engine FORD SIERRA 1993 2.G Introduction User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: SIERRA, Model: FORD SIERRA 1993 2.GPages: 18, PDF Size: 0.5 MB

Page 13 of 18

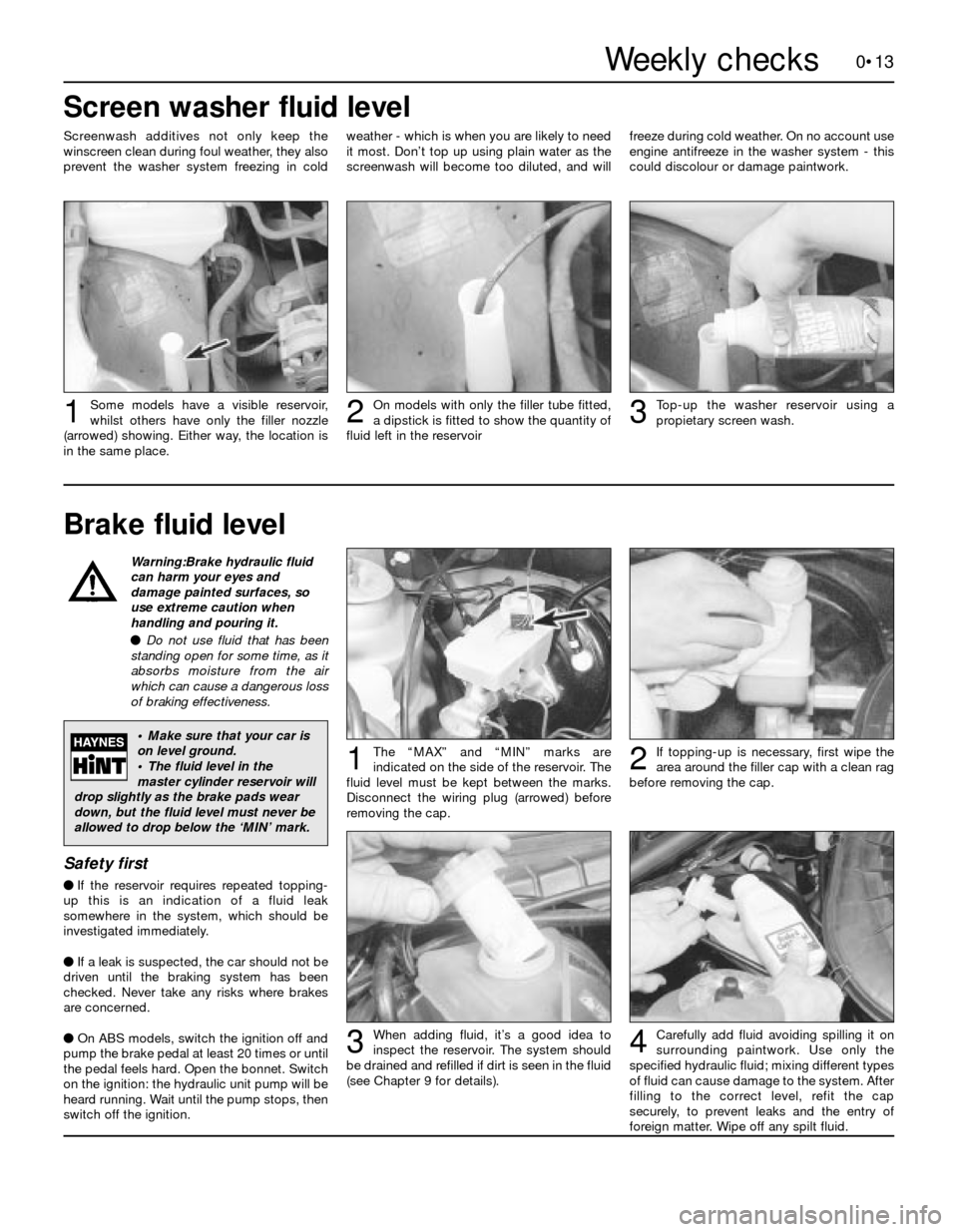

Warning:Brake hydraulic fluid

can harm your eyes and

damage painted surfaces, so

use extreme caution when

handling and pouring it.

l Do not use fluid that has been

standing open for some time, as it

absorbs moisture from the air

which can cause a dangerous loss

of braking effectiveness.

