lock FORD SIERRA 1992 2.G Introduction Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 18, PDF Size: 0.5 MB

Page 4 of 18

0•4

The Ford Sierra was first introduced in late 1982 with the option of

seven different engines and four different trim levels. This manual

covers the four cylinder in-line petrol engines, but other models in the

range are fitted with V6 or diesel engines.

The Sierra was introduced by Ford as the successor to the Cortina

and initially received a mixed reception as it was one of the first

vehicles to make use of the “aeroback” body style designed to reduce

the air drag coefficient to a minimum in the interests of fuel economy.

Mechanically the Sierra is similar to the Cortina with the exception of

all-round independent suspension.

Initially, 1.3, 1.6 and 2.0 litre SOHC carburettor engines were

available, with Hatchback and Estate body styles. In late 1984, a 1.8

litre SOHC engine became available and in 1985, a performance

orientated 2.0 litre SOHC fuel injection engine was introduced.Towards the end of 1986, the 1.3 litre engine was phased out. In order

to fill a gap in the range, a Saloon body style, designated the Sapphire,

was introduced in early 1987 and shortly afterwards, a 1.8 litre CVH

engine replaced the previously used 1.8 litre SOHC engine throughout

the model range.

A 1.6 litre CVH engine was introduced in September 1991 to replace

the 1.6 litre SOHC engine used previously, this engine being broadly

similar to the original 1.8 litre CVH engine which was in turn uprated in

March, 1992.

A 2.0 litre DOHC (Double OverHead Camshaft) engine was in-

troduced in August 1989 to replace the 2.0 litre SOHC engine.

In early 1988, a Sierra-based P100 pick-up model became available

to replace the previous Cortina-based design. The P100 consists of a

Sierra-type “cab” and front suspension, and a Ford Transit-type rear

suspension and 2.0 litre engine.

A wide range of standard and optional

equipment is available within the Sierra

range to suit most tastes, including an

anti-lock braking system.

For the home mechanic, the Sierra is a

straightforward vehicle to maintain and

repair since design features have been

incorporated to reduce the actual cost of

ownership to a minimum, and most of the

items requiring frequent attention are

easily accessible.

