jack points FORD SIERRA 1992 2.G Suspension And Steering User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1992, Model line: SIERRA, Model: FORD SIERRA 1992 2.GPages: 20, PDF Size: 0.94 MB

Page 18 of 20

Refitting

3When refitting the fluid hoses, use new

O-rings, and take care not to overtighten the

unions. Note that with the unions fully

tightened it is still possible to rotate and move

the hoses.

4On completion of refitting, bleed the power

steering fluid circuit (Section 34).

Note: New power steering fluid hose O-rings

will be required when refitting.

All engines except 1.8 litre (R6A)

CVH and 2.0 litre DOHC

1Place a suitable container under the power

steering pump, unscrew the fluid hose unions,

and drain the fluid. Ensure that fluid is not

allowed to spill onto the alternator.

2Remove the drivebelts and unbolt the

power steering pump pulley if necessary to

ease removal.

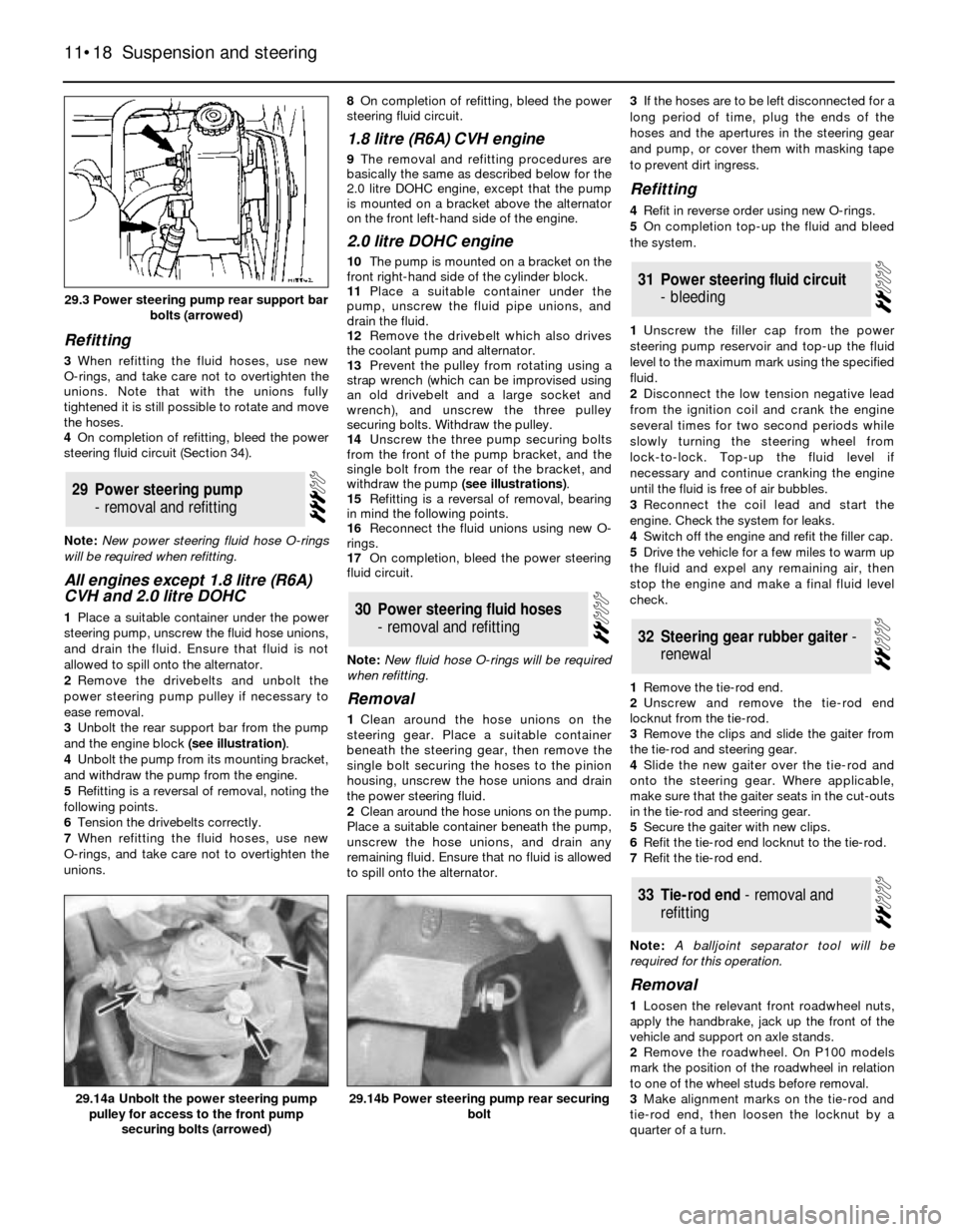

3Unbolt the rear support bar from the pump

and the engine block (see illustration).

4Unbolt the pump from its mounting bracket,

and withdraw the pump from the engine.

5Refitting is a reversal of removal, noting the

following points.

6Tension the drivebelts correctly.

7When refitting the fluid hoses, use new

O-rings, and take care not to overtighten the

unions. 8On completion of refitting, bleed the power

steering fluid circuit.

1.8 litre (R6A) CVH engine

9The removal and refitting procedures are

basically the same as described below for the

2.0 litre DOHC engine, except that the pump

is mounted on a bracket above the alternator

on the front left-hand side of the engine.

2.0 litre DOHC engine

10The pump is mounted on a bracket on the

front right-hand side of the cylinder block.

11Place a suitable container under the

pump, unscrew the fluid pipe unions, and

drain the fluid.

12Remove the drivebelt which also drives

the coolant pump and alternator.

13Prevent the pulley from rotating using a

strap wrench (which can be improvised using

an old drivebelt and a large socket and

wrench), and unscrew the three pulley

securing bolts. Withdraw the pulley.

14Unscrew the three pump securing bolts

from the front of the pump bracket, and the

