warning FORD SUPER DUTY 2009 2.G Diesel Supplement Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2009, Model line: SUPER DUTY, Model: FORD SUPER DUTY 2009 2.GPages: 103, PDF Size: 0.75 MB

Page 26 of 103

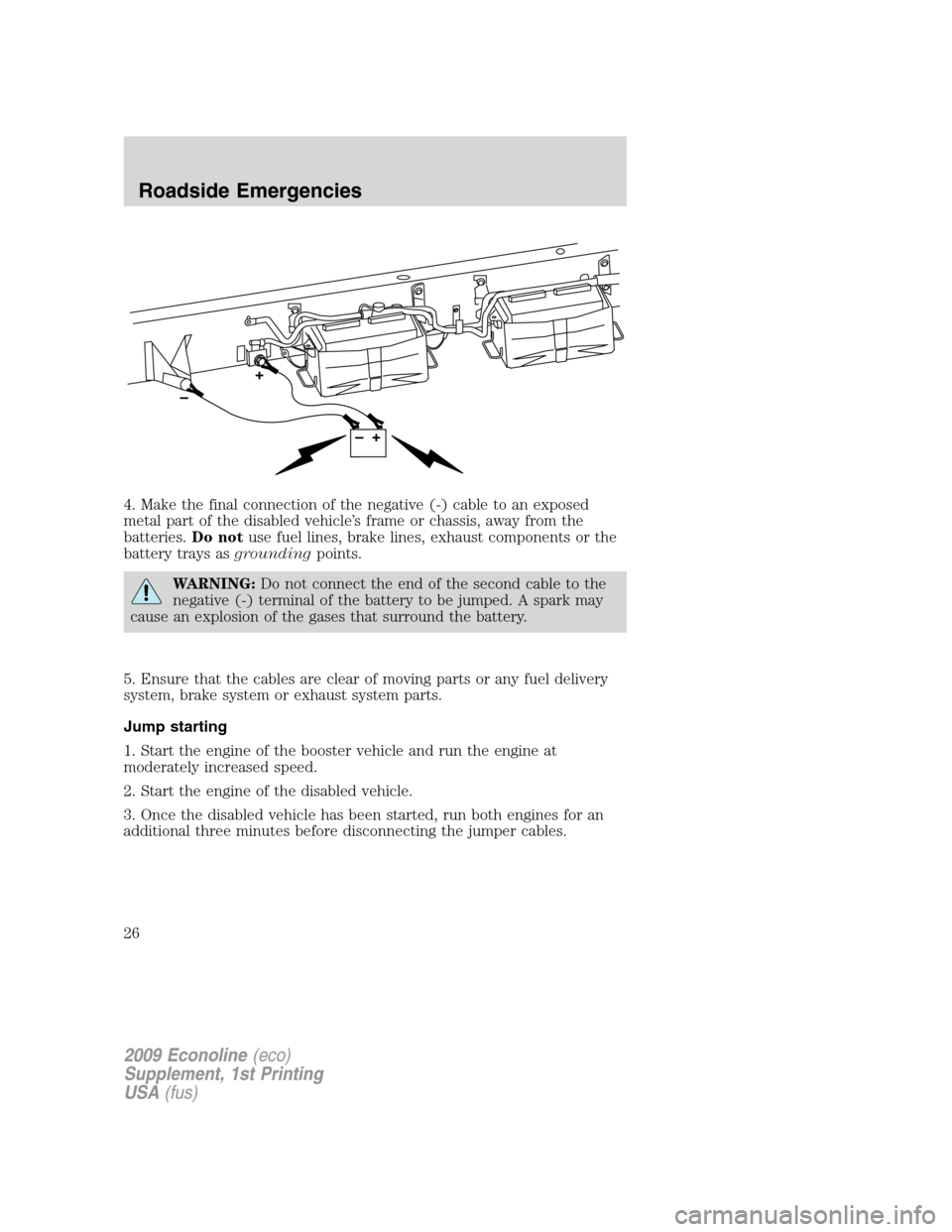

4. Make the final connection of the negative (-) cable to an exposed

metal part of the disabled vehicle’s frame or chassis, away from the

batteries.Do notuse fuel lines, brake lines, exhaust components or the

battery trays asgroundingpoints.