Safety first

lIf the reservoir requires repeated topping-

up this is an indication of a fluid leak

somewhere in the system, which should be

investigated immediately.

lIf a leak is suspected, the car should not be

driven until the braking system has been

checked. Never take any risks where brakes

are concerned.

lOn ABS models, switch the ignition off and

pump the brake pedal at least 20 times or until

the pedal feels hard. Open the bonnet. Switch

on the ignition: the hydraulic unit pump will be

heard running. Wait until the pump stops, then

switch off the ignition.

Brake fluid level

0•13

Carefully add fluid avoiding spilling it on

surrounding paintwork. Use only the

specified hydraulic fluid; mixing different types

of fluid can cause damage to the system. After

filling to the correct level, refit the cap

securely, to prevent leaks and the entry of

foreign matter. Wipe off any spilt fluid.When adding fluid, it’s a good idea to

inspect the reservoir. The system should

be drained and refilled if dirt is seen in the fluid

(see Chapter 9 for details).

The “MAX” and “MIN” marks are

indicated on the side of the reservoir. The

fluid level must be kept between the marks.

Disconnect the wiring plug (arrowed) before

removing the cap.1If topping-up is necessary, first wipe the

area around the filler cap with a clean rag

before removing the cap.2

34

Screen washer fluid level

Some models have a visible reservoir,

whilst others have only the filler nozzle

(arrowed) showing. Either way, the location is

in the same place.Top-up the washer reservoir using a

propietary screen wash.On models with only the filler tube fitted,

a dipstick is fitted to show the quantity of

fluid left in the reservoir

Screenwash additives not only keep the

winscreen clean during foul weather, they also

prevent the washer system freezing in coldweather - which is when you are likely to need

it most. Don’t top up using plain water as the

screenwash will become too diluted, and willfreeze during cold weather. On no account use

engine antifreeze in the washer system - this

could discolour or damage paintwork.

123

• Make sure that your car is

on level ground.

• The fluid level in the

master cylinder reservoir will

drop slightly as the brake pads wear

down, but the fluid level must never be

allowed to drop below the ‘MIN’ mark.

