service FORD SIERRA 1992 2.G Engine Electrical Systems Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 0.93 MB

Page 11 of 24

29Fit the two field brushes into their

locations in the brush box, then position the

commutator end plate on the yoke and fit the

two securing screws.

30Fit a new star clip to the end of the

armature shaft, ensuring that the clip is

pressed home firmly to eliminate any endfloat

in the armature (see illustration). Fit the

plastic cap over the end of the armature shaft.

Lucas 8M90 type

31The procedure is basically as described

previously for the 5M90 type starter motor

with the following difference(see illustration):

32The commutator end plate is secured by two

screws. The end plate and brush box are serviced

as an assembly and should be renewed.

Lucas M79 type

33With the starter motor removed from the

vehicle and cleaned, grip the unit in a vicefitted with soft jaw protectors.

34Unscrew the securing nut and washer and

disconnect the wiring from the solenoid terminal.

35Remove the two screws securing the

commutator end housing cap. Remove the cap.

36Remove the C-clip and spacers from the

end of the armature shaft.

37Remove the two commutator end housing

securing screws and withdraw the end

housing.

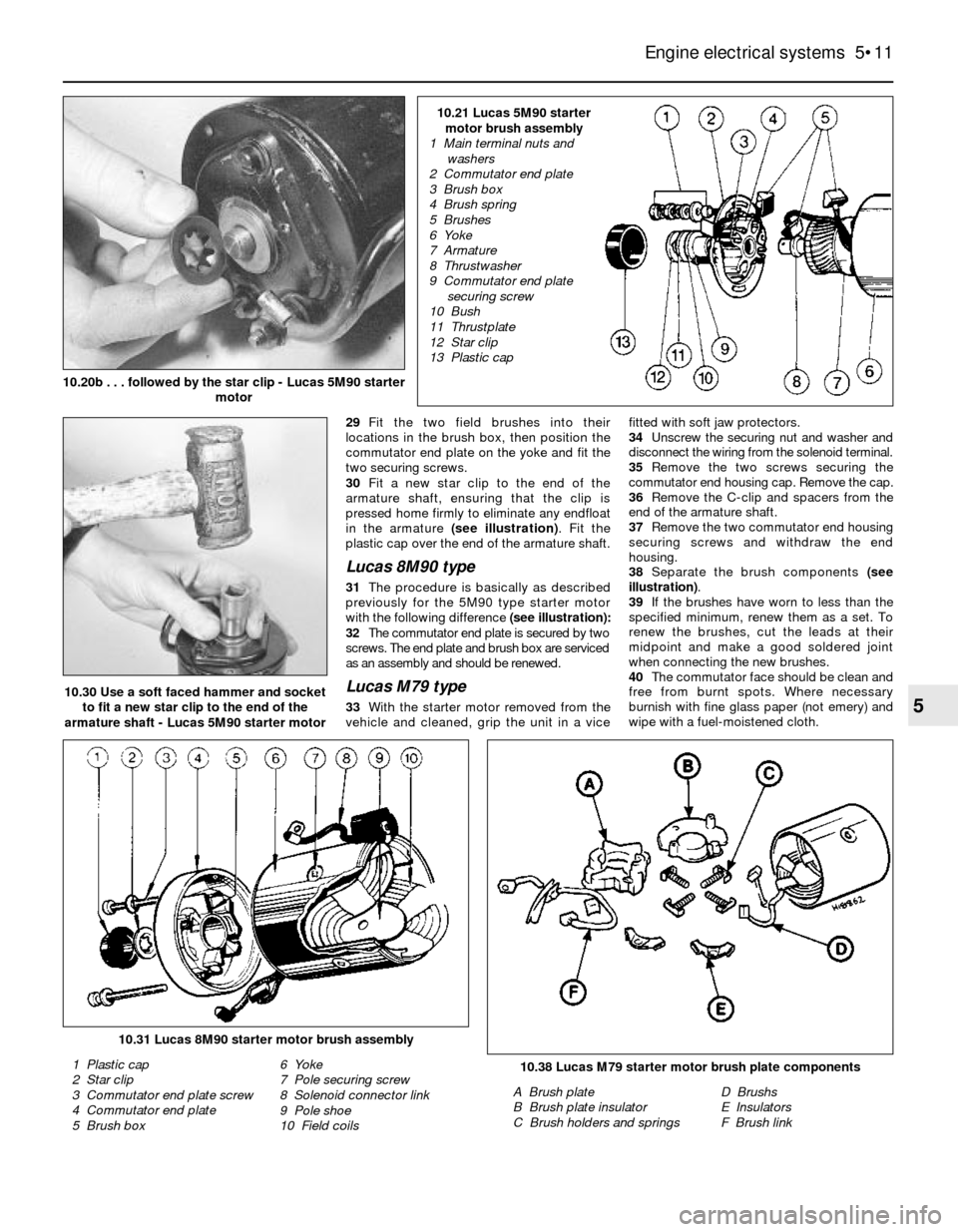

38Separate the brush components (see

illustration).