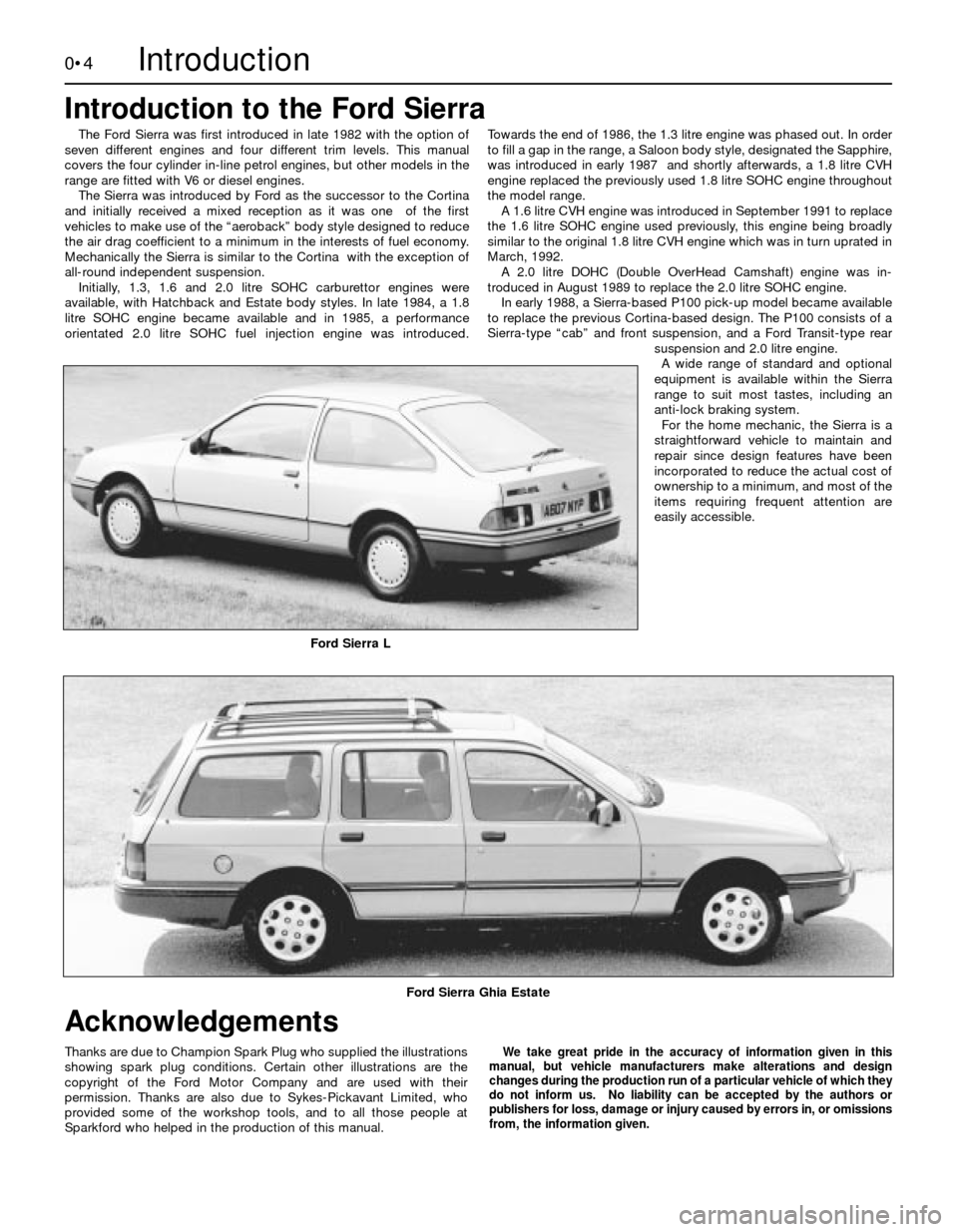

Ford Sierra L

Ford Sierra Ghia Estate

Introduction

We take great pride in the accuracy of information given in this

manual, but vehicle manufacturers make alterations and design

changes during the production run of a particular vehicle of which they

do not inform us. No liability can be accepted by the authors or

publishers for loss, damage or injury caused by errors in, or omissions

from, the information given.Thanks are due to Champion Spark Plug who supplied the illustrations

showing spark plug conditions. Certain other illustrations are the

copyright of the Ford Motor Company and are used with their

permission. Thanks are also due to Sykes-Pickavant Limited, who

provided some of the workshop tools, and to all those people at

Sparkford who helped in the production of this manual.

