weight FORD SIERRA 1992 2.G Reference Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 26, PDF Size: 0.57 MB

Page 1 of 26

General dimensions and Weights . . . . . . . . . . . .REF•1

Buying Spare Parts . . . . . . . . . . . . . . . . . . . . . . .REF•3

Vehicle Identification Numbers . . . . . . . . . . . . . .REF•3

General Repair Procedures . . . . . . . . . . . . . . . . .REF•4

Tools and Working Facilities . . . . . . . . . . . . . . . .REF•5MOT Test Checks . . . . . . . . . . . . . . . . . . . . . . . .REF•7

Fault Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . .REF•11

Glossary of Technical Terms . . . . . . . . . . . . . . .REF•18

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .REF•23

ReferenceREF•1

REF

General dimensions and weights

Dimensions

Overall length:

Saloon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4467.0 mm (176.0 in)

Hatchback:

All models up to 1987 except GLS, 2.0iS and Ghia . . . . . . . . . . . . 4407.0 mm (173.6 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 4460.0 mm (175.7 in)

Ghia models up to 1987 and all models from 1987 . . . . . . . . . . . . 4425.0 mm (174.3 in)

Estate:

All models up to 1987 except Ghia . . . . . . . . . . . . . . . . . . . . . . . . . 4506.0 mm (177.5 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4522.0 mm (178.2 in)

All models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4511.0 mm (177.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4900.0 mm (193.1 in)

Overall width:

All models up to 1987 except Base, GLS, 2.0iS and Ghia . . . . . . . . . 1867.0 mm (73.6 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1821.0 mm (71.7 in)

GLS, 2.0iS and Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

All models from 1987 except P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1920.0 mm (75.6 in)

Saloon models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1698.0 mm (66.9 in)

Hatchback models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1694.0 mm (66.7 ln)

Estate models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1720.0 mm (67.8 in)

Overall height:

Saloon:

All models except GLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Hatchback:

All models up to 1987 except GLS and 2.0iS . . . . . . . . . . . . . . . . . 1420.0 mm (55.9 in)

GLS and 2.0iS models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . 1392.0 mm (54.8 in)

All models from 1987 except GLS . . . . . . . . . . . . . . . . . . . . . . . . . 1359.0 mm (53.5 in)

GLS models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1352.0 mm (53.3 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1407.0 mm (55.4 in)

Estate:

All models up to 1987 except Base and Ghia . . . . . . . . . . . . . . . . . 1443.0 mm (56.9 in)

Base models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1417.0 mm (55.8 in)

Ghia models up to 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1506.0 mm (59.3 in)

Models from 1987 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1386.0 mm (54.6 in)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1428.0 mm (56.3 in)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1520.0 mm (59.9 in)

Weights

Kerb weight†:

Saloon:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1025 to 1135 kg (2260 to 2503 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Hatchback:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1010 to 1145 kg (2227 to 2525 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1240 kg (2343 to 2728 lbs)

Estate:

Models before 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1065 to 1186 kg (2348 to 2613 lbs)

Models from 1990 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1105 to 1190 kg (2431 to 2618 lbs)

P100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1370 kg (3021 lbs)

Maximum gross vehicle weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to VIN plate

Maximum roof rack load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 kg (165 lbs)

Minimum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . . 25 kg (55 lbs)

Maximum towing hitch downward load . . . . . . . . . . . . . . . . . . . . . . . . . 50 kg (110 lbs)