39If the brushes have worn to less than the

specified minimum, renew them as a set. To

renew the brushes, cut the leads at their

midpoint and make a good soldered joint

when connecting the new brushes.

40The commutator face should be clean and

free from burnt spots. Where necessary

burnish with fine glass paper (not emery) and

wipe with a fuel-moistened cloth.

Engine electrical systems 5•11

5

10.38 Lucas M79 starter motor brush plate components

A Brush plate

B Brush plate insulator

C Brush holders and springsD Brushs

E Insulators

F Brush link

10.31 Lucas 8M90 starter motor brush assembly

1 Plastic cap

2 Star clip

3 Commutator end plate screw

4 Commutator end plate

5 Brush box6 Yoke

7 Pole securing screw

8 Solenoid connector link

9 Pole shoe

10 Field coils

10.30 Use a soft faced hammer and socket

to fit a new star clip to the end of the

armature shaft - Lucas 5M90 starter motor

10.20b . . . followed by the star clip - Lucas 5M90 starter

motor

10.21 Lucas 5M90 starter

motor brush assembly

1 Main terminal nuts and

washers

2 Commutator end plate

3 Brush box

4 Brush spring

5 Brushes

6 Yoke

7 Armature

8 Thrustwasher

9 Commutator end plate

securing screw

10 Bush

11 Thrustplate

12 Star clip

13 Plastic cap

Page 13 of 24

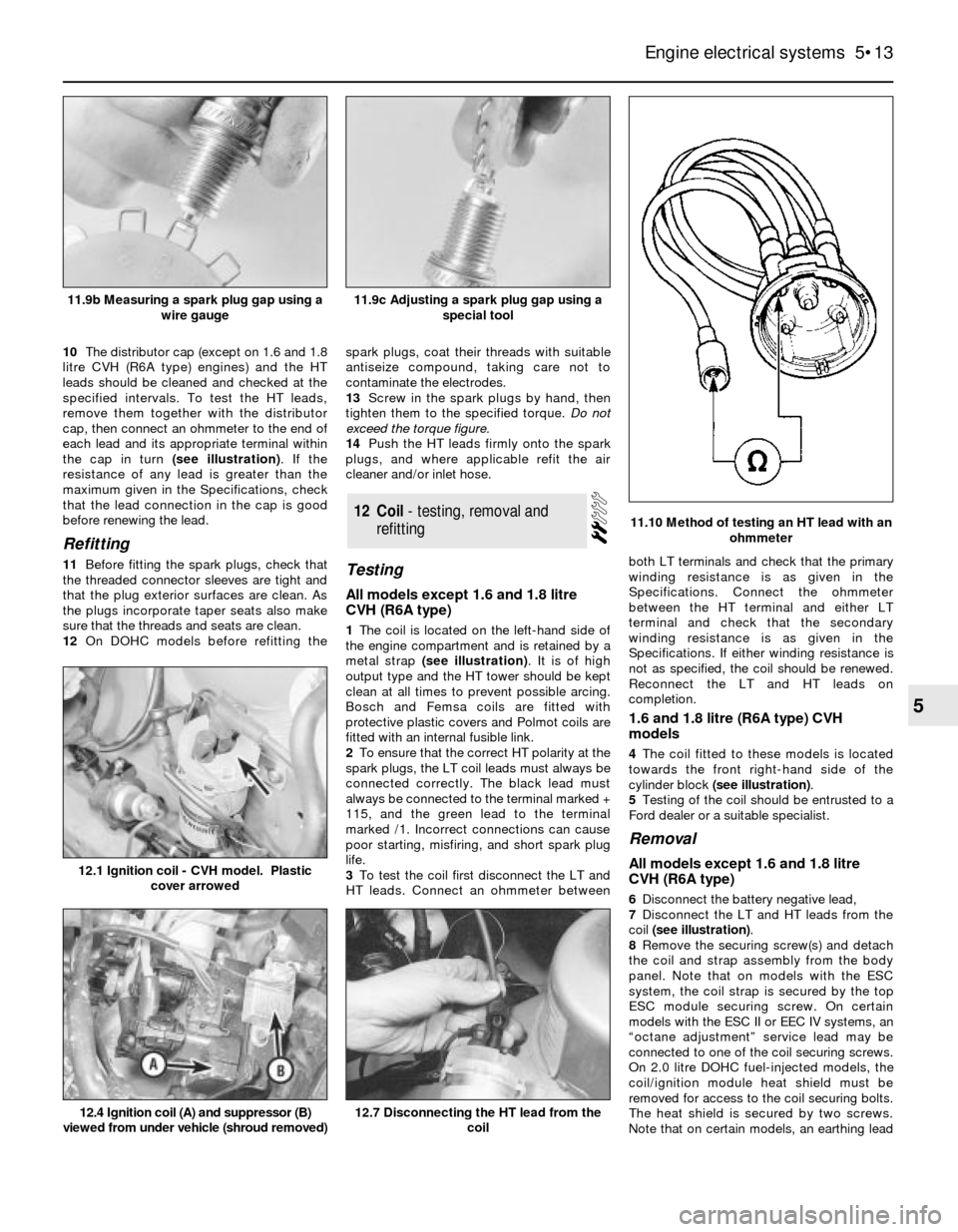

10The distributor cap (except on 1.6 and 1.8

litre CVH (R6A type) engines) and the HT

leads should be cleaned and checked at the

specified intervals. To test the HT leads,

remove them together with the distributor

cap, then connect an ohmmeter to the end of

each lead and its appropriate terminal within

the cap in turn (see illustration). If the

resistance of any lead is greater than the

maximum given in the Specifications, check

that the lead connection in the cap is good

before renewing the lead.

Refitting

11Before fitting the spark plugs, check that

the threaded connector sleeves are tight and

that the plug exterior surfaces are clean. As

the plugs incorporate taper seats also make

sure that the threads and seats are clean.

12On DOHC models before refitting thespark plugs, coat their threads with suitable

antiseize compound, taking care not to

contaminate the electrodes.

13Screw in the spark plugs by hand, then

tighten them to the specified torque. Do not

exceed the torque figure.

14Push the HT leads firmly onto the spark

plugs, and where applicable refit the air

cleaner and/or inlet hose.Testing