Introduction to the Ford Sierra

Acknowledgements

Page 7 of 18

0•7

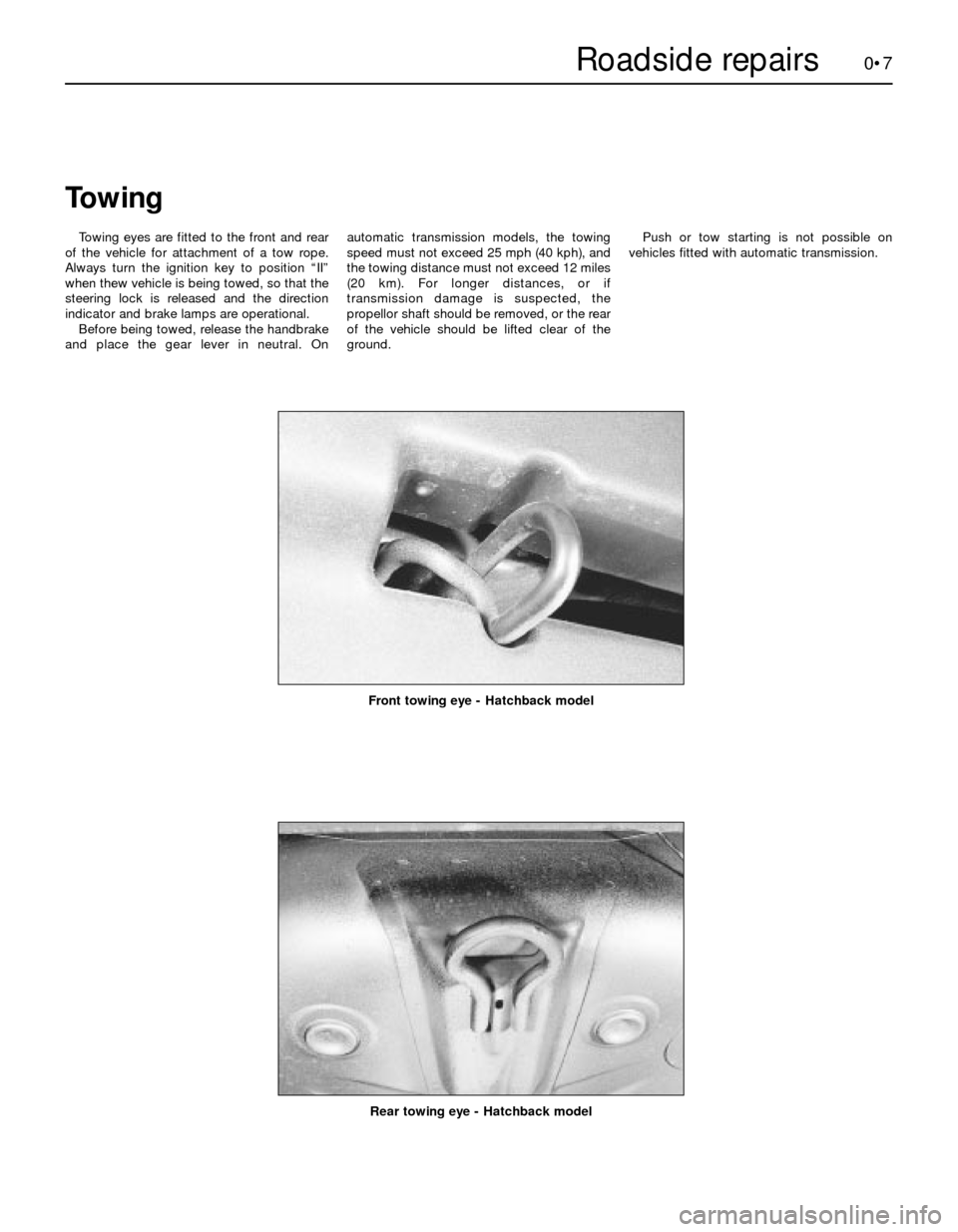

Rear towing eye - Hatchback model

Front towing eye - Hatchback model

Towing

Towing eyes are fitted to the front and rear

of the vehicle for attachment of a tow rope.

Always turn the ignition key to position “II”

when thew vehicle is being towed, so that the

steering lock is released and the direction

indicator and brake lamps are operational.

Before being towed, release the handbrake

and place the gear lever in neutral. Onautomatic transmission models, the towing

speed must not exceed 25 mph (40 kph), and

the towing distance must not exceed 12 miles

(20 km). For longer distances, or if

transmission damage is suspected, the

propellor shaft should be removed, or the rear

of the vehicle should be lifted clear of the

ground.Push or tow starting is not possible on

vehicles fitted with automatic transmission.