†Exact kerb weights depend upon model and specification

Page 2 of 26

REF•2

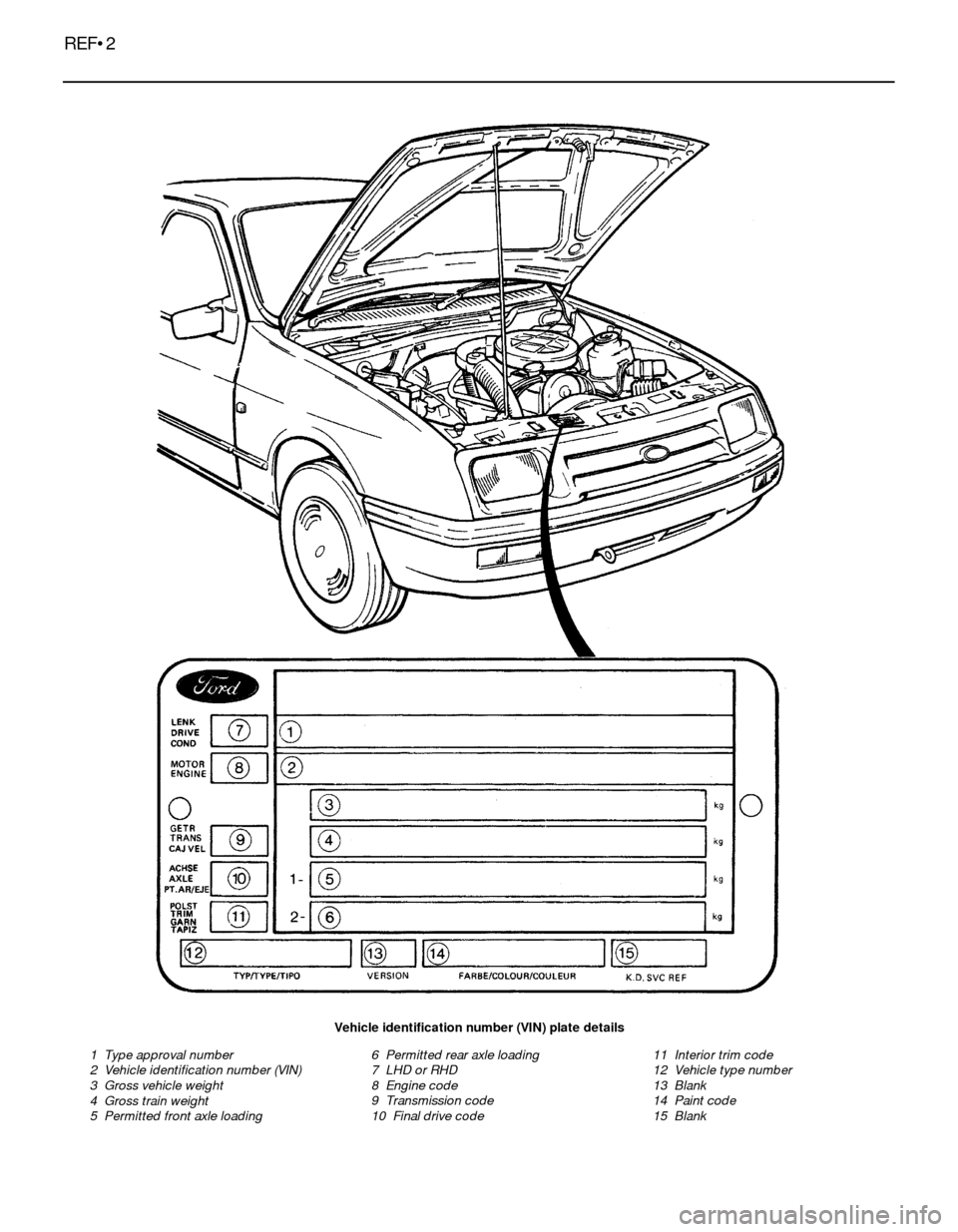

Vehicle identification number (VIN) plate details

1 Type approval number

2 Vehicle identification number (VIN)

3 Gross vehicle weight

4 Gross train weight

5 Permitted front axle loading6 Permitted rear axle loading

7 LHD or RHD

8 Engine code

9 Transmission code

10 Final drive code11 Interior trim code

12 Vehicle type number

13 Blank

14 Paint code

15 Blank

Page 15 of 26

Excessive final drive noise

MOil level low, or incorrect grade (Chapter 1)

MWorn bearings (Chapter 9)

MWorn or badly adjusted crownwheel and pinion (Chapter 9)

MLoose or deteriorated final drive mountings (Chapter 9)

Oil leakage from final drive

MPinion or output flange oil seal leaking (Chapter 9)MRear cover leaking (Chapter 9)

MCover or casing cracked (Chapter 9)

Grating, knocking or vibration from driveshafts

MFlange screws loose (Chapter 9)

MCV joints worn (Chapter 9)

MDriveshaft bent (Chapter 9)

Note:Before assuming that a brake problem exists, make sure that the

tyres are in good condition and correctly inflated, that the front wheel

alignment is correct, and that the vehicle is not loaded with weight in an

unequal manner. Apart from checking the condition of all pipe and

hose connections, any faults occurring on the anti-lock braking system

should be referred to a Ford dealer for diagnosis.