WARNING:Do not connect the end of the second cable to the

negative (-) terminal of the battery to be jumped. A spark may

cause an explosion of the gases that surround the battery.

5. Ensure that the cables are clear of moving parts or any fuel delivery

system, brake system or exhaust system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Roadside Emergencies

26

Page 31 of 103

WARNING:Failure to maintain the functional holes, in the

tailpipe section of the exhaust, clean and free of debris or

foreign material may result in the holes becoming blocked or plugged.

Do not modify or remove the tail-pipe section. Blocked or plugged

holes or removal/modification of the system could result in elevated

exhaust gas temperatures which may result in vehicle/property damage

or personal injury

WARNING:The normal operating temperature of the exhaust

system is very high. Never work around or attempt to repair any

part of the exhaust system until it has cooled. Use special care when

working around the diesel oxidation catalytic converter and/or the

diesel particulate filter (DPF). The diesel oxidation catalytic converter

and/or the DPF heats up to a high temperature after only a short

period of engine operation and can stay hot even after the engine is

turned off. Failure to follow these instructions may result in personal

injury.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Cleaning

31

Page 39 of 103

Fuel filler cap

Your fuel tank filler cap has an indexed design with a 1/4 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise until it spins off.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/4 of a turn until it clicks at least once.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The vehicle warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

WARNING:The fuel system may be under pressure. If the fuel

filler cap is venting vapor or if you hear a hissing sound, wait

until it stops before completely removing the fuel filler cap. Otherwise,

fuel may spray out and injure you or others.

WARNING:If you do not use the proper fuel filler cap,

excessive pressure or vacuum in the fuel tank may damage the

fuel system or cause the fuel cap to disengage in a collision, which may

result in possible personal injury.

FUEL FILTER/WATER SEPARATOR

Fuel Conditioner Module (FCM - E-Series)

The vehicle is equipped with a Fuel Conditioning Module (FCM) located

on the driver-side of the vehicle next to the transmission case.

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of water accumulates in the module.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

