft distributor

12.11b . . . and the suppressor wiring plug

12.8b Suppressor secured by one of the

coil securing bolts