All models except 1.6 and 1.8 litre

CVH (R6A type)

1The coil is located on the left-hand side of

the engine compartment and is retained by a

metal strap (see illustration). It is of high

output type and the HT tower should be kept

clean at all times to prevent possible arcing.

Bosch and Femsa coils are fitted with

protective plastic covers and Polmot coils are

fitted with an internal fusible link.

2To ensure that the correct HT polarity at the

spark plugs, the LT coil leads must always be

connected correctly. The black lead must

always be connected to the terminal marked +

115, and the green lead to the terminal

marked /1. Incorrect connections can cause

poor starting, misfiring, and short spark plug

life.

3To test the coil first disconnect the LT and

HT leads. Connect an ohmmeter betweenboth LT terminals and check that the primary

winding resistance is as given in the

Specifications. Connect the ohmmeter

between the HT terminal and either LT

terminal and check that the secondary

winding resistance is as given in the

Specifications. If either winding resistance is

not as specified, the coil should be renewed.

Reconnect the LT and HT leads on

completion.

1.6 and 1.8 litre (R6A type) CVH

models

4The coil fitted to these models is located

towards the front right-hand side of the

cylinder block (see illustration).

5Testing of the coil should be entrusted to a

Ford dealer or a suitable specialist.

Removal

All models except 1.6 and 1.8 litre

CVH (R6A type)

6Disconnect the battery negative lead,

7Disconnect the LT and HT leads from the

coil (see illustration).

8Remove the securing screw(s) and detach

the coil and strap assembly from the body

panel. Note that on models with the ESC

system, the coil strap is secured by the top

ESC module securing screw. On certain

models with the ESC II or EEC IV systems, an

“octane adjustment” service lead may be

connected to one of the coil securing screws.

On 2.0 litre DOHC fuel-injected models, the

coil/ignition module heat shield must be

removed for access to the coil securing bolts.

The heat shield is secured by two screws.

Note that on certain models, an earthing lead

12Coil - testing, removal and

refitting

Engine electrical systems 5•13

5

11.10 Method of testing an HT lead with an

ohmmeter

12.4 Ignition coil (A) and suppressor (B)

viewed from under vehicle (shroud removed)12.7 Disconnecting the HT lead from the