Weekly checks

Page 14 of 18

0•14

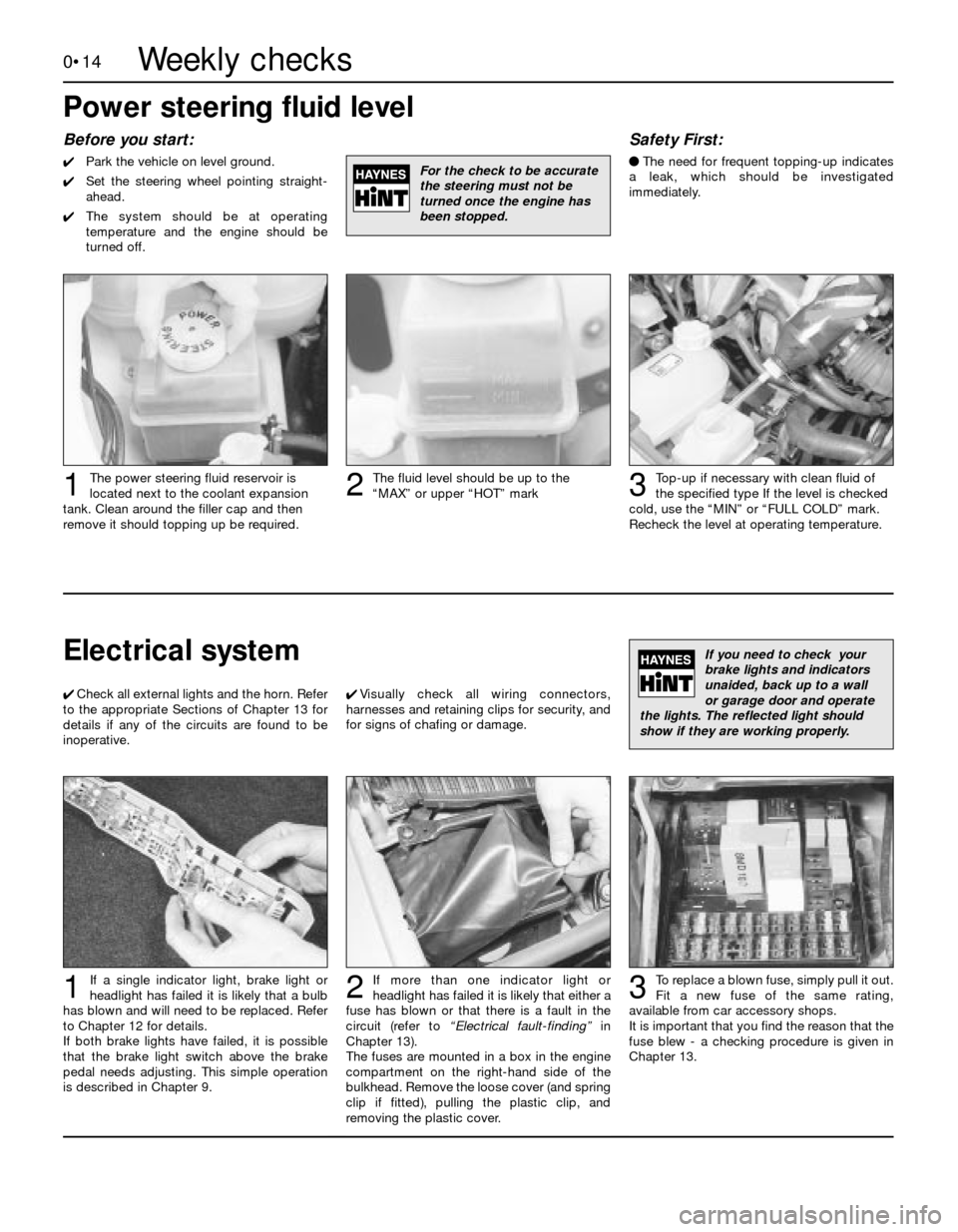

Before you start:

4Park the vehicle on level ground.

4Set the steering wheel pointing straight-

ahead.

4The system should be at operating

temperature and the engine should be

turned off.

Safety First:

lThe need for frequent topping-up indicates

a leak, which should be investigated

immediately.

Top-up if necessary with clean fluid of

the specified typeIf the level is checked

cold, use the “MIN” or “FULL COLD” mark.

Recheck the level at operating temperature.

The fluid level should be up to the

“MAX” or upper “HOT” markThe power steering fluid reservoir is

located next to the coolant expansion

tank. Clean around the filler cap and then

remove it should topping up be required.123

For the check to be accurate

the steering must not be

turned once the engine has

been stopped.

Power steering fluid level

Weekly checks

Electrical system

To replace a blown fuse, simply pull it out.

Fit a new fuse of the same rating,

available from car accessory shops.

It is important that you find the reason that the

fuse blew - a checking procedure is given in

Chapter 13.If more than one indicator light or

headlight has failed it is likely that either a

fuse has blown or that there is a fault in the

circuit (refer to“Electrical fault-finding”in

Chapter 13).

The fuses are mounted in a box in the engine

compartment on the right-hand side of the

bulkhead. Remove the loose cover (and spring

clip if fitted), pulling the plastic clip, and

removing the plastic cover.If a single indicator light, brake light or

headlight has failed it is likely that a bulb

has blown and will need to be replaced. Refer

to Chapter 12 for details.

