wheel size FORD SIERRA 1992 2.G SOHC Engines Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 24, PDF Size: 1.03 MB

Page 1 of 24

1.3 litre engine

General

Engine type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder, in-line, single overhead camshaft

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2

Engine code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . JCT

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.02 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66.00 mm

Cubic capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1294 cc

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0:1

Compression pressure at starter motor speed . . . . . . . . . . . . . . . . . . . . 11 to 13 bar

Maximum continuous engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5800 rpm

Maximum engine power (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 kW at 5700 rpm

Maximum engine torque (DIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 Nm at 3100 rpm

Cylinder bore diameter

Standard class 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.000 to 79.010 mm

Standard class 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.010 to 79.020 mm

Standard class 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.020 to 79.030 mm

Standard class 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.030 to 79.040 mm

Oversize class A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.510 to 79.520 mm

Oversize class B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.520 to 79.530 mm

Oversize class C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.530 to 79.540 mm

Standard service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.030 to 79.040 mm

Oversize 0.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.530 to 79.540 mm

Oversize 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.030 to 80.040 mm

Chapter 2 Part A:

SOHC engines

Auxiliary shaft - removal, inspection and refitting . . . . . . . . . . . . . . .25

Camshaft and cam followers - removal, inspection and refitting . . . .24

Compression test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Crankcase ventilation system - inspection and maintenance . . . . . . .4

Crankshaft and bearings - examination and renovation . . . . . . . . . .35

Crankshaft and main bearings - removal and refitting . . . . . . . . . . . .34

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Cylinder block and bores - examination and renovation . . . . . . . . . .36

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . . .22

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . . . .23

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . . .20

Cylinder head - removal and refitting (engine removed) . . . . . . . . . . .21

Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . . .14

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . . .13

Engine - removal leaving automatic transmission in vehicle . . . . . . .10

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . . .9

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Engine/automatic transmission assembly - removal and separation .12Engine dismantling,examination, renovation and reassembly - general

information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Engine/manual gearbox - reconnection and refitting . . . . . . . . . . . . .15

Engine/manual gearbox assembly - removal and separation . . . . . .11

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . . .26

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . . .37

Major operations possible with the engine in the vehicle . . . . . . . . . . .6

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . . .7

Method of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . .31

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Pistons and connecting rods - examination and renovation . . . . . . .33

Pistons and connecting rods - removal and refitting . . . . . . . . . . . . .32

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Timing belt and sprockets - removal and refitting . . . . . . . . . . . . . . .19

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . . . .3

2A¥1

Specifications Contents

2A

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Page 3 of 24

Inlet valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.025 to 8.043 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.225 to 8.243 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.425 to 8.443 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.625 to 8.643 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.825 to 8.843 mm

Exhaust valve stem diameter:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.999 to 8.017 mm

Oversize 0.2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.199 to 8.217 mm

Oversize 0.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.399 to 8.417 mm

Oversize 0.6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.599 to 8.617 mm

Oversize 0.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.799 to 8.817 mm

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Multigrade engine oil, viscosity range SAE 10W/30 to 20W/50 to API

SG/CD or better

Oil capacity:

With filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.75 litres (6.6 pints)

Without filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.25 litres (5.7 pints)

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion C102

Oil pump clearances:

Outer rotor to body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.153 to 0.304 mm (0.006 to 0.012 in)

Inner rotor to outer rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.050 to 0.200 mm (0.002 to 0.008 in)

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.039 to 0.104 mm (0.002 to 0.004 in)

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88 to 10265 to 75

Big-end bearing cap nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 4730 to 35

Crankshaft pulley bolt:

Strength class 8.8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 to 6041 to 44

Strength class 10.9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 to 11574 to 85

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5033 to 37

Auxiliary shaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5033 to 37

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64 to 7047 to 52

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Oil pump cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Sump bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 to 20.7 to 1.5

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Stage 3 (after running engine for 20 minutes) . . . . . . . . . . . . . . . . . . .8 to 106 to 7

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 21

Oil pressure warning lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 to 159 to 11

Valve adjustment ball-pin locknuts:

7 mm thick nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5033 to 37

8 mm thick nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 5537 to 41

Cylinder head bolts:

Splined type bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5530 to 41

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 to 7037 to 52

Stage 3 (after 20 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73 to 8354 to 61

Stage 4 (after running engine for 15 minutes at 1000 rpm) . . . . . .95 to 11570 to 85

