battery FORD SIERRA 1992 2.G Introduction Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 18, PDF Size: 0.5 MB

Page 2 of 18

LIVING WITH YOUR FORD SIERRAIntroduction to the Ford SierraPage0•4

AcknowledgementsPage0•4

Safety first!Page0•5

ROADSIDE REPAIRSJacking, vehicle support and wheel changingPage0•6

TowingPage0•7

Identifying leaksPage0•8

Jump startingPage0•9

Weekly Checks

IntroductionPage0•10

Underbonnet check pointsPage0•10

Engine Oil levelPage0•12

Coolant levelPage0•12

Screen washer fluid levelPage0•13

Brake fluid levelPage0•13

Power steering fluid levelPage0•14

Electrical systemsPage0•14

BatteryPage0•15

Wiper bladesPage0•15

Tyre condition and pressurePage0•16

Lubricants and fluidsPage0•17

Tyre pressuresPage0•18

MAINTENANCE

Routine Maintenance and ServicingPage1•1

Maintenance schedulePage1•4

Maintenance proceduresPage1•9

Contents

Page 5 of 18

0•5Safety First!

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

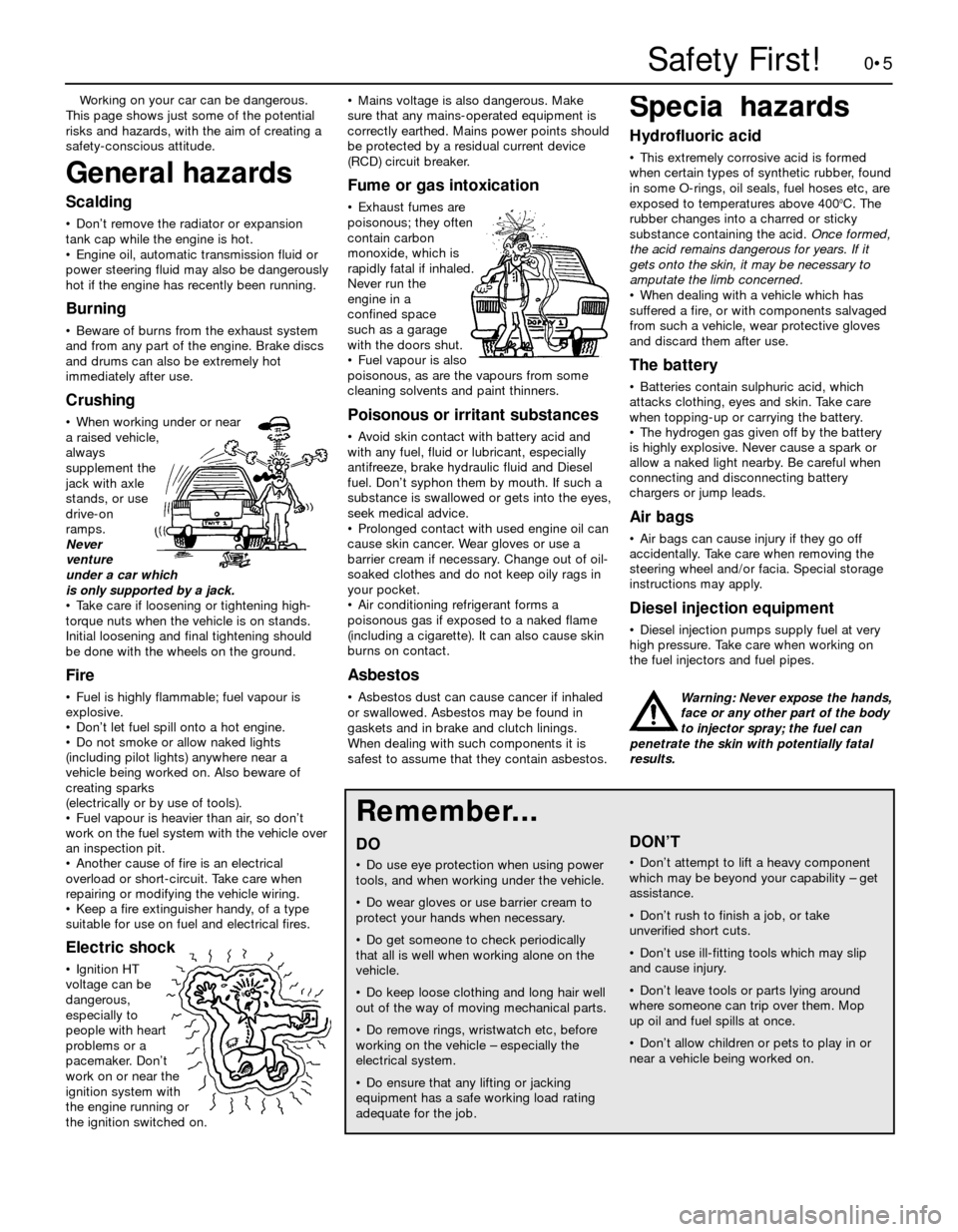

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Specia hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400