Roadside repairs

Page 9 of 18

0•9Roadside repairs

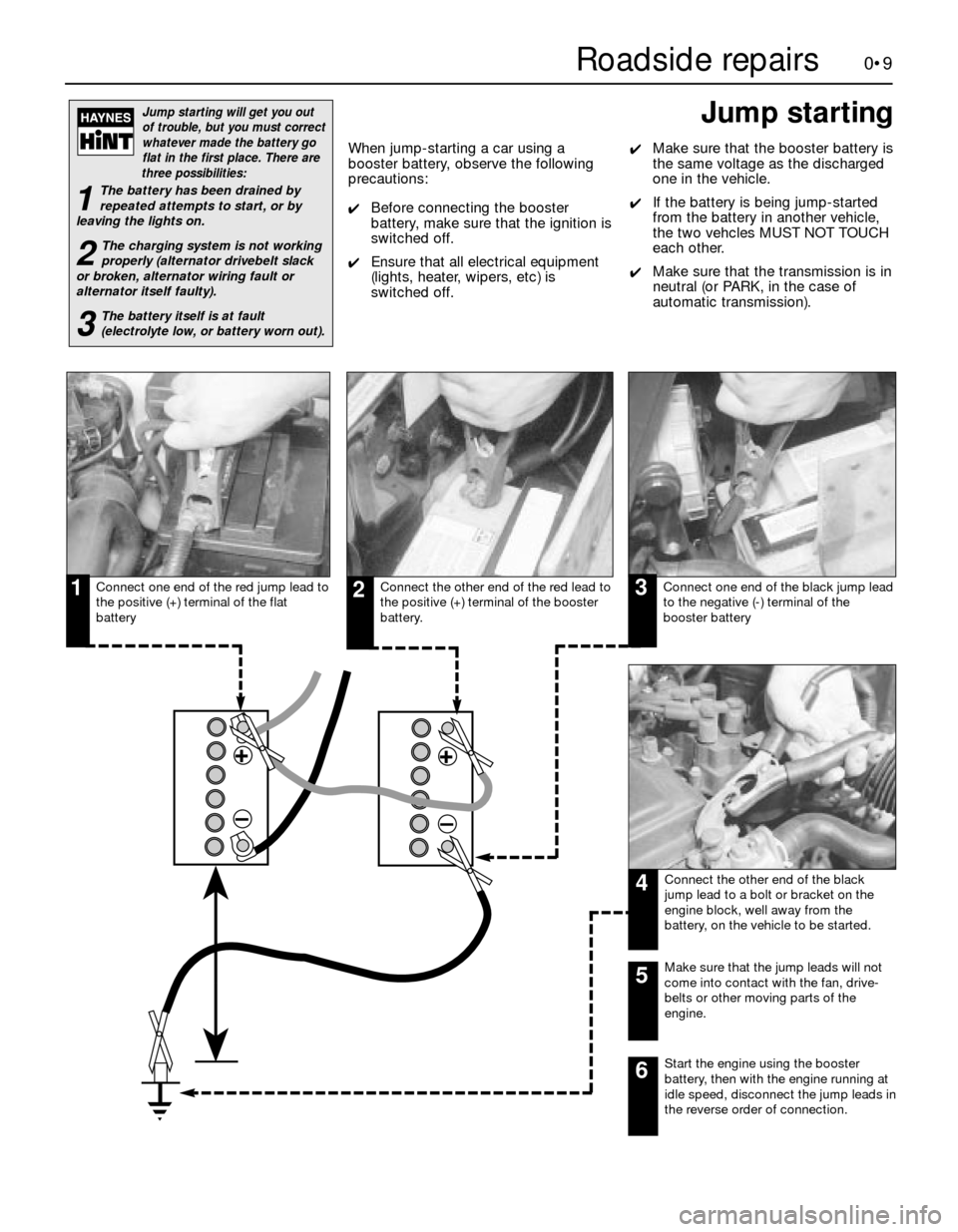

When jump-starting a car using a

booster battery, observe the following

precautions:

4Before connecting the booster

battery, make sure that the ignition is

switched off.

4Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

4Make sure that the booster battery is

the same voltage as the discharged

one in the vehicle.

4If the battery is being jump-started

from the battery in another vehicle,

the two vehcles MUST NOT TOUCH

each other.

4Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting will get you out

of trouble, but you must correct

whatever made the battery go

flat in the first place. There are

three possibilities:

1The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2The charging system is not working

properly (alternator drivebelt slack

or broken, alternator wiring fault or

alternator itself faulty).

3The battery itself is at fault

(electrolyte low, or battery worn out).

Connect one end of the red jump lead to

the positive (+) terminal of the flat

batteryConnect the other end of the red lead to

the positive (+) terminal of the booster

battery.Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started.