coil

12.1 Ignition coil - CVH model. Plastic

cover arrowed

11.9c Adjusting a spark plug gap using a

special tool11.9b Measuring a spark plug gap using a

wire gauge

Page 18 of 24

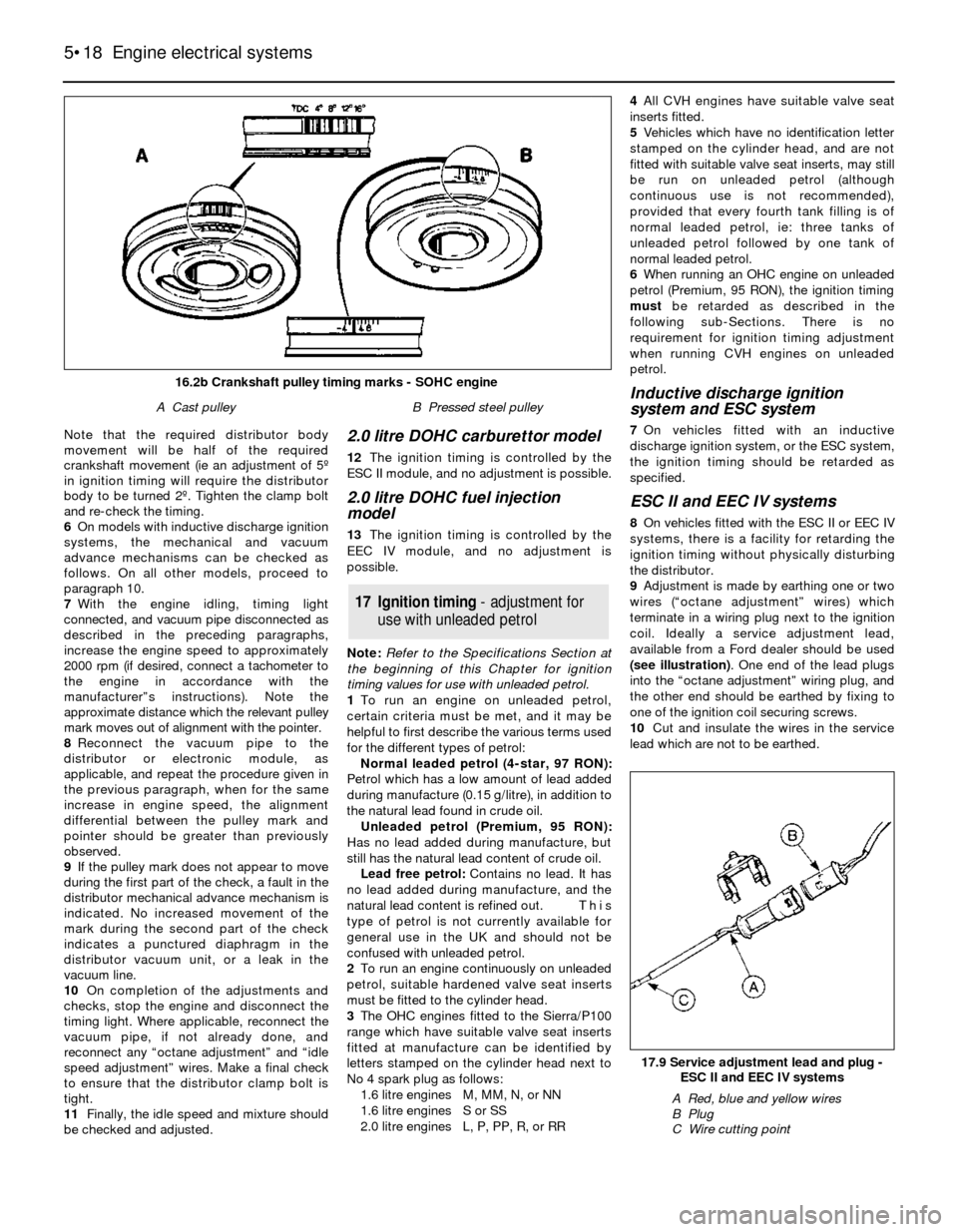

Note that the required distributor body

movement will be half of the required

crankshaft movement (ie an adjustment of 5º

in ignition timing will require the distributor

body to be turned 2º. Tighten the clamp bolt

and re-check the timing.

6On models with inductive discharge ignition

systems, the mechanical and vacuum

advance mechanisms can be checked as

follows. On all other models, proceed to

paragraph 10.

7With the engine idling, timing light

connected, and vacuum pipe disconnected as

described in the preceding paragraphs,

increase the engine speed to approximately

2000 rpm (if desired, connect a tachometer to

the engine in accordance with the

manufacturer”s instructions). Note the

approximate distance which the relevant pulley

mark moves out of alignment with the pointer.

8Reconnect the vacuum pipe to the

distributor or electronic module, as

applicable, and repeat the procedure given in

the previous paragraph, when for the same

increase in engine speed, the alignment

differential between the pulley mark and

pointer should be greater than previously

observed.

9If the pulley mark does not appear to move

during the first part of the check, a fault in the

distributor mechanical advance mechanism is

indicated. No increased movement of the

mark during the second part of the check

indicates a punctured diaphragm in the

distributor vacuum unit, or a leak in the

vacuum line.

10On completion of the adjustments and

checks, stop the engine and disconnect the

timing light. Where applicable, reconnect the

vacuum pipe, if not already done, and

reconnect any “octane adjustment” and “idle

speed adjustment” wires. Make a final check

to ensure that the distributor clamp bolt is

tight.