39

Page 40 of 103

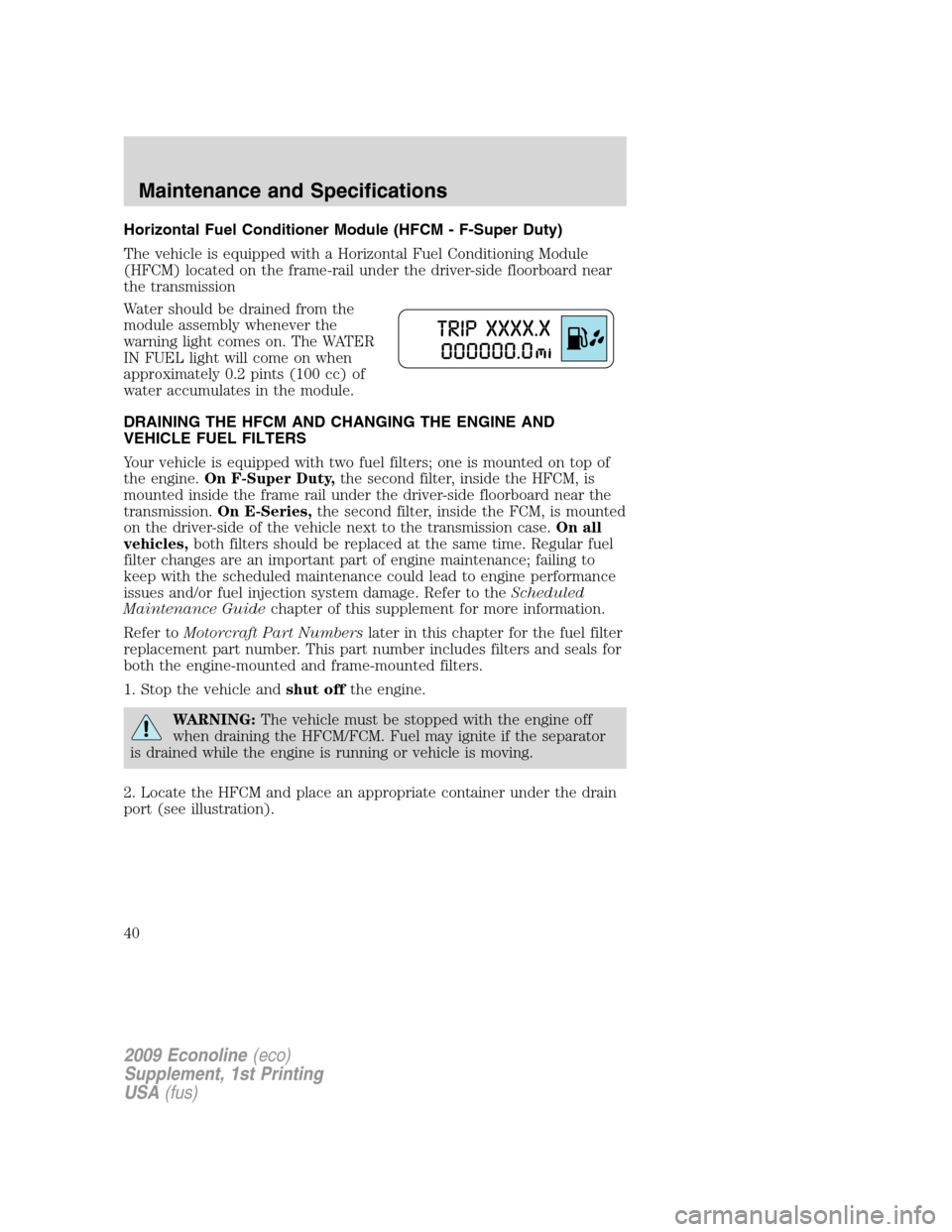

Horizontal Fuel Conditioner Module (HFCM - F-Super Duty)

The vehicle is equipped with a Horizontal Fuel Conditioning Module

(HFCM) located on the frame-rail under the driver-side floorboard near

the transmission

Water should be drained from the

module assembly whenever the

warning light comes on. The WATER

IN FUEL light will come on when

approximately 0.2 pints (100 cc) of

water accumulates in the module.

DRAINING THE HFCM AND CHANGING THE ENGINE AND

VEHICLE FUEL FILTERS

Your vehicle is equipped with two fuel filters; one is mounted on top of

the engine.On F-Super Duty,the second filter, inside the HFCM, is

mounted inside the frame rail under the driver-side floorboard near the

transmission.On E-Series,the second filter, inside the FCM, is mounted

on the driver-side of the vehicle next to the transmission case.On all

vehicles,both filters should be replaced at the same time. Regular fuel

filter changes are an important part of engine maintenance; failing to

keep with the scheduled maintenance could lead to engine performance

issues and/or fuel injection system damage. Refer to theScheduled

Maintenance Guidechapter of this supplement for more information.

Refer toMotorcraft Part Numberslater in this chapter for the fuel filter

replacement part number. This part number includes filters and seals for

both the engine-mounted and frame-mounted filters.

1. Stop the vehicle andshut offthe engine.

WARNING:The vehicle must be stopped with the engine off

when draining the HFCM/FCM. Fuel may ignite if the separator

is drained while the engine is running or vehicle is moving.

2. Locate the HFCM and place an appropriate container under the drain

port (see illustration).

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

40

Page 47 of 103

Changing engine oil and filter

Change your oil and filter according to thescheduled maintenance

informationin this supplement. Change more frequently if your vehicle

operation includes extended periods of idling or low-speed operation,

driving for a long time in cold temperatures or driving short distances.

See the following sectionEngine lubrication for severe service

operationfor all severe duty restrictions.

Refer toMotorcraft Part Numberslater in this chapter for the engine oil

filter part number. This filter protects your engine by filtering harmful,

abrasive or sludge particles and particles significantly smaller than most

available “will-fit” filters.

To replace the filter,

1. Unscrew the oil filter cap and wait a few seconds for the oil to drain

through the built-in drain valve.Note:The filter should be changed

before reinstalling the oil pan drain plug.

2. Reinstall and tighten the oil filter cap.

WARNING:Do not handle a hot oil filter with bare hands.

WARNING:Continuous contact with USED motor oil has caused

cancer in laboratory mice. Protect your skin by washing with

soap and water.

Engine lubrication for severe service operation

The following severe service operating conditions require unique engine

maintenance procedures:

•frequent or extended idling (over 10 minutes per hour of normal

driving).