If both brake lights have failed, it is possible

that the brake light switch above the brake

pedal needs adjusting. This simple operation

is described in Chapter 9.1

If you need to check your

brake lights and indicators

unaided, back up to a wall

or garage door and operate

the lights. The reflected light should

show if they are working properly.

4Check all external lights and the horn. Refer

to the appropriate Sections of Chapter 13 for

details if any of the circuits are found to be

inoperative.4Visually check all wiring connectors,

harnesses and retaining clips for security, and

for signs of chafing or damage.

23

Page 15 of 18

0•15

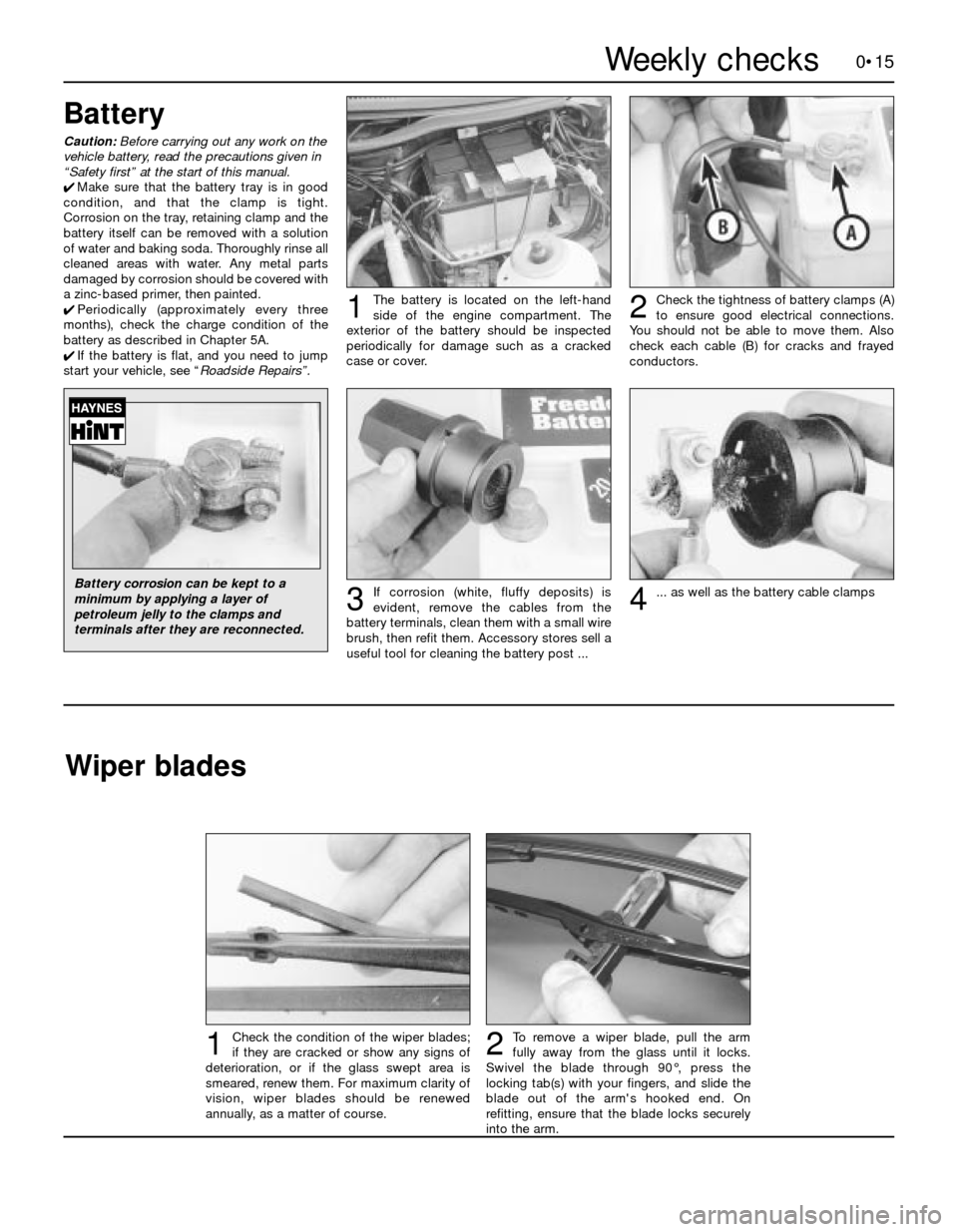

To remove a wiper blade, pull the arm

fully away from the glass until it locks.