Vehicle pulls to one side under braking

MWorn, defective, damaged or contaminated front or rear brake

pads on one side (Chapters 1 and 10).

MSeized or partially-seized front or rear brake caliper piston

(Chapter 10).

MA mixture of brake pad lining materials fitted between sides

(Chapter 10).

MBrake caliper mounting bolts loose (Chapter 10).

MWorn or damaged steering or suspension components (Chapters 1

and 11).

Noise (grinding or high-pitched squeal) when brakes

applied

MBrake pad friction lining material worn down to metal backing

(Chapters 1 and 10).

MExcessive corrosion of brake disc - may be apparent after the

vehicle has been standing for some time (Chapters 1 and 10).

Excessive brake pedal travel

MFaulty master cylinder (Chapter 10).

MAir in hydraulic system (Chapter 10).MFaulty vacuum servo unit (Chapter 10).

Brake pedal feels spongy when depressed

MAir in hydraulic system (Chapter 10).

MDeteriorated flexible rubber brake hoses (Chapters 1 and 10).

MMaster cylinder mountings loose (Chapter 10).

MFaulty master cylinder (Chapter 10).

Excessive brake pedal effort required to stop vehicle

MFaulty vacuum servo unit (Chapter 10).

MDisconnected, damaged or insecure brake servo vacuum hose

(Chapters 1 and 10).

MPrimary or secondary hydraulic circuit failure (Chapter 10).

MSeized brake caliper piston(s) (Chapter 10).

MBrake pads incorrectly fitted (Chapter 10).

MIncorrect grade of brake pads fitted (Chapter 10).

MBrake pads contaminated (Chapter 10).

Judder felt through brake pedal or steering wheel

when braking

MExcessive run-out or distortion of brake disc(s) (Chapter 10).

MBrake pad linings worn (Chapters 1 and 10).

MBrake caliper mounting bolts loose (Chapter 10).

MWear in suspension or steering components or mountings

(Chapters 1 and 11).

Pedal pulsates when braking hard

MNormal feature of ABS - no fault

Clunking or knocking noise when taking up drive

MWorn universal joints (Chapter 8).

MLoose flange bolt (Chapter 8).

Vibration when accelerating or decelerating

MWorn centre bearing or universal joints (Chapter 8).

MBent or distorted shaft (Chapter 8).

MDeteriorated rubber insulator on centre bearing ( Chapter 8)

Engine will not start in any gear, or starts in gears

other than Park or Neutral

MFaulty starter inhibitor switch (Chapter 7).

MIncorrect selector adjustment (Chapter 7).

Transmission slips, shifts roughly, is noisy, or has no

drive in forward or reverse gears

MThere are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility - fluid

level. Before taking the vehicle to a dealer or transmission specialist,

check the fluid level and condition of the fluid as described in Chapter

1. Correct the fluid level as necessary, or change the fluid and filter if

needed. If the problem persists, professional help will be necessary.