•if vehicle is operated in sustained ambient temperatures below -10°F

(-23°C) or above 100°F (38°C)

•frequent low speed operation, consistent heavy traffic less than

25 mph (40 km/h)

•operating in severe dust conditions.

•towing a trailer over 1,000 miles (1,600 km)

•sustained, high speed driving at Gross Vehicle Weight Rating

(maximum loaded weight for vehicle operation)

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

47

Page 48 of 103

•use of biodiesel, up to and including 5% Biodiesel (B5)

•use of high sulfur diesel fuel

If you are operating your vehicle under any of these conditions, change

engine oil and filter every 5,000 miles (8,000 km).

AIR FILTER RESTRICTION GAUGE AND AIR FILTER

REPLACEMENT

Air filter restriction gauge:

The restriction gauge, located on

the upper housing of the air filter

assembly, measures the vacuum

inside the air filter. The more the air

filter is restricted (dirty, clogged),

the higher the vacuum reading

Check the air filter restriction gauge

whenever the hood is raised to

perform general engine maintenance

at least every 7,500 miles (12,000 km). If the vehicle is operated in

extremely dusty conditions, check and reset the gauge at least every

500 miles (800 km), or two weeks, whichever comes first.

Change the air filter when the gauge reads near the “change filter” line

and the chamber is filled with yellow. Engine performance and fuel

economy are adversely affected when the maximum restriction is

reached.

Blowing-out the air filter element with compressed air is not

recommended as the compressed air may damage the filter paper.

Note:It is not possible to determine the level of filter clogging by visual

appearance alone. A filter which appears to be dirty may actually have

several thousand miles (kilometers) of life remaining.

Always use the underhood air filter restriction gauge to

determine when the air filter element needs to be changed. The

warning light on the instrument cluster should not be used

exclusively for determining when the air filter element needs

changing.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

48

Page 49 of 103

After installation of the new filter

element, reset the gauge by pressing

the reset button on top of the

gauge.

Note:Vehicle operation in heavy

snowfall or extreme rain conditions

may feed excessive amounts of

snow/water into the air intake

system. This could plug/soak the air

filter with snow and may cause the

engine to lose power and possibly

shut down. Either of these conditions may cause the CHECK AIR

FILTER message to appear in the message center.

You may not need to change the air filter and the vehicle may be driven

up to 200 miles (320 km) under the following conditions:

•Snow:At the earliest opportunity, open the hood and clear all the

snow and ice from the air filter housing inlet (do NOT remove the air

filter) and reset the air filter restriction gauge.

•Wet:The air filter will dry after about 15–30 minutes at highway

speeds. At the earliest opportunity, open the hood and reset the air

filter restriction gauge.

The air filter warning message on the instrument cluster may be used, in

addition to the underhood restriction gauge, to monitor the condition of

the air filter element. Refer to theEngine air filterwarning light in this

chapter of the supplement.

Air filter replacement:

When replacing the air filter element, use the Motorcraft air filter

element listed inMotorcraft Part Numberslater in this chapter.

WARNING:To reduce the risk of vehicle damage and/or

personal burn injuries do not start your engine with the air filter

removed and do not remove it while the engine is running.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

49

Page 53 of 103

right rear tire(s) are functional. The holes need to be kept clear of

mud/debris or foreign material to maintain proper function of the

exhaust system. Clean and remove debris or foreign material if present

as needed. Spraying with a hose during regular washing of vehicle should

help keep holes clean and clear of debris or foreign material.

Note:Additions of aftermarket devices or modifications to the exhaust

system can reduce the effectiveness of the exhaust system as well as

cause damage to the exhaust system and/or engine. These actions may

also affect the vehicle’s warranty. See the vehicle’s warranty guide for

more information.

WARNING:Failure to maintain the functional holes, in the

tailpipe section of the exhaust, clean and free of debris or

foreign material may result in the holes becoming blocked or plugged.

Do not modify or remove the tail-pipe section. Blocked or plugged

holes or removal/modification of the system could result in elevated

exhaust gas temperatures which may result in vehicle/property damage

or personal injury.

WARNING:The normal operating temperature of the exhaust

system is very high. Never work around or attempt to repair any

part of the exhaust system until it has cooled. Use special care when

working around the diesel oxidation catalytic converter and/or the

diesel particulate filter (DPF). The diesel oxidation catalytic converter

and/or the DPF heats up to a high temperature after only a short

period of engine operation and can stay hot even after the engine is

turned off. Failure to follow these instructions may result in personal

injury.

EMISSION CONTROL SYSTEM(S) LAWS

Federal law prohibits vehicle manufacturers, dealers and other persons

engaged in the business of repairing, servicing, selling, leasing or trading

motor vehicles as well as fleet operations from unknowingly removing or

rendering emission control system(s) inoperative. Further, modifications

of the emission control system(s) could create liability on the part of the

individual owners under the laws of some states. In Canada,

modifications of the emission control system(s) could create liability

under applicable Federal or Provincial laws.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

53

Page 55 of 103

•contaminated fuel.

•air in the fuel system, due to loose connections.

•an open or pinched sensor hose.

•low engine oil level.

•wrong fuel or oil viscosity for climactic conditions.

If these checks do not help you correct the engine performance problem

you are experiencing, consult an authorized dealer.

FUELING

WARNING:Do not use starting fluid such as ether or gasoline

in the diesel air intake system. Such fluids can cause immediate

explosive damage to the engine and possible personal injury.

If you fuel your vehicle at a truck stop, you may notice that the fuel

nozzle may shut off every 5–10 seconds. This is due to the flow rates

being designed for larger heavy duty trucks. You may have to fuel at a

slower rate (don’t depress the nozzle trigger fully).

Do not run your diesel vehicle out of fuel as this will allow air to enter

the fuel system which will make restarting difficult. The engine is

designed to run roughly as the fuel tank nears Empty. This is a warning

to the driver to add fuel as soon as possible. Longer engine cranking

time may be required once air is in the fuel system. If air enters the fuel

system (either through running the fuel tank(s) empty or during a fuel

filter change), the engine will self-purge the trapped air once it starts

running. The engine may run roughly and produce white smoke while air

is in the fuel system; this is normal and should stop after a short time.

MINOR TROUBLESHOOTING GUIDE

Air purge procedure

Turn the key on for 30 seconds, then turn off. Repeat procedure four or

five times.

If the engine won’t crank

Turn on the headlights. If the lights are dim, do not go on at all or when

the ignition is turned to START the lights become dim or go out, the

battery connections may be loose or corroded, or the battery may be

discharged. If there is a clicking or stuttering sound coming from the

engine compartment when you turn the key to START, this may also

indicate a loose or corroded battery connection.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

55

Page 56 of 103

Check the battery connections at the battery posts, cable connection to

the engine grounding point and at the starter connection.

If a discharged battery is suspected, have it checked and corrected.

WARNING:Battery posts, terminals and related accessories

contain lead and lead compounds.Wash hands after handling.

•For vehicles with manual transmissions,the clutch pedalmustbe

fully depressed in order for the starter to operate.

•For vehicles with automatic transmissions,the gearshift lever

must be in P (Park) or N (Neutral) in order for the starter to operate.

•Try operating the starter switch several times. Should the switch be

corroded, this operation may clean the contacts or make the switch

temporarily operable until you can reach the dealer.

•If all electrical connections are tight and you need assistance to start,

refer toJump startingin theRoadside Emergencieschapter of your

Owner’s Guide(F-Super Duty) or refer to theJump startingsection

in theRoadside Emergencieschapter of this supplement (E-Series).

If engine cranks but won’t start

Prolonged starter cranking (in excess of 30 seconds) could cause

damage to the starter motor.

•Check the fuel gauge. You may be out of fuel. If the gauge shows that

there is fuel in the tank, the trouble may be in the electrical system or

the fuel system. If equipped with an auxiliary tank, be sure that the

tank control switch is set for the tank with fuel and not on an empty

tank.

•Leaving the ignition key turned to ON for over two minutes without

starting may make starting difficult because the glow plugs will cease

activation. Reset the system by turning the ignition key to OFF and

then back to ON again.

If the engine runs hot

The following could cause the engine to overheat:

•Lack of coolant.

•Dirty cooling system.

•Plugged radiator fins, charge air cooler, A/C condenser and/or oil

cooler.

•Driving with frozen coolant.

2009 Econoline(eco)

Supplement, 1st Printing

USA(fus)

Maintenance and Specifications

56