Torx type bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4026 to 30

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 7552 to 55

Stage 3 (after 5 minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten through a further 90¼

Camshaft cover bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 to 31.5 to 2

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Timing cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13 to 1710 to 13

Timing belt tensioner bolts:

Models with tensioner spring:

Spring bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Pivot bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Models without tensioner spring . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Oil pick-up tube/strainer-to-oil pump bolts . . . . . . . . . . . . . . . . . . . . . .11 to 148 to 10

Oil pick-up tube/strainer-to-cylinder block bolts . . . . . . . . . . . . . . . . . .17 to 2113 to 15

SOHC engines 2A¥3

2A

Page 24 of 24

components, but there must be no tight spots

or binding.

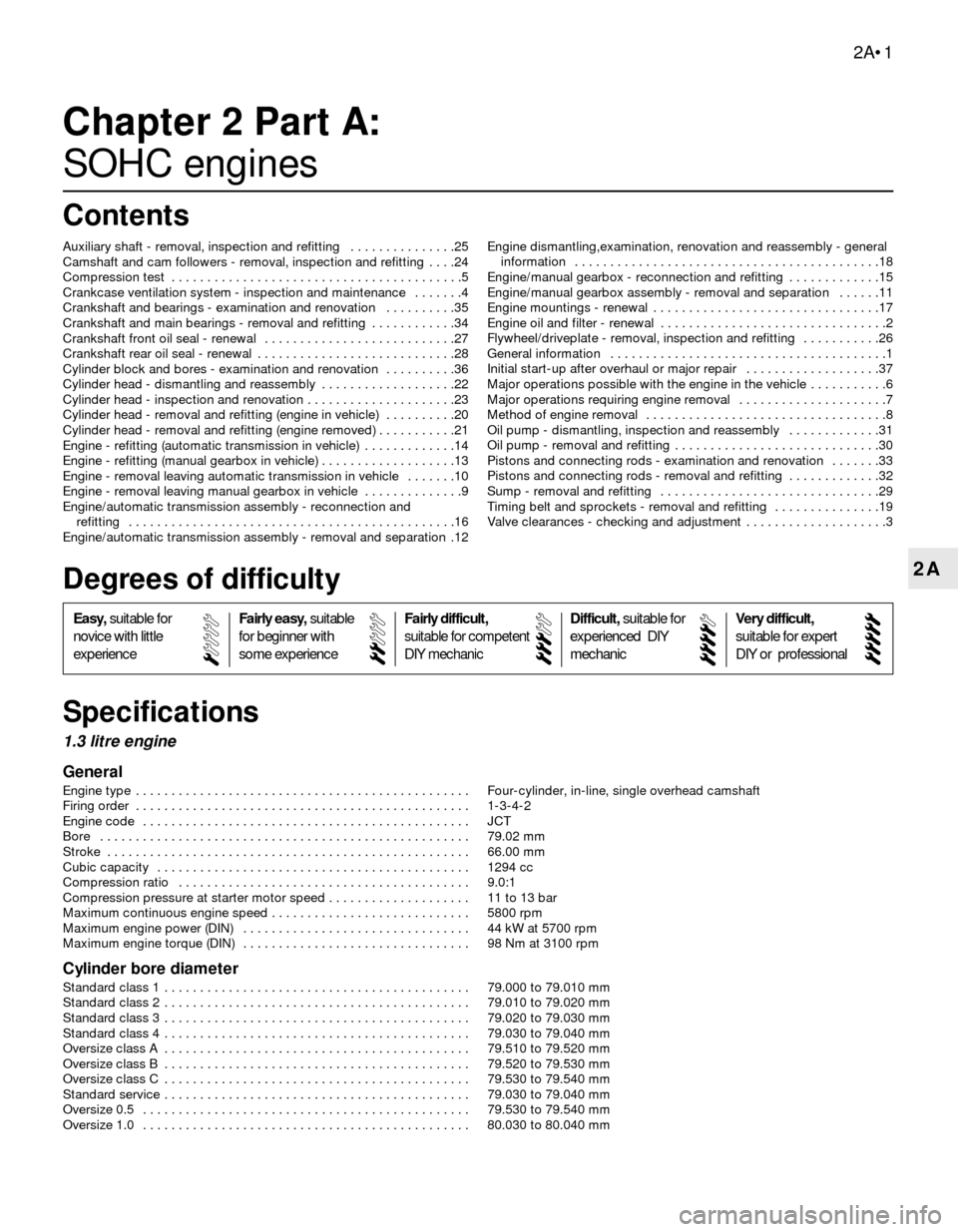

28Check that the crankshaft endfloat is

within the specified limits by inserting a feeler

blade between the centre crankshaft web and

the thrustwashers.