Fault diagnosisREF•15

REF

Propeller shaft

Final drive and driveshafts

Braking system

Page 21 of 26

Glossary of Technical termsREF•21

REF

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

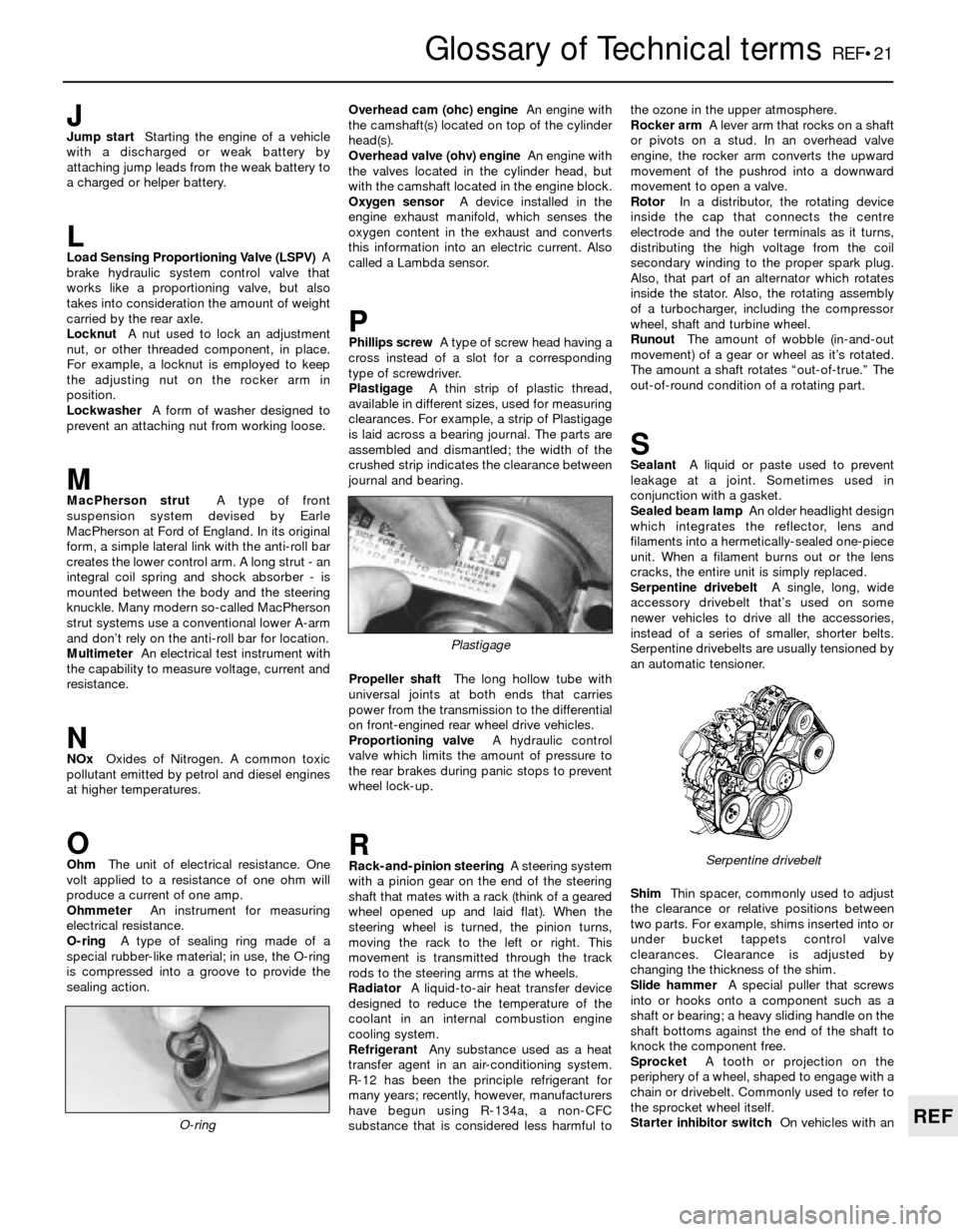

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).

Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful tothe ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

RotorIn a distributor, the rotating device

inside the cap that connects the centre

electrode and the outer terminals as it turns,

distributing the high voltage from the coil

secondary winding to the proper spark plug.

Also, that part of an alternator which rotates

inside the stator. Also, the rotating assembly

of a turbocharger, including the compressor

wheel, shaft and turbine wheel.

RunoutThe amount of wobble (in-and-out

movement) of a gear or wheel as it’s rotated.

The amount a shaft rotates “out-of-true.” The

out-of-round condition of a rotating part.

SSealantA liquid or paste used to prevent

leakage at a joint. Sometimes used in

conjunction with a gasket.

