height FORD SIERRA 1992 2.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 26, PDF Size: 0.57 MB

Page 1 of 26

General dimensions and Weights . . . . . . . . . . . .REF•1

Buying Spare Parts . . . . . . . . . . . . . . . . . . . . . . .REF•3

Vehicle Identification Numbers . . . . . . . . . . . . . .REF•3

General Repair Procedures . . . . . . . . . . . . . . . . .REF•4

Tools and Working Facilities . . . . . . . . . . . . . . . .REF•5MOT Test Checks . . . . . . . . . . . . . . . . . . . . . . . .REF•7

Fault Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . .REF•11

Glossary of Technical Terms . . . . . . . . . . . . . . .REF•18

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .REF•23

ReferenceREF•1

REF

General dimensions and weights

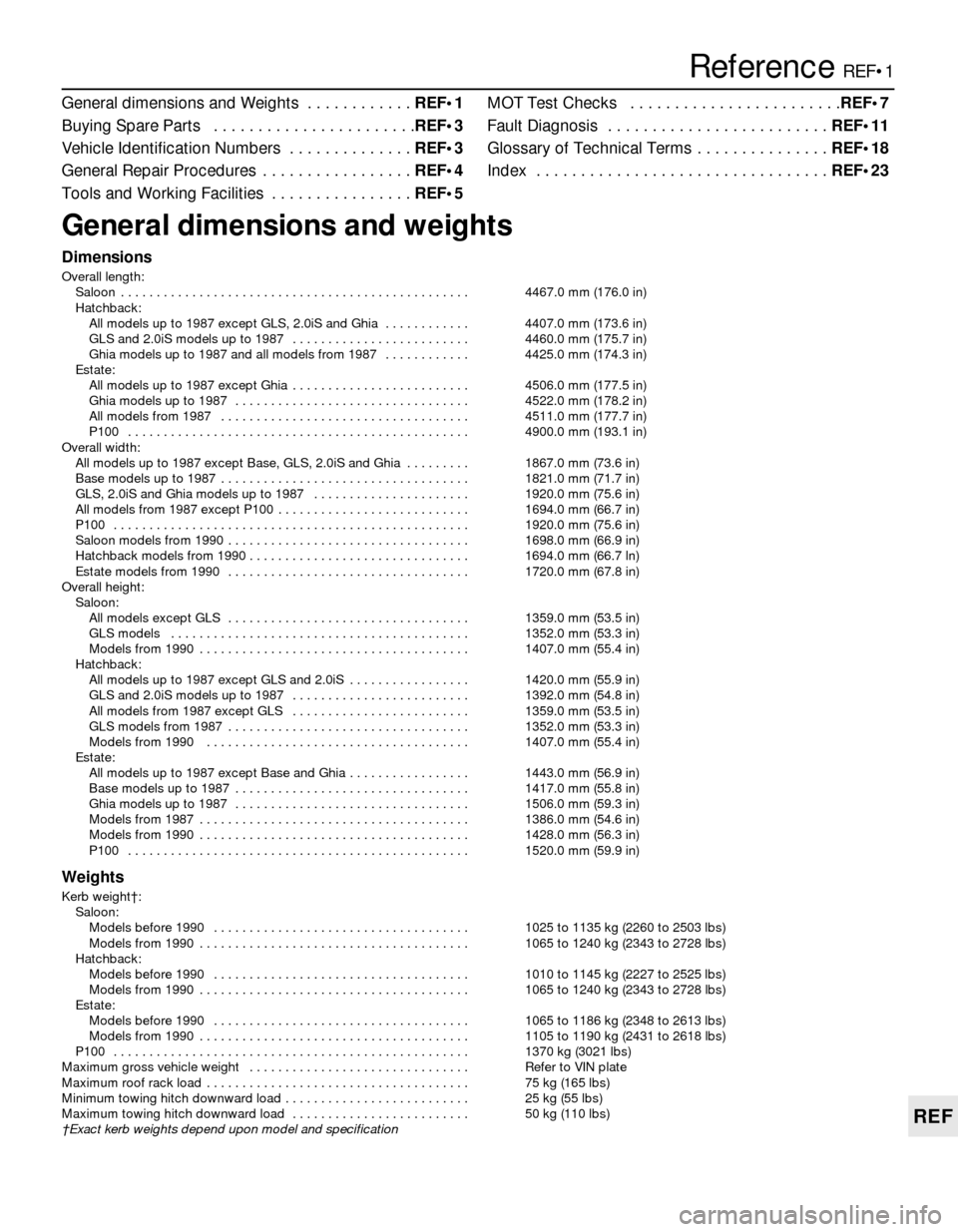

Dimensions

Overall length:

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4467.0 mm (176.0 in)

Hatchback:

All models up to 1987 except GLS, 2.0iS and Ghia . . . . . . . . . . . . 4407.0 mm (173.6 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 4460.0 mm (175.7 in)

Ghia models up to 1987 and all models from 1987 . . . . . . . . . . . . 4425.0 mm (174.3 in)

Estate:

All models up to 1987 except Ghia . . . . . . . . . . . . . . . . . . . . . . . . . 4506.0 mm (177.5 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4522.0 mm (178.2 in)

All models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4511.0 mm (177.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4900.0 mm (193.1 in)

Overall width:

All models up to 1987 except Base, GLS, 2.0iS and Ghia . . . . . . . . . 1867.0 mm (73.6 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1821.0 mm (71.7 in)

GLS, 2.0iS and Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

All models from 1987 except P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

Saloon models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1698.0 mm (66.9 in)

Hatchback models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 ln)

Estate models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1720.0 mm (67.8 in)

Overall height:

Saloon:

All models except GLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Hatchback:

All models up to 1987 except GLS and 2.0iS . . . . . . . . . . . . . . . . . 1420.0 mm (55.9 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 1392.0 mm (54.8 in)

All models from 1987 except GLS . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Estate:

All models up to 1987 except Base and Ghia . . . . . . . . . . . . . . . . . 1443.0 mm (56.9 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1417.0 mm (55.8 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1506.0 mm (59.3 in)

Models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1386.0 mm (54.6 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1428.0 mm (56.3 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1520.0 mm (59.9 in)

Weights

Kerb weight†:

Saloon:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1025 to 1135 kg (2260 to 2503 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Hatchback:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1010 to 1145 kg (2227 to 2525 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Estate:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1186 kg (2348 to 2613 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1105 to 1190 kg (2431 to 2618 lbs)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1370 kg (3021 lbs)

Maximum gross vehicle weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to VIN plate

Maximum roof rack load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg (165 lbs)

Minimum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . . 25 kg (55 lbs)

Maximum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . 50 kg (110 lbs)

†Exact kerb weights depend upon model and specification

Page 6 of 26

Special tools

The tools in this list are those which are not

used regularly, are expensive to buy, or which

need to be used in accordance with their

manufacturers’ instructions. Unless relatively

difficult mechanical jobs are undertaken

frequently, it will not be economic to buy

many of these tools. Where this is the case,

you could consider clubbing together with

friends (or joining a motorists’ club) to make a

joint purchase, or borrowing the tools against

a deposit from a local garage or tool hire

specialist. It is worth noting that many of the

larger DIY superstores now carry a large

range of special tools for hire at modest rates.

The following list contains only those tools

and instruments freely available to the public,

and not those special tools produced by the

vehicle manufacturer specifically for its dealer

network. You will find occasional references to

these manufacturers’ special tools in the text of

this manual. Generally, an alternative method

of doing the job without the vehicle

manufacturers’ special tool is given. However,

sometimes there is no alternative to using

them. Where this is the case and the relevant

tool cannot be bought or borrowed, you will

have to entrust the work to a franchised

garage.