11Finally, the idle speed and mixture should

be checked and adjusted.2.0 litre DOHC carburettor model

12The ignition timing is controlled by the

ESC II module, and no adjustment is possible.

2.0 litre DOHC fuel injection

model

13The ignition timing is controlled by the

EEC IV module, and no adjustment is

possible.

Note: Refer to the Specifications Section at

the beginning of this Chapter for ignition

timing values for use with unleaded petrol.

1To run an engine on unleaded petrol,

certain criteria must be met, and it may be

helpful to first describe the various terms used

for the different types of petrol:

Normal leaded petrol (4-star, 97 RON):

Petrol which has a low amount of lead added

during manufacture (0.15 g/litre), in addition to

the natural lead found in crude oil.

Unleaded petrol (Premium, 95 RON):

Has no lead added during manufacture, but

still has the natural lead content of crude oil.

Lead free petrol: Contains no lead. It has

no lead added during manufacture, and the

natural lead content is refined out. This

type of petrol is not currently available for

general use in the UK and should not be

confused with unleaded petrol.

2To run an engine continuously on unleaded

petrol, suitable hardened valve seat inserts

must be fitted to the cylinder head.

3The OHC engines fitted to the Sierra/P100

range which have suitable valve seat inserts

fitted at manufacture can be identified by

letters stamped on the cylinder head next to

No 4 spark plug as follows:

1.6 litre enginesM, MM, N, or NN

1.6 litre enginesS or SS

2.0 litre enginesL, P, PP, R, or RR4All CVH engines have suitable valve seat

inserts fitted.

5Vehicles which have no identification letter

stamped on the cylinder head, and are not

fitted with suitable valve seat inserts, may still

be run on unleaded petrol (although

continuous use is not recommended),

provided that every fourth tank filling is of

normal leaded petrol, ie: three tanks of

unleaded petrol followed by one tank of

normal leaded petrol.

6When running an OHC engine on unleaded

petrol (Premium, 95 RON), the ignition timing

must be retarded as described in the

following sub-Sections. There is no

requirement for ignition timing adjustment

when running CVH engines on unleaded

petrol.

Inductive discharge ignition

system and ESC system

7On vehicles fitted with an inductive

discharge ignition system, or the ESC system,

the ignition timing should be retarded as

specified.

ESC II and EEC IV systems

8On vehicles fitted with the ESC II or EEC IV

systems, there is a facility for retarding the

ignition timing without physically disturbing

the distributor.

9Adjustment is made by earthing one or two

wires (“octane adjustment” wires) which

terminate in a wiring plug next to the ignition

coil. Ideally a service adjustment lead,

available from a Ford dealer should be used

(see illustration). One end of the lead plugs

into the “octane adjustment” wiring plug, and

the other end should be earthed by fixing to

one of the ignition coil securing screws.

10Cut and insulate the wires in the service

lead which are not to be earthed.