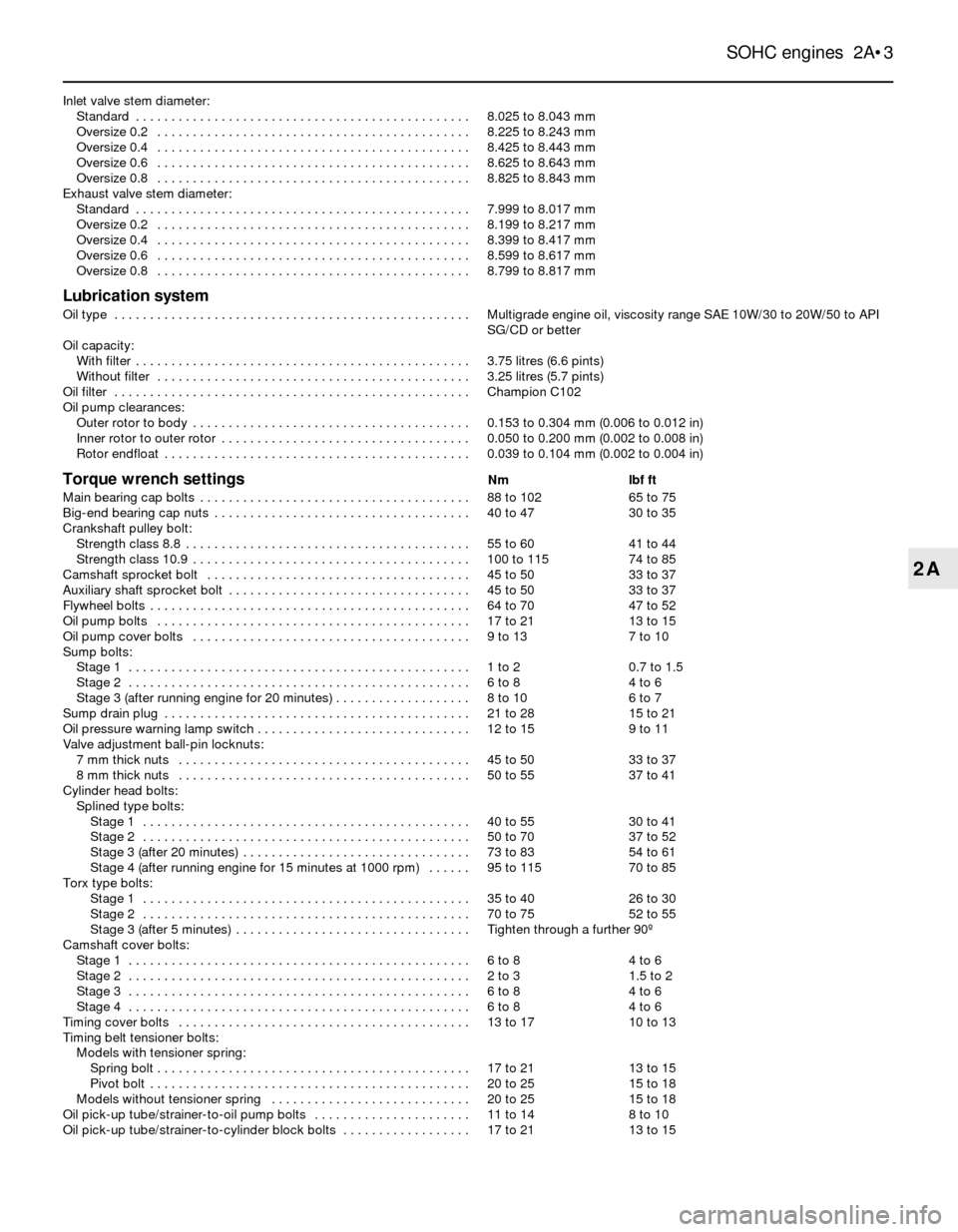

29Make sure that the rear oil seal is fully

located onto its seating. Coat the rear main

bearing cap sealing wedges with sealing

compound, then press them into position

using a blunt screwdriver with the rounded

red face towards the cap (see illustration).

30Refit the oil pump and pick-up tube.