MValve spring compressor

MValve grinding tool

MPiston ring compressor

MPiston ring removal/installation tool

MCylinder bore hone

MBalljoint separator

MCoil spring compressors (where applicable)

MTwo/three-legged hub and bearing puller

MImpact screwdriver

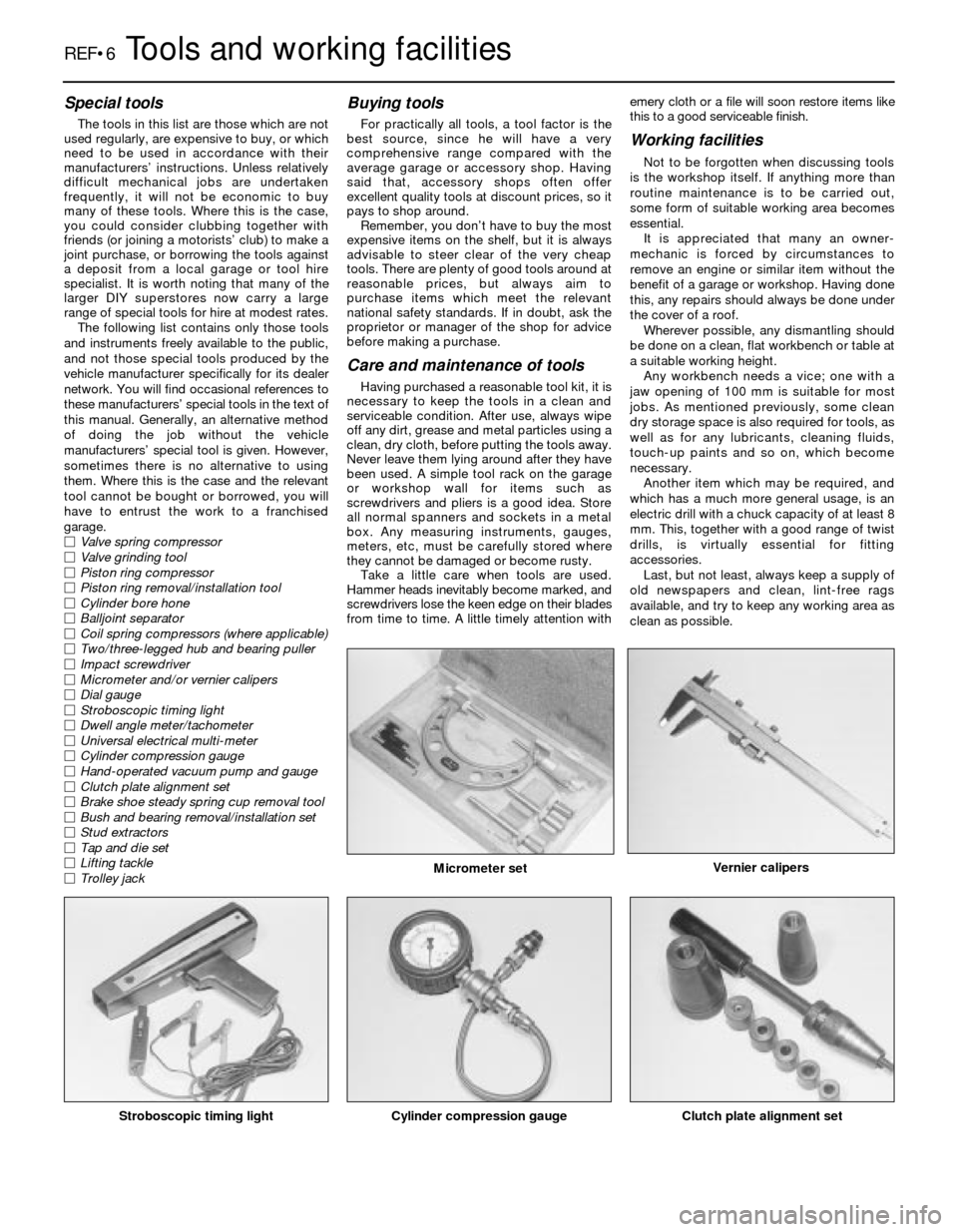

MMicrometer and/or vernier calipers

MDial gauge

MStroboscopic timing light

MDwell angle meter/tachometer

MUniversal electrical multi-meter

MCylinder compression gauge

MHand-operated vacuum pump and gauge

MClutch plate alignment set

MBrake shoe steady spring cup removal tool

MBush and bearing removal/installation set

MStud extractors

MTap and die set

MLifting tackle

MTrolley jack

Buying tools

For practically all tools, a tool factor is the

best source, since he will have a very

comprehensive range compared with the

average garage or accessory shop. Having

said that, accessory shops often offer

excellent quality tools at discount prices, so it

pays to shop around.

Remember, you don’t have to buy the most

expensive items on the shelf, but it is always

advisable to steer clear of the very cheap

tools. There are plenty of good tools around at

reasonable prices, but always aim to

purchase items which meet the relevant

national safety standards. If in doubt, ask the

proprietor or manager of the shop for advice

before making a purchase.

Care and maintenance of tools

Having purchased a reasonable tool kit, it is

necessary to keep the tools in a clean and

serviceable condition. After use, always wipe

off any dirt, grease and metal particles using a

clean, dry cloth, before putting the tools away.

Never leave them lying around after they have

been used. A simple tool rack on the garage

or workshop wall for items such as

screwdrivers and pliers is a good idea. Store

all normal spanners and sockets in a metal

box. Any measuring instruments, gauges,

meters, etc, must be carefully stored where