0C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

Page 9 of 18

0•9Roadside repairs

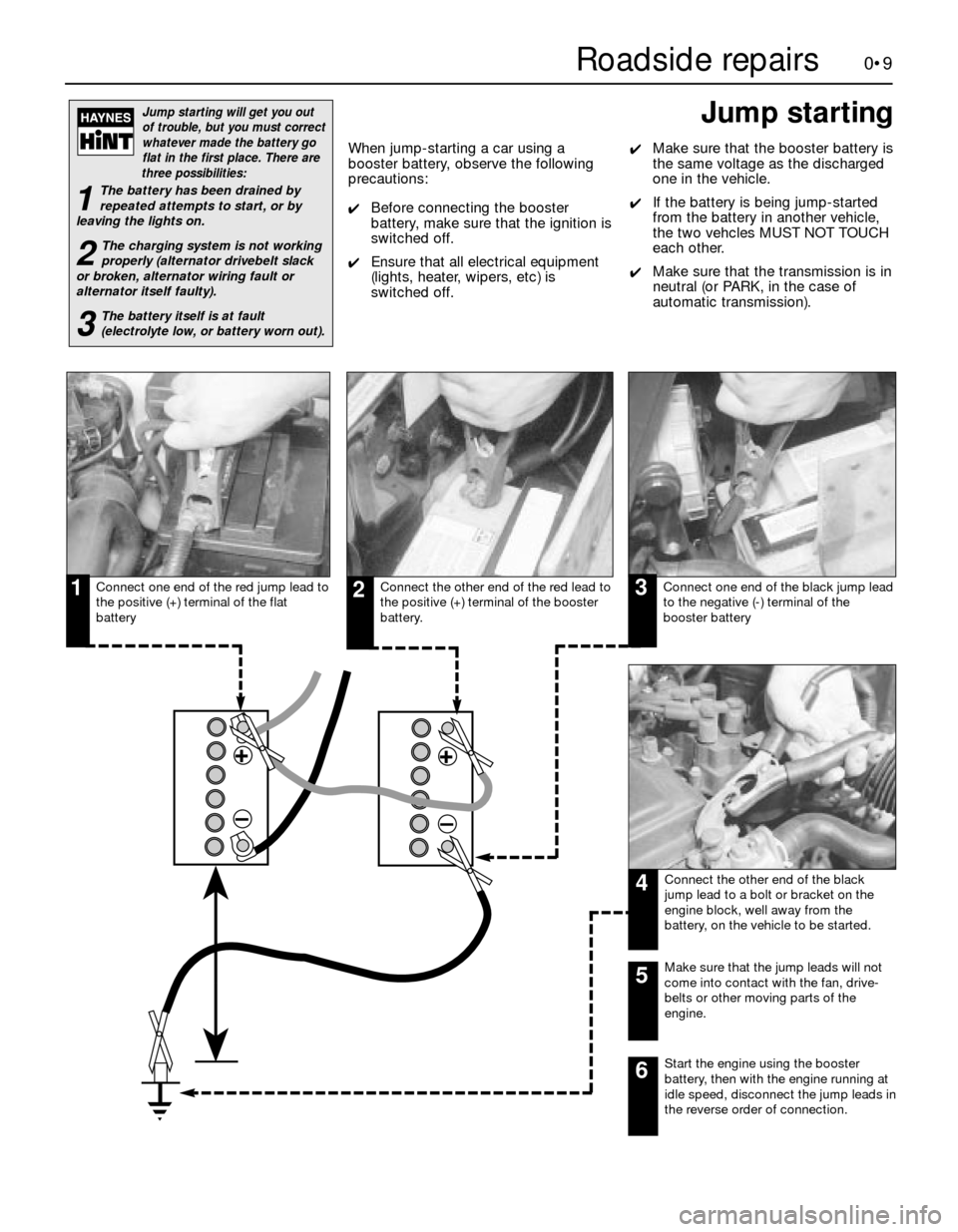

When jump-starting a car using a

booster battery, observe the following

precautions:

4Before connecting the booster

battery, make sure that the ignition is

switched off.

4Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

4Make sure that the booster battery is

the same voltage as the discharged

one in the vehicle.

4If the battery is being jump-started

from the battery in another vehicle,

the two vehcles MUST NOT TOUCH

each other.

4Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting will get you out

of trouble, but you must correct

whatever made the battery go

flat in the first place. There are

three possibilities:

1The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2The charging system is not working

properly (alternator drivebelt slack

or broken, alternator wiring fault or

alternator itself faulty).

3The battery itself is at fault

(electrolyte low, or battery worn out).

Connect one end of the red jump lead to

the positive (+) terminal of the flat

batteryConnect the other end of the red lead to

the positive (+) terminal of the booster

battery.Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started.

123

4

Make sure that the jump leads will not

come into contact with the fan, drive-

belts or other moving parts of the

engine.5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads in

the reverse order of connection.6

Jump starting

Page 10 of 18

0•10

There are some very simple checks which

need only take a few minutes to carry out, but

which could save you a lot of inconvenience

and expense.

These "Weekly checks" require no great skill

or special tools, and the small amount of time

they take to perform could prove to be very

well spent, for example;MKeeping an eye on tyre condition and

pressures, will not only help to stop them

wearing out prematurely, but could also save

your life.

MMany breakdowns are caused by electrical

problems. Battery-related faults are

particularly common, and a quick check on a

regular basis will often prevent the majority of

these.MIf your car develops a brake fluid leak, the

first time you might know about it is when your

brakes don't work properly. Checking the level

regularly will give advance warning of this kind

of problem.

MIf the oil or coolant levels run low, the cost

of repairing any engine damage will be far

greater than fixing the leak, for example.