17Ignition timing -adjustmentfor

usewithunleadedpetrol

5•18Engine electrical systems

17.9 Service adjustment lead and plug -

ESC II and EEC IV systems

A Red, blue and yellow wires

B Plug

C Wire cutting point

16.2b Crankshaft pulley timing marks - SOHC engine

A Cast pulleyB Pressed steel pulley

Page 19 of 24

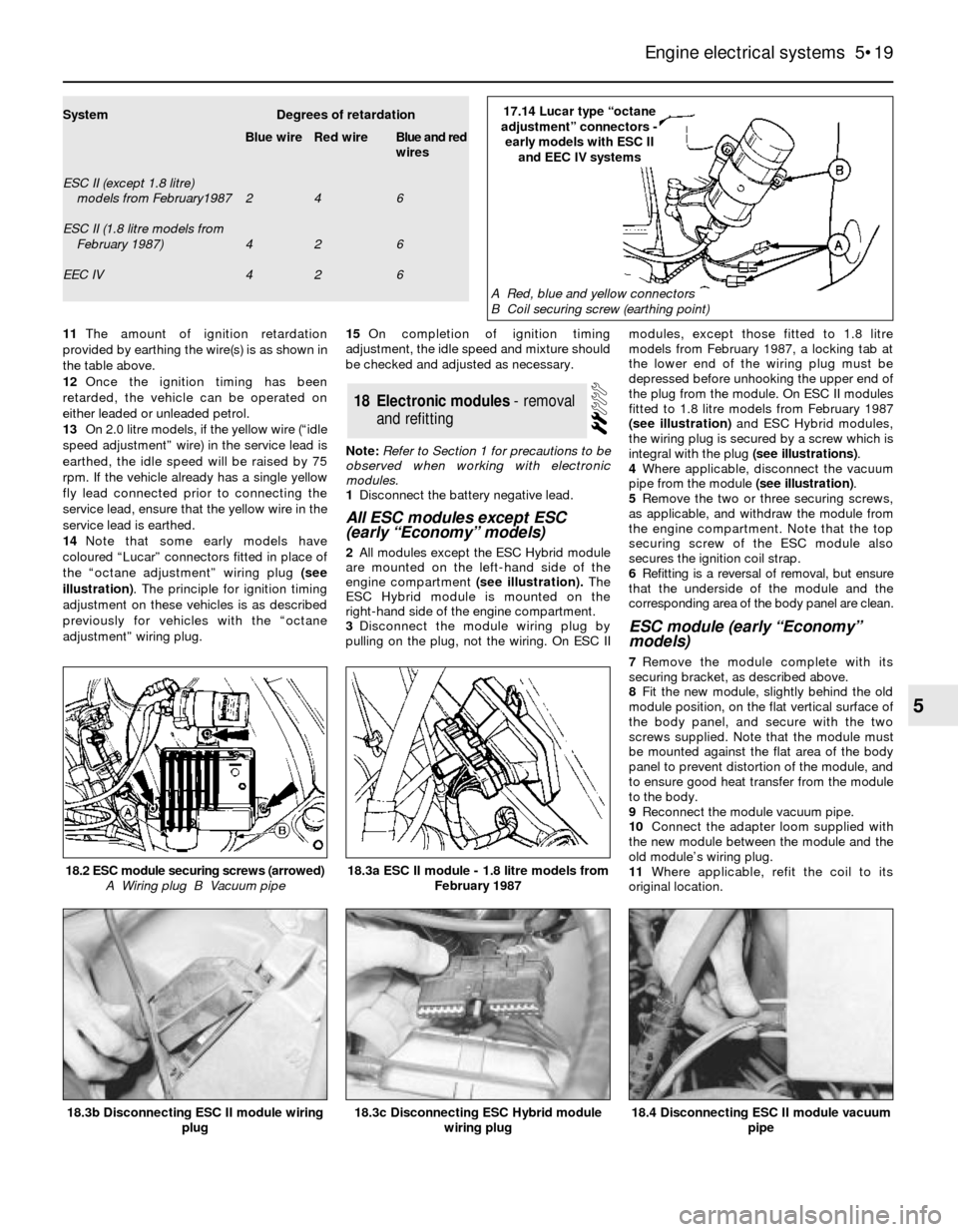

11The amount of ignition retardation

provided by earthing the wire(s) is as shown in

the table above.

12Once the ignition timing has been

retarded, the vehicle can be operated on

either leaded or unleaded petrol.

13On 2.0 litre models, if the yellow wire (“idle

speed adjustment” wire) in the service lead is

earthed, the idle speed will be raised by 75

rpm. If the vehicle already has a single yellow

fly lead connected prior to connecting the

service lead, ensure that the yellow wire in the

service lead is earthed.

14Note that some early models have

coloured “Lucar” connectors fitted in place of

the “octane adjustment” wiring plug (see

illustration). The principle for ignition timing

adjustment on these vehicles is as described

previously for vehicles with the “octane

adjustment” wiring plug.15On completion of ignition timing

adjustment, the idle speed and mixture should

be checked and adjusted as necessary.

Note: Refer to Section 1 for precautions to be

observed when working with electronic

modules.

1Disconnect the battery negative lead.

All ESC modules except ESC

(early “Economy” models)

2All modules except the ESC Hybrid module

are mounted on the left-hand side of the

engine compartment(see illustration).The

ESC Hybrid module is mounted on the

right-hand side of the engine compartment.

3Disconnect the module wiring plug by

pulling on the plug, not the wiring. On ESC IImodules, except those fitted to 1.8 litre

models from February 1987, a locking tab at

the lower end of the wiring plug must be

depressed before unhooking the upper end of

the plug from the module. On ESC II modules

fitted to 1.8 litre models from February 1987

(see illustration)and ESC Hybrid modules,

the wiring plug is secured by a screw which is

integral with the plug (see illustrations).

4Where applicable, disconnect the vacuum

pipe from the module (see illustration).

5Remove the two or three securing screws,

as applicable, and withdraw the module from

the engine compartment. Note that the top

securing screw of the ESC module also

secures the ignition coil strap.

6Refitting is a reversal of removal, but ensure

that the underside of the module and the

corresponding area of the body panel are clean.

ESC module (early “Economy”

models)

7Remove the module complete with its

securing bracket, as described above.

8Fit the new module, slightly behind the old

module position, on the flat vertical surface of

the body panel, and secure with the two

screws supplied. Note that the module must

be mounted against the flat area of the body

panel to prevent distortion of the module, and

to ensure good heat transfer from the module

to the body.

9Reconnect the module vacuum pipe.

10Connect the adapter loom supplied with

the new module between the module and the

old module’s wiring plug.

11Where applicable, refit the coil to its

original location.

18Electronic modules - removal

and refitting

Engine electrical systems 5•19

5

18.4 Disconnecting ESC II module vacuum

pipe18.3c Disconnecting ESC Hybrid module

wiring plug18.3b Disconnecting ESC II module wiring

plug

18.2 ESC module securing screws (arrowed)

A Wiring plug B Vacuum pipe18.3a ESC II module - 1.8 litre models from

February 1987

SystemDegrees of retardation

Blue wireRed wireBlue and red

wires

ESC II (except 1.8 litre)

models from February1987246

ESC II (1.8 litre models from

February 1987)426

EEC IV42617.14 Lucar type “octane

adjustment” connectors -

early models with ESC II

and EEC IV systems

A Red, blue and yellow connectors

B Coil securing screw (earthing point)

Page 23 of 24

25Remove the two securing screws and

detach the throttle damper and bracket

assembly from the carburettor (see

illustration).

26Commence refitting by securing the

throttle damper and bracket assembly to the

carburettor with the two screws. Ensure that

the throttle lever is correctly positioned in the

slot in the throttle damper actuating arm.

27Reconnect the vacuum pipe to the throttle

damper.

28Reconnect the air cleaner vacuum hose to

the inlet manifold, and reconnect the air

change temperature sensor wiring plug, then

place the air cleaner to one side to allow

access to the throttle damper.

29Reconnect the battery negative lead.

30Connect a tachometer to the engine in

accordance with the manufacturer’s

instructions.

31Start the engine, then check and if

necessary adjust the idle speed and mixture.

32Earth the “service adjustment” lead,

located in the battery negative wiring loom

(see illustration), for a minimum of 10

seconds. The throttle damper actuating arm

should move to the fully retracted position,

raising the engine speed.

33The engine speed should stabilise at 1700

±100 rpm. If adjustment is necessary, turn

the adjusting screw on the end of the throttle

damper actuating arm to give the correct

speed. Turn the screw clockwise to increase

the engine speed, or anti-clockwise to reduce

the engine speed.34On completion of adjustment, stop the

engine and disconnect the tachometer.

35Where necessary, ensure that any

tamperproof seals are refitted, then refit the

air cleaner, ensuring that the vacuum hose is

securely connected. Isolate the “service

adjustment” lead.

36Start the engine and check that normal

idle speed is resumed, then stop the engine.

Note:Procedures for removal and refitting of

the ignition system components and

electronic module are given elsewhere in the

relevant Sections of this Chapter.

Engine coolant temperature

sensor

2.0 litre SOHC fuel injection models

1For details of engine coolant temperature

sensor removal and refitting, refer to the

Section appertaining to the ESC II system.

1.6 and 1.8 litre (R6A type) CVH models

2The sensor is located in the side of the inlet

manifold.

3Disconnect the battery negative lead.

4Partially drain the cooling system.

5Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

6Unscrew the sensor from the inlet manifold

and remove it.

7Refitting is a reversal of removal. Refill the

cooling system.

2.0 litre DOHC fuel injection models

8The sensor is located in the side of the inlet

manifold, behind the throttle body. The

removal and refitting procedure is as

described for the 1.6 and 1.8 litre (R6A type)

CVH models above.

Crankshaft speed/position sensor

1.6 and 1.8 litre (R6A type) CVH

models

1.6 litre

9The sensor is located at the left-hand rear

of the cylinder block, above the starter motor

(see illustration).10Disconnect the battery negative lead.

11Remove the securing screw, and

withdraw the sensor shroud.

12Disconnect the sensor wiring plug.

13Remove the Torx securing screw, and

withdraw the sensor.

14Refitting is a reversal of removal.

1.8 litre

15Proceed as described for the ESC Hybrid

module. If a new sensor (not the original unit)

is being fitted, position it in the mounting

bracket so that it is in actual contact with one

of the teeth of the toothed wheel on the

crankshaft. Hold the sensor in this position,

and tighten the clamping screw. New sensors

have projections on their base, which will

wear away when the engine is cranking, and

automatically set the specified clearance.

2.0 litre DOHC fuel injection models

16This procedure is as described for the 2.0

litre DOHC carburettor models (ESC II

module).

Air charge temperature sensor

1.6 and 1.8 litre (R6A type) CVH

models

17The sensor is located in the side of the

CFI unit on 1.6 litre engines (see illustration),

and on the inlet manifold on 1.8 litre engines.

18Disconnect the battery negative lead.

19Disconnect the sensor wiring plug by

pulling on the plug, not the wiring.

20Unscrew the sensor from its location, and

remove it.