they cannot be damaged or become rusty.

Take a little care when tools are used.

Hammer heads inevitably become marked, and

screwdrivers lose the keen edge on their blades

from time to time. A little timely attention withemery cloth or a file will soon restore items like

this to a good serviceable finish.

Working facilities

Not to be forgotten when discussing tools

is the workshop itself. If anything more than

routine maintenance is to be carried out,

some form of suitable working area becomes

essential.

It is appreciated that many an owner-

mechanic is forced by circumstances to

remove an engine or similar item without the

benefit of a garage or workshop. Having done

this, any repairs should always be done under

the cover of a roof.

Wherever possible, any dismantling should

be done on a clean, flat workbench or table at

a suitable working height.

Any workbench needs a vice; one with a

jaw opening of 100 mm is suitable for most

jobs. As mentioned previously, some clean

dry storage space is also required for tools, as

well as for any lubricants, cleaning fluids,

touch-up paints and so on, which become

necessary.

Another item which may be required, and

which has a much more general usage, is an

electric drill with a chuck capacity of at least 8

mm. This, together with a good range of twist

drills, is virtually essential for fitting

accessories.

Last, but not least, always keep a supply of

old newspapers and clean, lint-free rags

available, and try to keep any working area as

clean as possible.

REF•6Tools and working facilities

Stroboscopic timing lightCylinder compression gaugeClutch plate alignment set

Micrometer setVernier calipers

Page 8 of 26

REF•8MOTtest checks

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

MExamine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

from inside the vehicle.

MThe front seats themselves must be

securely attached and the backrests must

lock in the upright position.