Sealed beam lampAn older headlight design

which integrates the reflector, lens and

filaments into a hermetically-sealed one-piece

unit. When a filament burns out or the lens

cracks, the entire unit is simply replaced.

Serpentine drivebeltA single, long, wide

accessory drivebelt that’s used on some

newer vehicles to drive all the accessories,

instead of a series of smaller, shorter belts.

Serpentine drivebelts are usually tensioned by

an automatic tensioner.

ShimThin spacer, commonly used to adjust

the clearance or relative positions between

two parts. For example, shims inserted into or

under bucket tappets control valve

clearances. Clearance is adjusted by

changing the thickness of the shim.

Slide hammerA special puller that screws

into or hooks onto a component such as a

shaft or bearing; a heavy sliding handle on the

shaft bottoms against the end of the shaft to

knock the component free.

SprocketA tooth or projection on the

periphery of a wheel, shaped to engage with a

chain or drivebelt. Commonly used to refer to

the sprocket wheel itself.

Starter inhibitor switchOn vehicles with an

O-ring

Serpentine drivebelt

Plastigage

Page 23 of 26

AAccelerator cable- 4A•8

Accelerator pedal- 4A•8

Acknowledgements- 0•4

Aerial- 13•20

Air cleaner- 1•18, 1•19, 4A•4, 4B•4

Air conditioning systems- 1•16, 3•1 et seq

Airflow meter- 4B•8

Alarm system- 13•19

Alternator- 5•6

Anti-roll bars- 11•6, 11•13

Anti-theft alarm- 13•19

Antifreeze- 0•17, 1•21, 3•3

ATF- 0•17, 1•3

Automatic transmission- 7B•1 et seq

extension housing oil seal - 7B•5

fault diagnosis - REF•11, REF•14

fluid - 0•17, 1•3

fluid checks - 1•13

gear selector mechanism - 7B•5

kickdown cable - 7B•3

removal and refitting - 7B•2

reversing lamp switch - 7B•6

selector rod - 7B•5

starter inhibitor switch - 7B•6

vacuum diaphragm unit - 7B•6

Auxiliary drivebelts- 1•14, 1•21

Auxiliary shaft- 2A•18

BBattery- 0•15, 1•15, 5•5

Bearings (engine) - 2A•23, 2B•17, 2C•23

Bleeding the power steering- 11•18

Bleeding the brakes- 10•2

Body damage- 12•2, 12•4

Body electrical systems - 13•1 et seq

Bodywork and fittings- 12•1 et seq

Bonnet release cable- 12•4

Bonnet lock- 12•4, 12•5

Boot lid lock- 12•5

Brake checks- 1•10

Brake fluid- 0•13, 0•1, 1•21

Braking system- 10•1 et seq

backplate - 10•12

bleeding the brakes - 10•2

brake caliper - 10•8, 10•10

brake disc - 10•3, 10•11

brake drum - 10•12

brake fluid pipes and hoses - 10•19

brake fluid reservoir - 10•15

brake lamp switch - 13•6

brake pads - 10•3

brake pedal - 10•22

brake shoes - 10•6

computer module (ABS) - 10•17

deceleration valve - 10•18

fault diagnosis - REF•11, REF•15

handbrake adjustment - 1•16, 10•20, 10•21

handbrake cables - 1•16, 10•20, 10•21

handbrake lever - 10•22

hoses brake - 10•19

hydraulic unit pressure switch - 10•17

hydraulic unit/pump/motor (ABS) - 10•15, 10•16

load apportioning valve - 10•19master cylinder (brake) - 10•13

pressure switch - 10•17

vacuum servo unit - 10•14

valve block (ABS) - 10•17

wheel cylinder - 10•12

wheel sensor - 10•18

Bulbs exterior- 13•16

Bulbs interior- 13•10

Bulbs ratings- 13•2

Bumpers- 12•13

Buying spare parts - REF•3

CCables:

accelerator - 4A•8

bonnet release - 12•4

clutch - 6•2

handbrake - 10•20, 10•21

kickdown - 7B•3

speedometer - 13•11

tailgate/boot lid/filler cap - 12•6

Caliper (brake) front/rear- 10•8, 10•10

Camshaft and followers- 2A•17, 2B•14, 2C•16

Capacities- 1•3

Carburettor:

Ford VV type - 1•12, 4A•8, 4A•13

Pierburg 2V type - 1•12, 4A•8, 4A•14

Weber 2V type - 1•12, 4A•8, 4A•14

Weber 2V TLD type - 1•12, 4A•8, 4A•15

Cargo area- 12•10

Carpets- 12•2

Catalytic converter- 4B•3, 4B•14

Central locking system- 13•18

Centre/overhead console- 12•18, 12•19

CFI unit- 4B•10

Charging system- 5•5

Cigarette lighter- 13•6

Clock- 13•6

Clutch- 6•1 et seq

assembly - 6•3

cable - 6•2

fault diagnosis - REF•11, REF•14

pedal - 6•2

release bearing - 6•5

Coil- 5•13

Coil spring (rear) - 11•10

Compression test- 2A•7

Computer module (ABS)- 10•17

Connecting rods- 2A•22, 2B•17, 2C•21

Contents- 0•2

Coolant- 0•12, 0•17, 1•21, 3•3

Coolant level- 0•12

Cooling, heating and air conditioning

systems- 3•1 et seq

antifreeze - 0•12, 0•17, 1•21, 3•3

coolant pump - 3•5

coolant temperature sender and sensor - 3•8

cooling fan - 3•7

draining - 1•21

drivebelt tensioner - 3•7

expansion tank/coolant sensor - 3•8

fan (radiator) - 3•7

fault diagnosis - REF•11, REF•13

filling - 1•21

flushing - 1•21heater - 3•9

radiator - 3•3

switches - 3•8

temperature gauge and sender unit - 3•8

thermostat - 3•4

Courtesy lamp switch- 13•5

Crankshaft oil seals- 2A•19, 2B•15, 2C•19

Crankshaft bearings- 2A•23, 2B•17, 2C•23

Cylinder bores- 2A•24

Cylinder head- 2A•14, 2B•10, 2C•13

DDents- 12•2

Depressurising fuel injection system- 4B•4

Dimensions and weights- REF•1

Disc brake - 10•3, 10•11

Distributor- 5•14, 5•15, 5•16

Door- 12•6

Door inner trim panel- 12•7

Door mirror switch- 13•5

Drivebelts check- 1•14, 1•21, 3•7

Driveplate- 2A•18, 2B•15, 2C•19

Driveshafts:

check - 1•17

fault diagnosis - REF•11, REF•15

overhaul - 9•5

removal and refitting - 9•4

Drum (brake)- 10•12

EEarth fault finding- 13•3

Electric windows- 13•18

Electrical fault finding- 13•2

Electrical system (body)- 13•1 et seq

Electrical system:

weekly checks - 0•14

fault diagnosis - REF•11, REF•16

Electronic vacuum regulator- 4B•11

Engine:

auxiliary shaft - 2A•18

bearings - 2A•23, 2B•17, 2C•23

bores - 2A•24

camshaft followers - 2A•17, 2B•14, 2C•16

codes - 2A•1, 2B•1, 2C•1

compartment views - 0•10, 1•5

compression test - 2A•7

connecting rods - 2A•22, 2B•17, 2C•21

crankshaft bearings - 2A•23, 2B•17, 2C•23

crankshaft oil seals - 2A•19, 2B•15, 2C•19

cylinder bores - 2A•24

cylinder head - 2A•14, 2B•10, 2C•13

dismantling - 2A•11, 2B•8, 2C•10

DOHC engines- 2B•1 et seq

driveplate - 2A•18, 2B•15, 2C•19

fault diagnosis - REF•11, REF•12

flywheel - 2A•18, 2B•15, 2C•19

main bearings - 2A•23, 2B•17, 2C•23

mountings - 2A•11, 2B•7, 2C•9

oils - 0•17, 1•3

oil and filter renewal - 1•9

oil level - 0•12

oil pump - 2A•21, 2B•16, 2C•20

oil seals crankshaft - 2A•19, 2B•15, 2C•19

piston - 2A•22, 2B•17, 2C•21

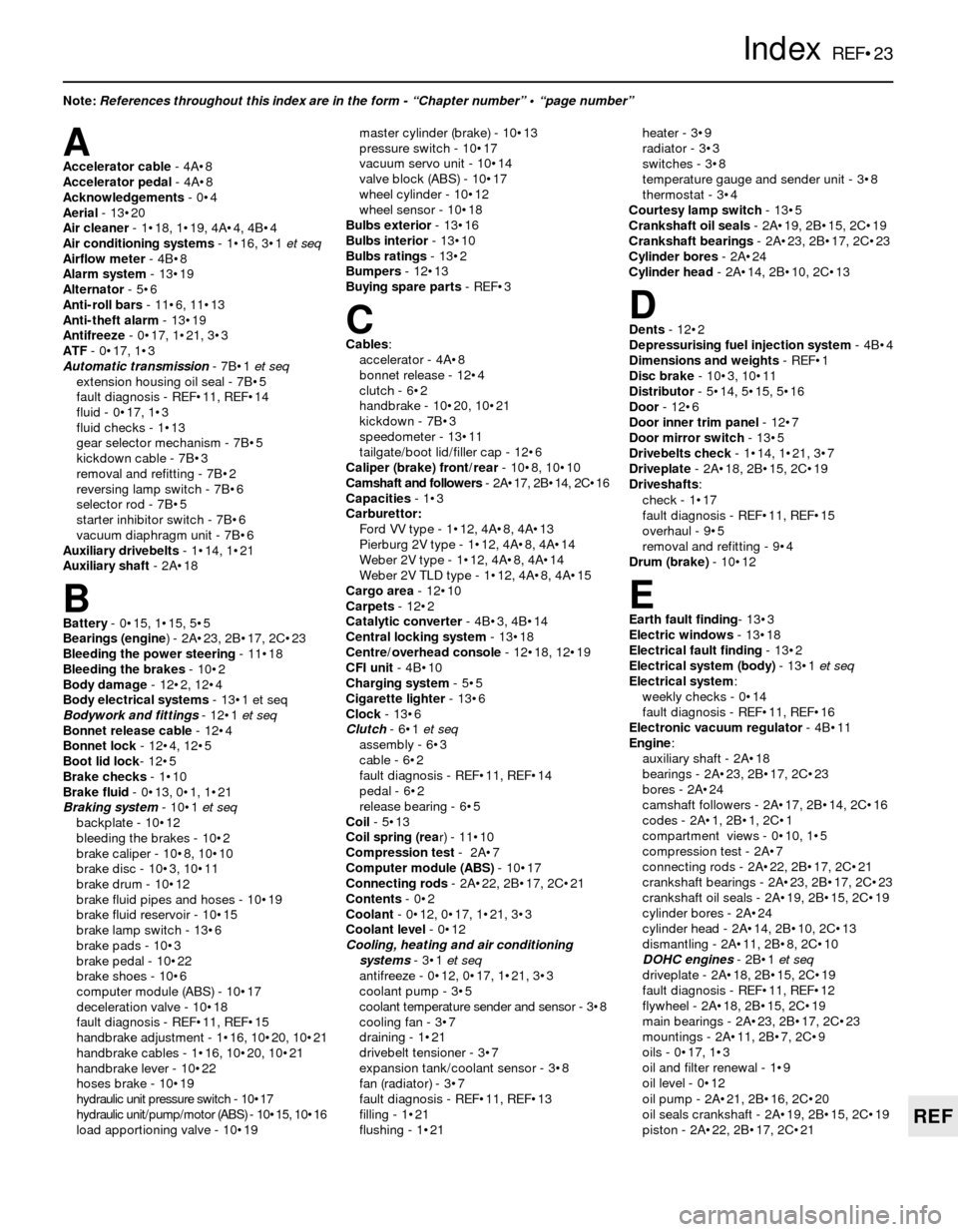

IndexREF•23

REF

Note: References throughout this index are in the form - “Chapter number” • “page number”