123

4

Make sure that the jump leads will not

come into contact with the fan, drive-

belts or other moving parts of the

engine.5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads in

the reverse order of connection.6

Jump starting

Page 12 of 18

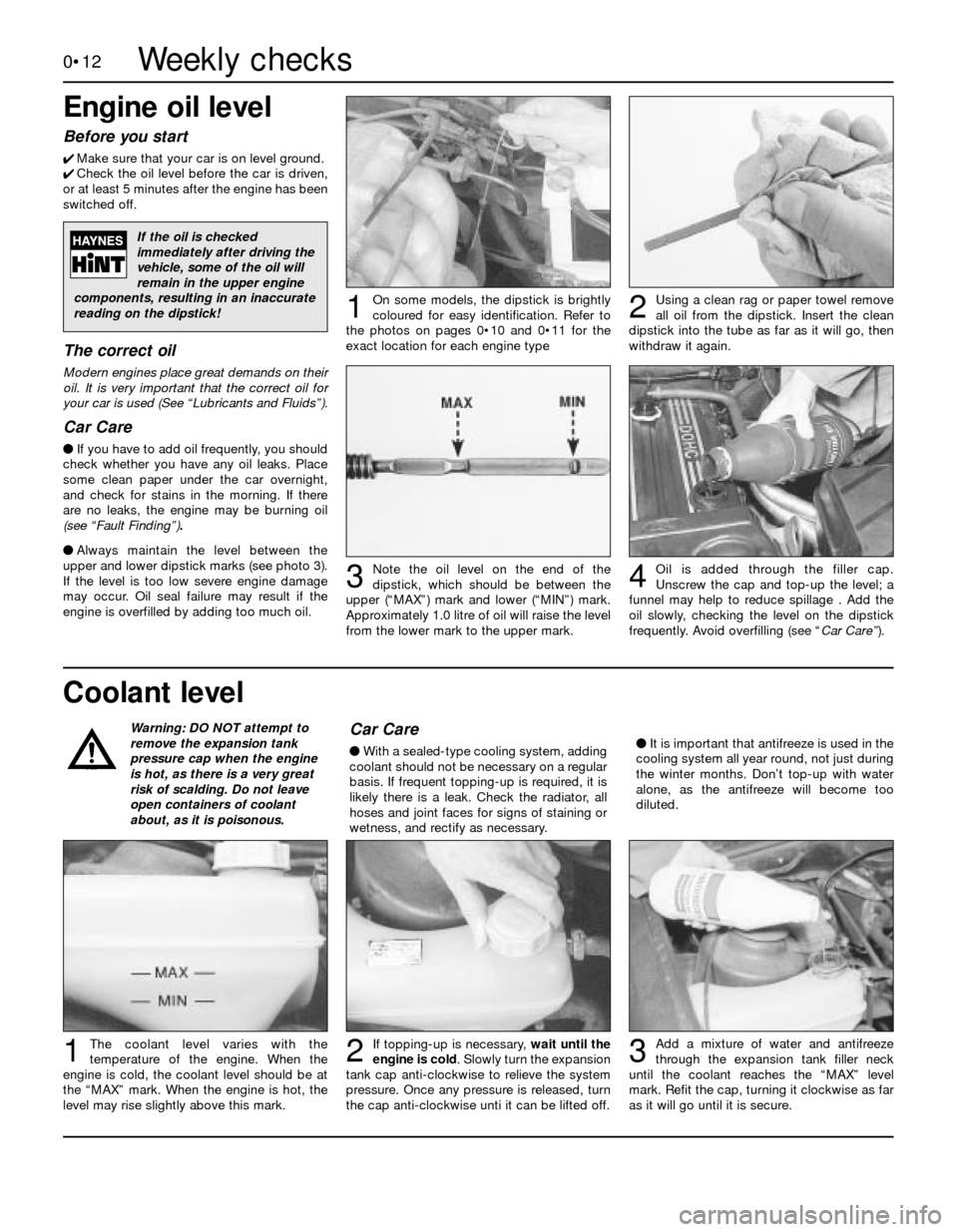

Coolant level Engine oil level

Before you start

4Make sure that your car is on level ground.

4Check the oil level before the car is driven,

or at least 5 minutes after the engine has been

switched off.