Swivel the blade through 90°, press the

locking tab(s) with your fingers, and slide the

blade out of the arm's hooked end. On

refitting, ensure that the blade locks securely

into the arm.Check the condition of the wiper blades;

if they are cracked or show any signs of

deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of

vision, wiper blades should be renewed

annually, as a matter of course.21Weekly checks

Battery

Caution:Before carrying out any work on the

vehicle battery, read the precautions given in

“Safety first” at the start of this manual.

4Make sure that the battery tray is in good

condition, and that the clamp is tight.

Corrosion on the tray, retaining clamp and the

battery itself can be removed with a solution

of water and baking soda. Thoroughly rinse all

cleaned areas with water. Any metal parts

damaged by corrosion should be covered with

a zinc-based primer, then painted.

4Periodically (approximately every three

months), check the charge condition of the

battery as described in Chapter 5A.

4If the battery is flat, and you need to jump

start your vehicle, see “Roadside Repairs”.The battery is located on the left-hand

side of the engine compartment. The

exterior of the battery should be inspected

periodically for damage such as a cracked

case or cover.

Check the tightness of battery clamps (A)

to ensure good electrical connections.

You should not be able to move them. Also

check each cable (B) for cracks and frayed

conductors.

If corrosion (white, fluffy deposits) is

evident, remove the cables from the

battery terminals, clean them with a small wire

brush, then refit them. Accessory stores sell a

useful tool for cleaning the battery post ...

12

3... as well as the battery cable clamps4

Battery corrosion can be kept to a

minimum by applying a layer of

petroleum jelly to the clamps and

terminals after they are reconnected.