single bolt from the rear of the bracket, and

withdraw the pump (see illustrations).

15Refitting is a reversal of removal, bearing

in mind the following points.

16Reconnect the fluid unions using new O-

rings.

17On completion, bleed the power steering

fluid circuit.

Note: New fluid hose O-rings will be required

when refitting.

Removal

1Clean around the hose unions on the

steering gear. Place a suitable container

beneath the steering gear, then remove the

single bolt securing the hoses to the pinion

housing, unscrew the hose unions and drain

the power steering fluid.

2Clean around the hose unions on the pump.

Place a suitable container beneath the pump,

unscrew the hose unions, and drain any

remaining fluid. Ensure that no fluid is allowed

to spill onto the alternator.3If the hoses are to be left disconnected for a

long period of time, plug the ends of the

hoses and the apertures in the steering gear

and pump, or cover them with masking tape

to prevent dirt ingress.

Refitting

4Refit in reverse order using new O-rings.

5On completion top-up the fluid and bleed

the system.

1Unscrew the filler cap from the power

steering pump reservoir and top-up the fluid

level to the maximum mark using the specified

fluid.

2Disconnect the low tension negative lead

from the ignition coil and crank the engine

several times for two second periods while

slowly turning the steering wheel from

lock-to-lock. Top-up the fluid level if

necessary and continue cranking the engine

until the fluid is free of air bubbles.

3Reconnect the coil lead and start the

engine. Check the system for leaks.

4Switch off the engine and refit the filler cap.

5Drive the vehicle for a few miles to warm up

the fluid and expel any remaining air, then

stop the engine and make a final fluid level

check.

1Remove the tie-rod end.

2Unscrew and remove the tie-rod end

locknut from the tie-rod.

3Remove the clips and slide the gaiter from

the tie-rod and steering gear.

4Slide the new gaiter over the tie-rod and

onto the steering gear. Where applicable,

make sure that the gaiter seats in the cut-outs

in the tie-rod and steering gear.

5Secure the gaiter with new clips.