The correct oil

Modern engines place great demands on their

oil. It is very important that the correct oil for

your car is used (See “Lubricants and Fluids”).

Car Care

l If you have to add oil frequently, you should

check whether you have any oil leaks. Place

some clean paper under the car overnight,

and check for stains in the morning. If there

are no leaks, the engine may be burning oil

(see “Fault Finding”).

lAlways maintain the level between the

upper and lower dipstick marks (see photo 3).

If the level is too low severe engine damage

may occur. Oil seal failure may result if the

engine is overfilled by adding too much oil.

0•12

Using a clean rag or paper towel remove

all oil from the dipstick. Insert the clean

dipstick into the tube as far as it will go, then

withdraw it again.

Add a mixture of water and antifreeze

through the expansion tank filler neck

until the coolant reaches the “MAX” level

mark. Refit the cap, turning it clockwise as far

as it will go until it is secure.

If topping-up is necessary, wait until the

engine is cold. Slowly turn the expansion

tank cap anti-clockwise to relieve the system

pressure. Once any pressure is released, turn

the cap anti-clockwise unti it can be lifted off.The coolant level varies with the

temperature of the engine. When the

engine is cold, the coolant level should be at

the “MAX” mark. When the engine is hot, the

level may rise slightly above this mark.

Note the oil level on the end of the

dipstick, which should be between the

upper (“MAX”) mark and lower (“MIN”) mark.

Approximately 1.0 litre of oil will raise the level

from the lower mark to the upper mark.Oil is added through the filler cap.

Unscrew the cap and top-up the level; a

funnel may help to reduce spillage . Add the

oil slowly, checking the level on the dipstick

frequently. Avoid overfilling (see “Car Care”).

On some models, the dipstick is brightly

coloured for easy identification. Refer to

the photos on pages 0•10 and 0•11 for the

exact location for each engine type12

3

123

4

Warning: DO NOT attempt to

remove the expansion tank

pressure cap when the engine

is hot, as there is a very great

risk of scalding. Do not leave

open containers of coolant

about, as it is poisonous.Car Care

lWith a sealed-type cooling system, adding

coolant should not be necessary on a regular

basis. If frequent topping-up is required, it is

likely there is a leak. Check the radiator, all

hoses and joint faces for signs of staining or

wetness, and rectify as necessary.lIt is important that antifreeze is used in the

cooling system all year round, not just during

the winter months. Don’t top-up with water

alone, as the antifreeze will become too

diluted.

If the oil is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper engine

components, resulting in an inaccurate

reading on the dipstick!