Doors

MBoth front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

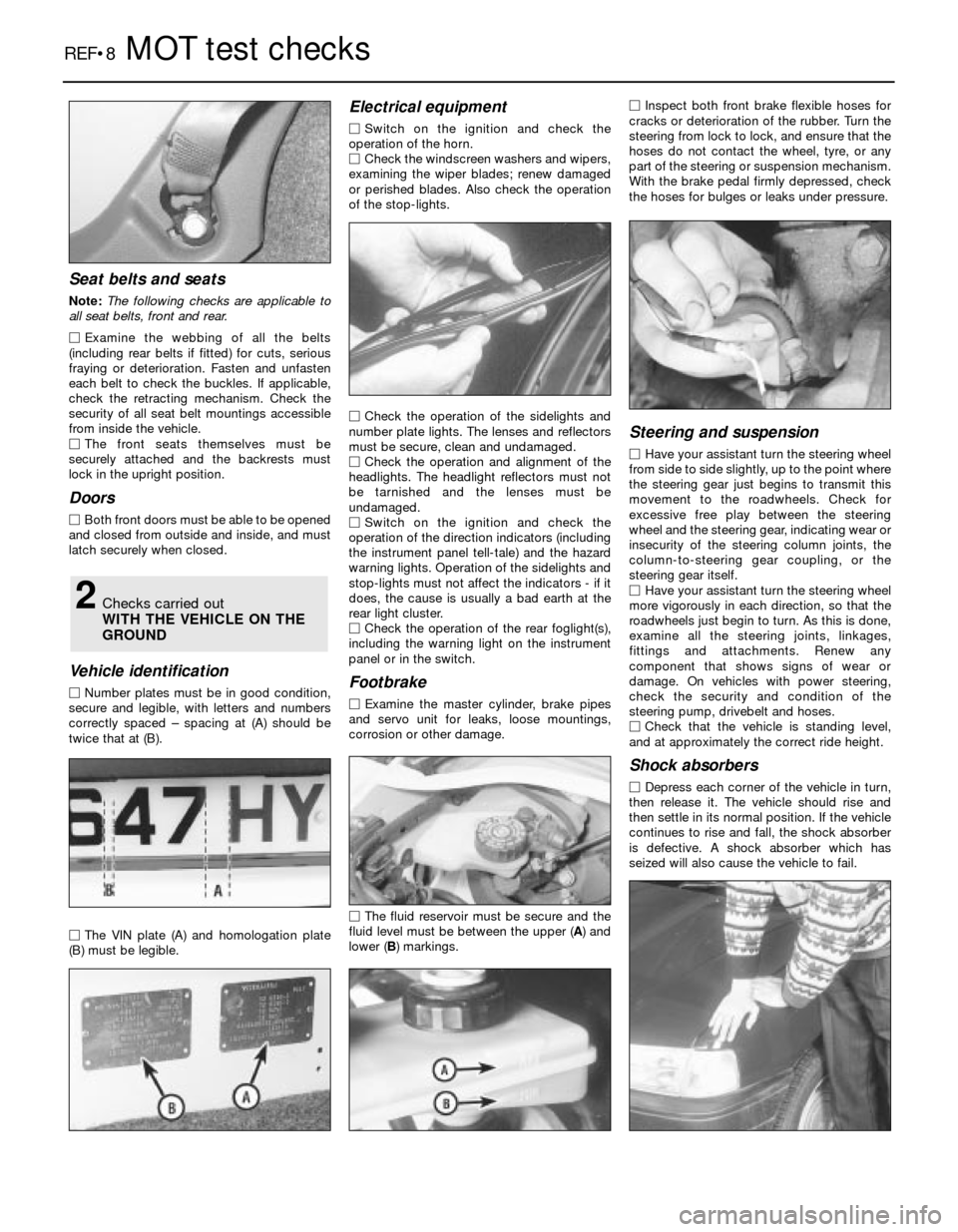

Vehicle identification

MNumber plates must be in good condition,

secure and legible, with letters and numbers

correctly spaced – spacing at (A) should be

twice that at (B).

MThe VIN plate (A) and homologation plate

(B) must be legible.

Electrical equipment

MSwitch on the ignition and check the

operation of the horn.

MCheck the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

MCheck the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

MCheck the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

MSwitch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

warning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

rear light cluster.

MCheck the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

MExamine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corrosion or other damage.

MThe fluid reservoir must be secure and the

fluid level must be between the upper (A) and

lower (B) markings.MInspect both front brake flexible hoses for

cracks or deterioration of the rubber. Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

MHave your assistant turn the steering wheel

from side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

MHave your assistant turn the steering wheel

more vigorously in each direction, so that the

roadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

MCheck that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

MDepress each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND