light FORD SUPER DUTY 2006 1.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2006, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2006 1.GPages: 72, PDF Size: 0.57 MB

Page 4 of 72

The FCM/HFCM should be drained

at regular intervals or when the

WATER IN FUEL light illuminates in

the instrument cluster.

The fuel injectors are located in the center of the combustion chambers

in the cylinder head between the rocker arm assemblies. The glow plug

system and fuel injection system are controlled through the Powertrain

Control Module (PCM) and Fuel Injection Control Module (FICM).

Fuel is drawn from the fuel tank by a frame-mounted electric fuel pump.

The fuel pump provides pressurized fuel to the engine and is

electronically controlled by the fuel pump PCM relay. The fuel pump

contains a pressure relief valve for overpressure protection in the event

of restricted flow.

Lubrication system

It is important to change the engine oil at the recommended service

intervals, because oil viscosity is important in maintaining the oil

pressure required to actuate the fuel injectors. Extended oil change

intervals can negatively affect engine performance, fuel economy and

engine life. Refer to the engine oil specification chart located under

Engine oil specificationsin theMaintenance and Specifications

chapter of this supplement.

Fast start glow plug system

The glow plug system consists of:

•eight glow plugs

•the glow plug control module (GPCM)

•engine oil temperature (EOT) sensor

•barometric pressure (BARO) sensor

The glow plug system is

electronically controlled by the

PCM. The GPCM energizes the glow

plugs immediately after the ignition

is placed in the ON position, then determines how long the glow plugs

will be on according to the EOT and BARO sensors. The required time

for the glow plugs to be energized decreases as the engine oil

temperature and barometric pressure increase.

2006 Econoline(eco)

Supplement

USA(fus)

Introduction

4

Page 7 of 72

Glow plug pre-heat indicator

With the key in the ON position,

the

light will illuminate if

glow plug heat is necessary as a

starting aid. Wait until the light goes

off before starting. The light should always illuminate briefly, when the

ignition key is in the ON position. If the light does not illuminate, there

may be a problem. Refer toCold weather startingin theDriving

chapter of this supplement. After the engine starts, the light should

remain off. The light should always illuminate at least momentarily when

the engine is cold and the ignition is turned to ON. If it does not

illuminate, the glow plug system should be checked and repaired

promptly to avoid difficulty in cold starting.

Waterinfuel

During refueling, it is possible for water-contaminated diesel fuel to be

pumped into your tank. Your vehicle fuel system is equipped with a fuel

filter/water separator to remove water from the fuel. The WATER IN

FUEL light will illuminate when the ignition is turned to START (as part

of the light function check) and when the FCM/HFCM has a significant

quantity of water in it.

Type A

Type B

Type C

If the light illuminates when the engine is running, stop the vehicle as

soon as safely possible, shut off the engine, then drain the FCM/HFCM.

Refer toDraining the FCM/HFCM and changing the fuel filtersin the

Maintenance and Specificationschapter of this supplement for the

drain procedure. Allowing water to stay in the system could result in

extensive damage to, or failure of, the fuel injection system.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

7

Page 8 of 72

Do not drain the water separator while the engine is running.

Fuel may ignite if the separator is drained while the engine is

running or the vehicle is moving.

Engine air filter (if equipped)

The engine air filter warning light illuminates when the air filter

restriction gauge reaches the CHANGE FILTER mark.

Type A

Type B

The condition should be verified by inspecting the underhood air filter

restriction gauge; the warning light is only a secondary indicator. Always

use the underhood air filter restriction gauge to determine when the air

filter element needs to be changed.

The vehicle may be driven with the engine air filter warning light

illuminated/or when the underhood air filter restriction gauge has moved

to the CHANGE FILTER mark for up to 250 miles (400 km) without

damaging the engine or related components. However, the air filter

element must be replaced at the earliest opportunity. Refer toAir filter

restriction gauge (if equipped)in this chapter for more information.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

8

Page 9 of 72

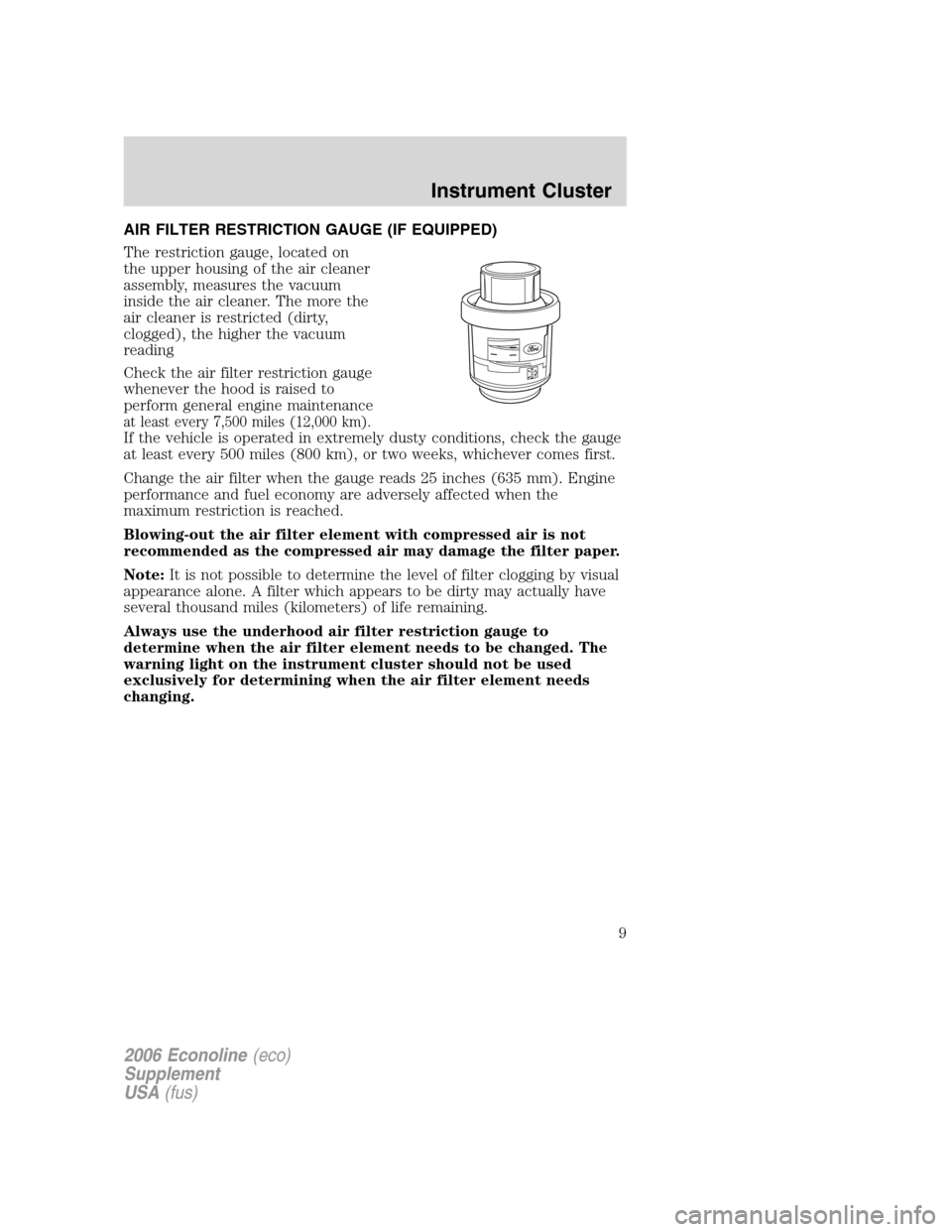

AIR FILTER RESTRICTION GAUGE (IF EQUIPPED)

The restriction gauge, located on

the upper housing of the air cleaner

assembly, measures the vacuum

inside the air cleaner. The more the

air cleaner is restricted (dirty,

clogged), the higher the vacuum

reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km).

If the vehicle is operated in extremely dusty conditions, check the gauge

at least every 500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads 25 inches (635 mm). Engine

performance and fuel economy are adversely affected when the

maximum restriction is reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

9

Page 10 of 72

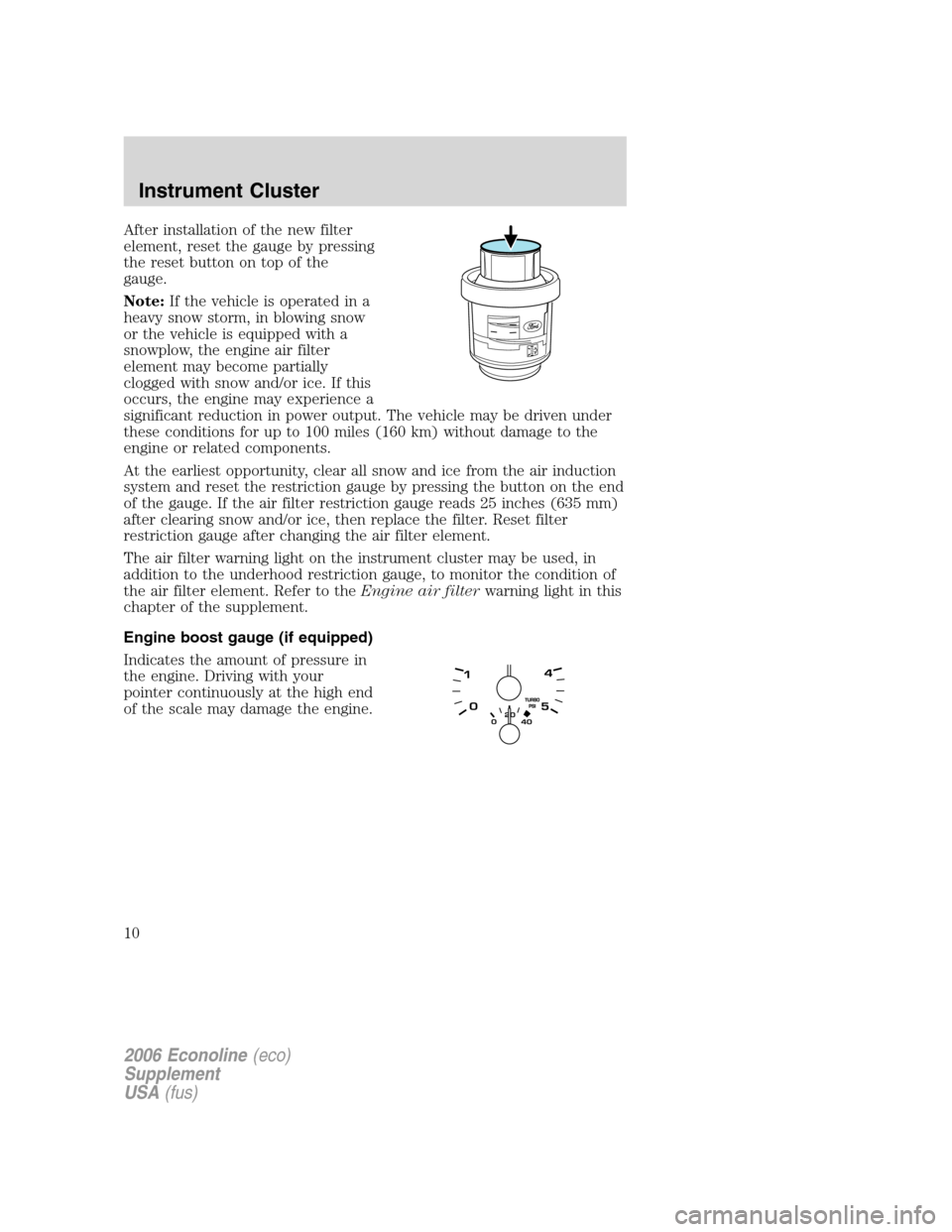

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:If the vehicle is operated in a

heavy snow storm, in blowing snow

or the vehicle is equipped with a

snowplow, the engine air filter

element may become partially

clogged with snow and/or ice. If this

occurs, the engine may experience a

significant reduction in power output. The vehicle may be driven under

these conditions for up to 100 miles (160 km) without damage to the

engine or related components.

At the earliest opportunity, clear all snow and ice from the air induction

system and reset the restriction gauge by pressing the button on the end

of the gauge. If the air filter restriction gauge reads 25 inches (635 mm)

after clearing snow and/or ice, then replace the filter. Reset filter

restriction gauge after changing the air filter element.

The air filter warning light on the instrument cluster may be used, in

addition to the underhood restriction gauge, to monitor the condition of

the air filter element. Refer to theEngine air filterwarning light in this

chapter of the supplement.

Engine boost gauge (if equipped)

Indicates the amount of pressure in

the engine. Driving with your

pointer continuously at the high end

of the scale may damage the engine.

2006 Econoline(eco)

Supplement

USA(fus)

Instrument Cluster

10

Page 12 of 72

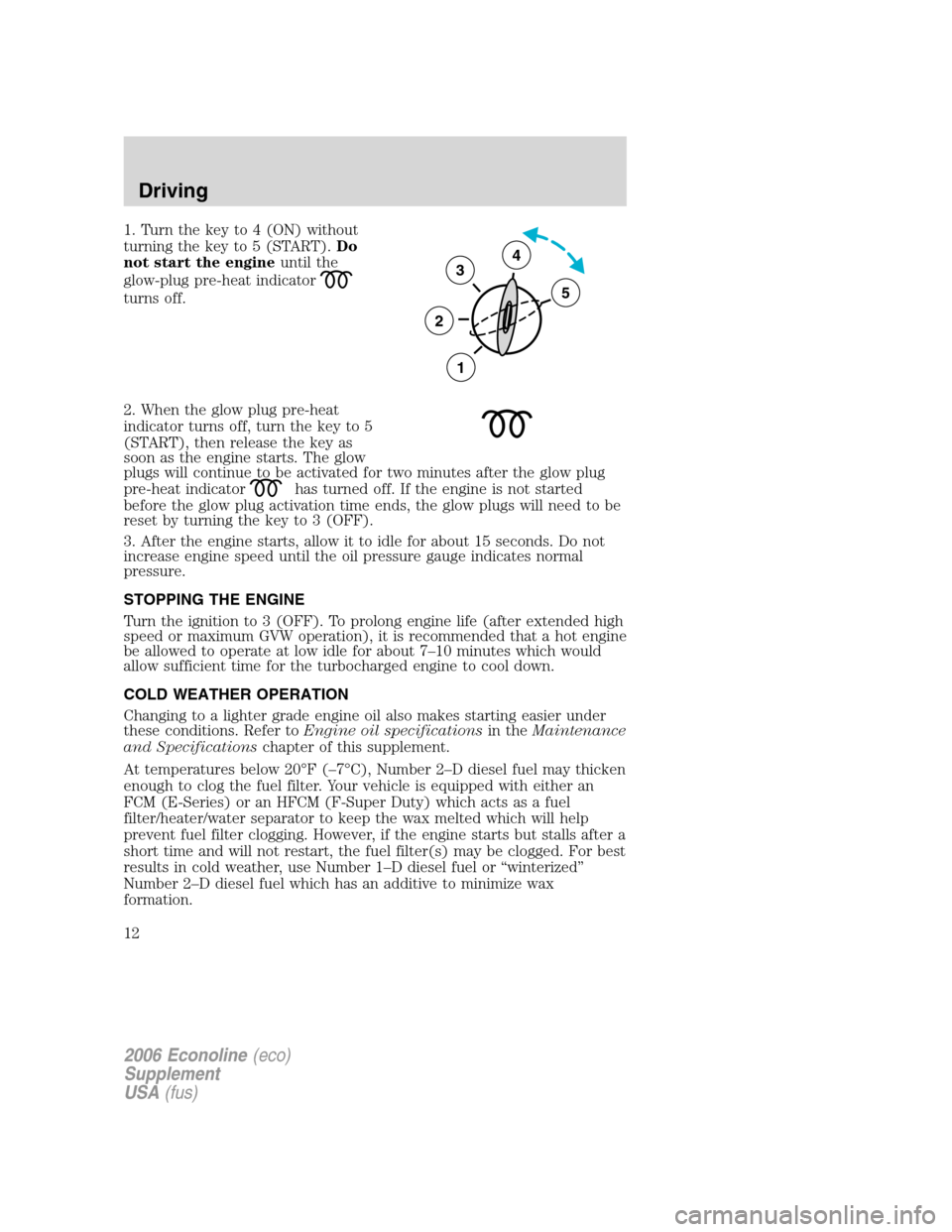

1. Turn the key to 4 (ON) without

turning the key to 5 (START).Do

not start the engineuntil the

glow-plug pre-heat indicator

turns off.

2. When the glow plug pre-heat

indicator turns off, turn the key to 5

(START), then release the key as

soon as the engine starts. The glow

plugs will continue to be activated for two minutes after the glow plug

pre-heat indicator

has turned off. If the engine is not started

before the glow plug activation time ends, the glow plugs will need to be

reset by turning the key to 3 (OFF).

3. After the engine starts, allow it to idle for about 15 seconds. Do not

increase engine speed until the oil pressure gauge indicates normal

pressure.

STOPPING THE ENGINE

Turn the ignition to 3 (OFF). To prolong engine life (after extended high

speed or maximum GVW operation), it is recommended that a hot engine

be allowed to operate at low idle for about 7–10 minutes which would

allow sufficient time for the turbocharged engine to cool down.

COLD WEATHER OPERATION

Changing to a lighter grade engine oil also makes starting easier under

these conditions. Refer toEngine oil specificationsin theMaintenance

and Specificationschapter of this supplement.

At temperatures below 20°F (–7°C), Number 2–D diesel fuel may thicken

enough to clog the fuel filter. Your vehicle is equipped with either an

FCM (E-Series) or an HFCM (F-Super Duty) which acts as a fuel

filter/heater/water separator to keep the wax melted which will help

prevent fuel filter clogging. However, if the engine starts but stalls after a

short time and will not restart, the fuel filter(s) may be clogged. For best

results in cold weather, use Number 1–D diesel fuel or “winterized”

Number 2–D diesel fuel which has an additive to minimize wax

formation.

3

2

1

5

4

2006 Econoline(eco)

Supplement

USA(fus)

Driving

12

Page 19 of 72

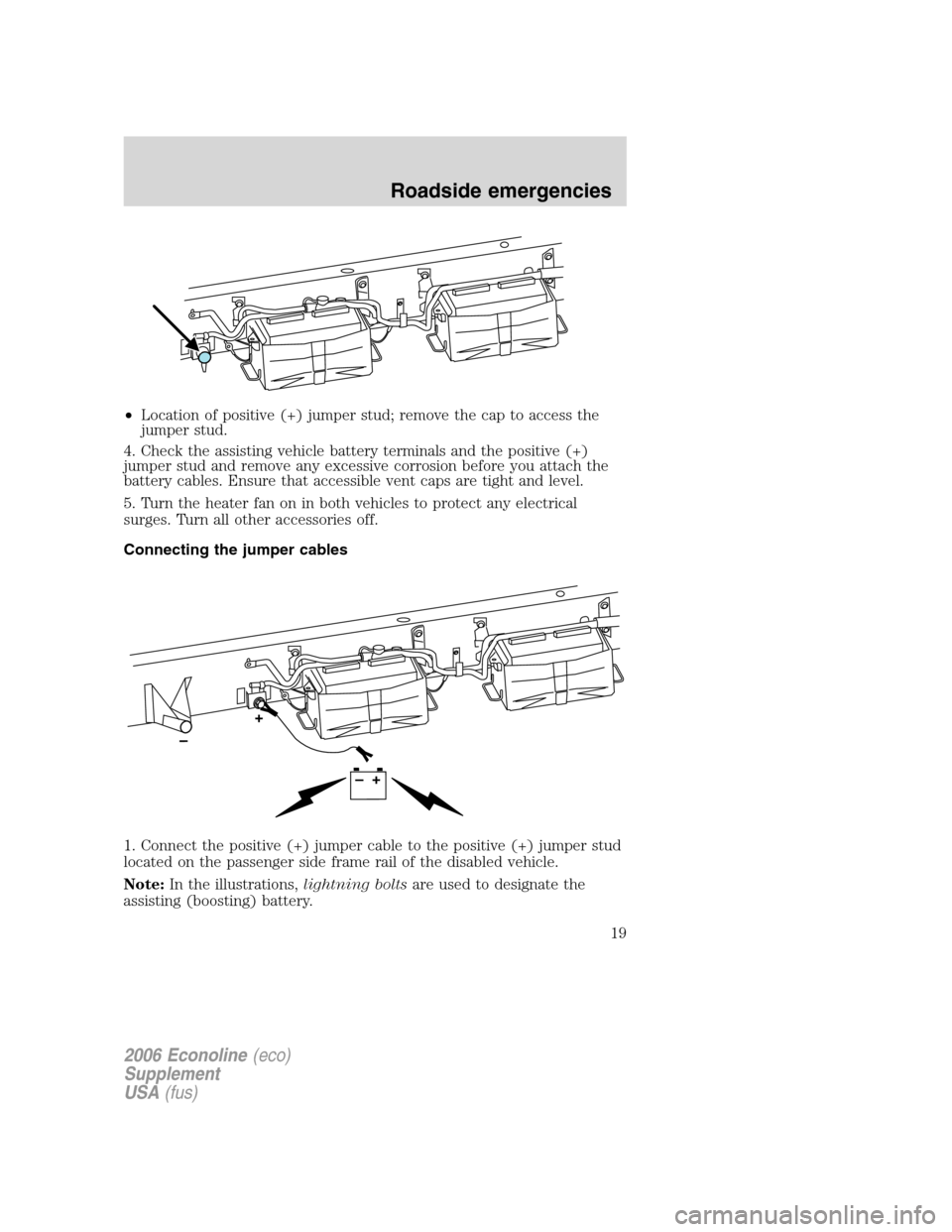

•Location of positive (+) jumper stud; remove the cap to access the

jumper stud.

4. Check the assisting vehicle battery terminals and the positive (+)

jumper stud and remove any excessive corrosion before you attach the

battery cables. Ensure that accessible vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) jumper stud

located on the passenger side frame rail of the disabled vehicle.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2006 Econoline(eco)

Supplement

USA(fus)

Roadside emergencies

19

Page 22 of 72

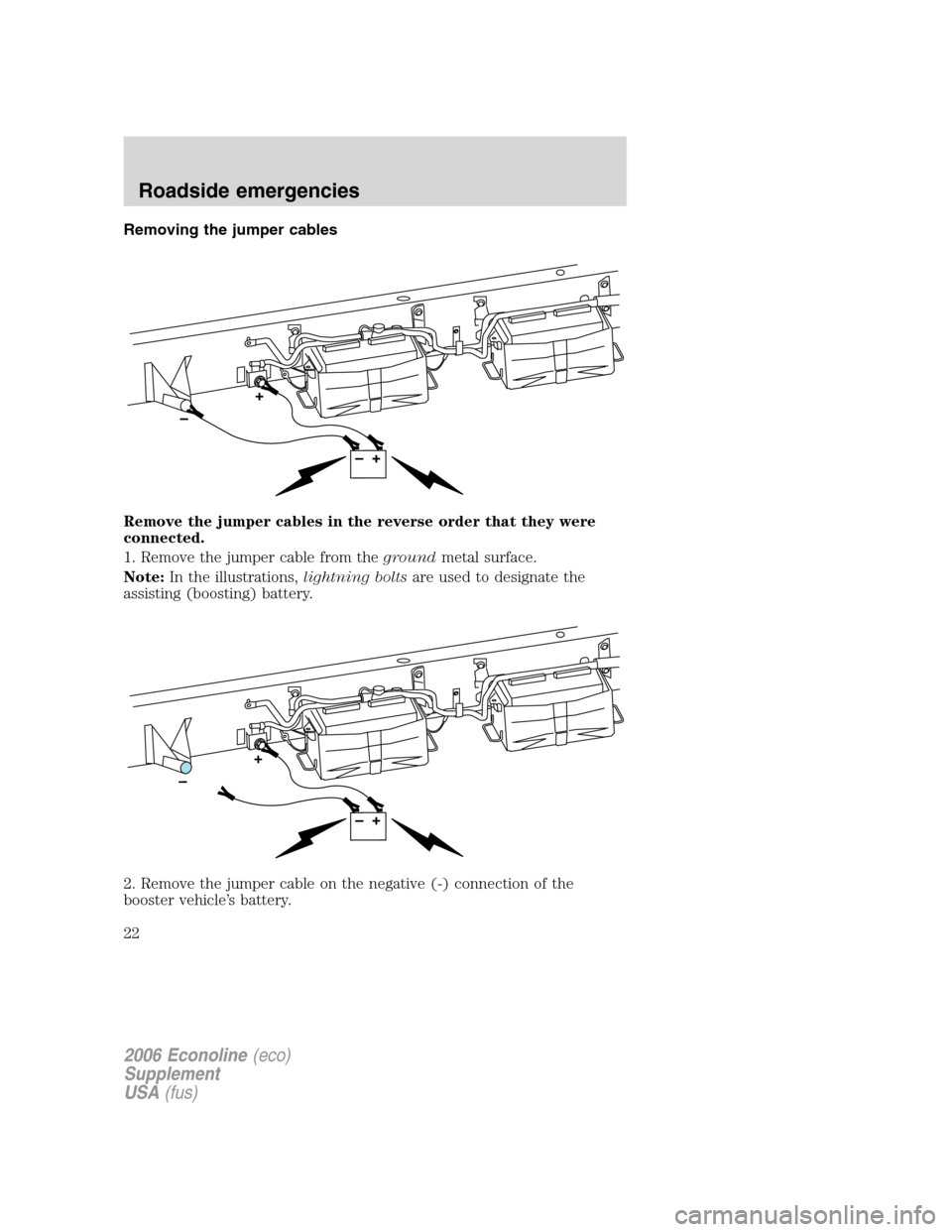

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

2006 Econoline(eco)

Supplement

USA(fus)