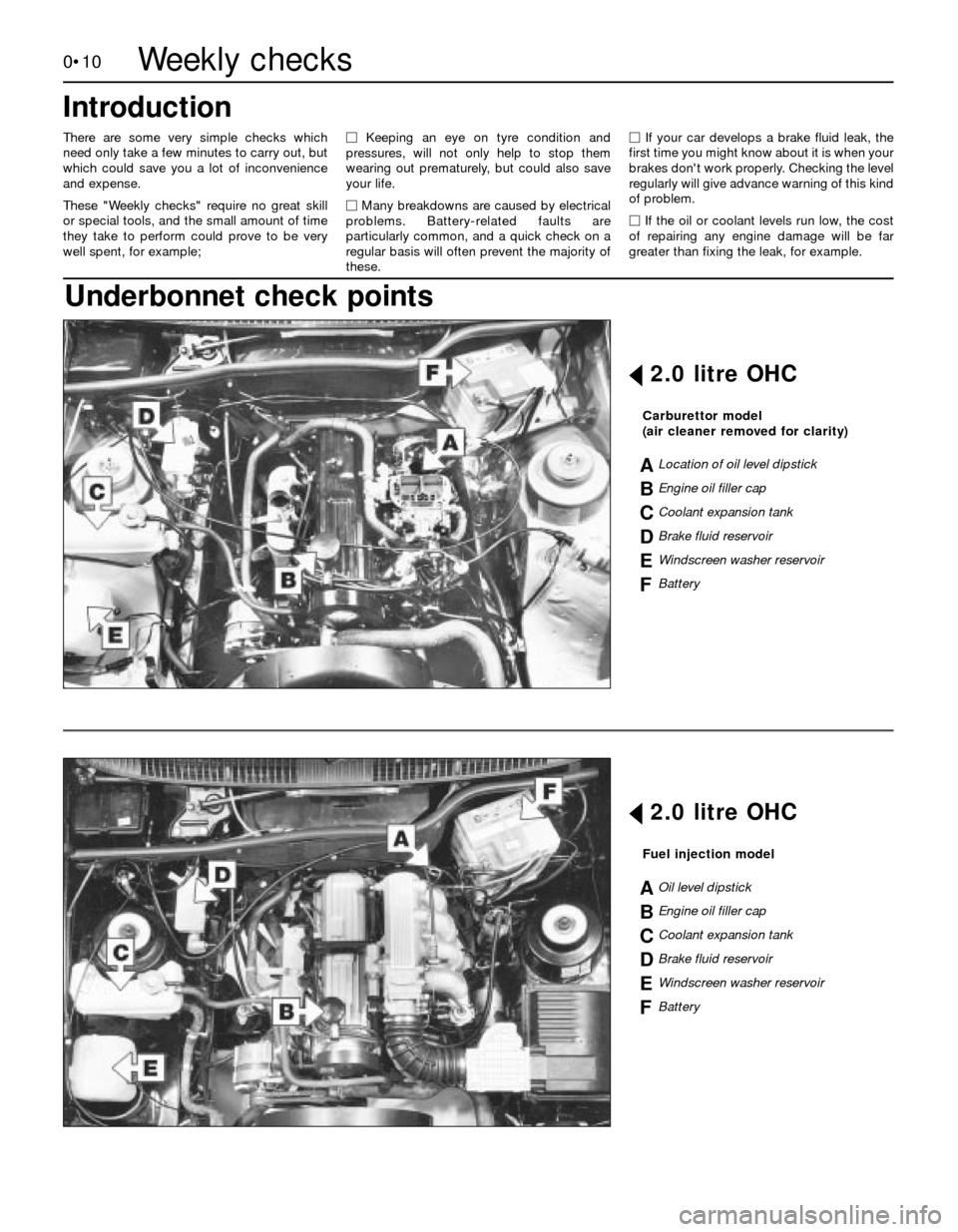

Underbonnet check points

§2.0 litre OHC

Carburettor model

(air cleaner removed for clarity)