6Refit the tie-rod end locknut to the tie-rod.

7Refit the tie-rod end.

Note: A balljoint separator tool will be

required for this operation.

Removal

1Loosen the relevant front roadwheel nuts,

apply the handbrake, jack up the front of the

vehicle and support on axle stands.

2Remove the roadwheel. On P100 models

mark the position of the roadwheel in relation

to one of the wheel studs before removal.

3Make alignment marks on the tie-rod and

tie-rod end, then loosen the locknut by a

quarter of a turn.

33Tie-rod end - removal and

refitting

32Steering gear rubber gaiter -

renewal

31Power steering fluid circuit

- bleeding

30Power steering fluid hoses

- removal and refitting

29Power steering pump

- removal and refitting

11•18Suspension and steering

29.3 Power steering pump rear support bar

bolts (arrowed)

29.14b Power steering pump rear securing

bolt29.14a Unbolt the power steering pump

pulley for access to the front pump

securing bolts (arrowed)

Page 19 of 20

4Extract the split pin and unscrew the

castellated nut (see illustration).

5Using a balljoint separator tool, release the

tie-rod end from the hub carrier (see

illustration).

6Unscrew the tie-rod end from the tie-rod,

noting the number of turns necessary to

remove it.

Refitting

7Refitting is a reversal of removal, bearing in

mind the following points.

8Screw the tie-rod end onto the tie-rod the

number of turns noted during removal.

9Tighten the nuts to the specified torque,

and fit a new split pin to the castellated nut.

10On P100 models, align the previously

made marks on the roadwheel and wheel

stud.

11On completion, check and if necessary

adjust the front wheel alignment.