Roadside emergencies

22

Page 24 of 72

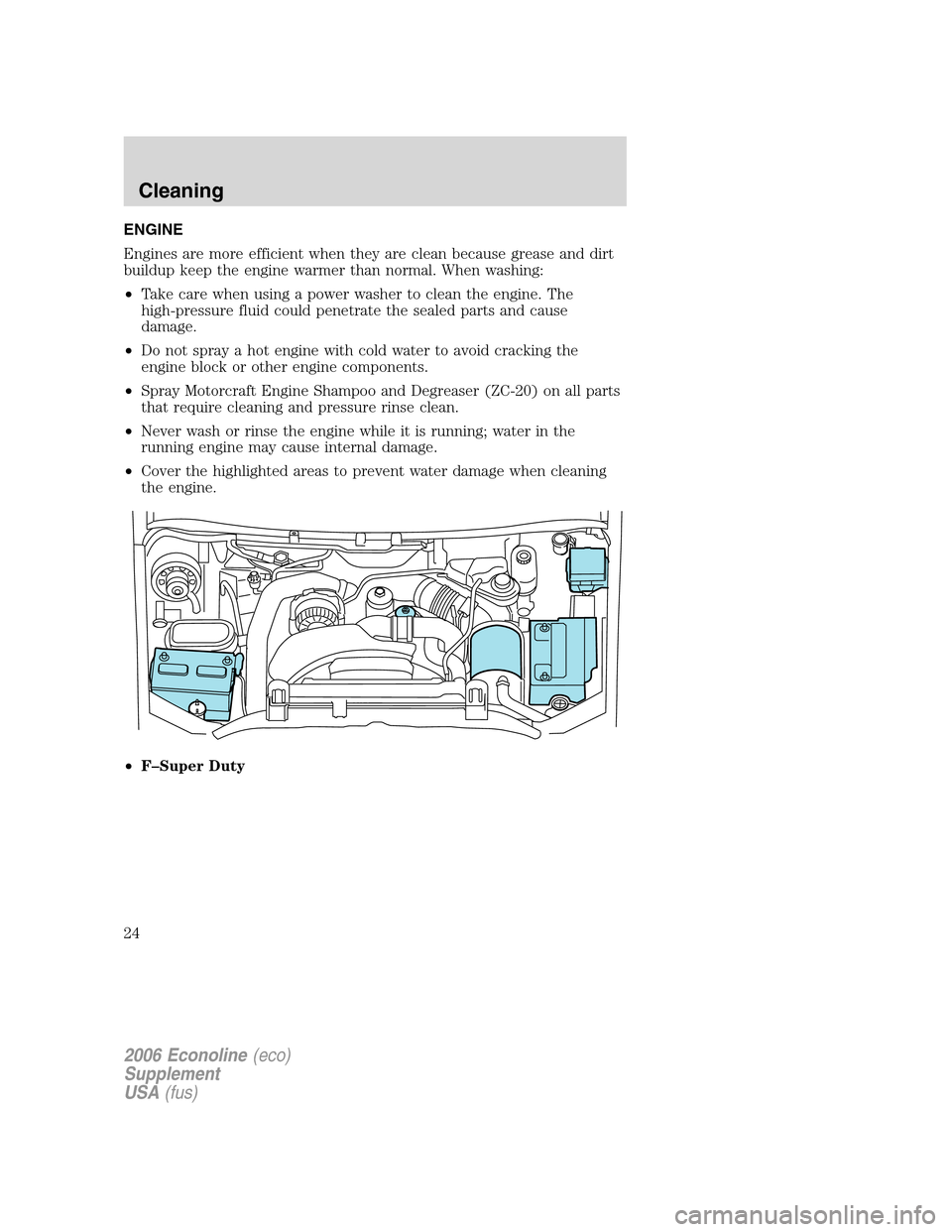

ENGINE

Engines are more efficient when they are clean because grease and dirt

buildup keep the engine warmer than normal. When washing:

•Take care when using a power washer to clean the engine. The

high-pressure fluid could penetrate the sealed parts and cause

damage.

•Do not spray a hot engine with cold water to avoid cracking the

engine block or other engine components.

•Spray Motorcraft Engine Shampoo and Degreaser (ZC-20) on all parts

that require cleaning and pressure rinse clean.

•Never wash or rinse the engine while it is running; water in the

running engine may cause internal damage.

•Cover the highlighted areas to prevent water damage when cleaning

the engine.

•F–Super Duty

2006 Econoline(eco)

Supplement

USA(fus)

Cleaning

24

Page 31 of 72

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of water accumulates in the module.

Replace the fuel filters with Ford Part No. FD–4604. This part number

includes filters and seals for both the engine-mounted and

frame-mounted filters.

FCM - E-Series

The vehicle is equipped with a Fuel Conditioning Module (FCM) located

on the driver-side of the vehicle next to the transmission case.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of water accumulates in the module.

Replace the fuel filters with Ford Part No. FD–4604. This part number

includes filters and seals for both the engine-mounted filter and the FCM

filter.

DRAINING THE FCM/HFCM AND CHANGING THE FUEL FILTERS

Your vehicle is equipped with two fuel filters; one is mounted on top of

the engine.On F-Super Duty,the second filter, inside the HFCM, is

mounted inside the frame rail under the driver-side floorboard near the

transmission.On E-Series vehicles,the second filter, inside the FCM, is

mounted on the driver-side of the vehicle next to the transmission case.

On all vehicles,both filters should be replaced at the same time. The

Motorcraft part number for the replacement filters is FD-4604.

FCM/HFCM drain procedure

1. Stop the vehicle andshut offthe engine.

The vehicle must be stopped with the engine off when draining

the HFCM/FCM. Fuel may ignite if the separator is drained while

the engine is running or vehicle is moving.

2. Locate the HFCM and place an appropriate container under the drain

port (see illustration).

2006 Econoline(eco)

Supplement

USA(fus)

Maintenance and Specifications

31