Weekly checks

Page 15 of 18

0•15

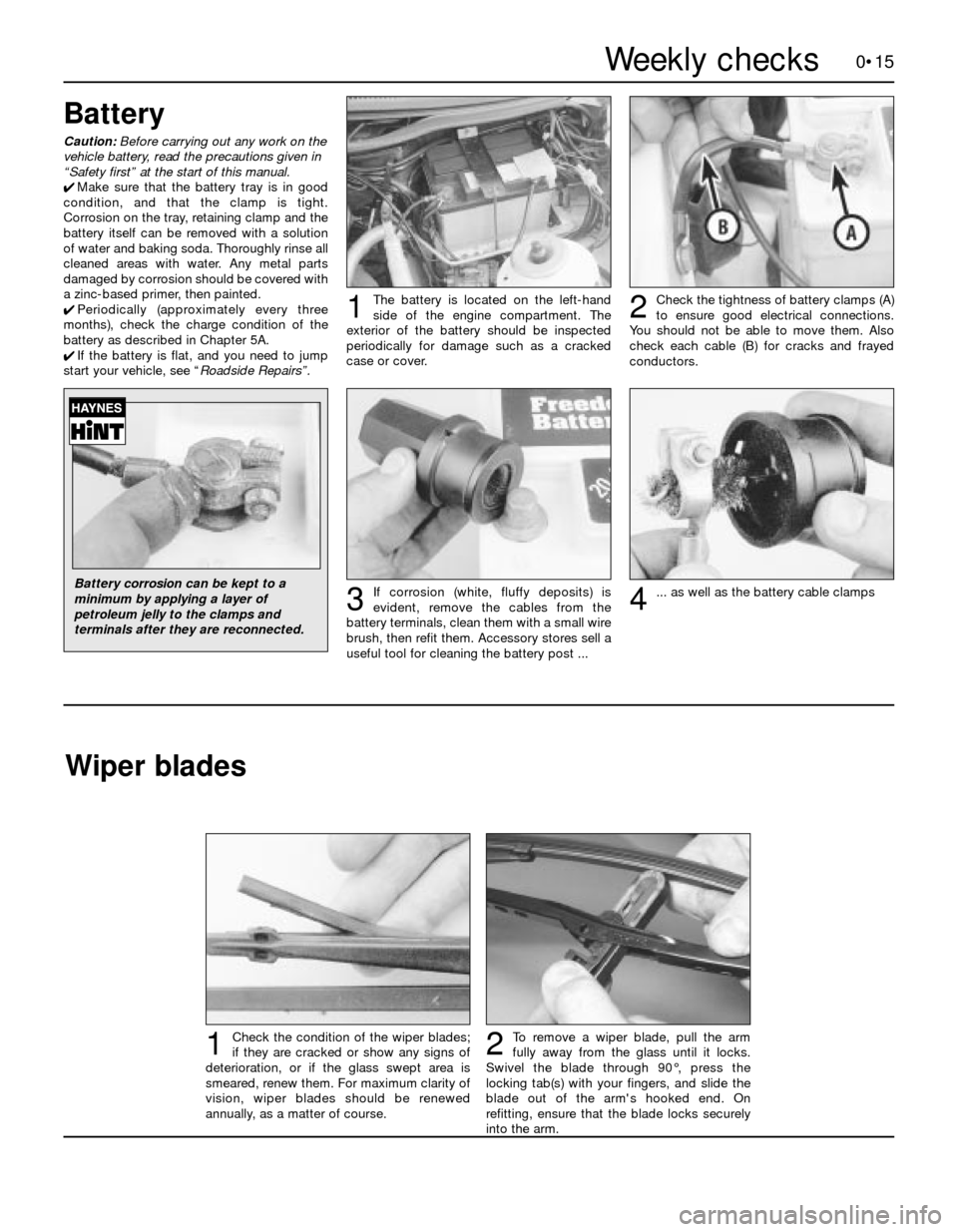

To remove a wiper blade, pull the arm

fully away from the glass until it locks.

Swivel the blade through 90°, press the

locking tab(s) with your fingers, and slide the

blade out of the arm's hooked end. On

refitting, ensure that the blade locks securely

into the arm.Check the condition of the wiper blades;

if they are cracked or show any signs of

deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of

vision, wiper blades should be renewed

annually, as a matter of course.21Weekly checks

Battery

Caution:Before carrying out any work on the

vehicle battery, read the precautions given in

“Safety first” at the start of this manual.

4Make sure that the battery tray is in good

condition, and that the clamp is tight.

Corrosion on the tray, retaining clamp and the

battery itself can be removed with a solution

of water and baking soda. Thoroughly rinse all

cleaned areas with water. Any metal parts

damaged by corrosion should be covered with

a zinc-based primer, then painted.

4Periodically (approximately every three

months), check the charge condition of the

battery as described in Chapter 5A.

4If the battery is flat, and you need to jump

start your vehicle, see “Roadside Repairs”.The battery is located on the left-hand

side of the engine compartment. The

exterior of the battery should be inspected

periodically for damage such as a cracked

case or cover.

Check the tightness of battery clamps (A)

to ensure good electrical connections.

You should not be able to move them. Also

check each cable (B) for cracks and frayed

conductors.

If corrosion (white, fluffy deposits) is

evident, remove the cables from the

battery terminals, clean them with a small wire

brush, then refit them. Accessory stores sell a

useful tool for cleaning the battery post ...

12

3... as well as the battery cable clamps4

Battery corrosion can be kept to a

minimum by applying a layer of

petroleum jelly to the clamps and

terminals after they are reconnected.

Wiper blades