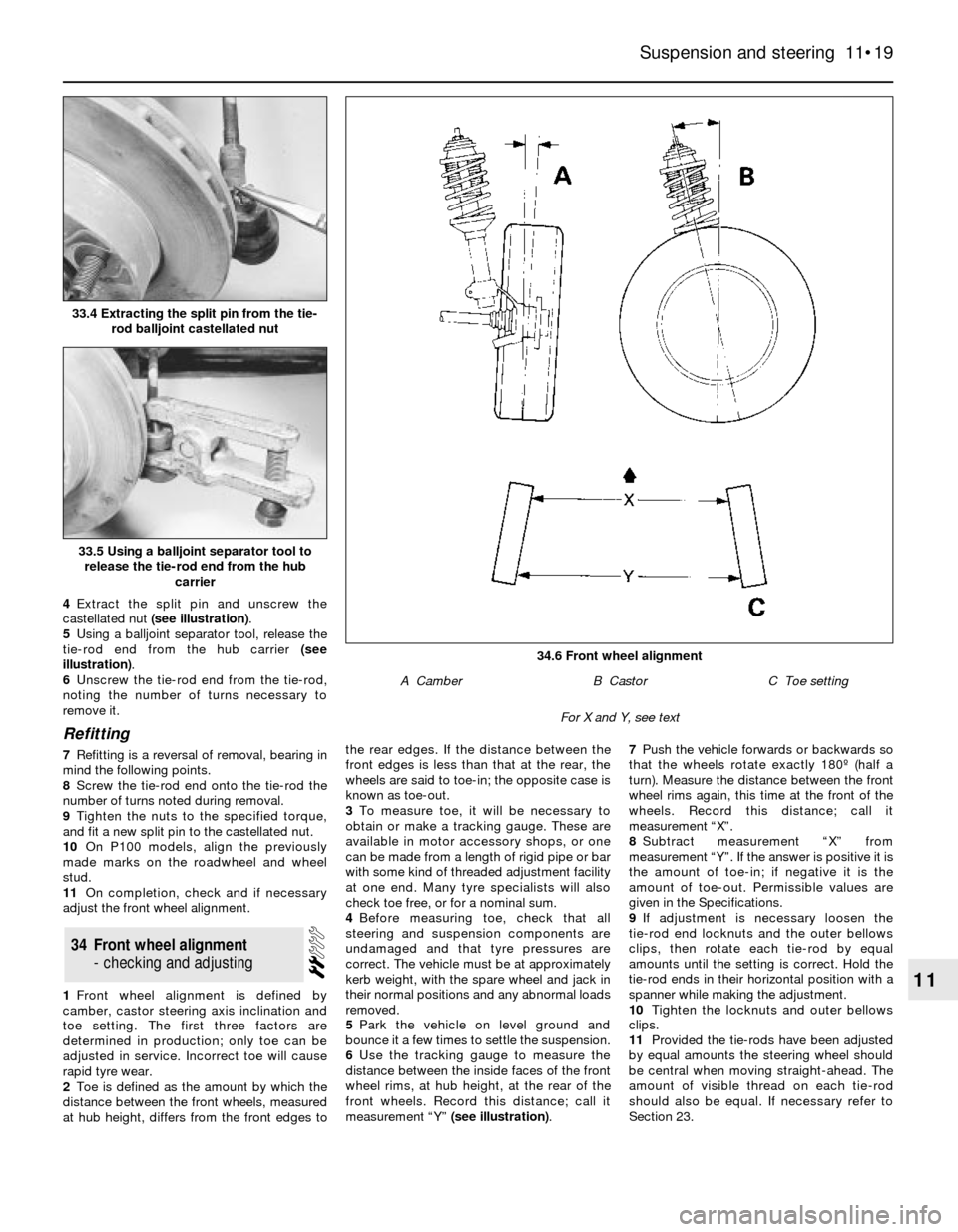

1Front wheel alignment is defined by

camber, castor steering axis inclination and

toe setting. The first three factors are

determined in production; only toe can be

adjusted in service. Incorrect toe will cause

rapid tyre wear.

2Toe is defined as the amount by which the

distance between the front wheels, measured

at hub height, differs from the front edges tothe rear edges. If the distance between the

front edges is less than that at the rear, the

wheels are said to toe-in; the opposite case is

known as toe-out.

3To measure toe, it will be necessary to

obtain or make a tracking gauge. These are

available in motor accessory shops, or one

can be made from a length of rigid pipe or bar

with some kind of threaded adjustment facility

at one end. Many tyre specialists will also

check toe free, or for a nominal sum.

4Before measuring toe, check that all

steering and suspension components are

undamaged and that tyre pressures are

correct. The vehicle must be at approximately

kerb weight, with the spare wheel and jack in

their normal positions and any abnormal loads

removed.

5Park the vehicle on level ground and

bounce it a few times to settle the suspension.

6Use the tracking gauge to measure the

distance between the inside faces of the front

wheel rims, at hub height, at the rear of the

front wheels. Record this distance; call it

measurement “Y” (see illustration).7Push the vehicle forwards or backwards so

that the wheels rotate exactly 180º (half a

turn). Measure the distance between the front

wheel rims again, this time at the front of the

wheels. Record this distance; call it

measurement “X”.

8Subtract measurement “X” from

measurement “Y”. If the answer is positive it is

the amount of toe-in; if negative it is the

amount of toe-out. Permissible values are

given in the Specifications.

9If adjustment is necessary loosen the

tie-rod end locknuts and the outer bellows

clips, then rotate each tie-rod by equal

amounts until the setting is correct. Hold the

tie-rod ends in their horizontal position with a

spanner while making the adjustment.

10Tighten the locknuts and outer bellows

clips.

11Provided the tie-rods have been adjusted

by equal amounts the steering wheel should

be central when moving straight-ahead. The

amount of visible thread on each tie-rod

should also be equal. If necessary refer to

Section 23.

34Front wheel alignment

- checking and adjusting

Suspension and steering 11•19

11

34.6 Front wheel alignment

A CamberB CastorC Toe setting

For X and Y, see text

33.5 Using a balljoint separator tool to

release the tie-rod end from the hub

carrier

33.4 Extracting the split pin from the tie-

rod balljoint castellated nut