21Refitting is a reversal of removal, but coat

the threads of the sensor with suitable sealant

before fitting.

2.0 litre DOHC fuel injection models

22The sensor is located in the upper section

of the inlet manifold.

23Disconnect the battery negative lead.

24Disconnect the sensor wiring plug by

pulling on the plug, not the wiring (see

illustration).

25Unscrew the sensor from the inlet

manifold, and remove it.

26Refitting is a reversal of removal, noting

the torque setting for the sensor.

21EEC IV system components -

removaland refitting

Engine electrical systems 5•23

5

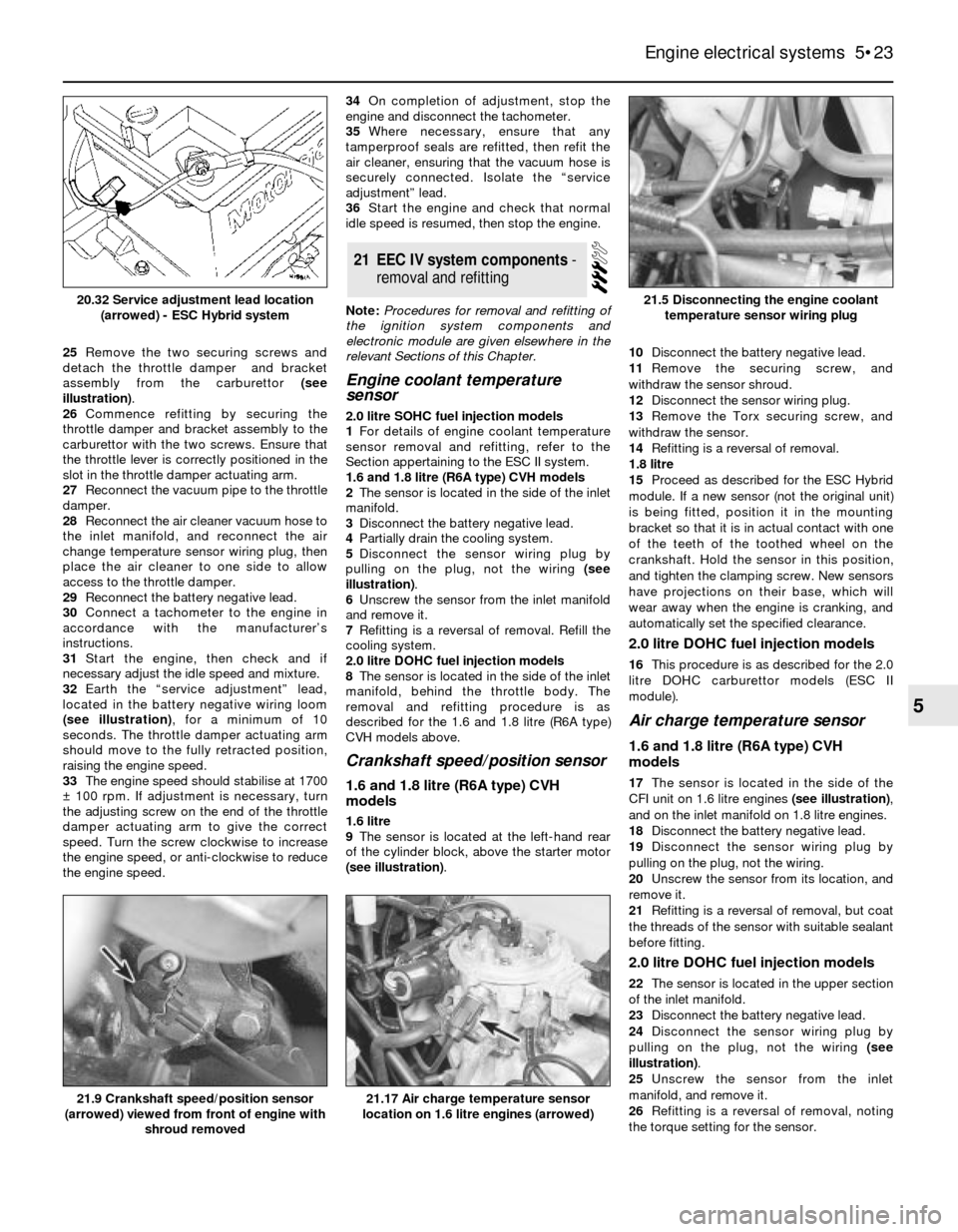

21.9 Crankshaft speed/position sensor

(arrowed) viewed from front of engine with

shroud removed21.17 Air charge temperature sensor

location on 1.6 litre engines (arrowed)

21.5 Disconnecting the engine coolant

temperature sensor wiring plug20.32 Service adjustment lead location

(arrowed) - ESC Hybrid system