31Refit the crankshaft front oil seal housing

and the auxiliary shaft front cover using a new

gasket, and tighten the securing bolts. Smear

the lip of the oil seal with clean engine oil

before fitting; and using a straight edge, ensure

that the bottom face of the oil seal housing is

aligned with the bottom face of the cylinder

block before finally tightening the bolts.

32Refit the pistons and connecting rods.

33Refit the flywheel/driveplate and the

auxiliary shaft sprocket, crankshaft sprocket,

and timing belt.

1Examine the bearing surfaces of the

crankshaft for scratches or scoring and, using

a micrometer, check each journal and

crankpin for ovality. Where this is found to be

in excess of 0.0254 mm (0.001 in) the

crankshaft will have to be reground and

undersize bearings fitted.

2Crankshaft regrinding should be carried out

by a suitable engineering works, who will

normally supply the matching undersize main

and big-end shell bearings.

3Note that undersize bearings may already

have been fitted, either in production or by a

previous repairer. Check the markings on the

backs of the old bearing shells, and if in doubt

take them along when buying new ones.

Production undersizes are also indicated by

paint marks as follows:

White line on main bearing cap - parent bore

0.40 mm oversize

Green line on crankshaft front counterweight

- main bearing journals 0.25 mm

undersize

Green spot on counterweight - big-end

bearing journals 0.25 mm undersize4If the crankshaft endfloat is more than the

maximum specified amount, new

thrustwashers should be fitted to the centre

main bearings. These are usually supplied

together with the main and big-end bearings

on a reground crankshaft.