ALocation of oil level dipstick

BEngine oil filler cap

CCoolant expansion tank

DBrake fluid reservoir

EWindscreen washer reservoir

FBattery

§2.0 litre OHC

Fuel injection model

AOil level dipstick

BEngine oil filler cap

CCoolant expansion tank

DBrake fluid reservoir

EWindscreen washer reservoir

FBattery

Introduction

Weekly checks

Page 11 of 18

0•11

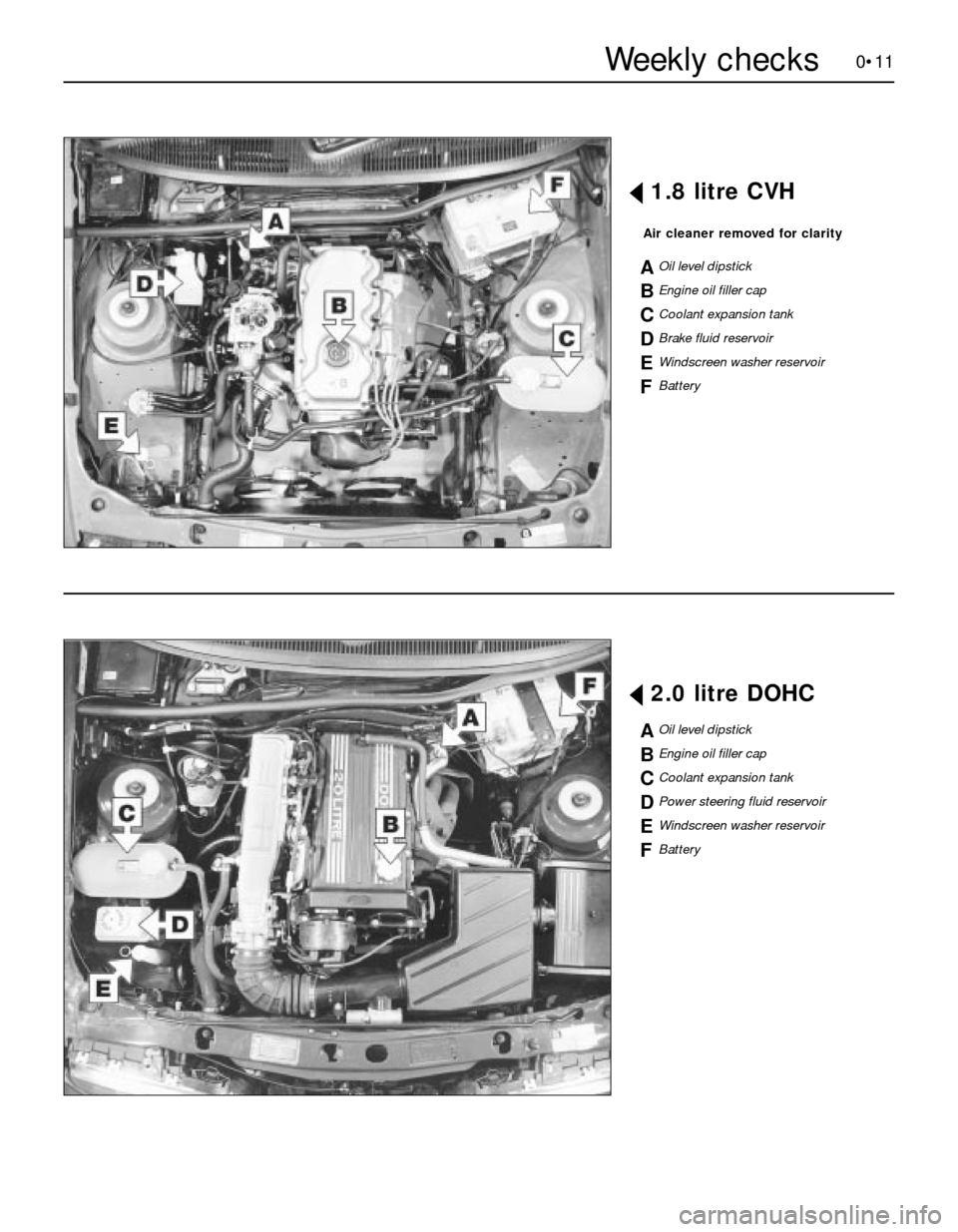

§1.8 litre CVH

Air cleaner removed for clarity

AOil level dipstick

BEngine oil filler cap

CCoolant expansion tank

DBrake fluid reservoir

EWindscreen washer reservoir

FBattery

§2.0 litre DOHC

AOil level dipstick

BEngine oil filler cap

CCoolant expansion tank

DPower steering fluid reservoir

EWindscreen washer reservoir

FBattery

Weekly checks

Page 15 of 18

0•15

To remove a wiper blade, pull the arm

fully away from the glass until it locks.

Swivel the blade through 90°, press the

locking tab(s) with your fingers, and slide the

blade out of the arm's hooked end. On

refitting, ensure that the blade locks securely

into the arm.Check the condition of the wiper blades;