Wiper blades

Page 17 of 18

0•17Weekly checks

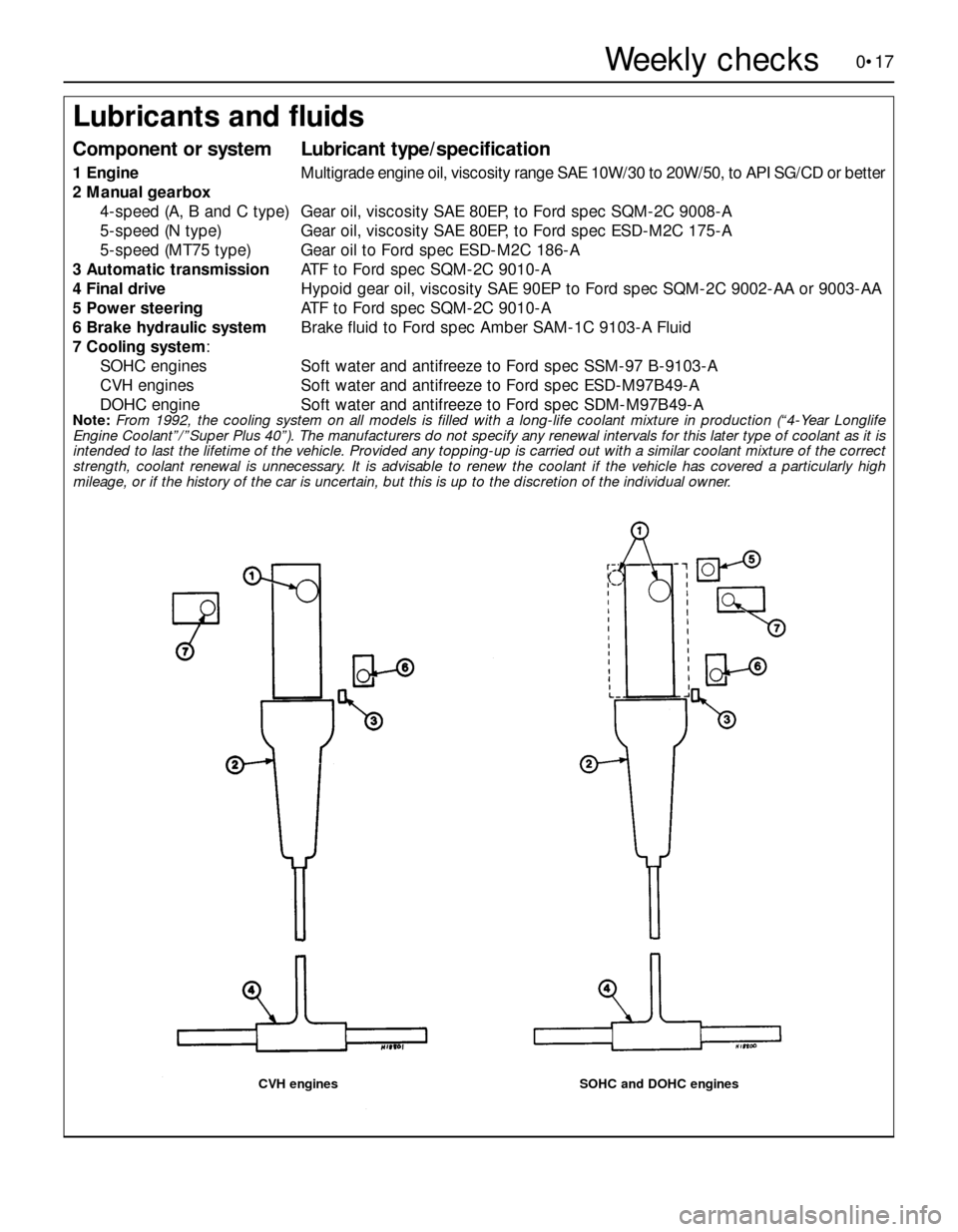

Lubricants and fluids

Component or systemLubricant type/specification

1EngineMultigrade engine oil, viscosity range SAE 10W/30 to 20W/50, to API SG/CD or better

2Manual gearbox

4-speed (A, B and C type)Gear oil, viscosity SAE 80EP, to Ford spec SQM-2C 9008-A

5-speed (N type)Gear oil, viscosity SAE 80EP, to Ford spec ESD-M2C 175-A

5-speed (MT75 type)Gear oil to Ford spec ESD-M2C 186-A

3Automatic transmissionATF to Ford spec SQM-2C 9010-A

4Final driveHypoid gear oil, viscosity SAE 90EP to Ford spec SQM-2C 9002-AA or 9003-AA

5Power steeringATF to Ford spec SQM-2C 9010-A

6Brake hydraulic systemBrake fluid to Ford spec Amber SAM-1C 9103-A Fluid

7Cooling system:

SOHC enginesSoft water and antifreeze to Ford spec SSM-97 B-9103-A

CVH enginesSoft water and antifreeze to Ford spec ESD-M97B49-A

DOHC engineSoft water and antifreeze to Ford spec SDM-M97B49-A

Note:From 1992, the cooling system on all models is filled with a long-life coolant mixture in production (“4-Year Longlife

Engine Coolant”/”Super Plus 40”). The manufacturers do not specify any renewal intervals for this later type of coolant as it is

intended to last the lifetime of the vehicle. Provided any topping-up is carried out with a similar coolant mixture of the correct

strength, coolant renewal is unnecessary. It is advisable to renew the coolant if the vehicle has covered a particularly high

mileage, or if the history of the car is uncertain, but this is up to the discretion of the individual owner.

CVH enginesSOHC and DOHC engines