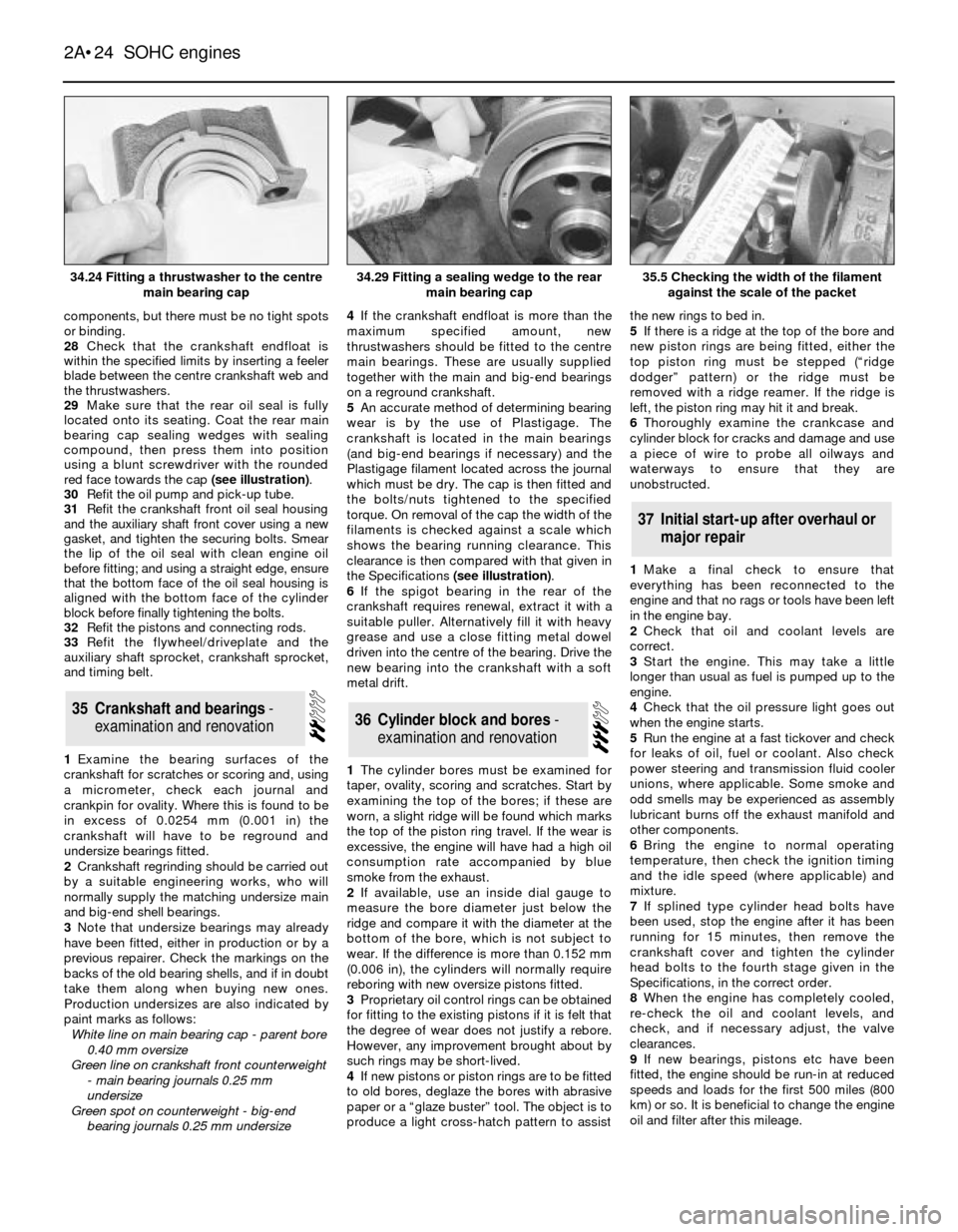

5An accurate method of determining bearing

wear is by the use of Plastigage. The

crankshaft is located in the main bearings

(and big-end bearings if necessary) and the

Plastigage filament located across the journal

which must be dry. The cap is then fitted and

the bolts/nuts tightened to the specified

torque. On removal of the cap the width of the

filaments is checked against a scale which

shows the bearing running clearance. This

clearance is then compared with that given in

the Specifications (see illustration).

6If the spigot bearing in the rear of the

crankshaft requires renewal, extract it with a

suitable puller. Alternatively fill it with heavy

grease and use a close fitting metal dowel

driven into the centre of the bearing. Drive the

new bearing into the crankshaft with a soft

metal drift.

1The cylinder bores must be examined for

taper, ovality, scoring and scratches. Start by

examining the top of the bores; if these are

worn, a slight ridge will be found which marks

the top of the piston ring travel. If the wear is

excessive, the engine will have had a high oil

consumption rate accompanied by blue

smoke from the exhaust.

2If available, use an inside dial gauge to

measure the bore diameter just below the

ridge and compare it with the diameter at the

bottom of the bore, which is not subject to

wear. If the difference is more than 0.152 mm

(0.006 in), the cylinders will normally require

reboring with new oversize pistons fitted.

3Proprietary oil control rings can be obtained

for fitting to the existing pistons if it is felt that

the degree of wear does not justify a rebore.

However, any improvement brought about by

such rings may be short-lived.

4If new pistons or piston rings are to be fitted

to old bores, deglaze the bores with abrasive

paper or a Òglaze busterÓ tool. The object is to

produce a light cross-hatch pattern to assistthe new rings to bed in.

5If there is a ridge at the top of the bore and

new piston rings are being fitted, either the

top piston ring must be stepped (Òridge

dodgerÓ pattern) or the ridge must be

removed with a ridge reamer. If the ridge is

left, the piston ring may hit it and break.

6Thoroughly examine the crankcase and

cylinder block for cracks and damage and use

a piece of wire to probe all oilways and

waterways to ensurethatthey are

unobstructed.

1Make a final check to ensure that

everything has been reconnected to the

engine and that no rags or tools have been left

in the engine bay.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little

longer than usual as fuel is pumped up to the

engine.

4Check that the oil pressure light goes out

when the engine starts.

5Run the engine at a fast tickover and check

for leaks of oil, fuel or coolant. Also check

power steering and transmission fluid cooler

unions, where applicable. Some smoke and

odd smells may be experienced as assembly

lubricant burns off the exhaust manifold and

other components.

6Bring the engine to normal operating

temperature, then check the ignition timing

and the idle speed (where applicable) and

mixture.

7If splined type cylinder head bolts have

been used, stop the engine after it has been

running for 15 minutes, then remove the

crankshaft cover and tighten the cylinder

head bolts to the fourth stage given in the

Specifications, in the correct order.

8When the engine has completely cooled,

re-check the oil and coolant levels, and

check, and if necessary adjust, the valve

clearances.

9If new bearings, pistons etc have been

fitted, the engine should be run-in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

37Initial start-up after overhaul or

major repair

36Cylinder block and bores -

examination and renovation35Crankshaft and bearings -

examination and renovation

2A¥24SOHC engines

34.24 Fitting a thrustwasher to the centre

main bearing cap35.5 Checking the width of the filament

against the scale of the packet34.29 Fitting a sealing wedge to the rear

main bearing cap