if they are cracked or show any signs of

deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of

vision, wiper blades should be renewed

annually, as a matter of course.21Weekly checks

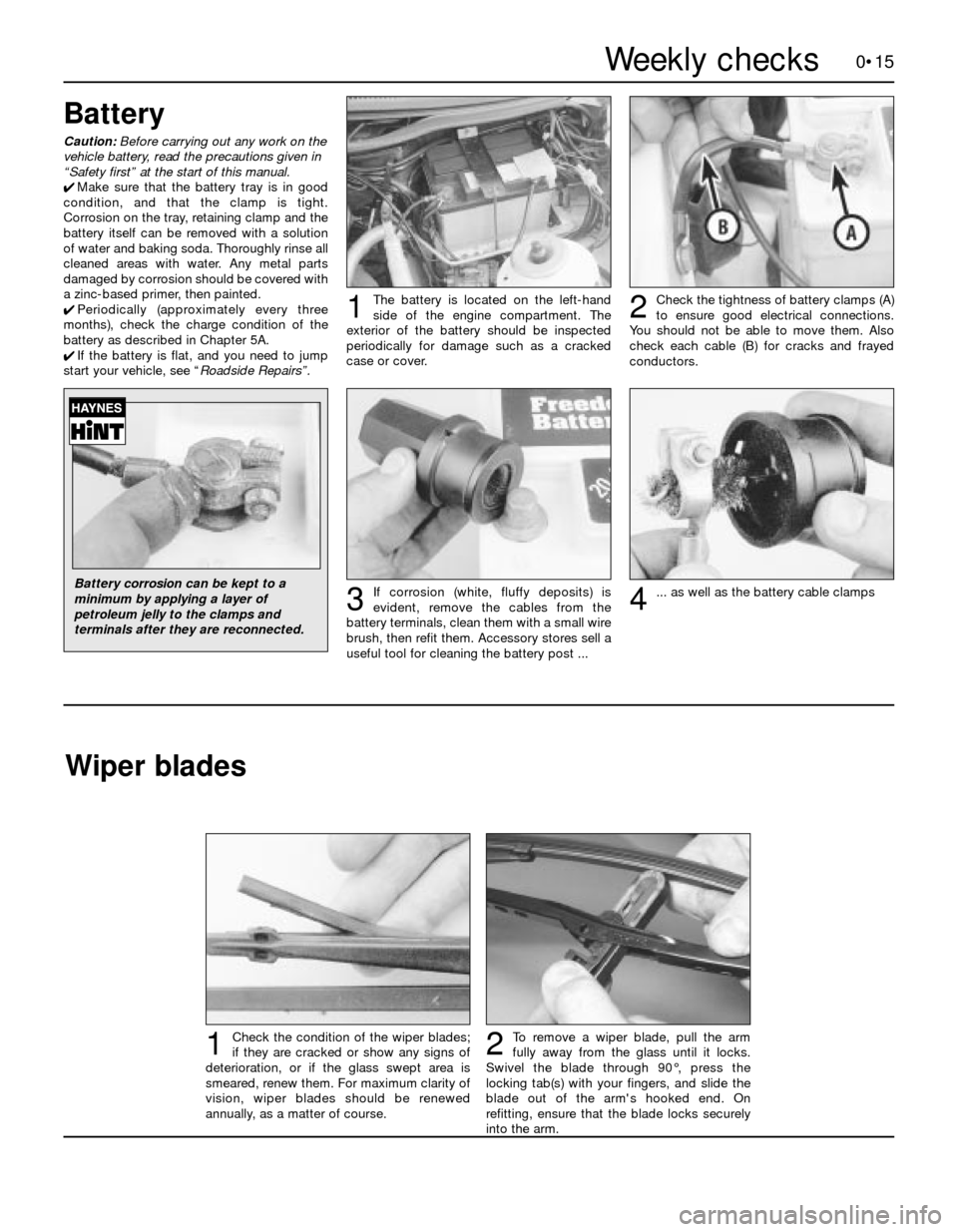

Battery

Caution:Before carrying out any work on the

vehicle battery, read the precautions given in

“Safety first” at the start of this manual.

4Make sure that the battery tray is in good

condition, and that the clamp is tight.

Corrosion on the tray, retaining clamp and the

battery itself can be removed with a solution

of water and baking soda. Thoroughly rinse all

cleaned areas with water. Any metal parts

damaged by corrosion should be covered with

a zinc-based primer, then painted.

4Periodically (approximately every three

months), check the charge condition of the

battery as described in Chapter 5A.

4If the battery is flat, and you need to jump

start your vehicle, see “Roadside Repairs”.The battery is located on the left-hand

side of the engine compartment. The

exterior of the battery should be inspected

periodically for damage such as a cracked

case or cover.

Check the tightness of battery clamps (A)

to ensure good electrical connections.

You should not be able to move them. Also

check each cable (B) for cracks and frayed

conductors.

If corrosion (white, fluffy deposits) is

evident, remove the cables from the

battery terminals, clean them with a small wire

brush, then refit them. Accessory stores sell a

useful tool for cleaning the battery post ...

12

3... as well as the battery cable clamps4

Battery corrosion can be kept to a

minimum by applying a layer of

petroleum jelly to the clamps and

terminals after they are reconnected.

Wiper blades